Content Menu

● Understanding Flex PCBs and SMT Reflow Soldering

>> What Are Flex PCBs?

>> SMT Reflow Soldering Basics

● Why SMT Reflow Fixtures Are Essential for Flex PCB Production

>> 1. Preventing Warpage and Distortion

>> 2. Ensuring Accurate Component Placement and Alignment

>> 3. Protecting Components and the PCB

>> 4. Facilitating Consistent Thermal Profiles

>> 5. Enabling Efficient Handling and Process Integration

● Design Considerations for SMT Reflow Fixtures for Flex PCBs

>> Material Selection

>> Mechanical Support Features

>> Thermal Management

>> Customization and Adaptability

● Best Practices for Using SMT Reflow Fixtures in Flex PCB Production

>> Pre-baking and Moisture Control

>> Optimizing Reflow Profiles

>> Secure Component Placement

>> Quality Control

● Conclusion

● FAQ

>> 1. What is an SMT reflow fixture for flex PCB, and why is it necessary?

>> 2. How do SMT reflow fixtures prevent warpage in flex PCBs?

>> 3. Can SMT reflow fixtures be used for both rigid and flex PCBs?

>> 4. What materials are SMT reflow fixtures made from?

>> 5. How does fixture design impact the quality of flex PCB assembly?

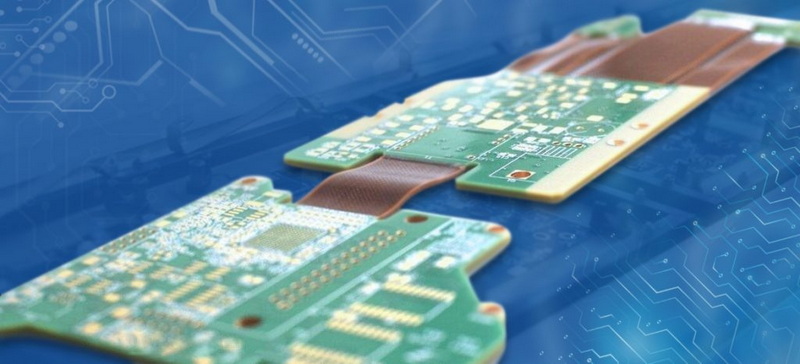

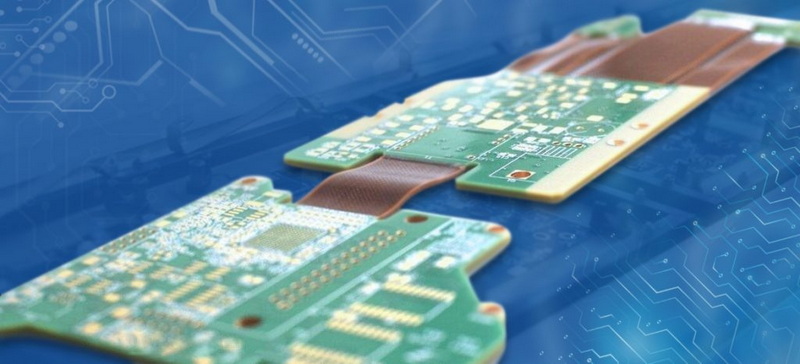

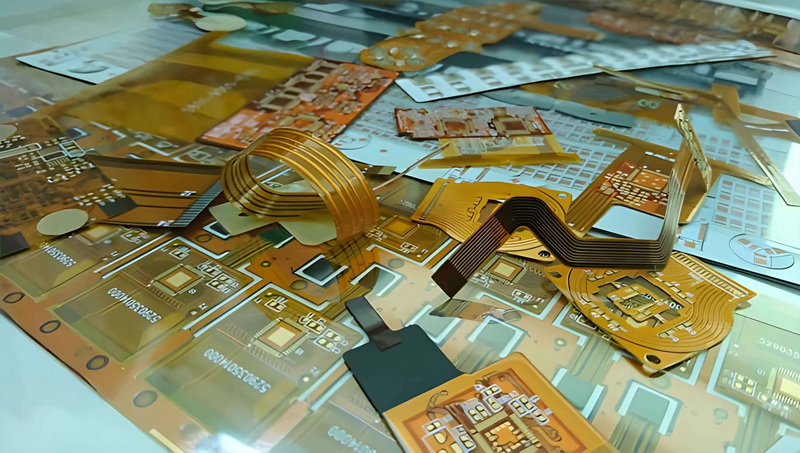

Flexible printed circuit boards (flex PCBs) have become a cornerstone in the evolution of modern electronics, enabling devices to be thinner, lighter, and more adaptable to complex shapes. Their ability to bend and conform to intricate device geometries opens up innovative design possibilities across industries such as consumer electronics, medical devices, automotive, aerospace, and defense. However, the very flexibility that makes these PCBs so valuable also introduces unique challenges during manufacturing, particularly in the surface mount technology (SMT) assembly process and, more specifically, during reflow soldering.

