Content Menu

● Introduction

● Understanding SMT Reel Sizes

>> Reel Diameter

>> Reel Width

● Importance of SMT Reel Size in Manufacturing

● Impact on SMT Manufacturing Processes

● Advantages of SMT Over Traditional Methods

● Challenges and Future Developments

>> Emerging Trends in SMT Reel Technology

>> Case Studies: Successful Implementation of Standardized Reel Sizes

● Conclusion

● FAQs

>> 1. What are the common standard SMT reel sizes?

>> 2. Why is reel width important in SMT manufacturing?

>> 3. How does SMT reel size impact manufacturing efficiency?

>> 4. What are the advantages of using SMT over traditional through-hole technology?

>> 5. How does miniaturization affect SMT reel sizes and handling?

Introduction

In the realm of electronics manufacturing, Surface Mount Technology (SMT) plays a pivotal role in the production of printed circuit boards (PCBs). One crucial aspect of SMT is the packaging and handling of components, particularly in tape and reel formats. The size of the reel, often referred to as the standard SMT reel size, is vital for efficient manufacturing processes. This article delves into the importance of SMT reel sizes, their specifications, and how they impact electronics manufacturing.

Understanding SMT Reel Sizes

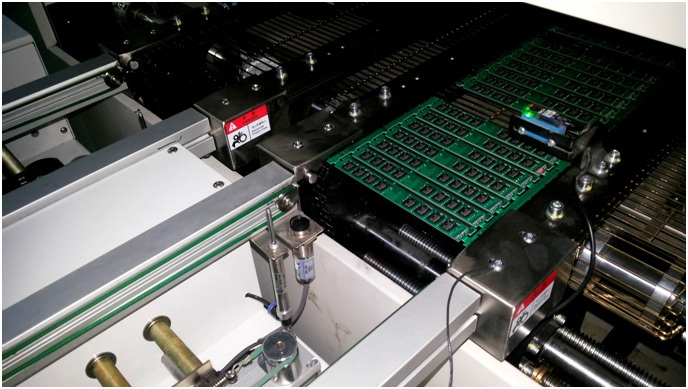

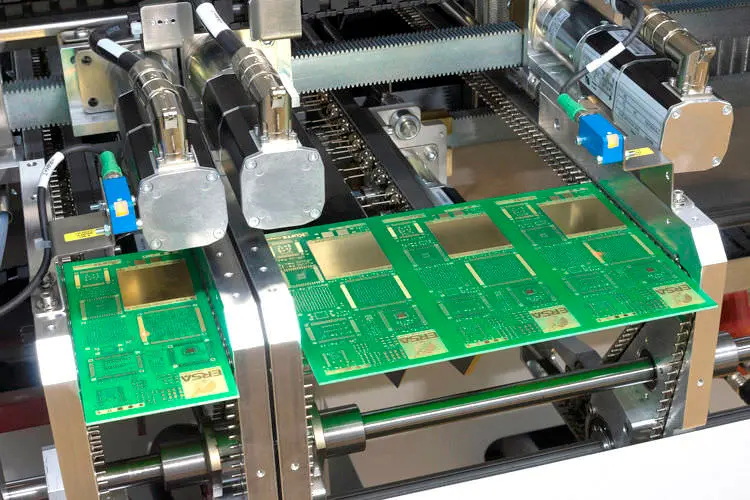

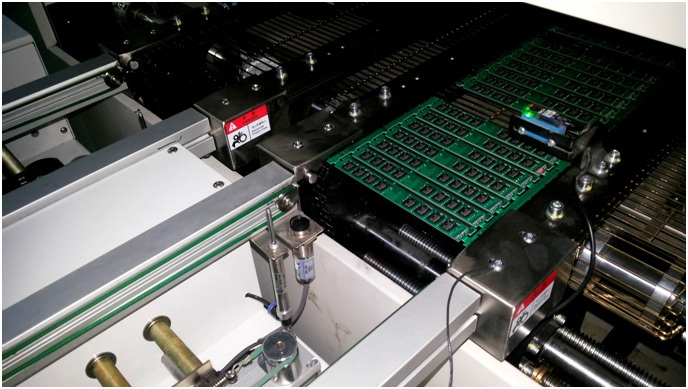

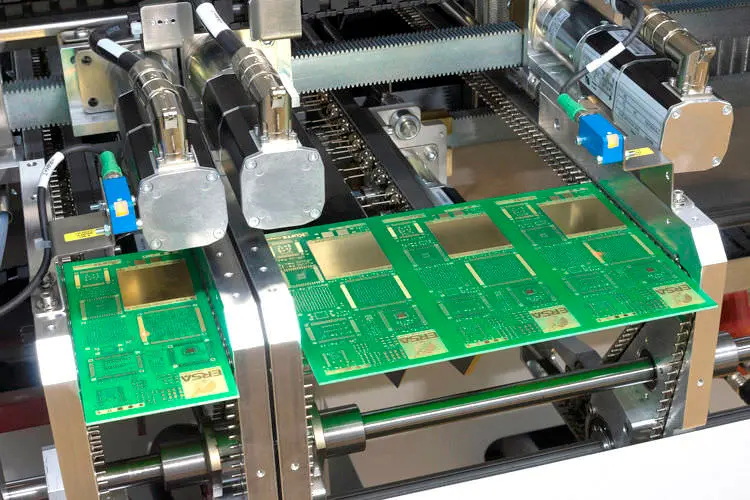

SMT components are typically packaged on reels, which are then fed into pick-and-place machines for assembly onto PCBs. The size of the reel is critical because it determines how components are fed into these machines. Common standard SMT reel sizes include diameters of 7 inches and 13 inches, with widths varying from 4mm to 56mm, depending on the component type and size.

