Content Menu

● Introduction to SMT Stencils

>> Designing SMT Stencils

● Benefits of SMT Stencils

>> Precise Solder Paste Deposition

>> Increased Production Efficiency

>> Cost-Effectiveness

>> Compatibility with a Wide Range of PCB Designs and Components

>> Environmental Considerations

>> Support for Advanced Technologies

● Types of SMT Stencils

● Challenges and Future Trends

>> Nano-coatings and Surface Treatments

>> Additive Manufacturing and Customization

>> Integrated Inspection and Quality Assurance

● Advanced Stencil Technologies

● Case Studies: Successful Implementation of SMT Stencils

● Emerging Trends in SMT Stencil Technology

● Conclusion

● FAQs

>> 1. What is the primary function of an SMT stencil in PCB assembly?

>> 2. How do SMT stencils improve production efficiency?

>> 3. What factors affect the accuracy of solder paste deposition using SMT stencils?

>> 4. What types of SMT stencils are available for different production needs?

>> 5. How do SMT stencils contribute to cost savings in PCB assembly?

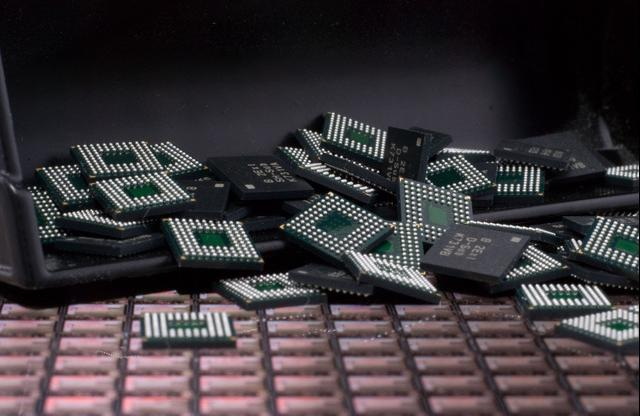

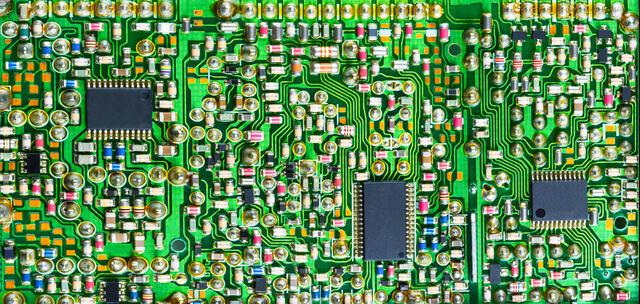

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the production of smaller, faster, and more reliable electronic devices. One of the key components in the SMT assembly process is the SMT stencil, which plays a crucial role in applying solder paste to the printed circuit board (PCB). In this article, we will explore the role of SMT stencils in improving PCB assembly efficiency, focusing on their design, benefits, and applications.

Introduction to SMT Stencils

An SMT stencil is a thin sheet of metal, typically made from stainless steel or nickel, with precision-cut apertures that correspond to the pads on a PCB. The stencil is placed over the PCB, and solder paste is applied using a squeegee, forcing the paste through the apertures and onto the pads. This process ensures that the correct amount of solder paste is deposited on each pad, enabling the accurate placement of surface mount components.

Designing SMT Stencils

Designing an SMT stencil involves several critical factors to ensure precise solder paste deposition. These include:

- Aperture Design: The size, shape, and position of the apertures directly influence the accuracy of solder paste deposition. Apertures that are too small or too large can lead to insufficient or excessive solder paste, respectively. The aperture design must be optimized based on the specific requirements of the PCB and the components being used. For instance, the aperture width should be slightly larger than the pad width to accommodate paste shrinkage during reflow, while the aperture length should be equal to or slightly longer than the pad length.

- Stencil Thickness: The thickness of the stencil determines the volume of solder paste deposited on each pad. Thicker stencils result in more solder paste, while thinner stencils produce a smaller volume of paste. Choosing the appropriate stencil thickness is essential for achieving the desired solder joint height and ensuring proper component attachment.

- Stencil Material: The choice of stencil material can impact the accuracy and consistency of solder paste deposition. Stainless steel is the most common material used for SMT stencils due to its durability, stability, and resistance to wear. Nickel stencils are also used in some applications, offering improved paste release properties and longer lifespan.

Benefits of SMT Stencils

SMT stencils offer numerous benefits that contribute to the overall efficiency, accuracy, and quality of the electronics assembly process.