SMT reflow fixtures designed explicitly for flex PCBs provide essential support and stability throughout the assembly process, ensuring high-quality, reliable solder joints without damaging the delicate flexible substrates. This article delves deeply into what makes SMT reflow fixtures ideal for flex PCB production, exploring their critical roles, benefits, design considerations, and best practices. We will also address common challenges faced during flex PCB reflow soldering and how fixtures help overcome these hurdles.

Understanding Flex PCBs and SMT Reflow Soldering

What Are Flex PCBs?

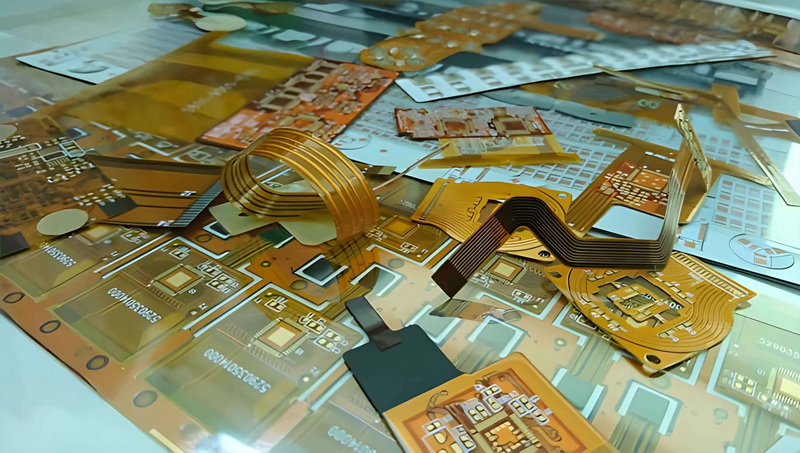

Flexible printed circuit boards, commonly known as flex PCBs, are made from flexible materials such as polyimide or polyester films. Unlike traditional rigid PCBs, flex PCBs can bend, twist, and fold while maintaining electrical performance. This flexibility allows them to fit into compact, irregular spaces within electronic devices, enabling innovative product designs that were previously impossible or impractical.

Flex PCBs are typically thinner and lighter than rigid boards, which makes them ideal for applications where weight and space are critical. They are widely used in smartphones, wearable devices, medical implants, automotive sensors, aerospace controls, and military equipment.

SMT Reflow Soldering Basics

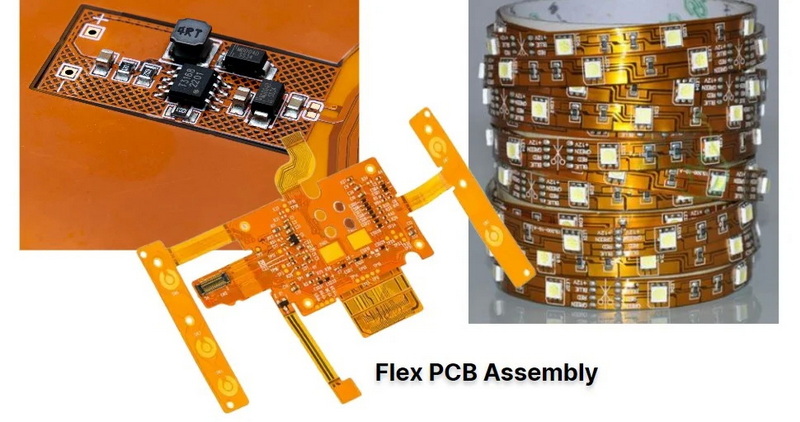

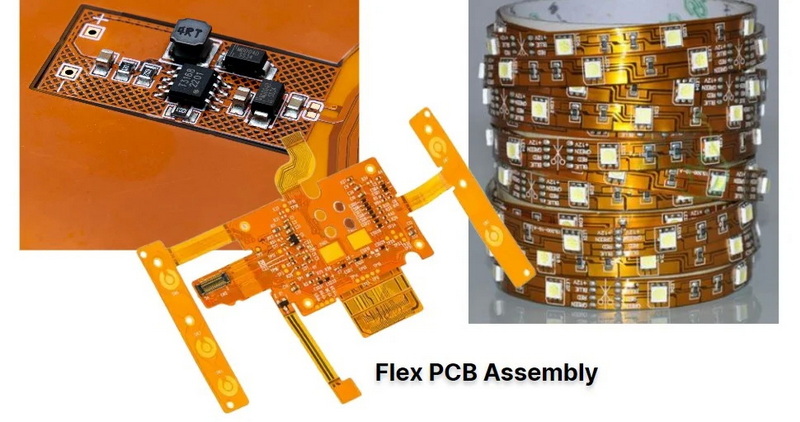

Surface mount technology (SMT) assembly involves mounting electronic components directly onto the surface of PCBs. After components are placed, solder paste is reflowed in an oven where it melts and solidifies to form strong mechanical and electrical connections.

