Content Menu

● Understanding SMT and Its Importance in PCB Manufacturing

● Essential Tools and Technologies for SMT PCB Training Programs

>> 1. Solder Paste Printing Equipment

>> 2. Automated Component Placement Machines

>> 3. Reflow Soldering Technology

>> 4. Inspection and Quality Assurance Tools

>> 5. Rework and Repair Equipment

>> 6. Material Handling and Storage

>> 7. Software and Data Management Systems

● Structuring a Training Plan for New SMT PCB Manufacturing Production Lines

>> Module 1: Introduction to SMT Assembly Process

>> Module 2: Component Identification and Handling

>> Module 3: Solder Paste Printing and Stencil Technology

>> Module 4: Automated Component Placement

>> Module 5: Reflow Soldering Process

>> Module 6: Inspection and Quality Control

>> Module 7: Rework and Repair Techniques

>> Module 8: Material and Consumable Management

>> Module 9: Maintenance and Troubleshooting

>> Module 10: Safety and Best Practices

● Integrating Industry Standards and Certifications

● Leveraging Technology for Enhanced Training

● Conclusion

● FAQ

>> 1. What is the most important equipment to include in SMT PCB training programs?

>> 2. How can new operators be effectively trained on SMT PCB production lines?

>> 3. Why is solder paste printing critical in SMT assembly?

>> 4. What role do industry standards play in SMT training?

>> 5. How can continuous learning be incorporated into SMT training programs?

Surface Mount Technology (SMT) has become the cornerstone of modern electronics manufacturing, enabling compact, high-performance printed circuit boards (PCBs) with automated precision. For companies launching or optimizing an SMT PCB manufacturing production line, a comprehensive training plan is essential to equip operators, technicians, and engineers with the skills and knowledge to operate sophisticated equipment, maintain quality standards, and troubleshoot issues effectively. This article explores the critical tools and technologies that should be included in SMT PCB training programs, focusing on a well-rounded training plan for new SMT PCB manufacturing production lines.

Understanding SMT and Its Importance in PCB Manufacturing

Before delving into specific tools and technologies, a foundational understanding of SMT principles is vital. SMT involves mounting electronic components directly onto the surface of PCBs, as opposed to through-hole technology where leads pass through holes in the board. This technology allows for smaller, lighter, and more reliable electronic assemblies.

Training programs must first cover:

- The basics of SMT, including component types such as resistors, capacitors, transistors, and integrated circuits.

- The advantages and disadvantages of SMT compared to other assembly methods.

- The growth history and evolution of SMT in electronics manufacturing.

This foundational knowledge sets the stage for more advanced training on equipment and process control.

Essential Tools and Technologies for SMT PCB Training Programs

A robust SMT PCB training plan for a new manufacturing production line should include hands-on instruction and theoretical knowledge of the following key tools and technologies:

1. Solder Paste Printing Equipment

- Stencil Printer: This machine applies solder paste precisely onto the PCB pads through a stencil. Training should cover stencil design, fabrication, and maintenance, as well as printer setup and parameter optimization. Operators must understand how stencil thickness, aperture size, and squeegee pressure affect solder paste deposition.

- Solder Paste Characteristics: Understanding solder paste composition, rheology, and behavior during printing is crucial for quality control. Trainees should learn about the importance of paste viscosity, particle size, and storage conditions to prevent defects.

- Solder Paste Inspection (SPI): Automated SPI systems verify the correct application of solder paste, detecting defects early. Training should include interpreting SPI data, recognizing common defects such as insufficient or excessive paste, and taking corrective actions.