Precise Solder Paste Deposition

One of the primary benefits of using SMT stencils is the precise deposition of solder paste on the PCB pads. The accuracy of solder paste application is critical to the success of the SMT assembly process, as it directly impacts the quality and reliability of the final product. Precise solder paste deposition minimizes common SMT defects, such as bridging, tombstoning, and insufficient or excessive solder joints.

Increased Production Efficiency

SMT stencils significantly enhance production efficiency by enabling faster solder paste application compared to manual methods. The use of a stencil allows for the simultaneous deposition of solder paste on multiple pads, reducing the time required to apply paste to an entire PCB. Automated stencil printing systems further increase efficiency by integrating the stencil printing process into a fully automated SMT assembly line, minimizing manual intervention and reducing the risk of human error.

Cost-Effectiveness

SMT stencils offer a cost-effective solution for solder paste application in electronics manufacturing. The precise aperture design of the stencil ensures that the correct amount of solder paste is deposited on each pad, minimizing waste and overuse of expensive solder paste materials. Additionally, the accuracy and consistency provided by SMT stencils help to minimize the occurrence of solder-related defects, reducing the need for manual rework or scrap.

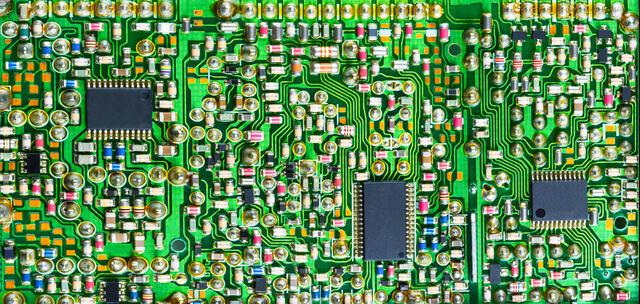

Compatibility with a Wide Range of PCB Designs and Components

SMT stencils are versatile and can be custom-designed to accommodate virtually any PCB layout, regardless of the complexity or component density. This flexibility allows manufacturers to use stencils for a broad range of products, from simple, single-layer boards to complex, multi-layer designs. SMT stencils can accommodate varying pad sizes and shapes, fine-pitch components, and mixed component types, making them suitable for diverse applications.

Environmental Considerations

SMT stencils contribute to sustainability by optimizing resource use and reducing material waste. Improved efficiency and minimized defects reduce energy consumption and carbon emissions. Advanced materials and coatings promote longevity and recyclability, reducing environmental impact.

Support for Advanced Technologies

SMT stencils support technological advancements like miniaturization and increased functionality. They enable precise solder paste deposition for small, delicate components and high-density interconnections, crucial for developing compact, sophisticated electronic products.

Types of SMT Stencils

SMT stencils come in different forms to meet varied production needs:

- Frameless SMT Stencils: These stencils are flexible and cost-effective, ideal for prototypes and small-scale production. They are made from stainless steel or nickel alloys and are easy to handle and store, adapting well to evolving PCB designs.

- Framed SMT Stencils: Known for their durability, framed stencils are perfect for high-volume manufacturing. The rigid frame provides stability during solder paste application, ensuring consistent results across multiple PCBs.

- Prototype SMT Stencils: Rapid prototyping benefits from these stencils, allowing engineers to quickly test new PCB layouts. They support agility in product development, enabling fast adjustments based on initial tests and feedback.

Challenges and Future Trends

Despite the numerous benefits of SMT stencils, there are challenges associated with their design and use. Maintaining correct aperture ratios and considering factors like the printing gap are crucial for optimal performance. Future trends in SMT stencil technology include advancements in materials and manufacturing processes to support miniaturization and increased functionality in electronic devices.

Nano-coatings and Surface Treatments

Advanced nano-coatings improve solder paste release and reduce adhesion, enhancing print quality and fine-pitch component printing. They also require less frequent cleaning, prolonging stencil life. For instance, NanoSlic coatings are highly hydrophobic and oleophobic, repelling solder paste and improving transfer efficiency, which results in higher yields and less rework.

Additive Manufacturing and Customization

3D printing enables custom-designed SMT stencils with intricate geometries and tailored aperture designs. This flexibility accommodates unique PCB layouts and component configurations. Additive manufacturing allows for the creation of highly specialized stencils that can meet the specific needs of complex and innovative PCB designs.

