Content Menu

● The Rise of China's PCB SMT Production Industry

● Key Components of China's PCB SMT Production Machine Lines

>> Solder Paste Printers

>> Pick and Place Machines

>> Reflow Ovens

>> Inspection Systems

● Technological Advancements Driving China's PCB SMT Production Machines

>> Automation and Industry 4.0 Integration

>> Artificial Intelligence and Machine Learning

>> Advanced Materials and Processes

● Cost-Effectiveness and Scalability

● Environmental Considerations

● Quality Control and Reliability

● Global Impact and Market Share

● Challenges and Future Outlook

● Conclusion

● FAQ

>> 1. What is SMT in PCB assembly?

>> 2. How do China's PCB SMT production machines compare to those from other countries?

>> 3. What are the main advantages of using China's PCB SMT production machine lines?

>> 4. How has China's PCB SMT production industry impacted global electronics manufacturing?

>> 5. What future developments can we expect in China's PCB SMT production machine industry?

● Citations:

China has become a global leader in the electronics manufacturing industry, with its PCB SMT production machine lines playing a crucial role in this dominance. These advanced production lines have revolutionized the way printed circuit boards (PCBs) are assembled, offering unparalleled efficiency, precision, and cost-effectiveness. In this article, we will explore the key factors that make China's PCB SMT production machines stand out in the global market.

The Rise of China's PCB SMT Production Industry

Over the past few decades, China has rapidly developed its capabilities in PCB SMT production, becoming the world's largest manufacturer of electronic components and assemblies. This growth can be attributed to several factors, including government support, massive investments in research and development, and a robust supply chain ecosystem.

China's PCB SMT production machine lines have evolved to meet the increasing demands of the electronics industry, incorporating cutting-edge technologies and innovative features that set them apart from their global competitors[1]. These advancements have not only improved the quality and efficiency of PCB assembly but have also significantly reduced production costs, making China an attractive destination for electronics manufacturers worldwide.

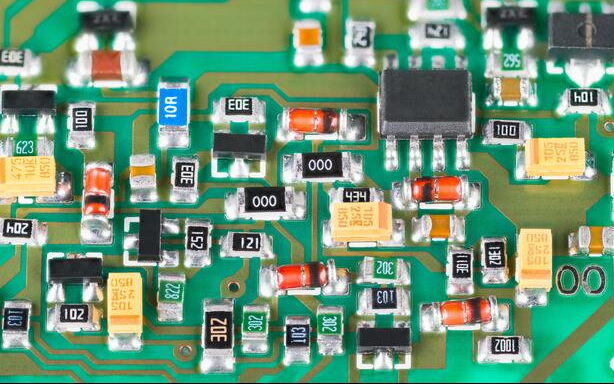

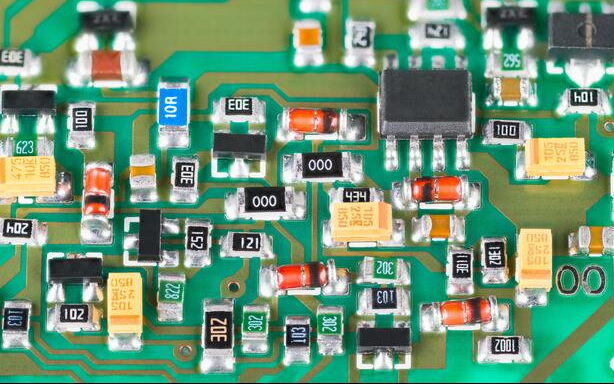

Key Components of China's PCB SMT Production Machine Lines

To understand what makes China's PCB SMT production machines stand out, it's essential to examine the key components that make up these advanced production lines:

Solder Paste Printers

Chinese manufacturers have developed high-precision solder paste printers that are capable of applying solder paste with exceptional accuracy. These printers utilize advanced vision systems and precise control mechanisms to ensure consistent and reliable solder paste deposition[2]. The ability to print solder paste with such precision is crucial for the overall quality of the assembled PCBs, as it directly affects the reliability of solder joints.

