Introduction

In the fast-evolving world of electronics manufacturing, efficiency and precision are paramount. The Juki SMT pick and place machines have emerged as a preferred solution for many manufacturers seeking to enhance their production capabilities. This article delves into the features, benefits, and operational aspects of Juki's pick and place machines, particularly focusing on their role in Surface Mount Technology (SMT). As a leading Juki SMT pick and place machine supplier, Global Soul Limited (GS-SMT LTD) plays a crucial role in providing these advanced solutions to the global market.

Understanding Juki SMT Pick and Place Machines

What is a Pick and Place Machine?

A pick and place machine is an automated device used in electronics manufacturing to place surface mount devices (SMDs) onto printed circuit boards (PCBs). These machines are essential for high-speed assembly processes, significantly reducing manual labor and increasing production efficiency.

The Juki Advantage

Juki Corporation, a renowned name in the SMT industry, offers a range of pick and place machines known for their reliability, speed, and adaptability. Their machines are designed to handle various component sizes and types, making them suitable for diverse manufacturing needs.

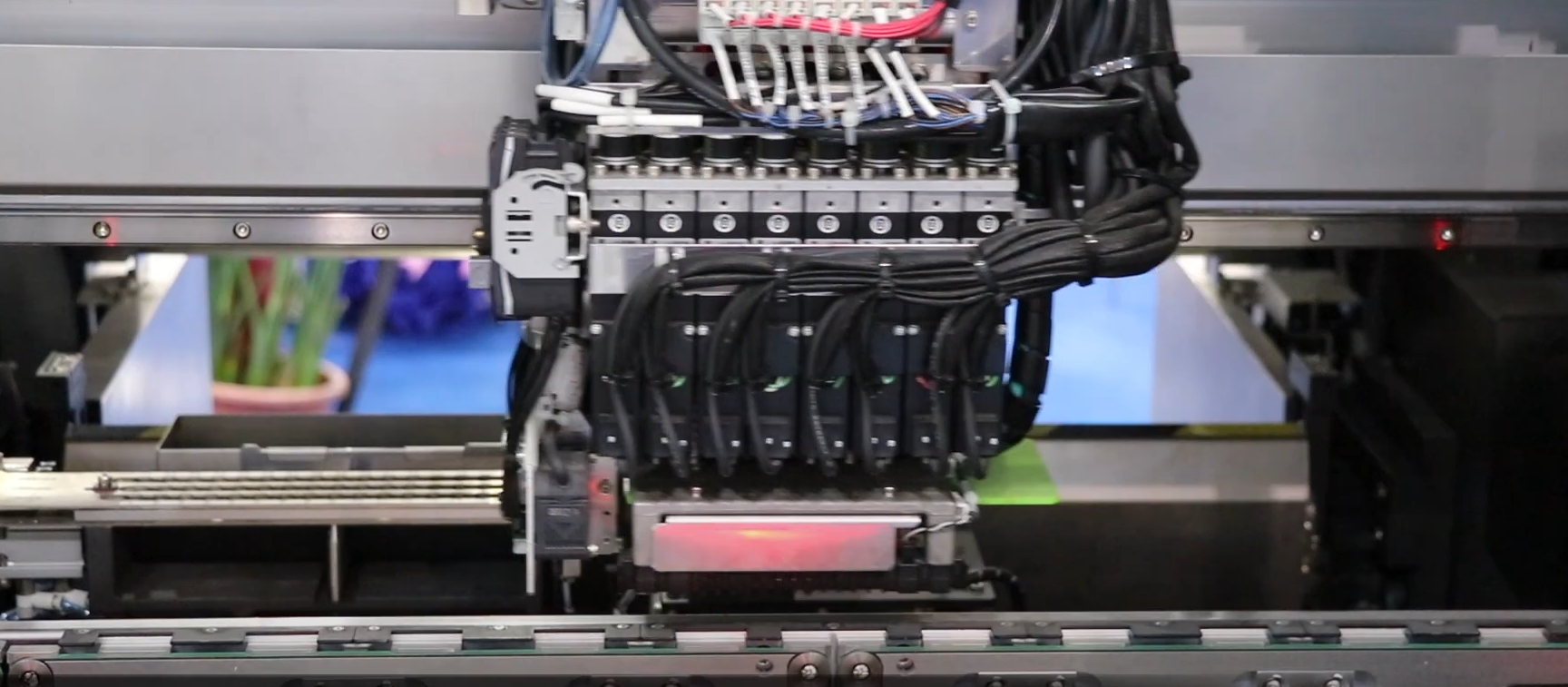

Key Features of Juki SMT Pick and Place Machines

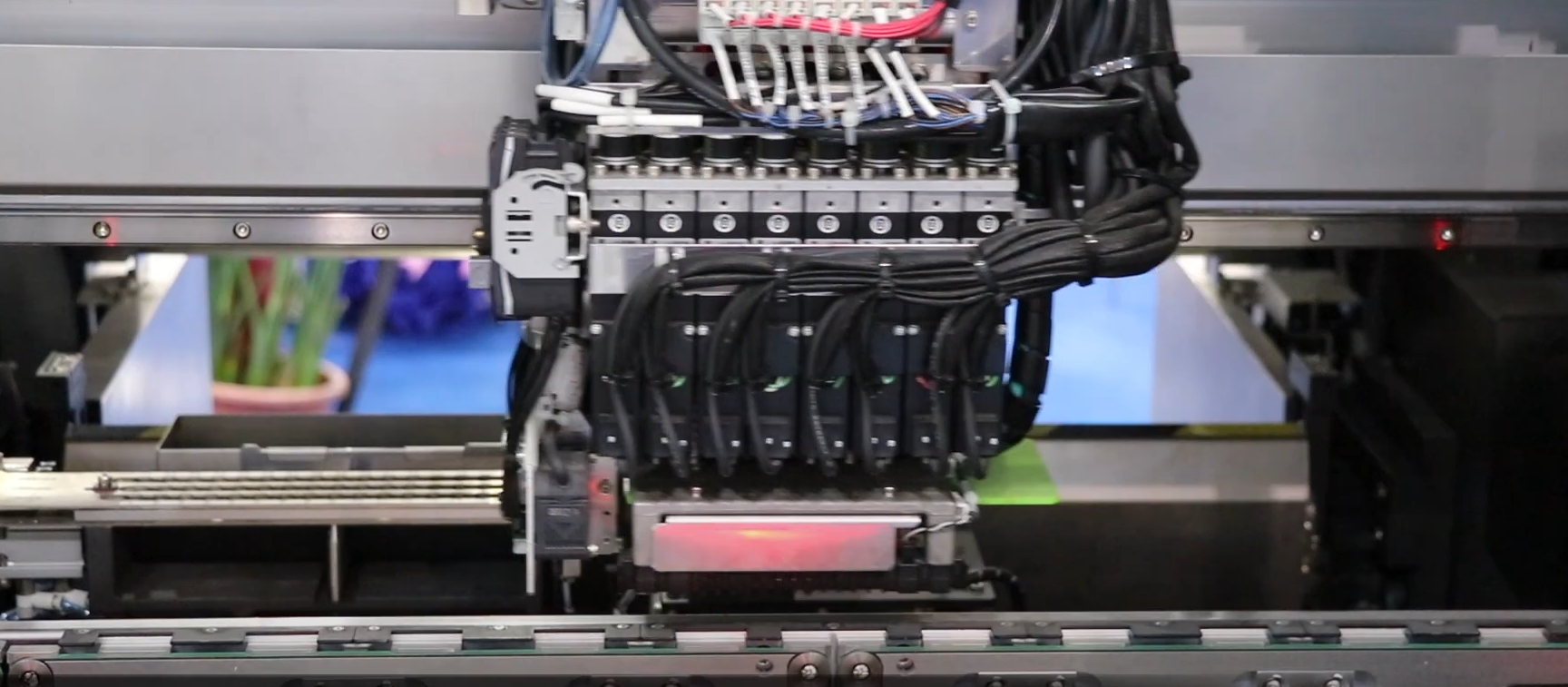

- High Speed: Juki machines can achieve placement speeds of up to 100,000 components per hour (CPH), making them ideal for high-volume production.

