Content Menu

● Overview of SMD Tape and Reel Machines

● Types of Components Processed

● Advantages of SMD Tape and Reel Machines

● Technical Specifications of SMD Tape and Reel Machines

● Applications in Electronics Manufacturing

● Challenges and Considerations

● Market Trends and Growth

● Customization and Flexibility

● Environmental and Sustainability Aspects

● Manual vs. Automated Reel Counting

● Future Developments in SMD Tape and Reel Technology

● Impact on Supply Chain Management

● Conclusion

● Frequently Asked Questions

>> 1. What types of components can be processed with SMD tape and reel machines?

>> 2. How do SMD tape and reel machines enhance production efficiency?

>> 3. What are the environmental benefits of using SMD tape and reel machines?

>> 4. Can SMD tape and reel machines handle special or custom components?

>> 5. How important are reel specifications in SMD tape and reel packaging?

The SMD tape and reel machine is a crucial piece of equipment in the electronics manufacturing industry, particularly for surface-mount technology (SMT). These machines are designed to efficiently package a wide range of surface-mount devices (SMDs) onto reels, which are then used in automated assembly processes. The process involves placing components into a continuous strip of tape, where each component is secured in its own pocket. This method ensures that components are protected, organized, and easily fed into pick-and-place machines for PCB assembly.

Overview of SMD Tape and Reel Machines

SMD tape and reel machines are versatile and can handle various types of components, from simple resistors and capacitors to complex integrated circuits (ICs). The machines are equipped with advanced features such as automatic feeding, inspection, and sealing, ensuring high precision and efficiency in the packaging process. They support different tape widths and reel sizes, accommodating various component sizes and types.

Types of Components Processed

1. Resistors and Capacitors: These are the backbone of electronic circuits and are commonly packaged using SMD tape and reel machines. Their small size and sensitivity to environmental factors make precise packaging essential.

2. Integrated Circuits (ICs): ICs, including those used in mobile phones and computer chips, are frequently packaged on reels. The complexity and variety of ICs require specialized handling to ensure they are properly secured and protected during transportation and assembly.

3. LEDs: LEDs are another type of component that benefits from tape and reel packaging. This method helps maintain their brightness and functionality by preventing physical damage during handling.

4. Transistors and Diodes: These components, though small, play a significant role in electronic circuits. They are efficiently packaged using SMD tape and reel machines to ensure consistent quality and performance.

5. Special Components: Beyond standard SMDs, tape and reel machines can also handle special components like contacts, springs, screening cans, PCBs, test points, transformers, and coils. This versatility makes them indispensable in diverse manufacturing environments.

Advantages of SMD Tape and Reel Machines

- Efficiency and Precision: These machines automate the packaging process, reducing manual intervention and the risk of component damage. They ensure components are placed in a standardized format, making them compatible with pick-and-place machines.

- Cost-Effectiveness: By minimizing material waste and reducing labor costs, SMD tape and reel machines contribute to cost-effective production processes.

- Environmental Benefits: The packaging materials used are often recyclable, reducing waste and supporting sustainable manufacturing practices.

Technical Specifications of SMD Tape and Reel Machines

Modern SMD tape and reel machines are equipped with advanced technology, including:

- Automatic Sealing and Furling: Machines like the JW-8000 SMD Taping Machine use heat-sealing or self-adhesive methods to secure components on the tape, ensuring a tight seal that protects components during storage and transportation.

- PLC Control: Programmable Logic Controllers (PLCs) provide stable and accurate control over the packaging process, allowing for adjustable speeds and precise component counting.

- Vision Inspection: Some machines integrate vision systems to inspect components for defects or misplacement, enhancing quality control.

