Content Menu

>> Overview of Fuji NXT Feeders

>> Key Features of Fuji NXT Feeders

>> Benefits of Choosing a Reliable Fuji NXT Feeder Supplier

>> Applications of Fuji NXT Feeders

>> Comparing Fuji NXT Feeders with Competitors

>>> Speed Comparison

>>> Precision Analysis

>>> User Experience

>> Case Studies

>>> Case Study 1: Consumer Electronics Manufacturer

>>> Case Study 2: Automotive Supplier

>> Future Trends in SMT Technology

>> Conclusion

>> Frequently Asked Questions

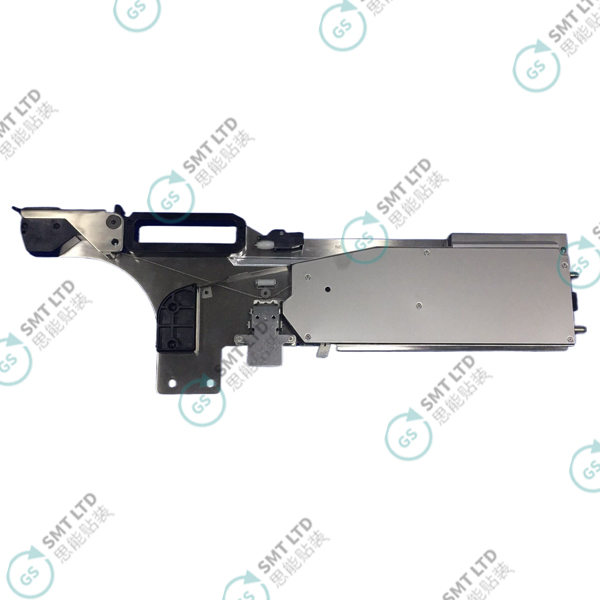

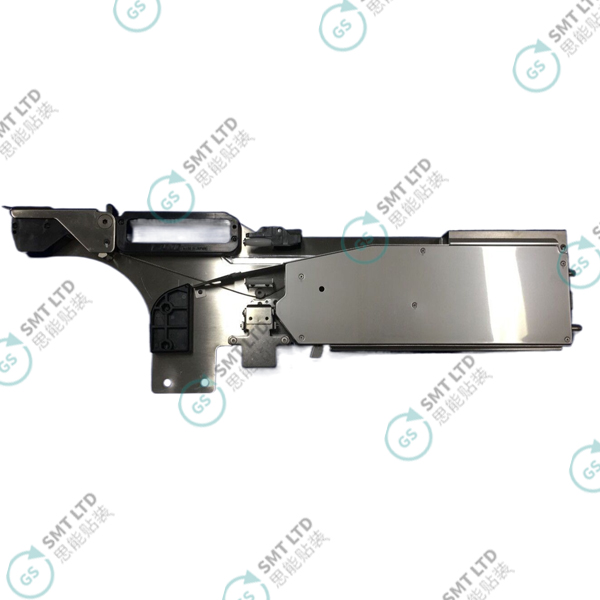

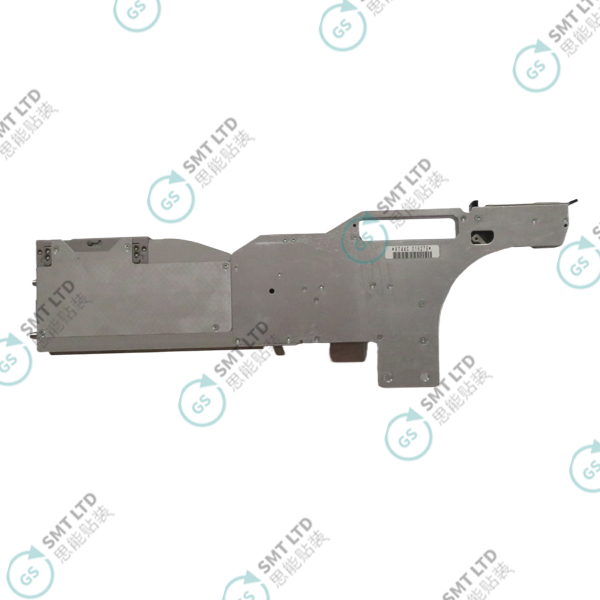

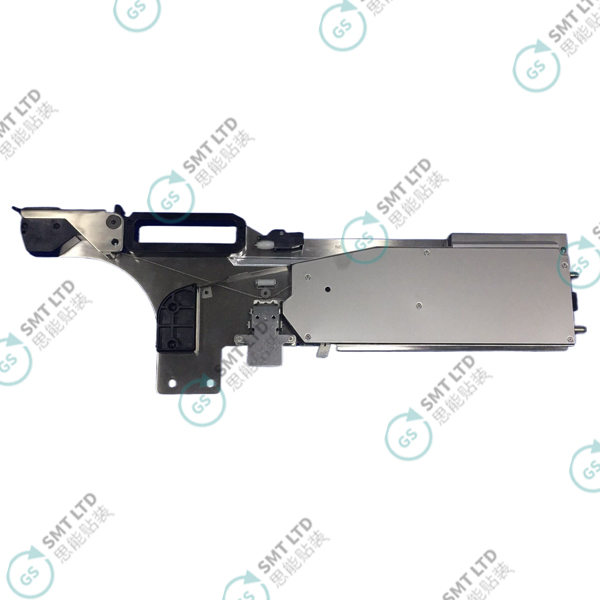

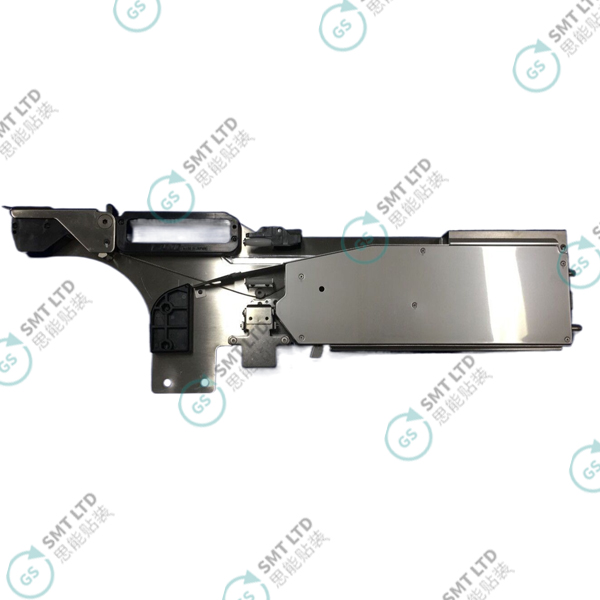

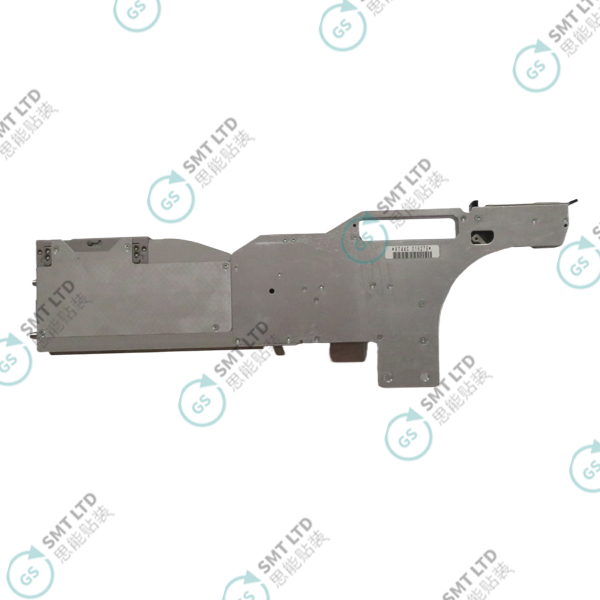

Overview of Fuji NXT Feeders

Fuji NXT feeders are designed to work seamlessly with Fuji's advanced SMT placement machines, such as the NXT III series. These feeders are known for their high-speed operation, precision, and versatility in handling various component sizes. The NXT III feeder series includes models that can accommodate tape widths ranging from 8mm to 24mm, making them suitable for a wide array of electronic components.

Fuji NXT Feeder

*Image Source: Fuji NXT Feeder*

Key Features of Fuji NXT Feeders

1. High Speed and Efficiency: The NXT III feeders are engineered to support high-speed placement operations, achieving up to 37,500 chips per hour with the new H24G head. This speed is essential for meeting the demands of high-volume production environments.

2. Versatility: These feeders can handle various types of components, including small chip parts (0402 mm) and larger components, making them adaptable to different manufacturing needs.

3. Precision Placement: With an impressive placing accuracy of ±0.025 mm, Fuji NXT feeders ensure that components are accurately positioned on PCBs, reducing defects and improving overall product quality.

4. User-Friendly Design: The intuitive graphical user interface (GUI) combined with touchscreen functionality simplifies operation and reduces the likelihood of errors during setup and operation.

5. Compatibility: Many components from previous models, such as placing heads and nozzle stations, are compatible with the NXT III without modifications, facilitating easy upgrades for existing users.

Benefits of Choosing a Reliable Fuji NXT Feeder Supplier

Selecting a reputable supplier for Fuji NXT feeders is vital for ensuring quality and support. Here are some benefits:

- Quality Assurance: Trusted suppliers provide genuine parts that meet strict quality standards.