- Precision: Equipped with advanced vision systems, these machines ensure accurate placement of components, reducing errors and rework.

- Flexibility: Juki's modular design allows manufacturers to customize their machines according to specific production requirements.

- User-Friendly Interface: The intuitive software makes it easy for operators to program and operate the machines efficiently.

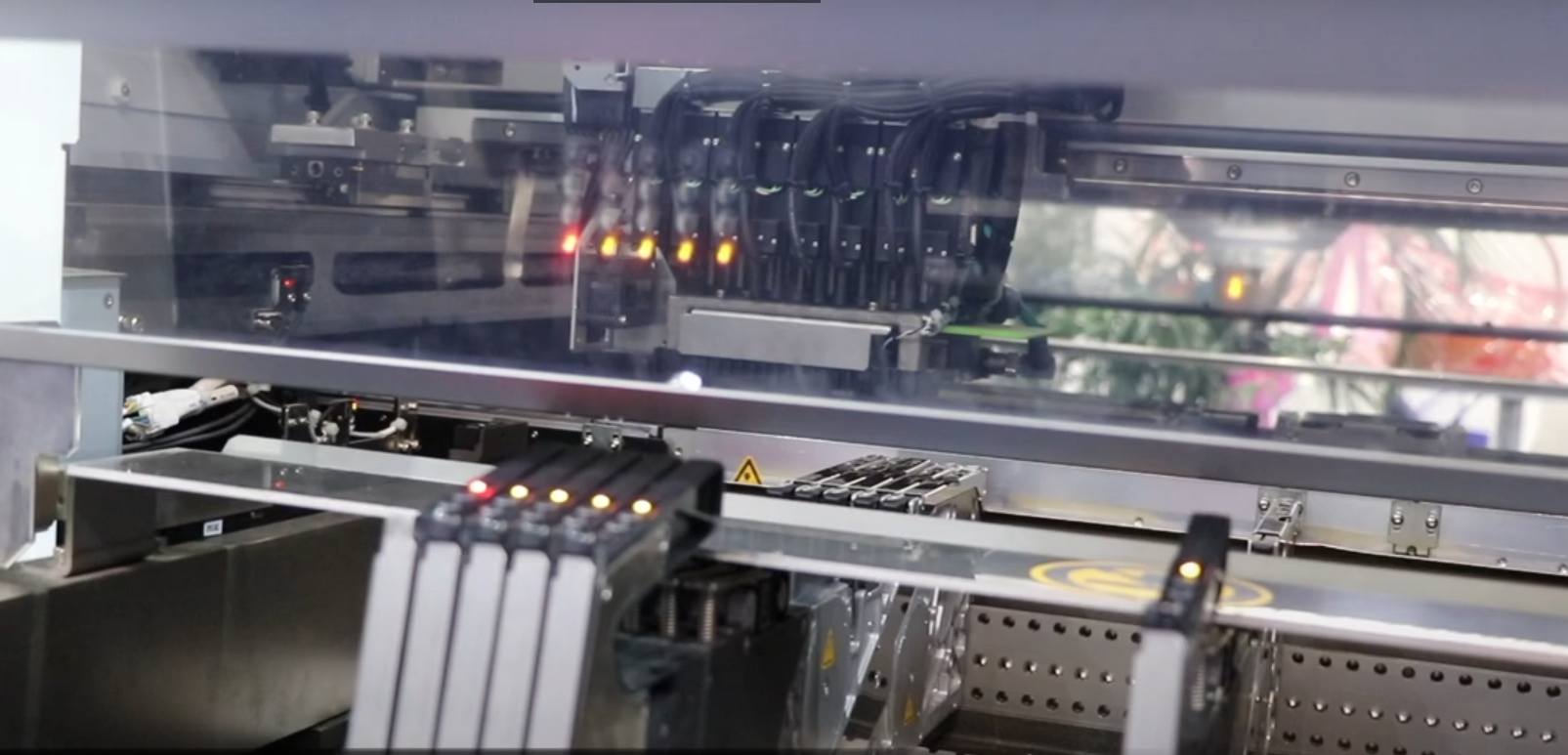

Juki Pick and Place Machine

Applications of Juki SMT Pick and Place Machines

Electronics Manufacturing

Juki pick and place machines are widely used in various sectors of electronics manufacturing, including:

- Consumer Electronics: For assembling devices like smartphones, tablets, and laptops.

- Automotive Industry: Used in the production of electronic components for vehicles.

- Industrial Equipment: Essential for manufacturing control systems and machinery.

Benefits of Using Juki SMT Machines

1. Increased Productivity: The speed of Juki machines allows manufacturers to meet tight production deadlines without compromising quality.

2. Cost Efficiency: Automating the placement process reduces labor costs and minimizes material waste.

3. Enhanced Quality Control: With integrated inspection systems, manufacturers can maintain high-quality standards throughout the assembly process.

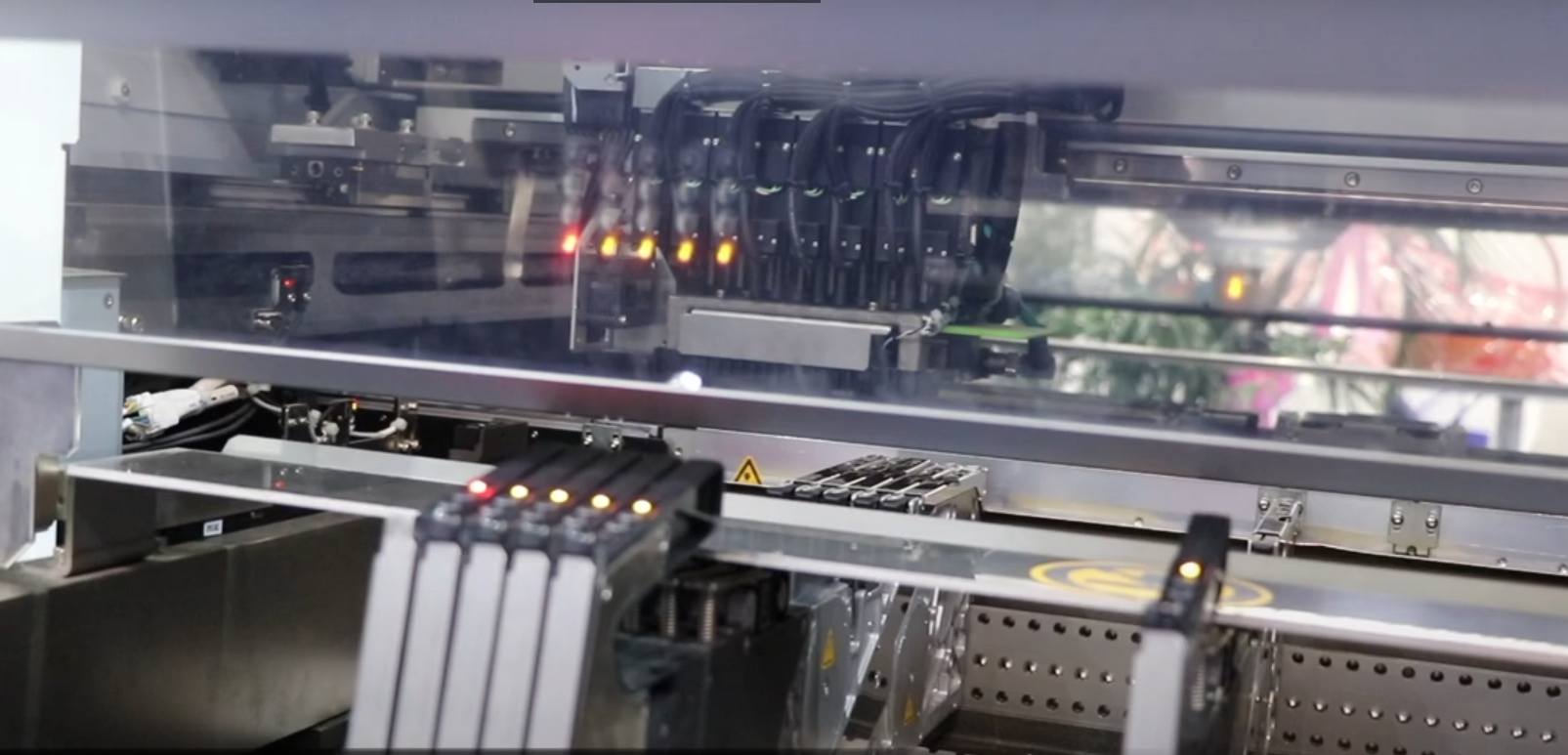

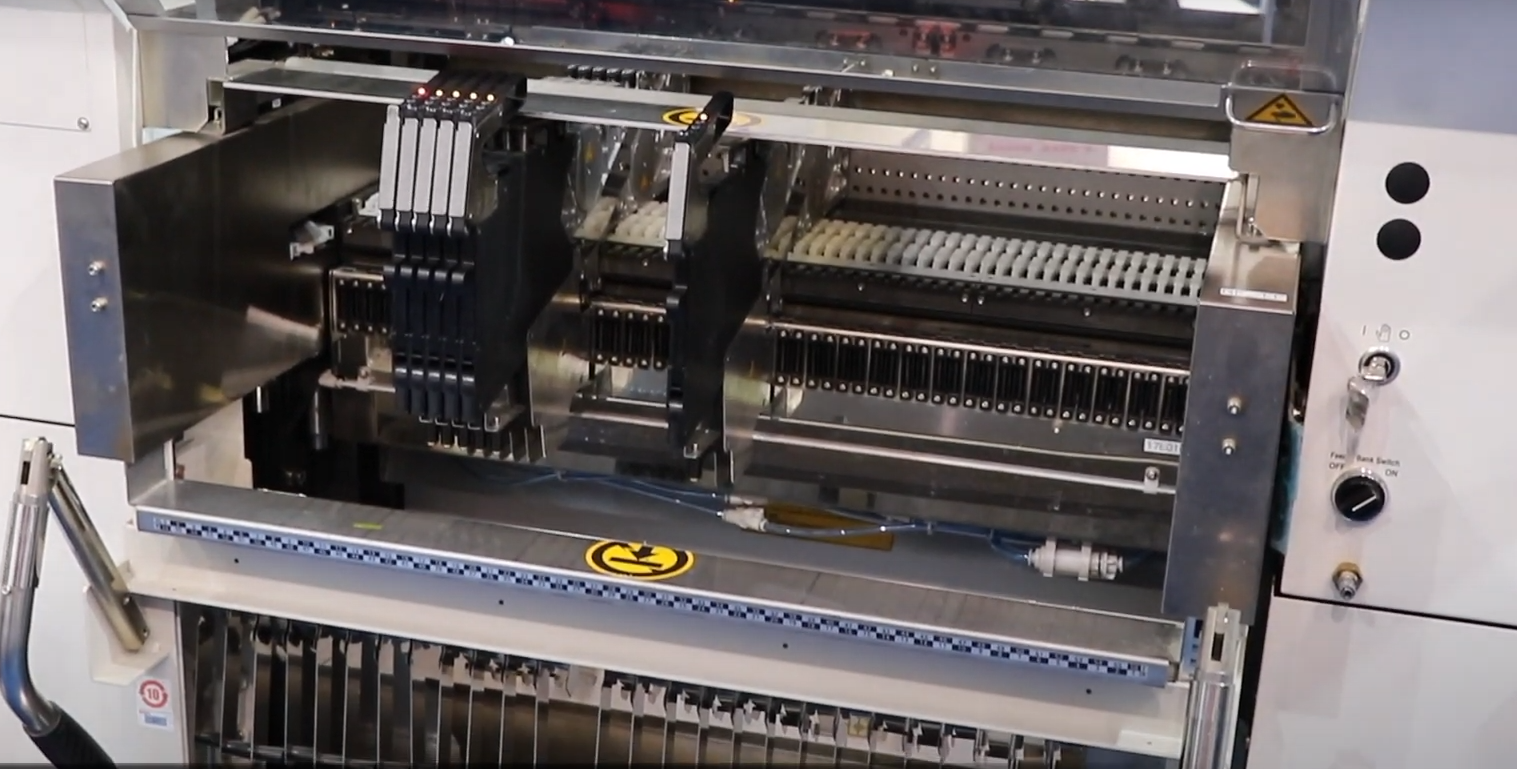

Juki Production Line

Choosing the Right Juki SMT Pick and Place Machine Supplier

When selecting a supplier for Juki SMT pick and place machines, consider the following factors:

- Experience: Look for suppliers with a proven track record in providing high-quality SMT solutions.

- Support Services: Ensure that the supplier offers comprehensive support services, including installation, training, and maintenance.

- Product Range: A supplier with a wide range of models can better meet your specific needs.

Global Soul Limited: Your Trusted Juki SMT Pick and Place Machine Supplier

Founded in 2011 and located in Shenzhen, China, Global Soul Limited (GS-SMT LTD) specializes in providing innovative solutions for Surface Mount Technology (SMT). As a key player in the industry, GS-SMT LTD offers a variety of Juki pick and place machines tailored to meet diverse manufacturing requirements.

Why Choose GS-SMT LTD?

- Customer-Centric Approach: Prioritizing customer satisfaction through quality products and services.

- Competitive Pricing: Offering cost-effective solutions without compromising on quality.

- Expert Team: A professional team dedicated to innovation and technological advancement.

