Content Menu

● Understanding SMT and Its Importance in Manufacturing

>> Key Factors That Make a Supplier Stand Out

>> 1. Product Quality and Innovation

>> 2. Comprehensive Product Range

>> 3. Customization Options

>> 4. Customer Support and Service

>> 5. Reputation and Track Record

>> 6. Competitive Pricing

>> 7. Delivery Time and Logistics

● Additional Considerations When Choosing an SMT Supplier

>> 1. Technological Compatibility

>> 2. Sustainability Practices

>> 3. Global Presence

>> 4. Training Programs

>> 5. Industry Certifications

● Evaluating Potential Suppliers

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How do I choose the right SMT machine?

>> 3. What are some leading brands in SMT machinery?

>> 4. Why is customer support important when selecting an SMT supplier?

>> 5. Can I customize my SMT machinery?

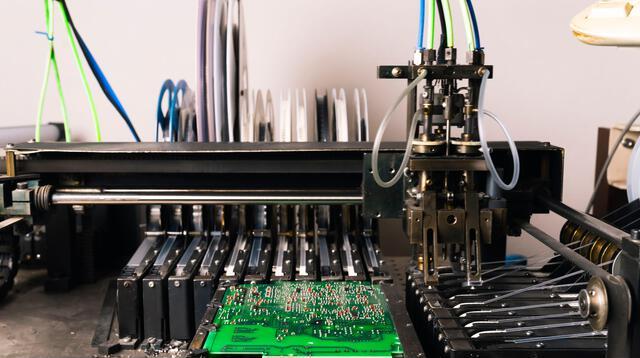

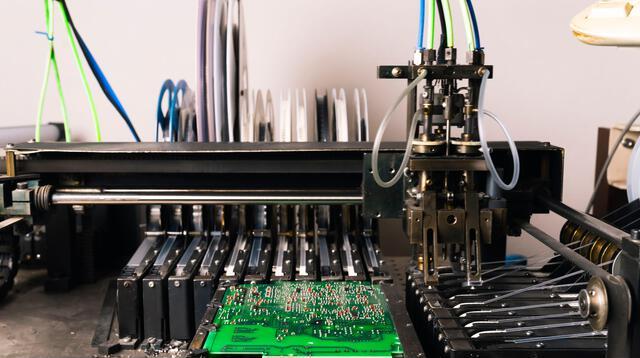

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, allowing for more efficient assembly processes and higher quality products. As companies seek to optimize their production lines, the choice of an SMT machine supplier becomes critical. This article explores the key factors that distinguish the best SMT line machine suppliers from the rest, providing insights into their offerings, reputation, and service quality.

Understanding SMT and Its Importance in Manufacturing

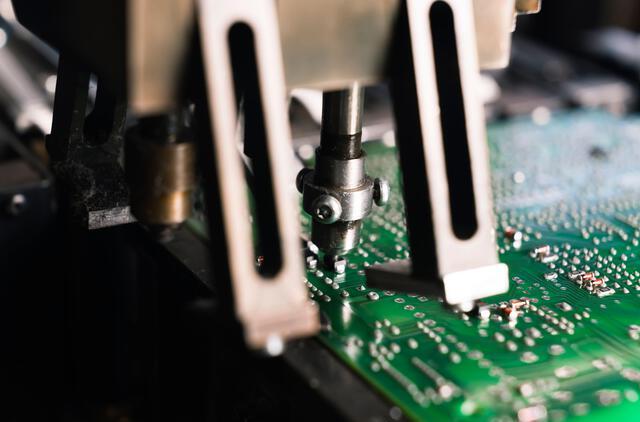

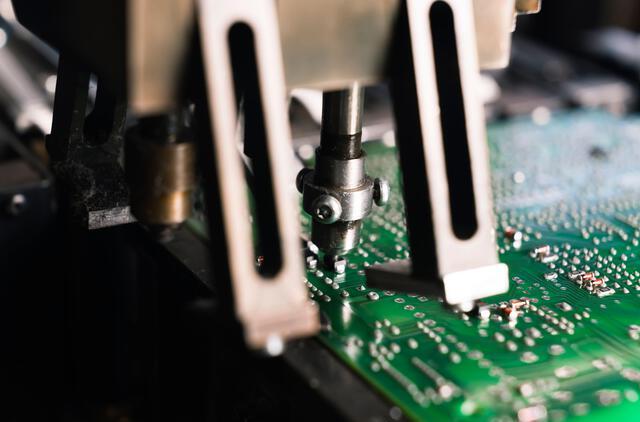

SMT is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). This technology has several advantages over traditional through-hole mounting, including:

- Higher Component Density: SMT allows for smaller components to be placed closer together, enabling more complex circuits in a smaller footprint.

- Improved Performance: The shorter electrical paths reduce resistance and inductance, leading to better performance.

- Cost Efficiency: SMT can lower manufacturing costs due to reduced material usage and faster assembly times.

- Flexibility in Design: Designers can utilize a wider range of components, including those with complex shapes and sizes, which enhances product innovation.

Given these benefits, selecting the right SMT line machine supplier is essential for businesses aiming to enhance their production capabilities.

Key Factors That Make a Supplier Stand Out

When evaluating potential SMT line machine suppliers, several factors can indicate their quality and reliability:

1. Product Quality and Innovation

The best suppliers consistently offer high-quality machines that incorporate the latest technological advancements. They invest in research and development to ensure their products meet industry standards and customer needs. For instance, suppliers like ASM Assembly Systems and Yamaha Motor IM are known for their innovative designs that enhance speed and accuracy in component placement. Continuous innovation leads to machines that not only perform better but also integrate seamlessly with other technologies, such as Industry 4.0 solutions.

