Content Menu

● Introduction

● Overview of SMT PCB Carriers

>> Types of SMT Carriers

● Common Materials for SMT PCB Carriers

>> 1. FR4 (Flame Retardant 4)

>> 2. Aluminum Alloy

>> 3. Durostone (Nanometer Composite Stone)

>> 4. Stainless Steel

>> 5. Thermoset Plastic (ESD Composite)

● Design Considerations for SMT Carriers

● Applications and Benefits

● Customization and Ordering Process

>> Steps to Order a Custom SMT Carrier:

● Challenges and Future Developments

● Conclusion

● FAQs

>> 1. What are the primary functions of SMT PCB carriers?

>> 2. What materials are commonly used for SMT PCB carriers?

>> 3. Why is Durostone widely used in reflow carriers?

>> 4. What are the key design considerations for SMT carriers?

>> 5. How do SMT carriers improve production efficiency?

● Citations:

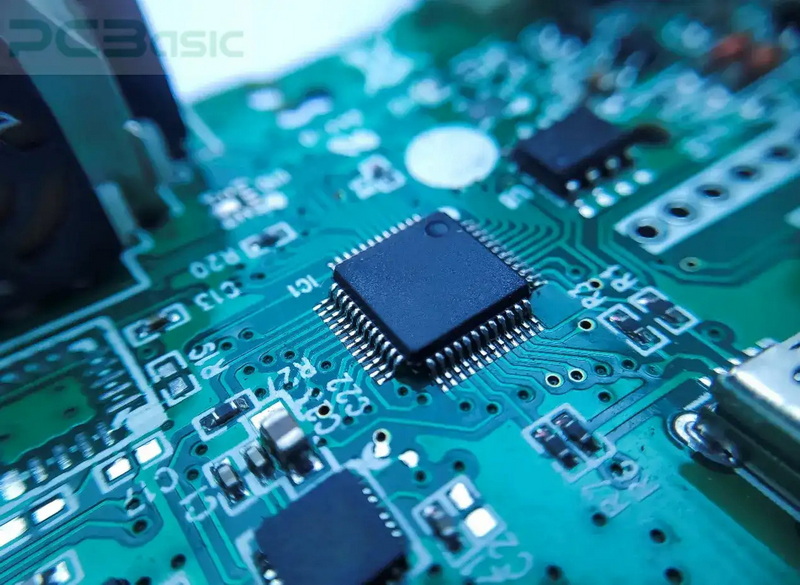

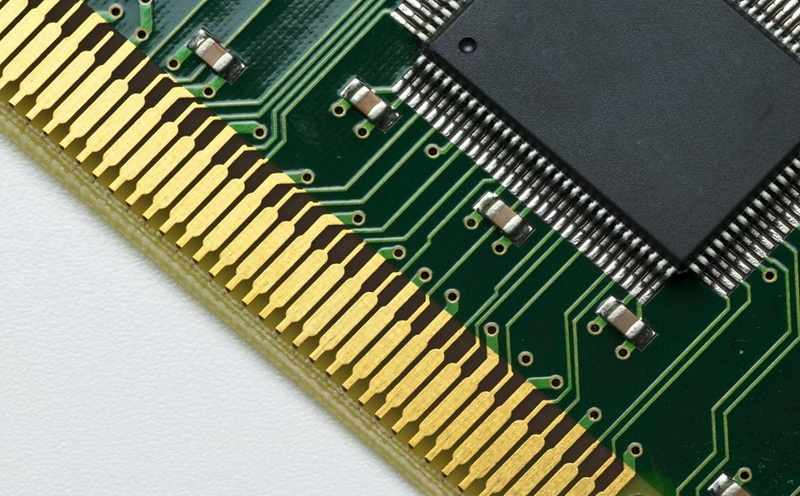

Introduction

In the realm of Surface Mount Technology (SMT), PCB carriers play a crucial role in ensuring the efficient and reliable assembly of printed circuit boards. These carriers are designed to support, protect, and transport PCBs throughout the entire SMT process, from solder paste application to reflow soldering. The choice of material for SMT PCB carriers is critical, as it directly affects the performance, durability, and cost-effectiveness of the assembly process. This article will delve into the commonly used materials for SMT PCB carriers, their properties, and applications.

