Content Menu

● Overview of PCB SMT Stencils

● Current Market Trends

● Market Dynamics

>> Drivers

>> Challenges

● Future Outlook

● Latest Market Trends and Technological Advancements

>> Innovations in Stencil Manufacturing

>> Case Studies and Best Practices

● Advantages of Using PCB Stencils

● Future Trends in SMT Stencil Technology

>> Nano-coatings and Surface Treatments

>> Additive Manufacturing

● Conclusion

● FAQ

>> 1. What are PCB SMT stencils used for?

>> 2. What materials are commonly used for SMT stencils?

>> 3. How does automation impact the use of SMT stencils?

>> 4. What trends are influencing the PCB SMT stencil market?

>> 5. What is the projected growth rate for the PCB SMT stencil market?

● Citations:

The market for PCB (Printed Circuit Board) SMT (Surface Mount Technology) stencils is evolving rapidly, driven by advancements in technology, the miniaturization of electronic components, and the increasing demand for high-quality electronic products. This article explores the current trends, drivers, and challenges in the PCB SMT stencil market, providing insights into its future direction.

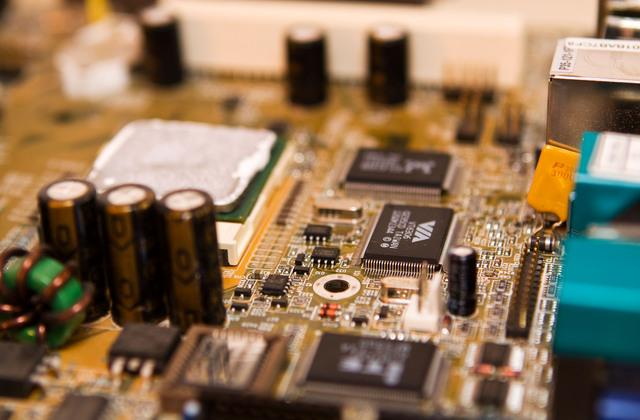

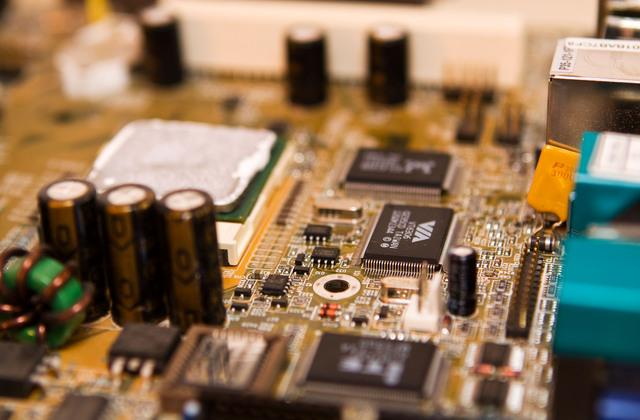

Overview of PCB SMT Stencils

PCB SMT stencils are essential tools used in the assembly of electronic circuits. They facilitate the precise application of solder paste onto PCBs before components are mounted. The accuracy of solder paste application is critical as it directly impacts the reliability and performance of electronic devices.

The stencils are typically made from stainless steel or polymer materials, featuring laser-cut apertures that align with the pads on the PCB. The process involves placing the stencil over the PCB, applying solder paste through the apertures using a squeegee, and then removing the stencil to leave behind a precise amount of solder paste ready for component placement.