Pick and Place Machines

One of the most critical components in China's PCB SMT production machine lines is the pick and place machine. Chinese manufacturers have made significant strides in developing high-speed, multi-head pick and place machines that can handle a wide range of component sizes and types[1]. These machines are equipped with advanced vision systems and sophisticated algorithms that enable them to place components with incredible speed and accuracy.

The latest pick and place machines from China feature:

- Multiple pick-up heads for simultaneous component placement

- High-speed linear motors for rapid movement

- Advanced vision systems for precise component alignment

- Flexible feeder systems to accommodate various component types

- Intelligent software for optimized placement sequences

These features allow Chinese PCB SMT production lines to achieve placement speeds of up to 14,000 components per hour (CPH), significantly boosting overall production efficiency[1].

Reflow Ovens

China's PCB SMT production machine lines incorporate state-of-the-art reflow ovens that ensure consistent and reliable soldering of components. These ovens feature precise temperature control systems and multiple heating zones, allowing for optimal reflow profiles for different PCB designs and component types[2]. The advanced reflow ovens used in Chinese production lines contribute to higher yield rates and improved solder joint quality.

Inspection Systems

To maintain high quality standards, China's PCB SMT production machine lines integrate sophisticated inspection systems throughout the assembly process. These systems include:

- Solder Paste Inspection (SPI) machines

- Automated Optical Inspection (AOI) systems

- X-ray inspection equipment

These inspection systems work in tandem to detect defects at various stages of the assembly process, ensuring that only high-quality PCBs make it through to the final product[3]. The integration of these advanced inspection technologies has significantly improved the overall quality and reliability of PCBs produced in China.

Technological Advancements Driving China's PCB SMT Production Machines

Several technological advancements have contributed to the superiority of China's PCB SMT production machines:

Automation and Industry 4.0 Integration

Chinese manufacturers have embraced automation and Industry 4.0 principles in their PCB SMT production machine lines. This integration has resulted in highly efficient, interconnected production systems that can operate with minimal human intervention[3]. The use of advanced sensors, real-time data analytics, and machine learning algorithms allows for continuous optimization of the production process, leading to improved efficiency and reduced downtime.

Artificial Intelligence and Machine Learning

The incorporation of AI and machine learning technologies has significantly enhanced the capabilities of China's PCB SMT production machines. These technologies are used to optimize component placement, predict maintenance needs, and improve overall production efficiency[3]. AI-powered systems can quickly adapt to changes in production requirements, allowing for greater flexibility and responsiveness to market demands.

Advanced Materials and Processes

Chinese manufacturers have invested heavily in research and development of advanced materials and processes for PCB assembly. This includes the development of new solder paste formulations, innovative flux chemistries, and improved thermal management techniques[4]. These advancements have enabled the production of higher-quality PCBs that can withstand more demanding operating conditions.

Cost-Effectiveness and Scalability

One of the most significant advantages of China's PCB SMT production machine lines is their cost-effectiveness. Chinese manufacturers have managed to develop high-performance machines at competitive prices, making advanced PCB assembly technology accessible to a wider range of companies[5]. This cost-effectiveness, combined with the scalability of Chinese production facilities, has made China the go-to destination for electronics manufacturers looking to optimize their production costs without compromising on quality.

Environmental Considerations

As global awareness of environmental issues grows, China's PCB SMT production machine manufacturers have been focusing on developing more environmentally friendly solutions. This includes:

- Energy-efficient machines that consume less power

- Reduced use of hazardous materials in the assembly process

- Improved waste management systems

- Development of recyclable and biodegradable PCB materials

These efforts have not only helped to reduce the environmental impact of PCB production but have also positioned Chinese manufacturers as leaders in sustainable electronics manufacturing[6].

Quality Control and Reliability

China's PCB SMT production machine lines have made significant strides in quality control and reliability. The integration of advanced inspection systems, combined with stringent quality control processes, has resulted in PCBs that meet or exceed international standards[7]. Chinese manufacturers have implemented comprehensive quality management systems, including ISO 9001 certification, to ensure consistent product quality and customer satisfaction.