Overview of SMT PCB Carriers

SMT PCB carriers are customized tools used to align and hold printed circuit boards during the assembly process. They are essential when dealing with small, irregularly shaped, or thin PCBs that are prone to deformation or warping, especially during high-temperature processes like reflow soldering. The primary function of these carriers is to minimize PCB deformation, prevent component misalignment, and ensure consistent soldering quality.

Types of SMT Carriers

1. Reflow Carriers: These are specifically designed for use in the reflow oven to support PCBs during the soldering process. They often feature positioning pillars and ribs to secure the PCB and prevent deformation.

2. Full Process Carriers: These carriers provide support throughout the entire SMT process, including solder paste application, component placement, and reflow soldering. They are particularly useful for thin or complex PCBs that require additional support to maintain flatness during all stages of assembly.

Common Materials for SMT PCB Carriers

The selection of materials for SMT PCB carriers depends on several factors, including thermal stability, mechanical strength, cost, and ease of processing. Here are some of the most commonly used materials:

1. FR4 (Flame Retardant 4)

FR4 is a widely used material in PCB manufacturing due to its cost-effectiveness and mechanical strength. However, when used as a carrier material, it is typically without copper to avoid any electrical conductivity issues. FR4 carriers are suitable for processes like printing and reflowing but may not be ideal for high-temperature applications due to their relatively low glass transition temperature (Tg) compared to other materials.

2. Aluminum Alloy

Aluminum alloy is another popular choice for SMT carriers due to its lightweight nature, high thermal conductivity, and cost-effectiveness. It is often used for reflow carriers because it can efficiently dissipate heat, reducing the risk of PCB deformation. However, aluminum can absorb heat, requiring operators to handle it with care after use. In recent years, aluminum has faced competition from newer materials like synthetic stone, which offers better thermal properties and lower heat absorption[2].

3. Durostone (Nanometer Composite Stone)

Durostone is a glass fiber reinforced composite material known for its high strength, dimensional stability, and excellent thermal properties. It is widely used in reflow carriers due to its ability to withstand high temperatures (up to 400°C) without significant deformation. Durostone carriers can be used over 20,000 times, making them a cost-effective option in the long run[3].

4. Stainless Steel

Stainless steel carriers are durable and resistant to corrosion but are less commonly used due to their higher cost and weight. They are suitable for processes like printing and component placement but are not recommended for reflow due to thermal expansion issues[1][5].

5. Thermoset Plastic (ESD Composite)

Thermoset plastics, often used in combination with pressed fibers, are another material option for SMT carriers. They offer good mechanical strength and can be machined to create custom fixtures. These materials are suitable for all stages of the SMT process, including reflow[1][5].

Design Considerations for SMT Carriers

When designing SMT carriers, several factors must be considered to ensure optimal performance:

- Thermal Stability: The material should have a high softening deformation temperature to withstand repeated exposure to high temperatures without losing shape.

- Mechanical Strength: The carrier must provide sufficient support to prevent PCB deformation and maintain flatness.

- Cost-Effectiveness: The material should be affordable and suitable for mass production.

- Machinability: Easy processing is crucial for creating custom designs and features.

- Thermal Expansion: Minimal thermal expansion is essential to prevent damage to the PCB during heating and cooling cycles.

Applications and Benefits

SMT PCB carriers are essential in various electronic manufacturing processes, including:

- Automatic Insertion and Assembly: They ensure precise alignment and support during component placement.

- Wave Soldering and Reflow Soldering: Carriers prevent PCB warping and maintain component positioning during high-temperature soldering processes.

- In-Line Testing: They provide mechanical support during testing phases, ensuring reliable contact and accurate results.

The use of SMT carriers improves production efficiency by reducing setup time, minimizing handling errors, and enhancing soldering quality. They are particularly beneficial for thin or complex PCBs that require additional support to maintain integrity throughout the assembly process.

