Content Menu

● Understanding SMT Production Lines

● Factors Influencing Layout Configuration

● Common Layout Configurations

>> 1. Inline Configuration

>> 2. U-Shaped Configuration

>> 3. L-Shaped Configuration

>> 4. Circular Configuration

● Best Practices for Designing Facing SMT Production Lines

>> Optimize Material Flow

>> Implement Lean Manufacturing Principles

>> Incorporate Modular Design Elements

>> Prioritize Ergonomics and Safety

● Advanced Considerations in Layout Design

>> Integration of Automation Technologies

>> Balancing Workloads Across Lines

>> Continuous Improvement Practices

● The Role of Technology in Layout Optimization

● Conclusion

● FAQ

>> 1. What is the most efficient layout configuration for two SMT production lines?

>> 2. How does ergonomics impact SMT production line efficiency?

>> 3. Can I easily change my SMT line layout if my production needs change?

>> 4. What role does safety play in designing an SMT production line?

>> 5. How can I measure the effectiveness of my SMT line layout?

● Citations:

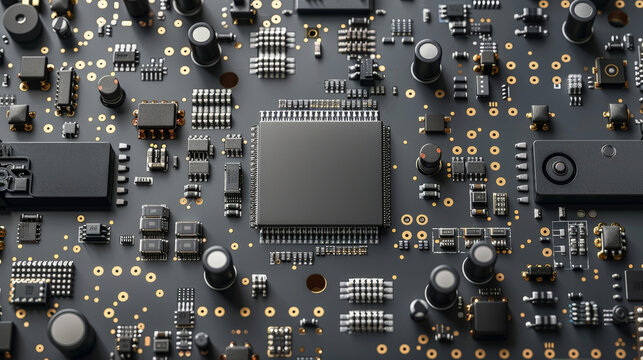

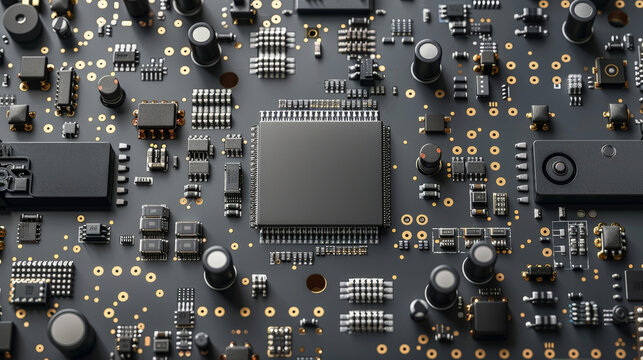

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by allowing for the assembly of components directly onto the surface of printed circuit boards (PCBs). As demand for electronic devices continues to grow, manufacturers are often faced with the challenge of optimizing their production lines. This article explores the best layout configurations for facing two SMT production lines, considering factors such as efficiency, space utilization, workflow, and flexibility.

Understanding SMT Production Lines

Before diving into layout configurations, it is essential to understand what constitutes an SMT production line. An SMT line typically includes several key components:

- Pick and Place Machines: These machines are responsible for placing components onto the PCBs.

- Solder Paste Printers: They apply solder paste to the PCB pads before component placement.

- Reflow Ovens: After placement, PCBs pass through reflow ovens where solder paste is melted to create connections.

- Inspection Stations: These stations ensure that components are correctly placed and soldered.

The configuration of these components significantly impacts the overall efficiency and productivity of the production line.

Factors Influencing Layout Configuration

When configuring a layout for two facing SMT production lines, several factors must be considered:

- Workflow Efficiency: The layout should facilitate a smooth flow of materials and minimize bottlenecks.

- Space Utilization: Efficient use of available space is crucial, especially in facilities with limited square footage.

- Flexibility: The layout should allow for easy adjustments as production needs change.

- Safety and Ergonomics: Ensuring a safe working environment is vital for employee well-being and productivity.

Common Layout Configurations

Several common layout configurations can be employed when facing two SMT production lines:

1. Inline Configuration

In an inline configuration, both SMT lines are arranged in a straight line. This configuration allows for a streamlined workflow, as materials can flow from one machine to the next without significant interruptions.

Advantages:

- Simplified material handling

- Reduced travel distance for operators

- Easy monitoring of both lines

Disadvantages:

- Limited flexibility in adjusting equipment positions

- Potential bottlenecks if one line experiences delays

2. U-Shaped Configuration

The U-shaped configuration arranges the two SMT lines in a U shape, allowing operators to access both lines from a central point. This design promotes efficient communication and collaboration among team members.

Advantages:

- Enhanced visibility and accessibility

- Improved teamwork and communication

- More efficient use of space compared to inline configurations

Disadvantages:

- May require more floor space than inline configurations

- Potential confusion if not properly organized

3. L-Shaped Configuration

An L-shaped configuration places the two SMT lines at right angles to each other. This layout can be particularly useful in facilities with limited linear space.

Advantages:

- Efficient use of corner spaces

- Allows for easy access to both lines from multiple angles

Disadvantages:

- May complicate workflow if not designed carefully

- Potential for increased travel distances between machines

4. Circular Configuration

In a circular configuration, both SMT lines are arranged in a circular or semi-circular shape. This design can facilitate easy access to all machines from various points around the circle.

