Content Menu

● Understanding SMT and AOI

● The Importance of AOI in SMT Production Lines

● How AOI Works

● Types of Defects Detected by AOI

● Integration of AOI in SMT Production Lines

● Benefits of Implementing AOI

● Challenges Associated with AOI

● Future Trends in AOI Technology

● Conclusion

● FAQ

>> 1. What types of defects can AOI detect?

>> 2. How does AOI improve efficiency in SMT production?

>> 3. What challenges do manufacturers face when implementing AOI?

>> 4. How often should an AOI system be calibrated?

>> 5. What future trends should we expect in AOI technology?

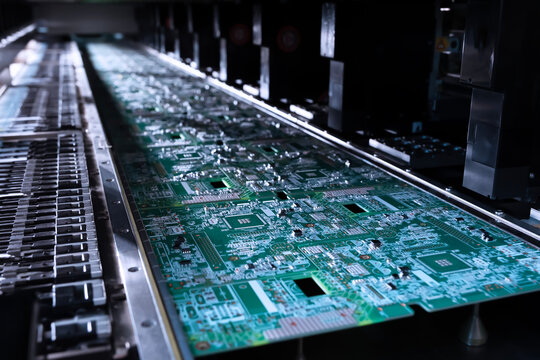

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, allowing for more compact and efficient designs. Within this context, Automated Optical Inspection (AOI) plays a pivotal role in ensuring the quality and reliability of electronic assemblies. This article explores the significance of AOI in an SMT production line, detailing its functions, benefits, and integration into the manufacturing process.

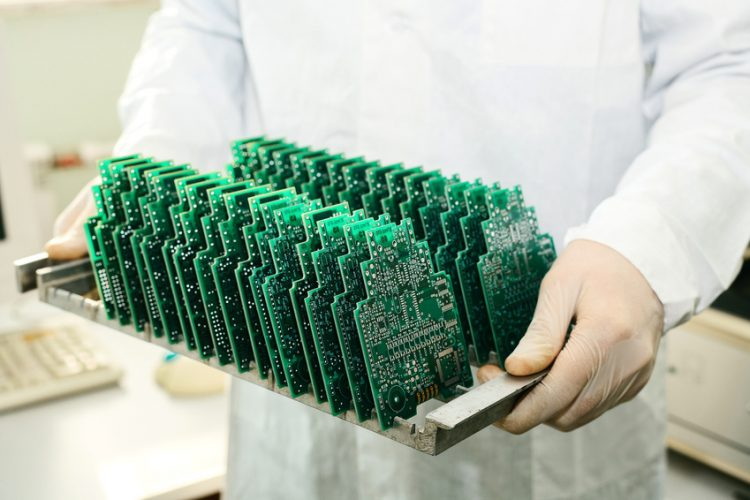

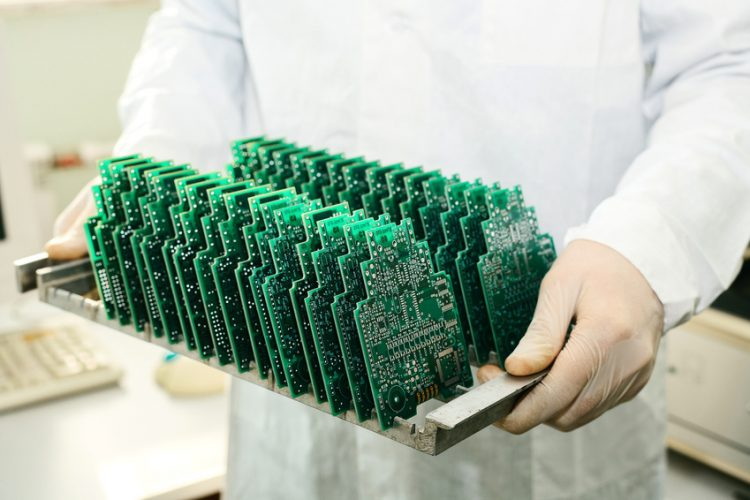

Understanding SMT and AOI

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). This technology has gained popularity due to its ability to accommodate smaller components, which leads to higher component density and improved performance. SMT allows for automated assembly processes, reducing labor costs and increasing production speed.

Automated Optical Inspection (AOI) is a non-contact inspection method that utilizes cameras and image processing software to detect defects in PCBs during the manufacturing process. AOI systems are designed to identify various issues, including:

- Misalignment of components

- Solder joint defects

- Missing components

- Component polarity errors

By integrating AOI into the SMT process, manufacturers can enhance their quality control measures significantly.

The Importance of AOI in SMT Production Lines

The integration of AOI into SMT production lines is crucial for several reasons:

1. Quality Assurance: AOI systems help ensure that only defect-free products move forward in the production process. By identifying defects early, manufacturers can prevent costly rework or scrap.