Reflow soldering is the most common method for SMT assembly due to its precision and efficiency. However, with flex PCBs, the reflow process is more complex because the thin, flexible substrates are susceptible to warping, distortion, and thermal damage. This makes it essential to use specialized SMT reflow fixtures tailored for flex PCBs to ensure a successful assembly.

Why SMT Reflow Fixtures Are Essential for Flex PCB Production

1. Preventing Warpage and Distortion

One of the biggest challenges in flex PCB assembly is controlling warpage and distortion during the reflow process. The thin, flexible nature of these boards means they can easily deform under the heat and mechanical stresses of soldering.

SMT reflow fixtures hold the flex PCB flat and stable, preventing warpage that could cause solder joint defects or misalignment of components. By applying uniform pressure or support, these fixtures maintain the PCB's shape throughout solder paste printing, component placement, and reflow heating.

For example, fixtures may use mechanical clips, pins, or clamps designed to secure the flex section firmly without damaging the substrate. This support is crucial during the preheat and soak phases of reflow when thermal expansion can cause the most deformation.

2. Ensuring Accurate Component Placement and Alignment

Accurate component placement is critical for high-quality SMT assembly, especially for fine-pitch components and complex layouts common in flex PCBs. Without proper support, the flexible substrate can shift or wrinkle, leading to misalignment and solder defects such as bridging or tombstoning.

SMT reflow fixtures provide a stable base that enables precise pick-and-place operations and consistent stencil alignment for solder paste printing. Many fixtures incorporate fiducials or tooling pins that align the PCB accurately with assembly equipment, improving yield and reducing costly rework.

3. Protecting Components and the PCB

Flex PCBs often have components mounted on both sides or close to edges, making them vulnerable during reflow. SMT reflow fixtures protect bottom-side components and delicate flex areas by providing a secure, flat surface and shielding from excessive thermal gradients or mechanical stress.

Some fixtures feature heat shielding or are designed to distribute temperature evenly across the PCB, minimizing thermal stress and reducing the risk of damage to heat-sensitive components. This protection is especially important for flex PCBs with embedded components or thin copper layers that can be damaged by uneven heating.

4. Facilitating Consistent Thermal Profiles

The thermal mass and heat conduction properties of flex PCBs differ significantly from rigid boards. This can lead to uneven heating during reflow, resulting in solder defects such as cold joints, voids, or delamination.

SMT reflow fixtures help maintain consistent temperature distribution by providing mechanical support and thermal stability. They reduce thermal gradients across the PCB, ensuring that all solder joints reach the correct temperature for proper melting and solidification.

Fixtures made from materials with good thermal conductivity or those designed with heat distribution features contribute to achieving uniform thermal profiles, which is critical for the reliability of flex PCB assemblies.

5. Enabling Efficient Handling and Process Integration

Handling flex PCBs during SMT assembly can be challenging due to their thinness and flexibility. Reflow fixtures or carriers standardize the handling process throughout the SMT line-from solder paste printing to component placement, reflow, and inspection.

Fixtures simplify machine changeovers, reduce operator training time, and eliminate the need for custom vacuum or support plates. They also allow the processing of odd-shaped or thin flex PCBs that conveyors or standard carriers cannot handle directly, improving production throughput and efficiency.

Design Considerations for SMT Reflow Fixtures for Flex PCBs

Material Selection

The choice of materials for SMT reflow fixtures is critical. Fixtures must be made from ESD-safe composite materials to prevent static damage to sensitive components. They must also withstand high reflow temperatures-typically peaking between 235°C and 245°C-without deforming, outgassing, or contaminating the PCB.

Common materials include high-temperature plastics, ceramics, or composite materials engineered for thermal stability and mechanical strength.

Mechanical Support Features

- Flush-mounted holddowns: These secure the PCB without creating pressure points that could damage the flexible substrate. They provide gentle but firm support to maintain flatness.

- Tapered tooling pins and pushers: These create a wedge effect to hold the PCB flat while allowing easy loading and unloading.