Advantages:

- Promotes collaboration among operators

- Allows for flexible movement around the workspace

Disadvantages:

- Requires more space than other configurations

- Can complicate material handling logistics

Best Practices for Designing Facing SMT Production Lines

To optimize the layout of facing SMT production lines, consider implementing the following best practices:

Optimize Material Flow

Ensure that materials flow smoothly between machines without unnecessary delays. Use conveyor systems or automated guided vehicles (AGVs) to transport materials efficiently.

Implement Lean Manufacturing Principles

Adopt lean manufacturing principles to minimize waste and maximize efficiency. Techniques such as value stream mapping can help identify areas for improvement in your layout.

Incorporate Modular Design Elements

Consider using modular equipment that can be easily reconfigured as production needs change. This flexibility allows manufacturers to adapt quickly to new product demands or changes in volume.

Prioritize Ergonomics and Safety

Design workstations that promote good ergonomics to reduce fatigue and injury risks among operators. Ensure that safety measures are integrated into the layout, such as clear pathways and emergency exits.

Advanced Considerations in Layout Design

In addition to basic configurations, advanced considerations can further enhance the effectiveness of facing two SMT production lines:

Integration of Automation Technologies

The incorporation of automation technologies can significantly improve efficiency on SMT production lines. Automated systems such as conveyors, robotic arms, and automated guided vehicles (AGVs) streamline material handling processes. For instance, AGVs can transport PCBs between workstations without human intervention, reducing labor costs while increasing throughput[1][2].

Balancing Workloads Across Lines

Balancing workloads between two facing SMT lines is essential for maximizing productivity. This involves analyzing cycle times and ensuring that each line operates at optimal capacity without overloading one line while underutilizing another. Techniques like load balancing can help distribute tasks evenly across both lines[6][10].

Continuous Improvement Practices

Implementing continuous improvement practices such as Kaizen can foster an environment where employees regularly suggest enhancements to workflows or layouts based on their experiences on the floor. Regular feedback loops involving operators can lead to incremental improvements that collectively enhance productivity[7][8].

The Role of Technology in Layout Optimization

Technology plays a pivotal role in optimizing SMT line layouts. Advanced software tools allow manufacturers to simulate different configurations before implementation, helping identify potential bottlenecks or inefficiencies in proposed layouts[4][9]. Additionally, machine learning algorithms can analyze historical data from production runs to predict optimal configurations based on product types and volumes.

Conclusion

Choosing the best layout configuration for facing two SMT production lines requires careful consideration of various factors including workflow efficiency, space utilization, flexibility, safety, and ergonomics. Each configuration—inline, U-shaped, L-shaped, or circular—has its advantages and disadvantages that must align with specific operational goals and constraints. By optimizing material flow, implementing lean principles, incorporating modular designs, prioritizing ergonomics and safety, integrating automation technologies, balancing workloads across lines, and embracing continuous improvement practices, manufacturers can significantly enhance their production capabilities.

In summary, there is no one-size-fits-all solution; rather, companies must analyze their unique situations to determine which layout will yield the best results for their specific needs. The continuous evolution of technology also provides new opportunities for enhancing efficiency within these layouts.

FAQ

1. What is the most efficient layout configuration for two SMT production lines?

The most efficient layout often depends on specific operational needs; however, many manufacturers find that an inline configuration offers streamlined material handling and reduced travel distances.

2. How does ergonomics impact SMT production line efficiency?

Good ergonomic design reduces operator fatigue and injury risks, leading to improved productivity and job satisfaction among employees working on SMT production lines.

3. Can I easily change my SMT line layout if my production needs change?

Yes, adopting modular design elements allows manufacturers to reconfigure their layouts easily in response to changing production demands or product types.

4. What role does safety play in designing an SMT production line?

Safety is critical; layouts should include clear pathways, emergency exits, and ergonomic workstations to ensure a safe working environment for all employees involved in the SMT process.

5. How can I measure the effectiveness of my SMT line layout?

You can measure effectiveness through key performance indicators (KPIs) such as cycle time, throughput rates, defect rates, and overall equipment effectiveness (OEE) metrics.

Citations:

[1] https://insights.aimtecglobal.com/en/planning-of-smt-lines/

[2] https://www.smtfactory.com/Optimizing-Efficiency-Strategies-for-A-Smooth-SMT-Line-Production-Process-id47463586.html

[3] https://www.linkedin.com/pulse/perfect-layout-analysis-design-smt-electronics-factory-mia-feng-vxw6c

[4] https://www.smtfactory.com/Perfecting-Your-SMT-Line-Layout-for-Efficiency-id47017676.html

[5] https://www.electronicspecifier.com/news/surface-mount-technology-best-practice-guide

[6] https://iconnect007.com/article/110962/modeling-an-smt-line-to-improve-throughput/110965/smt

[7] https://www.adoptsmt.com/en/efficiency-enhancement-in-smt-manufacturing/

[8] https://www.smtfactory.com/Strategic-SMT-Production-Line-Layout-Design-id40117676.html

[9] https://www.smtfactory.com/Essential-Steps-for-SMT-Production-Line-Setup-id49117676.html

[10] https://www.neodensmt.com/news/improve-smt-production-efficiency-48868013.html