Global Impact and Market Share

The advancements in China's PCB SMT production machine lines have had a profound impact on the global electronics manufacturing industry. Chinese-made machines and assembled PCBs are now used in a wide range of electronic devices, from smartphones and laptops to automotive electronics and industrial equipment[8].

China's dominance in the PCB SMT production machine market has led to:

- Increased competition, driving innovation across the industry

- Lower costs for electronic components and devices

- Faster time-to-market for new electronic products

- Greater accessibility to advanced electronics manufacturing capabilities for smaller companies

Challenges and Future Outlook

Despite the many advantages of China's PCB SMT production machines, the industry faces some challenges:

- Increasing labor costs in China

- Growing competition from other emerging markets

- Geopolitical tensions and trade disputes

- Concerns about intellectual property protection

However, Chinese manufacturers are actively addressing these challenges by:

- Investing in further automation to reduce labor costs

- Expanding their global presence through partnerships and acquisitions

- Strengthening intellectual property protection measures

- Diversifying their supply chains to mitigate geopolitical risks

The future outlook for China's PCB SMT production machine industry remains positive, with continued growth expected in the coming years. As the demand for more advanced and miniaturized electronic devices increases, Chinese manufacturers are well-positioned to meet these challenges with their innovative and cost-effective solutions[9].

Conclusion

China's PCB SMT production machine lines have emerged as a dominant force in the global electronics manufacturing industry. Their ability to combine cutting-edge technology, cost-effectiveness, and scalability has set them apart from competitors. The continuous innovation in automation, AI integration, and environmental sustainability ensures that China will remain at the forefront of PCB assembly technology for years to come.

As the electronics industry continues to evolve, China's PCB SMT production machines will play a crucial role in shaping the future of electronic device manufacturing. Their impact extends beyond just the production of PCBs, influencing the entire electronics ecosystem and driving innovation across multiple sectors.

FAQ

1. What is SMT in PCB assembly?

SMT stands for Surface Mount Technology, which is a method used in PCB assembly where electronic components are mounted directly onto the surface of a printed circuit board. This technology allows for more compact and efficient circuit designs compared to traditional through-hole mounting techniques.

2. How do China's PCB SMT production machines compare to those from other countries?

China's PCB SMT production machines are known for their excellent balance of performance and cost-effectiveness. They often incorporate advanced features such as high-speed placement, precision control, and AI-powered optimization, while remaining more affordable than machines from some Western manufacturers. This combination has made Chinese machines increasingly popular in the global market.

3. What are the main advantages of using China's PCB SMT production machine lines?

The main advantages include high production efficiency, cost-effectiveness, advanced technological features, scalability, and the ability to handle a wide range of component types and sizes. Chinese manufacturers also offer comprehensive support and maintenance services, making their machines an attractive option for both small-scale and large-scale production.

4. How has China's PCB SMT production industry impacted global electronics manufacturing?

China's PCB SMT production industry has significantly impacted global electronics manufacturing by driving down costs, increasing production efficiency, and making advanced manufacturing capabilities more accessible to a wider range of companies. This has led to faster innovation cycles and more affordable electronic products for consumers worldwide.

5. What future developments can we expect in China's PCB SMT production machine industry?

Future developments in China's PCB SMT production machine industry are likely to focus on further automation, integration of AI and machine learning technologies, improved energy efficiency, and the ability to handle increasingly miniaturized components. We can also expect advancements in sustainable manufacturing practices and the development of machines capable of assembling next-generation flexible and 3D-printed PCBs.

Citations:

[1] https://www.neodensmt.com/other-products/high-speed-smd-pick-and-place-machine.html

[2] https://www.pcbasic.com/blog/smt_production_line.html

[3] https://es.hct-smt.com/blog/enhancing-efficiency--exploring-china-pcb-smt-production-machine-lines

[4] https://www.hayawin.com/news-smt-machine-types-and-features-of-excellent-smt-machines.html

[5] https://www.ourpcb.com/smt-line.html

[6] https://www.fs-pcba.com/smt-pcba/

[7] https://www.ourpcb.com/smt-machine.html

[8] https://www.youtube.com/watch?v=kwByEB6fxLE

[9] https://www.neodensmt.com/other-products/smt-pick-and-place-machine-for-led-lighting.html