Content Menu

● Introduction

● Key Factors to Consider When Choosing an SMT Line Assembling Manufacturer

>> Direct SMT Manufacturing Capability

>> Turnkey Solutions

>> Advanced Equipment and Technology

>> Quality Assurance and Testing

>> Financial Stability and Long-term Partnership

>> Experience and Expertise

>> Certifications and Compliance

>> Flexibility and Scalability

>> Communication and Support

● Benefits of Partnering with a Reliable SMT Manufacturer

● Conclusion

● FAQ

>> 1. What is the importance of turnkey solutions in SMT manufacturing?

>> 2. How can I verify the quality of an SMT manufacturer?

>> 3. What role does advanced equipment play in SMT assembly?

>> 4. Why is financial stability important in choosing an SMT partner?

>> 5. How do I assess the testing capabilities of an SMT manufacturer?

Introduction

Surface Mount Technology (SMT) line assembling is a cornerstone of modern electronics manufacturing, enabling efficient and high-quality production of printed circuit boards (PCBs). As the demand for electronic devices continues to rise, selecting the right SMT line assembling manufacturer becomes crucial for businesses aiming to ensure reliable product quality, cost-effectiveness, and timely delivery. This article delves into the essential factors to consider when choosing an SMT manufacturer and highlights the benefits of partnering with a reputable one.

Key Factors to Consider When Choosing an SMT Line Assembling Manufacturer

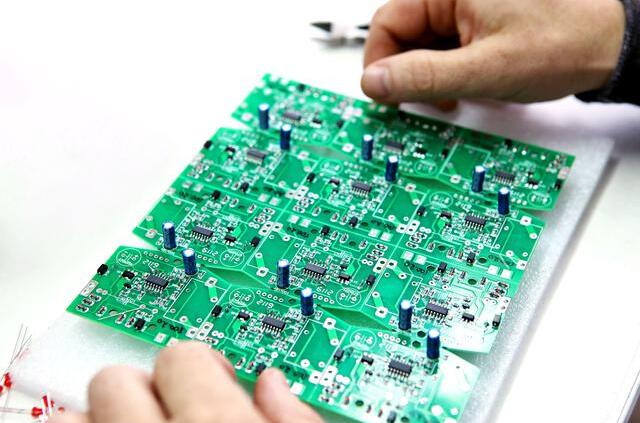

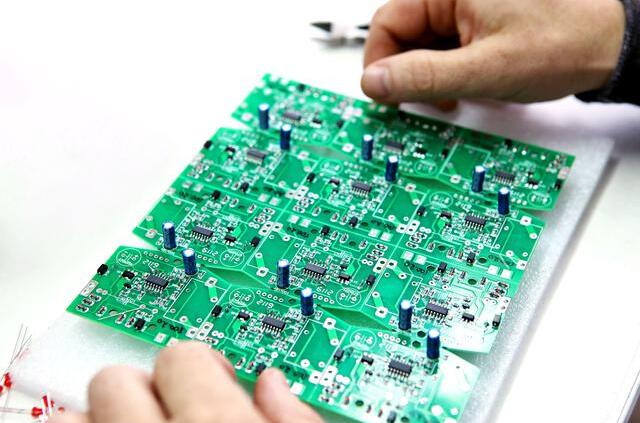

Direct SMT Manufacturing Capability

When evaluating potential manufacturers, it is vital to determine whether they are direct SMT manufacturers. Direct manufacturers operate their own assembly lines, which allows for greater control over quality and costs. By eliminating intermediaries, businesses can enjoy a more transparent and efficient production process. Moreover, direct manufacturers tend to offer more competitive pricing compared to distributors who may mark up costs due to additional handling fees.

Turnkey Solutions

Turnkey solutions are another critical factor in selecting an SMT manufacturer. These solutions encompass PCB fabrication, assembly, and testing services all under one roof. The advantages of this approach include reduced shipping costs, minimized delays, and seamless coordination across all stages of production. By opting for a manufacturer that offers turnkey solutions, businesses can streamline their operations and focus on core activities rather than managing multiple suppliers.

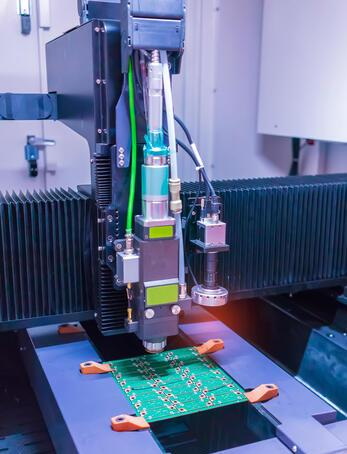

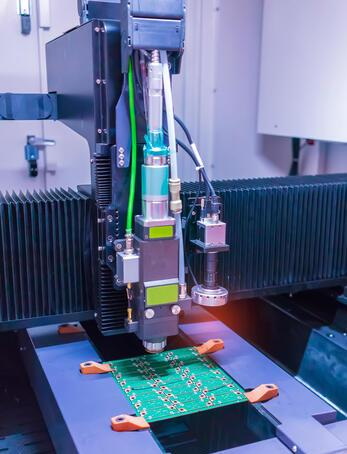

Advanced Equipment and Technology

The technology employed by an SMT manufacturer significantly impacts production quality and efficiency. Manufacturers should invest in advanced equipment such as high-speed pick-and-place machines, automated solder paste printers, and reflow ovens. These machines not only enhance precision but also enable the handling of complex designs with high component density. Additionally, incorporating inspection tools like Automated Optical Inspection (AOI) systems ensures that any defects are identified early in the process.