2. Increased Efficiency: Automated inspections are faster than manual inspections, allowing for higher throughput rates. This efficiency is vital in meeting production deadlines.

3. Cost Reduction: By minimizing defects and improving yield rates, AOI contributes to lower production costs. Fewer defects mean less rework and waste.

4. Data Collection: AOI systems can collect valuable data on defect types and frequencies, enabling manufacturers to analyze trends and implement continuous improvement strategies.

5. Flexibility: Modern AOI systems are adaptable to various PCB designs and can be programmed to inspect different types of assemblies without significant downtime.

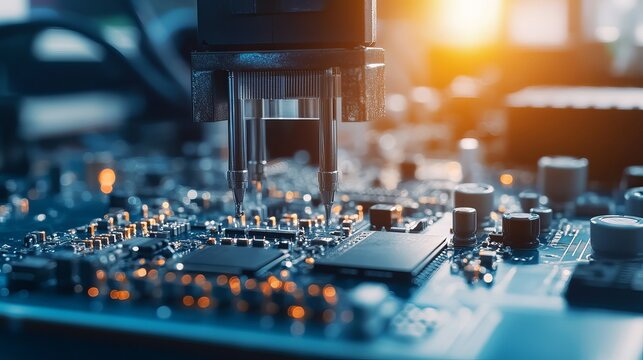

How AOI Works

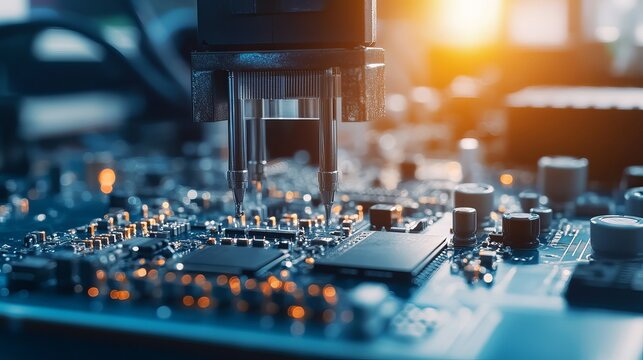

The operation of an AOI system involves several key steps:

1. Image Acquisition: High-resolution cameras capture images of the PCB at various stages of assembly.

2. Image Processing: Advanced algorithms analyze the captured images to detect discrepancies between the actual assembly and predefined specifications or templates.

3. Defect Classification: The system categorizes detected defects based on severity and type, providing operators with actionable insights.

4. Reporting: The results are compiled into reports that detail the inspection outcomes, allowing for quick decision-making regarding quality control measures.

Types of Defects Detected by AOI

AOI systems are capable of identifying a wide range of defects, including:

- Component Placement Errors: Misaligned or incorrectly placed components can lead to functional failures.

- Soldering Issues: Problems such as insufficient solder, solder bridging, or cold solder joints can compromise electrical connections.

- Component Damage: Physical damage to components during handling or assembly can be detected early in the process.

- Missing Components: The absence of required components can be identified before further processing occurs.

- Foreign Object Debris (FOD): Unwanted particles or materials on the PCB can interfere with component functionality and reliability.

By addressing these defects early in the production cycle, manufacturers can significantly reduce the likelihood of product failures in the field.

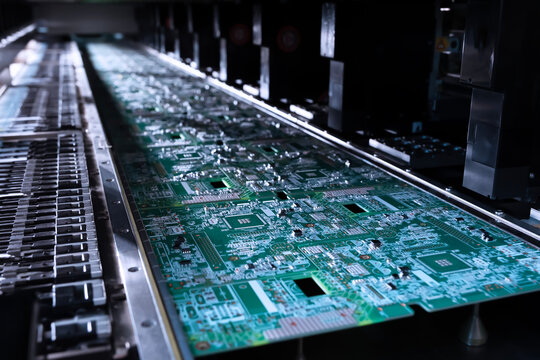

Integration of AOI in SMT Production Lines

Integrating AOI into an SMT production line involves several considerations:

1. Placement in the Production Flow: Typically, AOI is positioned after critical processes such as solder paste printing and component placement but before reflow soldering. This strategic placement allows for immediate feedback on potential issues before they become more difficult or costly to rectify.

2. System Calibration: Regular calibration ensures that the AOI system maintains accuracy over time. This process involves adjusting settings based on specific PCB designs and environmental factors that could affect inspection results.

3. Operator Training: Personnel must be trained not only on how to operate the AOI system but also on interpreting results and taking corrective actions when defects are identified. Training programs should include both theoretical knowledge and practical experience with real-world scenarios.

4. Maintenance Protocols: Regular maintenance is essential for optimal performance; this includes cleaning optical components and updating software as needed. A proactive maintenance schedule helps prevent unexpected downtimes that could disrupt production flow.

5. Software Integration: Many modern AOI systems integrate with other manufacturing execution systems (MES) for seamless data exchange. This integration allows for real-time monitoring of production metrics and enables quicker responses to quality issues as they arise.