Reel Diameter

The diameter of the reel is crucial for compatibility with different pick-and-place machines. Some machines are designed to handle only specific reel diameters, such as the "mini-reels" with a diameter of 7 inches. Using the correct reel diameter avoids costly downtime and unnecessary re-reeling of components before production.

Reel Width

Reel width is another important specification, as it affects how components are protected and fed into machines. Common reel widths include 4mm, 8mm, 12mm, 16mm, 24mm, 32mm, 44mm, and 56mm. The choice of reel width depends on the component size, weight, and the level of protection required during handling.

Importance of SMT Reel Size in Manufacturing

The importance of standard SMT reel sizes in electronics manufacturing can be seen in several key areas:

1. Efficiency and Compatibility: Ensuring that components are packaged on reels that match the specifications of the manufacturing equipment is essential for smooth production. Incorrect reel sizes can lead to inefficiencies, downtime, and increased costs.

2. Component Protection: The width and material of the reel tape provide protection to components during shipping and storage. Proper reel sizes ensure that components are not damaged due to excessive movement or exposure to environmental factors.

3. Space Optimization: In high-density PCB designs, optimizing reel sizes helps in managing inventory space and reducing waste. Standardized reel sizes facilitate easier storage and handling, making the manufacturing process more streamlined.

4. Cost Reduction: By using reels that are compatible with the manufacturing equipment, companies can avoid the costs associated with re-reeling components or purchasing specialized machinery to accommodate non-standard reel sizes.

5. Quality Control: Standardized reel sizes aid in quality control by ensuring that components are consistently fed into machines, reducing the risk of misplacement or damage during assembly.

Impact on SMT Manufacturing Processes

SMT manufacturing involves several processes where reel size plays a critical role:

- Pick-and-Place Machines: These machines are designed to handle specific reel sizes. Incorrect reel sizes can lead to inefficiencies or require additional setup time.

- Component Feeding: The width and pitch of the reel tape determine how components are fed into the machine. Proper alignment is crucial for accurate placement on the PCB.

- Inventory Management: Standard reel sizes simplify inventory management by allowing for easier tracking and storage of components.

Advantages of SMT Over Traditional Methods

SMT offers several advantages over traditional through-hole technology, including:

- Small Footprint: SMT components are smaller, allowing for more compact PCB designs.

- Low Cost: Reduced material and labor costs due to smaller board sizes and fewer drilled holes.

- Higher Density: More components can be placed on a smaller area, increasing PCB functionality.

- Quick Turnaround: Faster assembly times due to the use of solder paste instead of drilling holes.

Challenges and Future Developments

Despite the advantages of SMT, there are challenges related to reel size and component handling:

- Miniaturization: As components become smaller, there is a need for more precise reel sizes and handling techniques to prevent damage.

- Automation: Advances in automation require standardized reel sizes to ensure seamless integration with new machinery.

Emerging Trends in SMT Reel Technology

The electronics industry is witnessing several emerging trends that impact SMT reel sizes:

1. Smart Reels: Some manufacturers are integrating RFID tags or other tracking technologies into reels to enhance inventory management and traceability.

2. Sustainable Packaging: There is a growing focus on environmentally friendly packaging solutions, such as biodegradable reel materials, to reduce waste.

3. Custom Reel Solutions: With the rise of specialized components, there is an increasing demand for custom reel sizes tailored to specific component types.

4. 3D Printing Integration: The integration of 3D printing with SMT manufacturing may require new reel designs to accommodate unique component geometries.

5. Industry 4.0 Integration: The adoption of Industry 4.0 technologies, such as AI and IoT, in manufacturing processes will further emphasize the need for standardized reel sizes to ensure seamless automation.

Case Studies: Successful Implementation of Standardized Reel Sizes

Several companies have successfully implemented standardized reel sizes to improve their manufacturing processes:

- Increased Efficiency: By standardizing reel sizes, companies have reduced setup times and improved the overall efficiency of their production lines.

- Cost Savings: Standardized reels have helped companies avoid unnecessary re-reeling costs and reduce waste, leading to significant cost savings.

- Improved Quality: Consistent reel sizes have enhanced quality control by minimizing component misplacement and damage during assembly.

Conclusion

In conclusion, the size of SMT reels is a critical factor in electronics manufacturing, impacting efficiency, compatibility, and cost. Standardizing reel sizes ensures smooth production processes, reduces downtime, and enhances quality control. As technology advances and components become smaller, the importance of precise reel sizes will only grow. The integration of emerging technologies and sustainable practices will continue to shape the future of SMT reel sizes.

FAQs

1. What are the common standard SMT reel sizes?

Common reel sizes include diameters of 7 inches and 13 inches, with widths ranging from 4mm to 56mm, depending on the component type.

2. Why is reel width important in SMT manufacturing?

Reel width is important because it affects how components are protected and fed into machines. Different widths are used based on component size and weight.

3. How does SMT reel size impact manufacturing efficiency?

Incorrect reel sizes can lead to inefficiencies, downtime, and increased costs. Standardized reel sizes ensure compatibility with manufacturing equipment, optimizing production processes.

4. What are the advantages of using SMT over traditional through-hole technology?

SMT offers advantages such as a smaller footprint, lower cost, higher component density, and quicker assembly times compared to through-hole technology.

5. How does miniaturization affect SMT reel sizes and handling?

As components become smaller, there is a greater need for precise reel sizes and handling techniques to prevent damage during manufacturing.