- Clamps or magnetic covers: These prevent warping and maintain PCB position during thermal cycling without exerting excessive force.

The fixture design must balance firm support with the flexibility to avoid damaging the PCB or components.

Thermal Management

Fixtures should minimize thermal mass to allow rapid heating and cooling cycles, which are essential for efficient SMT production. At the same time, they should distribute heat evenly to avoid hot or cold spots.

Some fixtures integrate heat shields or use materials with good thermal conductivity to protect sensitive areas and ensure uniform temperature profiles across the PCB.

Customization and Adaptability

Because flex PCBs vary widely in shape, size, and component layout, fixtures are often custom-designed to match specific PCB geometries and assembly process requirements.

Modular or adjustable fixtures can accommodate multiple PCB variants, reducing tooling costs and increasing flexibility in production lines.

Best Practices for Using SMT Reflow Fixtures in Flex PCB Production

Pre-baking and Moisture Control

Flex PCBs are hygroscopic and can absorb moisture from the environment. During reflow, this moisture can vaporize and cause defects such as delamination or “popcorning.”

Pre-baking the PCB before assembly and storing it in dry or nitrogen environments are essential steps to mitigate moisture-related defects. The fixture must be compatible with these pre-baking processes.

Optimizing Reflow Profiles

Careful control of the reflow temperature profile is vital for flex PCBs. Parameters such as ramp rates, soak times, and peak temperatures must be tailored to the PCB materials and solder paste used.

Typical reflow profile parameters for flex PCBs include:

| Parameter | Recommended Range |

| Peak Temperature | 235°C to 245°C |

| Time Above Liquidus (TAL) | 60 to 90 seconds |

| Heating Ramp Rate | 1°C/s to 3°C/s |

| Cooling Ramp Rate | < 4°C/s |

| Preheat Temperature | 150°C to 180°C |

| Soak Duration | 60 to 120 seconds |

Using an SMT reflow fixture helps maintain these profiles consistently by stabilizing the PCB and improving heat transfer.

Secure Component Placement

Using pick-and-place machines in conjunction with fixtures ensures components are firmly positioned before reflow. This reduces the risk of tombstoning, bridging, or shifting during soldering.

Fixtures also help maintain the flatness of the flex PCB during component placement, which is critical for fine-pitch and small components.

Quality Control

Post-reflow inspection is crucial to detect solder defects, misalignments, or substrate damage early. Visual inspections, X-ray imaging, and electrical testing are common methods.

The use of SMT reflow fixtures enhances quality control by reducing variability in the assembly process and improving the consistency of solder joints.

Conclusion

SMT reflow fixtures are indispensable tools in flex PCB production, addressing the unique challenges posed by flexible substrates during soldering. By providing mechanical support, preventing warpage, ensuring precise alignment, protecting components, and facilitating consistent thermal profiles, these fixtures enable high-yield, reliable SMT assembly of flex PCBs.

Their design flexibility and integration into the SMT line enhance production efficiency and quality control, making them ideal for modern electronics manufacturing where flex PCBs are increasingly prevalent.

As flex PCB applications continue to expand in consumer electronics, medical devices, automotive, aerospace, and beyond, the role of specialized SMT reflow fixtures will only grow in importance, ensuring the performance and reliability of these advanced circuits.

FAQ

1. What is an SMT reflow fixture for flex PCB, and why is it necessary?

An SMT reflow fixture for flex PCB is a specialized tool that holds and supports flexible printed circuit boards during the SMT assembly and reflow soldering process. It prevents warping, distortion, and misalignment of the flex PCB, ensuring accurate component placement and reliable solder joints.

2. How do SMT reflow fixtures prevent warpage in flex PCBs?

Fixtures use mechanical clamps, pins, or magnetic covers to hold the flex PCB flat and stable throughout solder paste printing, placement, and reflow heating. This support counters the natural tendency of flexible substrates to bend or warp under thermal stress.

3. Can SMT reflow fixtures be used for both rigid and flex PCBs?

While some fixtures can accommodate both types, flex PCBs require more specialized fixtures due to their flexibility and sensitivity. Flex-specific fixtures often include features like reduced thermal mass, flush-mounted holddowns, and custom shapes to prevent damage.

4. What materials are SMT reflow fixtures made from?

They are typically constructed from ESD-safe composite materials that can withstand high reflow temperatures without deforming. Materials are chosen to balance mechanical strength, thermal conductivity, and process transparency.

5. How does fixture design impact the quality of flex PCB assembly?

A well-designed fixture ensures consistent PCB positioning, reduces thermal gradients, and prevents mechanical stress during reflow. This leads to fewer soldering defects, improved yields, and enhanced reliability of the final product.