Integrated Inspection and Quality Assurance

Emerging technologies integrate automated inspection systems into the stencil printing process, enabling real-time monitoring of solder paste deposition quality. Automated systems detect defects like insufficient solder paste volume or misalignment, ensuring adherence to manufacturing specifications.

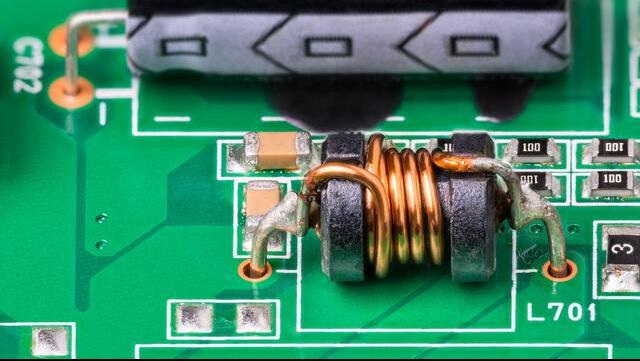

Advanced Stencil Technologies

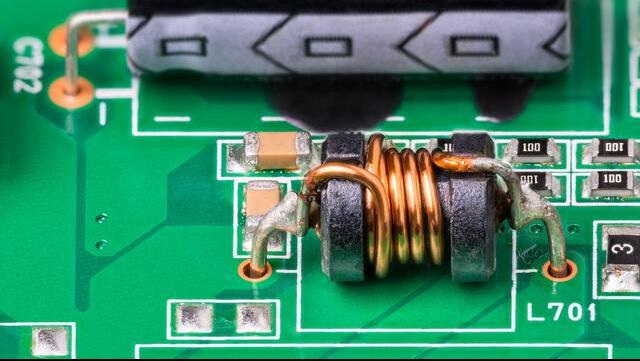

Recent advancements in stencil technology have led to the development of specialized coatings and multi-level stencils. These innovations enhance stencil performance and adaptability:

- NanoSlic Coatings: These coatings improve solder paste transfer efficiency, minimize bridging, and reduce underside cleaning. They are compatible with current assembly equipment and processes, offering a durable and efficient solution for high-yield production.

- Multi-Level Stencils: Also known as stepped stencils, these are engineered to enhance stencil printing by allowing for different solder paste volumes on the same PCB. They are crucial for mixed technology assemblies where varying component types require different amounts of solder paste.

Case Studies: Successful Implementation of SMT Stencils

Several electronics manufacturers have successfully integrated SMT stencils into their production lines, achieving significant improvements in efficiency and quality. For instance, a leading smartphone manufacturer implemented automated stencil printing systems to increase production throughput while maintaining high-quality solder joints. This resulted in reduced production costs and faster time-to-market for new products.

Emerging Trends in SMT Stencil Technology

The future of SMT stencil technology is promising, with ongoing research into advanced materials and manufacturing techniques. One emerging trend is the use of laser direct structuring (LDS) to enhance stencil longevity and transfer efficiency without sacrificing performance. Additionally, the integration of artificial intelligence (AI) in stencil design and inspection is expected to further optimize the PCB assembly process, enabling real-time adjustments and predictive maintenance.

Conclusion

SMT stencils play a pivotal role in improving PCB assembly efficiency by ensuring precise solder paste deposition, increasing production speed, and reducing costs. Their versatility and adaptability make them essential tools for enhancing manufacturing efficiency, improving product quality, and maintaining consistent production standards in PCB assembly processes.

FAQs

1. What is the primary function of an SMT stencil in PCB assembly?

An SMT stencil is used to apply solder paste to the PCB pads accurately, ensuring the correct amount of solder paste is deposited for reliable component placement and solder joint quality.

2. How do SMT stencils improve production efficiency?

SMT stencils improve production efficiency by enabling faster solder paste application compared to manual methods. They allow for simultaneous deposition on multiple pads, reducing assembly time and increasing throughput.

3. What factors affect the accuracy of solder paste deposition using SMT stencils?

Factors affecting accuracy include stencil thickness, aperture design, and stencil material. Proper design and selection of these factors are crucial for precise solder paste deposition.

4. What types of SMT stencils are available for different production needs?

There are frameless, framed, and prototype SMT stencils. Frameless stencils are ideal for prototypes and small-scale production, while framed stencils are used for high-volume manufacturing. Prototype stencils support rapid product development.

5. How do SMT stencils contribute to cost savings in PCB assembly?

SMT stencils contribute to cost savings by reducing solder paste consumption and minimizing defects. This reduces the need for manual rework or scrap, lowering overall production costs and enhancing profitability.