Customization and Ordering Process

To order a suitable SMT carrier, manufacturers typically require detailed specifications, including Gerber files, BOM lists, and photos of the assembled PCBs. This information helps in designing a custom carrier that precisely fits the PCB dimensions and requirements. The production process involves evaluating these specifications, providing a detailed quotation, and then manufacturing the carrier based on approved designs[4].

Steps to Order a Custom SMT Carrier:

1. Provide Specifications: Share Gerber files, BOM lists, and photos of the assembled PCBs.

2. Quotation and Design: Receive a detailed quotation and review the proposed design.

3. Approval and Production: Approve the design and proceed with production.

4. Quality Control: Conduct tolerance tests and measurements before shipment.

Challenges and Future Developments

As electronic products become thinner and more compact, the demand for materials that can support these advancements is increasing. New materials like synthetic stone are gaining popularity due to their thermal stability and cost-effectiveness compared to traditional materials like aluminum alloy[2]. The future of SMT carriers will likely involve more innovative materials and designs that cater to the evolving needs of the electronics industry.

Conclusion

SMT PCB carriers are indispensable tools in the surface mount technology assembly process, offering support, protection, and precision alignment for printed circuit boards. The choice of material for these carriers is critical and depends on factors such as thermal stability, mechanical strength, and cost-effectiveness. Common materials include FR4, aluminum alloy, Durostone, stainless steel, and thermoset plastics, each with its unique advantages and applications. By selecting the appropriate material and design, manufacturers can optimize their SMT processes, improve product quality, and reduce production costs.

FAQs

1. What are the primary functions of SMT PCB carriers?

SMT PCB carriers are designed to support, protect, and transport printed circuit boards throughout the SMT process, minimizing deformation and ensuring consistent soldering quality.

2. What materials are commonly used for SMT PCB carriers?

Common materials include FR4, aluminum alloy, Durostone, stainless steel, and thermoset plastics. Each material has specific properties that make it suitable for different stages of the SMT process.

3. Why is Durostone widely used in reflow carriers?

Durostone is favored for reflow carriers due to its high thermal stability, dimensional stability, and ability to withstand high temperatures without deformation. It offers a long lifespan and is cost-effective in the long term.

4. What are the key design considerations for SMT carriers?

Key considerations include thermal stability, mechanical strength, cost-effectiveness, machinability, and minimal thermal expansion to ensure optimal performance and prevent PCB damage.

5. How do SMT carriers improve production efficiency?

SMT carriers improve efficiency by reducing setup time, minimizing handling errors, enhancing soldering quality, and providing consistent support throughout the assembly process.

Citations:

[1] https://www.pcbunlimited.com/smt-carriers

[2] https://mpe.researchmfg.com/reflow-carrier/

[3] https://madpcb.com/reflow-carrier/

[4] https://smartsmttools.com/how-to-order-a-suitable-smt-carrier-to-highly-improve-your-smt-process-efficiency%EF%BC%9F/

[5] https://www.pentalogix.com/products/smt-carriers

[6] https://www.pcbunlimited.com/pcb-assembly-tooling

[7] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[8] https://www.protoexpress.com/kb/smt-assembly/

[9] https://www.pentalogix.com/blog/2023/02/22/materials-used-in-printed-circuit-board-substrates/

[10] https://picamfg.com/navigating-smt-assembly-methods-for-flexible-circuits/

[11] https://www.stentech.com/products/solder-pallet/surface-mount-process-carriers

[12] https://www.nordson.com/en/divisions/electronics-solutions/your-process/industries/pcb-and-smt-assembly

[13] https://smartsmttools.com/product-item/smt-process-carriers/

[14] https://www.nexpcb.com/blog/the-basics-of-smt-material-package-type

[15] https://www.stencilsunlimited.com/surface-mount-carriers

[16] https://smartsmttools.com/what-materials-are-used-in-smt-fixtures-a-comprehensive-guide-by-smart-smt-tools/

[17] https://www.pcbway.com/pcb_prototype/SMT_Assembly_Capabilities.html

[18] https://beamon.com/smt-carriers.php

[19] https://www.acimaterials.com/applications/surface-mount-technology/

[20] https://www.pcbelec.com/smt-materials.html