GS-SMT LTD Office

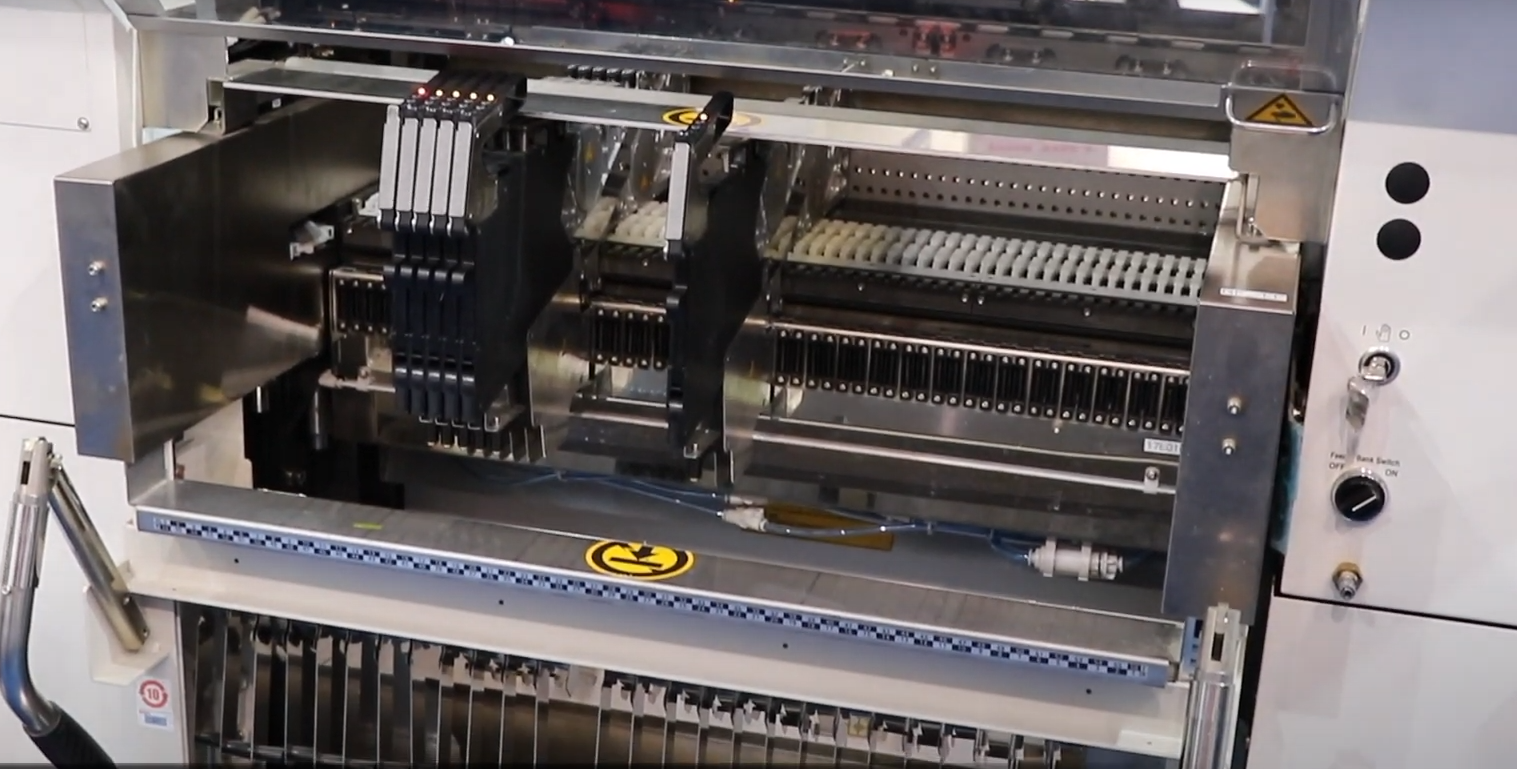

Operational Process of Juki SMT Pick and Place Machines

Setup Process

1. Machine Calibration: Proper calibration is essential for optimal performance. This involves adjusting settings based on component specifications.

2. Feeder Setup: Load feeders with components according to the production plan.

3. Programming: Use the machine's software interface to input production data, including component types, placements, and board layout.

Production Workflow

1. Component Feeding: The machine automatically feeds components from feeders into the placement area.

2. Vision Inspection: Advanced cameras inspect components before placement to ensure accuracy.

3. Placement: The machine picks components using robotic arms and places them onto PCBs with precision.

4. Quality Control: Integrated inspection systems check for correct placement before moving to the next step.

Juki Machine Workflow

Maintenance Tips for Juki SMT Pick and Place Machines

Regular maintenance is vital to ensure the longevity and efficiency of your Juki pick and place machine. Here are some tips:

1. Routine Cleaning: Keep the machine clean from dust and debris that may affect performance.

2. Regular Inspections: Conduct periodic inspections of mechanical parts to identify wear or damage early.

3. Software Updates: Keep the machine's software updated to benefit from new features and improvements.

Conclusion

The Juki SMT pick and place machines represent a significant advancement in electronics manufacturing technology. With their high speed, precision, and flexibility, they have become indispensable tools for manufacturers worldwide. Partnering with a reliable supplier like Global Soul Limited ensures access to top-quality equipment tailored to meet specific production needs.

Frequently Asked Questions (FAQs)

1. What are the main advantages of using Juki SMT pick and place machines?

- They offer high speed, precision placement, flexibility in handling various components, and enhanced productivity.

2. How do I choose a reliable Juki SMT pick and place machine supplier?

- Look for experience, support services offered, product range available, and customer reviews.

3. What industries benefit most from using Juki pick and place machines?

- Consumer electronics, automotive manufacturing, industrial equipment production are among the key industries.

4. What maintenance practices should I follow for my Juki machine?

- Regular cleaning, routine inspections of mechanical parts, software updates are essential maintenance practices.

5. Can I customize my Juki pick and place machine?

- Yes, Juki machines are designed with modularity in mind allowing customization based on specific production requirements.