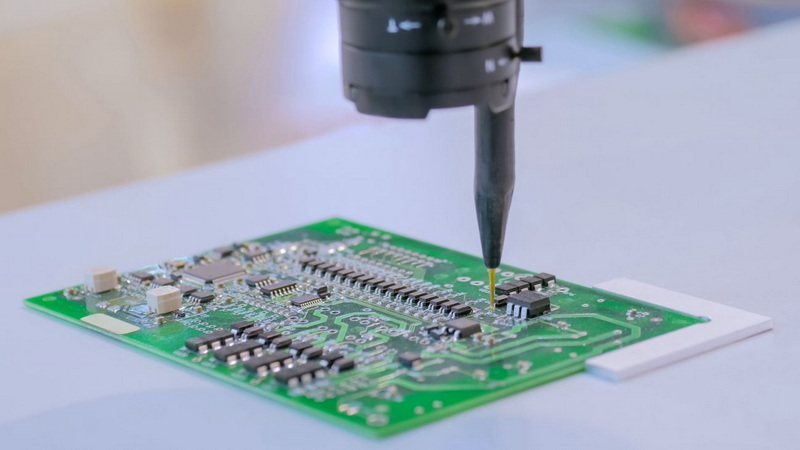

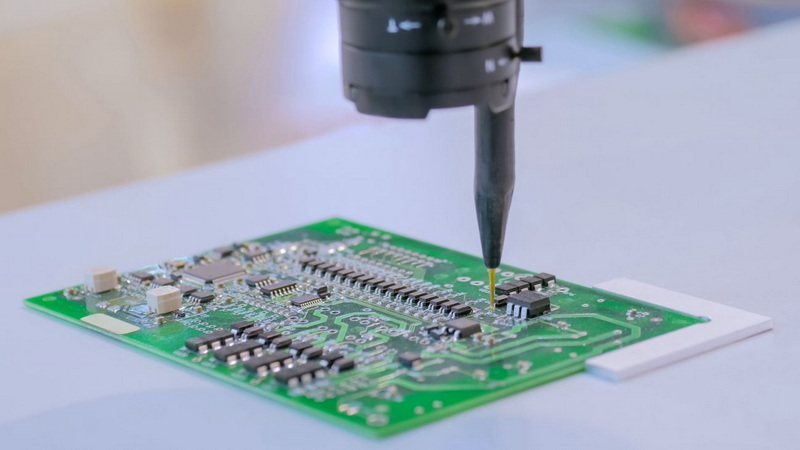

2. Automated Component Placement Machines

- Pick-and-Place Machines: These machines automatically place surface mount devices (SMDs) onto the solder-pasted PCB. Training should include machine operation, programming, feeder setup, nozzle selection, and troubleshooting common placement defects. Operators need to understand the importance of placement accuracy and speed, as well as how to optimize machine parameters for different component types and sizes.

- Component Identification and Handling: Trainees must learn how to identify components, understand their specifications, and handle them properly to avoid damage from electrostatic discharge (ESD) or moisture sensitivity. Proper component tape loading, reel handling, and storage practices are essential to maintain component integrity.

3. Reflow Soldering Technology

- Reflow Oven Operation: Training on configuring reflow profiles, understanding thermal profiling, and managing different oven types is essential. Proper reflow soldering ensures reliable solder joints by melting the solder paste without damaging components or PCBs.

- Reflow Profile Development: Instruction on how to develop and validate reflow profiles using thermocouples and temperature measurement techniques. Trainees should learn to balance the preheat, soak, reflow, and cooling zones to optimize solder joint quality and minimize thermal stress.

- Common Reflow Defects: Training should also cover common defects such as tombstoning, solder balling, and insufficient wetting, along with their causes and remedies.

4. Inspection and Quality Assurance Tools

- Automated Optical Inspection (AOI): AOI machines scan assembled PCBs for defects such as misaligned components, solder bridges, and insufficient solder. Training should include programming AOI machines, interpreting inspection results, and understanding false calls versus real defects.

- X-ray Inspection: For complex assemblies, particularly with Ball Grid Array (BGA) components, X-ray inspection detects hidden solder joint defects such as voids and insufficient solder. Operators should be trained in operating X-ray equipment and analyzing images for quality assessment.

- Manual Inspection Techniques: Training should also cover visual inspection standards and defect recognition based on industry guidelines, teaching operators to identify solder joint quality, component orientation, and cleanliness.

