Content Menu

● What Is an SMD Pick and Place Machine?

>> Key Components of an SMD Pick and Place Machine

● Factors Affecting the Cost of an SMD Pick and Place Machine

>> 1. Machine Specifications

>> 2. Technology and Features

>> 3. Brand and Manufacturer Reputation

>> 4. Market and Geographic Factors

● Typical Price Ranges of SMD Pick and Place Machines

>> Examples of Machines by Price Segment

● Additional Costs to Consider Beyond the Machine Price

>> Installation and Training

>> Maintenance and Spare Parts

>> Software Licensing and Upgrades

>> Facility Requirements

● How to Choose the Right SMD Pick and Place Machine for Your Needs

● Conclusion

● FAQ

>> 1. What is the price range for entry-level SMD pick and place machines?

>> 2. How does machine speed affect the cost?

>> 3. Why do vision systems increase the price of pick and place machines?

>> 4. Are there ongoing costs after purchasing an SMD pick and place machine?

>> 5. Can I buy used SMD pick and place machines to reduce costs?

Surface Mount Device (SMD) pick and place machines are indispensable in today's electronics manufacturing landscape. These machines automate the precise placement of tiny electronic components onto printed circuit boards (PCBs), enabling manufacturers to achieve high production volumes with exceptional accuracy and efficiency. For businesses considering investing in or upgrading to an SMD pick and place machine, understanding the typical cost and the factors that influence pricing is essential. This comprehensive guide will explore what an SMD pick and place machine is, the key factors affecting its cost, typical price ranges, and additional considerations to help you make an informed purchasing decision.

What Is an SMD Pick and Place Machine?

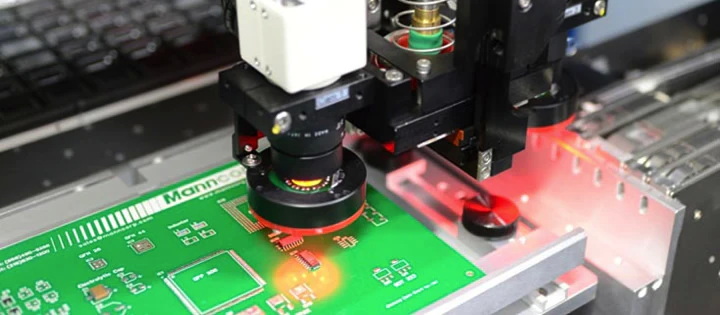

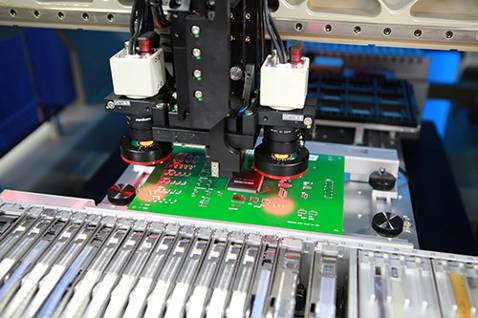

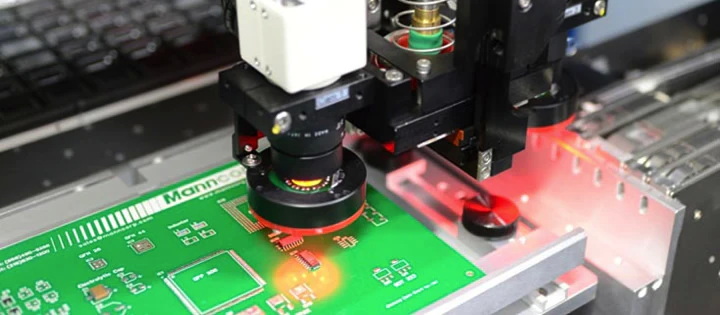

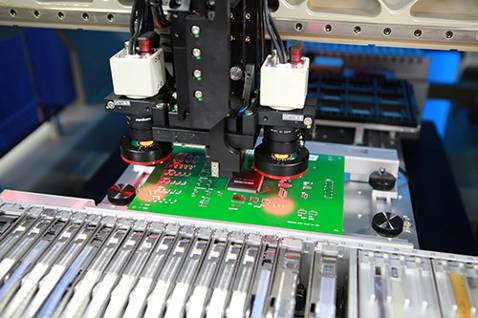

An SMD pick and place machine is a highly automated piece of equipment used in Surface Mount Technology (SMT) assembly lines. Its primary function is to pick small electronic components - such as resistors, capacitors, integrated circuits, and other surface-mount devices - from feeders and accurately place them onto PCBs for soldering.

Key Components of an SMD Pick and Place Machine

- Component Feeders: These hold reels or trays containing electronic components. Feeders can be tape feeders, tray feeders, or tube feeders, depending on the packaging of the components.

- Placement Heads and Nozzles: The machine uses vacuum nozzles to pick components from feeders and place them onto the PCB. Some machines have multiple heads or nozzles to increase speed.

- Vision Systems: Cameras and image recognition software ensure components are picked and placed correctly by verifying orientation and position.

- Motion System: High-precision motors and linear guides move the placement heads and PCBs with accuracy.

- Control Software: The software programs the machine, controls the placement sequence, and monitors performance.

The complexity and sophistication of these components vary widely, influencing the machine's capabilities and cost.

Factors Affecting the Cost of an SMD Pick and Place Machine

When evaluating the cost of an SMD pick and place machine, several key factors come into play:

1. Machine Specifications

- Placement Speed and Throughput:

Speed is one of the most significant cost drivers. Machines capable of placing thousands to tens of thousands of components per hour require advanced mechanics and control systems, which increase the price. For example, a machine that places 5,000 components per hour will be less expensive than one that handles 30,000+ components per hour.