- Technical Support: Suppliers often offer comprehensive after-sales support, including troubleshooting and maintenance services.

- Competitive Pricing: Established suppliers can provide competitive pricing due to their relationships with manufacturers and economies of scale.

- Access to Spare Parts: A reliable supplier will have access to a wide range of spare parts and accessories necessary for maintenance and upgrades.

- Expert Guidance: Experienced suppliers can offer valuable insights into optimizing feeder performance based on specific production needs.

Applications of Fuji NXT Feeders

Fuji NXT feeders are widely used in various sectors of electronics manufacturing:

- Consumer Electronics: Used in assembling devices like smartphones and tablets where precision is critical.

- Automotive Electronics: Essential for placing components in automotive control systems that require high reliability.

- Industrial Equipment: Utilized in manufacturing complex industrial machines where diverse component types are needed.

- Medical Devices: Critical in the assembly of medical electronics where accuracy can impact safety and functionality.

- Telecommunications: Used in producing communication devices that require high-density component placement.

Comparing Fuji NXT Feeders with Competitors

When considering a Fuji NXT feeder supplier, it's important to understand how these feeders stack up against competitors like Panasonic or Yamaha.

Speed Comparison

While many competitors offer high-speed feeders, the Fuji NXT feeder consistently ranks among the fastest in the industry. For example, Panasonic's feeders may reach speeds up to 30,000 chips per hour; however, they often lack the same level of versatility when handling different component sizes.

Precision Analysis

In terms of precision, Fuji's ±0.025 mm accuracy is often superior compared to many other brands that may have tolerances closer to ±0.05 mm. This difference can be critical in applications requiring tight tolerances.

User Experience

The user interface on Fuji machines is frequently cited as more intuitive compared to others on the market. This ease of use can significantly reduce training time for operators and increase overall productivity.

Case Studies

Case Study 1: Consumer Electronics Manufacturer

A leading consumer electronics manufacturer implemented Fuji NXT feeders in their assembly line for smartphones. By switching from their previous feeder system to Fuji's technology, they reported a 20% increase in production speed while maintaining a defect rate below 0.1%. The flexibility of handling various component sizes allowed them to streamline their production process significantly.

Case Study 2: Automotive Supplier

An automotive supplier faced challenges with component placement accuracy in their electronic control units (ECUs). After integrating Fuji NXT feeders into their production line, they achieved an accuracy improvement that reduced rework costs by 15%. The ability to quickly switch between different component types also enhanced their responsiveness to changing customer demands.

Future Trends in SMT Technology

As technology continues to evolve, several trends are shaping the future of SMT solutions:

1. Increased Automation: The integration of AI and machine learning into feeder systems is expected to enhance predictive maintenance capabilities and optimize production schedules.

2. Miniaturization of Components: As electronic devices become smaller and more complex, feeders will need to adapt to handle increasingly miniature components with precision.

3. Sustainability Practices: There is a growing emphasis on sustainable manufacturing practices within the electronics industry. Suppliers that focus on eco-friendly materials and energy-efficient machines will likely gain a competitive edge.

4. Enhanced Connectivity: IoT-enabled feeders will allow for real-time monitoring and data analysis, enabling manufacturers to make informed decisions quickly.

5. Customization Options: As manufacturers seek tailored solutions for unique production needs, suppliers offering customizable feeder options will be well-positioned in the market.

Conclusion

The Fuji NXT feeder stands out as a leading solution in the SMT industry due to its speed, precision, versatility, and user-friendly design. As manufacturers continue to seek ways to enhance productivity while maintaining high-quality standards, the demand for reliable Fuji NXT feeder suppliers will only grow. By choosing reputable suppliers who understand both technology and customer needs, businesses can ensure they remain competitive in an ever-evolving market.

Frequently Asked Questions

1. What types of components can be used with the Fuji NXT feeder?

- The Fuji NXT feeder can handle a wide range of components from small chips (0402 mm) to larger parts used in various applications.

2. How does the speed of the Fuji NXT feeder compare to other feeders?

- The Fuji NXT feeder achieves speeds up to 37,500 chips per hour, making it one of the fastest options available on the market.

3. What is the placing accuracy of the Fuji NXT feeder?

- The placing accuracy is ±0.025 mm, ensuring precise component placement on PCBs.

4. Can I use old parts from previous Fuji models with the NXT III?

- Yes, many components from earlier models are compatible with the NXT III without any modifications needed.

5. Why should I choose a specific supplier for my Fuji NXT feeders?

- A reputable supplier ensures quality products, provides technical support, and often offers competitive pricing compared to less established vendors.