2. Comprehensive Product Range

A supplier that provides a wide variety of machines can cater to different production needs. This includes offering various types of pick-and-place machines, solder paste printers, reflow ovens, and inspection systems. Companies like Rayming Technology stand out due to their extensive product portfolio that addresses various market segments from low-volume to high-volume production. A comprehensive range allows manufacturers to source all necessary equipment from a single supplier, simplifying logistics and reducing compatibility issues.

3. Customization Options

Every manufacturing operation has unique requirements. The best suppliers offer customization options to tailor machines to specific production needs. For example, Europlacer is recognized for its flexible solutions that allow manufacturers to adapt their equipment as production demands change. Customization can involve software modifications, hardware upgrades, or even bespoke machinery designed specifically for a client's unique processes.

4. Customer Support and Service

Exceptional customer support is crucial for maintaining operational efficiency. Suppliers should provide comprehensive training, technical support, and maintenance services. A company like JUKI Automation Systems excels in this area by offering extensive after-sales support and training programs to ensure customers can maximize their equipment's potential. Additionally, proactive maintenance services help prevent downtime by addressing issues before they escalate into significant problems.

5. Reputation and Track Record

A supplier's reputation within the industry can be a strong indicator of reliability. Companies with positive customer feedback and long-standing relationships with clients tend to be more trustworthy. For instance, Panasonic Factory Solutions has built a solid reputation over decades by delivering consistent quality and service. Investigating case studies or testimonials from existing customers can provide valuable insights into a supplier's reliability.

6. Competitive Pricing

While price should not be the sole factor in decision-making, it is essential to find a balance between cost and quality. Suppliers that offer competitive pricing without compromising on quality will stand out in a crowded market. Companies like DDM Novastar provide affordable options while maintaining high standards of performance. It is also important to consider total cost of ownership (TCO), which includes maintenance costs, energy consumption, and potential downtime.

7. Delivery Time and Logistics

Timely delivery of equipment is critical for maintaining production schedules. Suppliers with efficient logistics systems ensure that machines arrive on time, minimizing downtime for manufacturers. A supplier's ability to meet deadlines can significantly impact overall productivity; therefore, understanding their supply chain management practices is vital.

Additional Considerations When Choosing an SMT Supplier

In addition to the key factors listed above, there are several other considerations that can influence your choice of an SMT line machine supplier:

1. Technological Compatibility

As technology rapidly evolves, ensuring that your SMT equipment is compatible with existing systems is crucial for seamless integration into your production line. The best suppliers will offer machines that support various software platforms and communication protocols.

2. Sustainability Practices

With growing awareness around environmental issues, many manufacturers are looking for suppliers committed to sustainability practices. This includes energy-efficient machinery designs and environmentally friendly manufacturing processes.

3. Global Presence

For companies operating in multiple regions or countries, selecting a supplier with a global presence can facilitate easier access to support services and spare parts. Suppliers with international reach often have established networks that enhance reliability.

4. Training Programs

Effective training programs are essential for ensuring that staff members are well-equipped to operate new machinery efficiently. Suppliers who invest in comprehensive training initiatives demonstrate their commitment to customer success.

5. Industry Certifications

Certifications from recognized industry bodies can provide assurance regarding a supplier's adherence to quality standards and best practices in manufacturing processes.

Evaluating Potential Suppliers

To effectively evaluate potential SMT line machine suppliers, consider the following steps:

- Request Proposals: Gather quotes from multiple suppliers to compare pricing structures and offerings.

- Conduct Site Visits: If possible, visit the supplier's facility to see their operations firsthand and assess their capabilities.

- Check References: Speak with other customers who have worked with the supplier to gauge satisfaction levels regarding product performance and support services.

- Trial Periods: Some suppliers may offer trial periods or sample orders which allow you to test equipment before making a significant investment.

- Assess Financial Stability: Understanding a supplier's financial health can provide insights into their ability to support your business long-term without disruptions.

Conclusion

Choosing the right SMT line machine supplier is a strategic decision that can significantly impact your manufacturing efficiency and product quality. By focusing on factors such as product quality, comprehensive offerings, customization options, customer support, reputation, competitive pricing, delivery logistics, technological compatibility, sustainability practices, global presence, training programs, and industry certifications; businesses can identify suppliers that will help them thrive in a competitive landscape.

In summary, the best SMT line machine suppliers stand out by combining innovation with reliability while providing exceptional service tailored to meet diverse customer needs.

FAQ

1. What is Surface Mount Technology (SMT)?

SMT refers to a method used in electronics manufacturing where components are mounted directly onto the surface of PCBs rather than being inserted through holes. This technology allows for higher density circuits and improved performance.

2. How do I choose the right SMT machine?

Consider factors such as your production volume, component types, required speed and accuracy, budget constraints, and available space when selecting an SMT machine.

3. What are some leading brands in SMT machinery?

Some of the top brands include JUKI Automation Systems, Yamaha Motor IM, Panasonic Factory Solutions, ASM Assembly Systems, and DDM Novastar.

4. Why is customer support important when selecting an SMT supplier?

Effective customer support ensures that you can resolve issues quickly and maintain operational efficiency. It also provides training opportunities for staff on how to use the equipment effectively.

5. Can I customize my SMT machinery?

Yes! Many leading suppliers offer customization options to tailor machines according to specific production requirements or changes in demand.