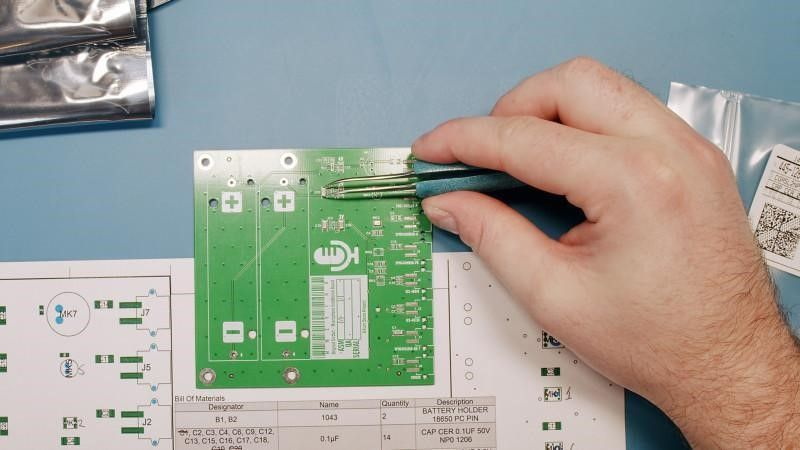

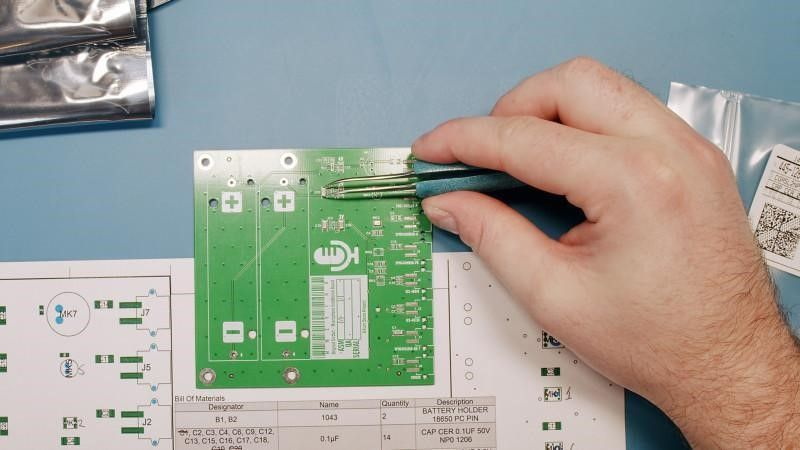

5. Rework and Repair Equipment

- Rework Stations: Tools for removing and replacing defective components, including hot air rework stations and soldering irons. Training should focus on safe and effective rework procedures to avoid PCB damage.

- Pad Repair and BGA Rework: Specialized techniques and equipment for repairing pads and reworking BGAs are critical for maintaining board integrity and reducing scrap rates.

- Rework Process Control: Emphasizing the importance of controlled heating, precise component placement, and post-rework inspection ensures the reliability of repaired assemblies.

6. Material Handling and Storage

- PCB Loaders and Unloaders: Automation for handling PCBs throughout the production line reduces manual handling errors and improves throughput.

- Component Storage: Proper storage conditions for components to maintain solderability and prevent moisture damage are vital. Training should include moisture barrier bag usage, dry storage cabinets, and first-in-first-out (FIFO) inventory management.

- Consumable Management: Training on inventory control for solder paste, flux, and other consumables ensures material quality and availability, preventing production delays.

7. Software and Data Management Systems

- Machine Programming and Control Software: Operators must learn to program pick-and-place machines, stencil printers, and reflow ovens, including uploading and editing job files, and managing recipe parameters.

- Data Collection and Analysis: Using software tools to monitor production metrics, defect rates, and process parameters supports continuous improvement initiatives. Training should emphasize interpreting data trends and implementing corrective actions.

- Traceability Systems: Understanding how to maintain traceability of components and assemblies through barcoding and database systems improves quality control and regulatory compliance.

Structuring a Training Plan for New SMT PCB Manufacturing Production Lines

A comprehensive training plan should be modular, combining classroom theory with extensive hands-on practice. Below is an outline of key modules to include:

Module 1: Introduction to SMT Assembly Process

- Overview of SMT technology and production line workflow.

- Introduction to industry standards and quality requirements.

- Explanation of the roles and responsibilities of production line personnel.

Module 2: Component Identification and Handling

- Recognizing various SMD components and their functions.

- ESD and moisture sensitivity handling procedures.

- Proper storage and handling techniques to prevent component damage.

Module 3: Solder Paste Printing and Stencil Technology

- Stencil design, fabrication, and maintenance.

- Printer setup and solder paste application techniques.

- SPI operation and defect detection.

- Hands-on practice with stencil printers and SPI machines.

Module 4: Automated Component Placement

- Pick-and-place machine operation and programming.

- Feeder and nozzle management.

- Troubleshooting placement defects such as misalignment and tombstoning.

- Practical exercises on machine setup and component placement.

Module 5: Reflow Soldering Process

- Thermal profiling and reflow oven operation.