Quality Assurance and Testing

Quality assurance is paramount in electronics manufacturing. A reliable SMT manufacturer should implement comprehensive testing processes throughout the assembly stages. This includes solder paste inspection (SPI), AOI, functional testing, and thermal aging tests. Such rigorous testing protocols help ensure that assembled PCBs meet industry standards and customer specifications. A commitment to quality assurance reflects a manufacturer's dedication to delivering reliable products.

Financial Stability and Long-term Partnership

The financial stability of an SMT manufacturer is essential for establishing a long-term partnership. A financially sound manufacturer is more likely to invest in technology upgrades and maintain consistent operations over time. Businesses should assess a manufacturer's track record of revenue growth and customer base diversity to gauge their stability. Aligning with a financially stable partner reduces risks associated with supply chain disruptions and ensures ongoing support for future projects.

Experience and Expertise

Experience plays a crucial role in the success of an SMT manufacturer. Companies with a long-standing history in the industry are often better equipped to handle complex projects and unexpected challenges. They have likely encountered various issues over time, allowing them to develop effective solutions and best practices. When assessing potential manufacturers, inquire about their experience with specific technologies or industries relevant to your product needs.

Certifications and Compliance

Certifications serve as indicators of a manufacturer's commitment to quality standards and regulatory compliance. Look for manufacturers that hold certifications such as ISO 9001 or IPC-A-610, which demonstrate adherence to international quality management systems and industry standards for electronic assemblies. Compliance with environmental regulations (such as RoHS) is also essential for companies aiming to produce eco-friendly products.

Flexibility and Scalability

In today's fast-paced market, flexibility is vital for meeting changing customer demands. An ideal SMT manufacturer should be able to adapt quickly to fluctuations in order volumes without compromising quality or delivery timelines. Scalability is equally important; as your business grows or faces seasonal variations in demand, your manufacturing partner should be capable of scaling operations accordingly.

Communication and Support

Effective communication is essential in any partnership, especially in manufacturing where precision matters greatly. A good SMT manufacturer should provide clear channels of communication throughout the project lifecycle. This includes regular updates on production status, prompt responses to inquiries, and proactive problem-solving when issues arise. Strong customer support fosters trust and collaboration between businesses and their manufacturing partners.

Benefits of Partnering with a Reliable SMT Manufacturer

Collaborating with a reputable SMT manufacturer offers numerous advantages:

- Enhanced Productivity: A skilled manufacturer can optimize production processes, leading to increased output without sacrificing quality.

- Cost Reduction: By leveraging economies of scale and efficient manufacturing practices, reliable manufacturers can help reduce overall production costs.

- Improved Product Quality: With advanced technology and rigorous quality control measures in place, partnering with a reputable manufacturer enhances the reliability of the final product.

- Focus on Innovation: By outsourcing PCB assembly to a trusted partner, businesses can concentrate on research and development efforts rather than getting bogged down in manufacturing logistics.

- Scalability: A reliable manufacturer can easily adapt to changing production demands, whether it involves ramping up for large orders or scaling down during slower periods.

- Access to Expertise: Partnering with experienced manufacturers provides access to specialized knowledge regarding best practices in design for manufacturability (DFM), which can improve product performance while reducing costs.

- Faster Time-to-Market: Efficient processes combined with advanced technology enable quicker turnaround times on orders, allowing businesses to bring products to market faster than competitors who may not have such capabilities.

Conclusion

Choosing the right SMT line assembling manufacturer requires careful consideration of various factors including manufacturing capabilities, technological investments, quality assurance processes, financial stability, experience, certifications, flexibility, communication practices, and the potential for long-term collaboration. By prioritizing these elements during the selection process, businesses can forge partnerships that drive efficiency, reduce costs, enhance product quality in an increasingly competitive electronics market while ensuring they meet customer expectations consistently.

FAQ

1. What is the importance of turnkey solutions in SMT manufacturing?

Turnkey solutions streamline the process by integrating PCB fabrication, assembly, and testing under one roof, saving time and costs.

2. How can I verify the quality of an SMT manufacturer?

Check for certifications such as ISO 9001; review their testing processes (like AOI); read customer testimonials or case studies.

3. What role does advanced equipment play in SMT assembly?

Advanced equipment ensures precision in component placement; increases efficiency in production processes; improves overall product quality.

4. Why is financial stability important in choosing an SMT partner?

It ensures that the partner can sustain operations over time; invest in necessary upgrades; provide consistent support for your projects.

5. How do I assess the testing capabilities of an SMT manufacturer?

Look for comprehensive testing processes that include SPI (Solder Paste Inspection), AOI (Automated Optical Inspection), functional testing; other relevant inspections throughout the assembly process.