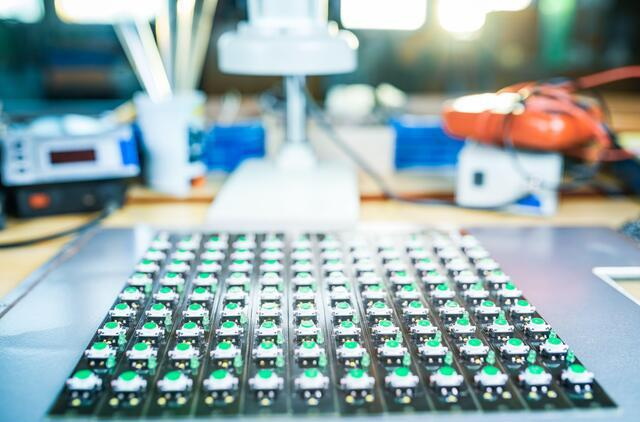

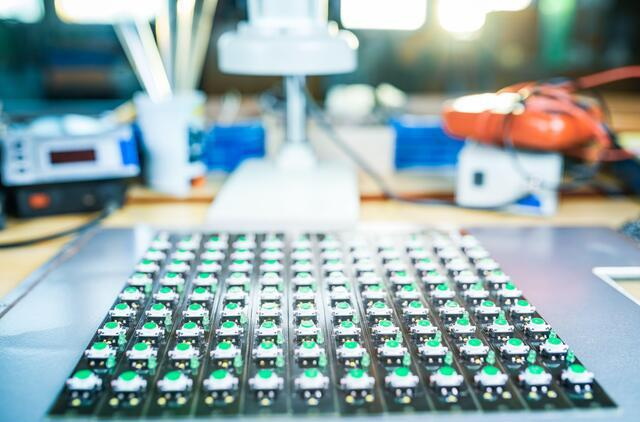

Applications in Electronics Manufacturing

SMD tape and reel machines are essential for high-volume production of printed circuit boards (PCBs). They ensure that components are consistently oriented and protected, which is critical for maintaining assembly quality and efficiency. The machines support various reel sizes and tape lengths, allowing customization based on specific production requirements or component types.

Challenges and Considerations

While SMD tape and reel machines offer numerous benefits, there are challenges to consider:

- Component Compatibility: Not all components are suitable for tape and reel packaging. Some may require alternative packaging methods, such as tubes or trays, especially for low-volume or prototype production.

- Reel Specifications: The width and diameter of reels can be critical for compatibility with pick-and-place machines. Incorrect reel sizes can lead to production downtime and additional costs.

Market Trends and Growth

The global SMD taping machine market is experiencing significant growth, driven by the increasing demand for automation in electronics manufacturing. According to recent forecasts, the market is expected to grow at a CAGR of 7.6% during the forecast period, with the Asia-Pacific region holding the largest share due to its status as a global electronics manufacturing hub. The consumer electronics segment is particularly driving this growth, with its need for rapid and precise packaging solutions to meet the high volume and fast-paced innovation in this sector.

Customization and Flexibility

SMD tape and reel machines are highly customizable, allowing manufacturers to tailor packaging solutions to specific component types and production needs. This flexibility is crucial for accommodating diverse components and ensuring compatibility with various pick-and-place systems. Machines can be configured for different feeding modes, such as pallet feeding or vibrating disc feeding, and can perform automatic sealing and furling to ensure secure packaging.

Environmental and Sustainability Aspects

In addition to improving production efficiency, SMD tape and reel machines contribute to sustainable manufacturing practices by optimizing packaging material usage and reducing waste. The automation of the packaging process also helps in minimizing the environmental impact by reducing the need for manual handling and associated material waste.

Manual vs. Automated Reel Counting

Manual reel counting is a labor-intensive task prone to human error, leading to inaccuracies in inventory management. In contrast, automated solutions like the Seamark Manual SMD Reel Counter offer precision and efficiency, minimizing errors and enhancing inventory management capabilities. This shift towards automation is essential for maintaining accuracy and reducing production costs in high-volume manufacturing environments.

Future Developments in SMD Tape and Reel Technology

Future advancements in SMD tape and reel machines are expected to focus on further automation and integration with Industry 4.0 technologies. This includes the use of AI for predictive maintenance, real-time monitoring of production processes, and enhanced quality control through advanced vision systems. Additionally, there will be a greater emphasis on sustainability, with innovations aimed at reducing energy consumption and increasing the recyclability of packaging materials.

Impact on Supply Chain Management

The use of SMD tape and reel machines also impacts supply chain management by ensuring consistent and reliable component delivery. This consistency is crucial for maintaining production schedules and meeting customer demands. Furthermore, the standardized packaging format facilitates easier inventory tracking and management, reducing logistical complexities and costs.

Conclusion

In conclusion, SMD tape and reel machines play a pivotal role in the efficient packaging of surface-mount devices, enhancing production efficiency and precision in the electronics manufacturing industry. Their versatility in handling a wide range of components makes them indispensable for both high-volume and customized production needs.

Frequently Asked Questions

1. What types of components can be processed with SMD tape and reel machines?

SMD tape and reel machines can process a variety of components, including resistors, capacitors, integrated circuits, LEDs, transistors, diodes, and even special components like contacts and springs.

2. How do SMD tape and reel machines enhance production efficiency?

These machines automate the packaging process, reducing manual intervention and minimizing the risk of component damage. They ensure components are packaged in a standardized format, making them compatible with pick-and-place machines and streamlining the assembly process.

3. What are the environmental benefits of using SMD tape and reel machines?

The machines help reduce material waste by optimizing packaging material usage. Additionally, the materials used are often recyclable, contributing to sustainable manufacturing practices.

4. Can SMD tape and reel machines handle special or custom components?

Yes, these machines are capable of handling special components beyond standard SMDs. They can be customized to accommodate unique packaging needs, making them versatile for diverse manufacturing environments.

5. How important are reel specifications in SMD tape and reel packaging?

Reel specifications, such as width and diameter, are crucial for ensuring compatibility with pick-and-place machines. Incorrect reel sizes can lead to production inefficiencies and additional costs.