- Profile development and defect analysis.

- Understanding solder joint formation and common defects.

- Hands-on thermal profiling and reflow oven adjustment.

Module 6: Inspection and Quality Control

- AOI and X-ray inspection fundamentals.

- Manual inspection standards and defect recognition.

- Defect classification and corrective action procedures.

- Practical inspection exercises using AOI and visual inspection tools.

Module 7: Rework and Repair Techniques

- Rework station operation and safety.

- Pad repair and BGA rework procedures.

- Post-rework inspection and quality verification.

- Hands-on rework practice with common defect scenarios.

Module 8: Material and Consumable Management

- Proper storage and handling of PCBs and components.

- Inventory control and documentation.

- Managing solder paste shelf life and storage conditions.

- Training on consumable usage and waste reduction.

Module 9: Maintenance and Troubleshooting

- Preventive maintenance of SMT equipment.

- Common issues and corrective actions for each machine.

- Documentation and reporting of maintenance activities.

- Hands-on troubleshooting exercises.

Module 10: Safety and Best Practices

- Workplace safety procedures and personal protective equipment (PPE).

- ESD control and cleanroom protocols.

- Lean manufacturing principles to optimize workflow.

- Continuous improvement culture and teamwork.

Integrating Industry Standards and Certifications

Training programs should incorporate relevant industry standards such as IPC-A-610 for acceptability of electronic assemblies, IPC J-STD-001 for soldering processes, and IPC-7711/7721 for rework and repair. Certification upon completion validates the skills of trainees and enhances workforce credibility.

Including these standards in the curriculum helps ensure that trainees understand the criteria for quality workmanship and the importance of compliance in meeting customer and regulatory expectations. Encouraging certification also motivates personnel to maintain high standards and pursue ongoing professional development.

Leveraging Technology for Enhanced Training

Modern SMT training programs can benefit significantly from leveraging technology such as virtual reality (VR), augmented reality (AR), and simulation software. These tools provide immersive, interactive learning experiences that can accelerate skill acquisition and improve retention.

- VR and AR Training: Simulating SMT production line environments allows trainees to practice equipment operation, identify defects, and perform troubleshooting in a risk-free setting.

- Simulation Software: Virtual pick-and-place programming and reflow profile tuning help trainees understand the impact of parameter changes without consuming materials.

- E-Learning Platforms: Online modules and video tutorials support flexible learning and refresher training.

Integrating these technologies into the training plan enhances engagement and prepares the workforce for real-world production challenges.

Conclusion

An effective SMT PCB training program for a new manufacturing production line must comprehensively cover the essential tools and technologies that define modern SMT assembly. This includes solder paste printing equipment, automated placement machines, reflow ovens, inspection systems, rework tools, and material handling solutions. Combining theoretical knowledge with hands-on practice ensures that operators and technicians can maintain high production quality and efficiency. Integrating industry standards and continuous learning further strengthens the workforce's capability to meet evolving manufacturing demands. Leveraging modern training technologies can accelerate skill development and improve overall training effectiveness. A well-structured training plan is the foundation for a successful SMT PCB production line, driving quality, productivity, and competitiveness in the electronics industry.

FAQ

1. What is the most important equipment to include in SMT PCB training programs?

The most important equipment includes stencil printers for solder paste application, pick-and-place machines for component placement, reflow ovens for soldering, and inspection tools like AOI and X-ray machines. Training should also cover rework stations and material handling equipment.

2. How can new operators be effectively trained on SMT PCB production lines?

Effective training combines classroom instruction on theory and standards with hands-on practice on actual SMT equipment. Modules should cover component handling, machine operation, defect recognition, and maintenance procedures.

3. Why is solder paste printing critical in SMT assembly?

Solder paste printing determines the quality of solder joints by depositing the correct amount of solder paste on PCB pads. Improper printing leads to defects like insufficient solder or bridging, affecting assembly reliability.

4. What role do industry standards play in SMT training?

Industry standards such as IPC-A-610 and IPC J-STD-001 provide guidelines for quality and workmanship. Including these standards in training ensures that assembled PCBs meet customer and regulatory requirements.

5. How can continuous learning be incorporated into SMT training programs?

Continuous learning can be supported through refresher courses, advanced workshops, certification renewals, and access to updated materials reflecting new technologies and best practices in SMT assembly.