Benefits of Implementing AOI

Implementing AOI in an SMT production line offers numerous advantages:

- Enhanced Product Quality: With early detection of defects, manufacturers can produce higher-quality products that meet customer expectations and industry standards.

- Reduced Inspection Time: Automated inspections significantly decrease the time required for quality checks compared to manual methods, allowing operators to focus on more complex tasks that require human intervention.

- Improved Traceability: The data collected during inspections can be used for traceability purposes, helping manufacturers comply with industry standards and regulations while also providing valuable insights for future projects.

- Increased Productivity: Faster inspections lead to shorter production cycles, enabling manufacturers to meet market demands more effectively while maintaining competitive pricing structures.

- Customer Satisfaction: Delivering high-quality products consistently enhances customer satisfaction and loyalty, which is crucial for long-term business success in a competitive market environment.

Challenges Associated with AOI

Despite its many advantages, implementing AOI also presents challenges:

1. Initial Investment Costs: The cost of purchasing and installing an AOI system can be substantial, particularly for smaller manufacturers who may have limited budgets for equipment upgrades.

2. Complexity of Setup: Setting up an AOI system requires careful planning and configuration to ensure it meets specific production needs. Manufacturers must consider factors such as lighting conditions, camera angles, and software calibration during installation.

3. False Positives/Negatives: While advanced algorithms minimize these occurrences, false positives (incorrectly identifying a defect) and false negatives (failing to identify a defect) can still happen, necessitating human oversight to verify results when necessary.

4. Continuous Updates Required: As technology evolves, regular updates may be necessary to keep the AOI system relevant and effective against new defect types or PCB designs. Manufacturers must allocate resources for ongoing training and system upgrades as part of their operational strategy.

5. Resistance to Change: Some staff may resist adopting new technologies due to fear of job loss or discomfort with unfamiliar processes. Addressing these concerns through effective communication and training initiatives is essential for successful implementation.

Future Trends in AOI Technology

As technology advances, several trends are shaping the future of AOI systems:

- Artificial Intelligence (AI): AI algorithms are increasingly being integrated into AOI systems for enhanced defect detection capabilities through machine learning techniques that improve over time with data input. These algorithms can learn from past inspection results to refine their accuracy continuously.

- 3D Inspection Capabilities: Next-generation AOI systems are incorporating 3D imaging technologies that allow for more thorough inspections by analyzing component height and volume alongside traditional 2D imaging techniques. This capability enhances detection rates for certain types of defects that may not be visible in 2D images alone.

- Increased Automation: Future developments will likely focus on further automating inspection processes within SMT lines to reduce human intervention while increasing efficiency. Automation may extend beyond inspection tasks to include data analysis and reporting functions as well.

- Integration with Industry 4.0 Initiatives: As manufacturers move toward smart factories characterized by interconnected devices and real-time data flow, AOI systems will play a critical role in ensuring quality control within these environments by providing immediate feedback on production performance metrics.

- Cloud-Based Solutions: The adoption of cloud-based platforms will enable manufacturers to store inspection data remotely while facilitating easier access for analysis across multiple sites or teams globally. This shift could enhance collaboration among engineering teams working on product improvements based on historical defect trends identified through AOI data analysis.

Conclusion

Automated Optical Inspection plays a vital role in ensuring quality control within SMT production lines. By detecting defects early in the manufacturing process, AOI enhances product reliability while reducing costs associated with rework and waste. As technology continues to advance, integrating AI and 3D imaging capabilities into AOI systems will further improve inspection accuracy and efficiency. Ultimately, embracing these innovations will empower manufacturers to meet evolving market demands while maintaining high standards of quality assurance.

FAQ

1. What types of defects can AOI detect?

AOI can detect various defects such as misalignment of components, solder joint issues, missing components, component damage during assembly, and foreign object debris (FOD).

2. How does AOI improve efficiency in SMT production?

AOI improves efficiency by automating inspection processes that are typically time-consuming when performed manually, allowing for faster throughput rates in manufacturing lines.

3. What challenges do manufacturers face when implementing AOI?

Manufacturers may face challenges such as high initial investment costs, complexity in setup and calibration, potential false positives/negatives during inspections, continuous updates needed as technology evolves, and resistance from staff towards adopting new technologies.

4. How often should an AOI system be calibrated?

Regular calibration is essential for maintaining accuracy; it is recommended that calibration occurs periodically based on production volume or whenever significant changes occur in PCB designs or processes.

5. What future trends should we expect in AOI technology?

Future trends include greater integration of artificial intelligence for improved defect detection capabilities, advancements in 3D inspection technologies for comprehensive evaluations, increased automation within inspection processes, integration with Industry 4.0 initiatives for smart factories, and cloud-based solutions for enhanced data accessibility across teams globally.