- Placement Accuracy:

Higher precision is necessary for modern electronics with fine-pitch components (e.g., 0201 size or smaller). Machines with sub-10 micron accuracy cost more due to better motion control and vision systems.

- Component Variety and Size Range:

Machines that can handle a wide range of component sizes - from tiny 01005 resistors to large connectors - require versatile nozzles and feeders, increasing complexity and cost.

2. Technology and Features

- Vision and Inspection Systems:

Advanced vision systems with multiple cameras and AI-based image recognition improve placement accuracy and reduce errors but add to the machine's cost.

- Feeder Capacity and Flexibility:

Machines with more feeder slots can handle larger production runs without stopping for feeder changes. Automatic feeder loading and nozzle changers also raise the price.

- Automation Level:

Fully automated machines with features like automatic PCB loading/unloading, inline solder paste inspection, and real-time process monitoring cost more but increase production efficiency.

3. Brand and Manufacturer Reputation

- Established Brands:

Manufacturers like Yamaha, Juki, Panasonic, and Mycronic are known for reliability and advanced technology, which often comes at a premium price.

- Support and Warranty:

Comprehensive after-sales support, including training, maintenance, and spare parts availability, adds value and can justify higher upfront costs.

4. Market and Geographic Factors

- Supply Chain and Import Fees:

Global supply chain disruptions, tariffs, and shipping costs can influence the final purchase price, especially for imported machines.

- Local Service Availability:

Machines sourced from local distributors or manufacturers may have lower total cost of ownership due to easier access to service and parts.

Typical Price Ranges of SMD Pick and Place Machines

The cost of SMD pick and place machines varies widely depending on specifications and features. Below is a general breakdown of typical price ranges:

| Machine Category | Price Range (USD) | Description |

| Entry-Level / Low-Capacity | $4,000 – $50,000 | Suitable for prototyping, small production runs; lower speed and fewer features. |

| Mid-Range | $50,000 – $150,000 | Higher speed, more feeders, better accuracy; suitable for medium volume manufacturing. |

| High-End / High-Speed | $150,000 and above | Advanced automation, very high throughput, exceptional precision for large-scale production. |

Examples of Machines by Price Segment

- Entry-Level: Neoden 4 or Neoden 5 models are popular for small manufacturers and hobbyists, costing around $5,000 to $10,000.

- Mid-Range: Machines like the Juki KE-3020V or Yamaha YS12 offer better speed and automation, priced between $30,000 and $50,000.

- High-End: Yamaha YSM20 or Mycronic MY200 models can cost $100,000 or more, offering high throughput and precision for demanding industrial environments.

Additional Costs to Consider Beyond the Machine Price

Purchasing the machine is only part of the total investment. Other costs include:

Installation and Training

Some manufacturers include installation and operator training in the purchase price, but others charge extra. Proper setup and training are critical to maximize machine performance and avoid costly errors.

Maintenance and Spare Parts

Regular maintenance is essential to keep a pick and place machine running smoothly. Maintenance contracts and the availability of spare parts can add to ongoing costs. High-end machines might require more specialized service.

Software Licensing and Upgrades

Many machines rely on proprietary software for programming and operation. Software licenses may require renewal, and upgrades to new versions or additional modules can incur extra fees.

Facility Requirements

Some machines require specific environmental conditions such as temperature control, clean room standards, or vibration-free floors, which might necessitate facility upgrades.

How to Choose the Right SMD Pick and Place Machine for Your Needs

Selecting the right machine involves balancing cost with production requirements:

- Assess Production Volume:

For low-volume or prototype work, an entry-level machine may suffice. Medium to high-volume production demands faster, more automated machines.

- Consider Component Complexity:

If your products use fine-pitch or very small components, prioritize machines with high placement accuracy and advanced vision systems.

- Plan for Growth:

Investing in a machine with some scalability (e.g., additional feeder slots or automation options) can save money in the long run.

- Evaluate Support and Warranty:

Choose a brand or distributor that offers strong after-sales support to minimize downtime.

Conclusion

The typical cost of an SMD pick and place machine varies significantly based on machine speed, accuracy, component handling capabilities, automation features, and brand reputation. Entry-level machines designed for small-scale or prototype production start around $4,000 to $15,000, while high-end industrial machines with full automation and high throughput can exceed $150,000. Beyond the initial purchase price, installation, training, maintenance, software, and facility requirements contribute to the total investment.

By carefully evaluating your production needs, component types, and budget, you can select an SMD pick and place machine that delivers the best value and supports your manufacturing goals effectively.

FAQ

1. What is the price range for entry-level SMD pick and place machines?

Entry-level machines typically range from $4,000 to $15,000, offering basic placement capabilities suitable for small-scale or prototype production.

2. How does machine speed affect the cost?

Higher speed machines that place more components per hour are more expensive due to advanced mechanics, control systems, and quality components.

3. Why do vision systems increase the price of pick and place machines?

Advanced vision systems use cameras and image recognition to ensure precise component placement and reduce errors, adding complexity and cost to the machine.

4. Are there ongoing costs after purchasing an SMD pick and place machine?

Yes, ongoing costs include installation, operator training, maintenance contracts, spare parts, and software upgrades.

5. Can I buy used SMD pick and place machines to reduce costs?

Used machines can be more affordable but may come with risks such as outdated technology, less reliability, and limited support. Careful evaluation and testing are recommended before purchasing used equipment.