Current Market Trends

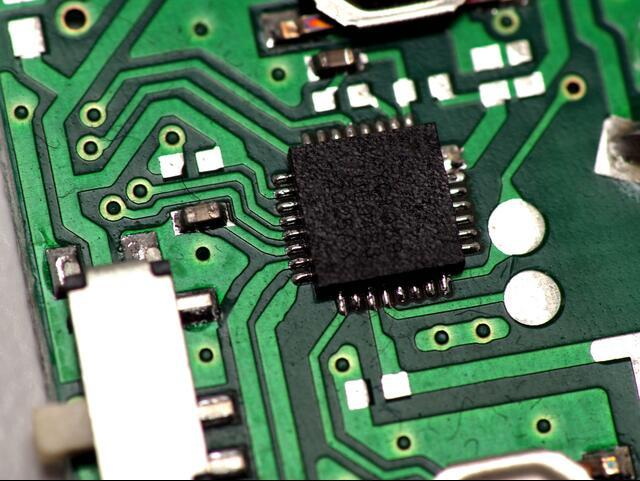

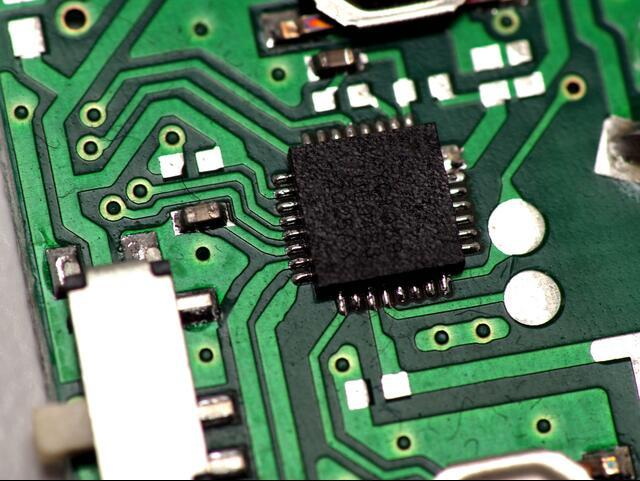

1. Growth in Demand for Miniaturized Electronics: The trend towards smaller and more compact electronic devices has increased the need for high-precision solder paste application. As devices shrink, traditional soldering methods become less effective, making SMT stencils indispensable in modern manufacturing processes.

2. Technological Advancements: Innovations in manufacturing technologies, such as laser cutting and electroforming, have significantly improved stencil production quality and efficiency. Electroformed stencils, known for their superior paste release characteristics, are gaining popularity due to their ability to handle fine-pitch components effectively.

3. Automation and Industry 4.0: The integration of automation in manufacturing processes is transforming the PCB assembly landscape. Automated stencil printers equipped with AI capabilities enhance production speed and accuracy while reducing human error. This shift towards smart manufacturing is expected to continue driving demand for advanced stencil technologies.

4. Sustainability Initiatives: As environmental concerns grow, manufacturers are increasingly focusing on sustainable practices. This includes developing eco-friendly stencil materials and processes that minimize waste and energy consumption. The adoption of lead-free soldering materials is also becoming more prevalent due to regulatory pressures.

5. Customization and Flexibility: Manufacturers are seeking stencils that can accommodate a wide range of PCB sizes and component types. This demand is leading to the development of modular stencil systems that can be easily adjusted to meet specific production needs.

Market Dynamics

Drivers

- Rising Consumer Electronics Demand: The global surge in consumer electronics consumption has significantly increased the need for efficient PCB assembly processes, thereby driving demand for advanced SMT stencils.

- Complexity in PCB Designs: As electronic devices become more sophisticated, with higher component densities and smaller pad sizes, there is a growing need for precise solder paste deposition techniques that SMT stencils provide.

- Expansion of Emerging Markets: Rapid industrialization in regions like Asia-Pacific is fostering increased demand for SMT stencils as these areas become hubs for electronics manufacturing.

Challenges

- Cost Pressures: The highly competitive nature of the market necessitates cost efficiency in production processes. Manufacturers must balance quality and cost while maintaining competitiveness.

- Supply Chain Issues: Fluctuations in raw material prices and global supply chain disruptions can impact stencil production timelines and costs.

Future Outlook

The future of the PCB SMT stencil market looks promising, with projections indicating steady growth. According to recent reports, the global market size for PCB SMT stencils is expected to reach approximately USD 590.9 million by 2030, growing at a CAGR of 7.4% from 2024 to 2030.

Key factors contributing to this growth include:

- Continued advancements in electronics manufacturing technologies.

- Increased adoption of automation across various sectors.

- Growing emphasis on sustainability within manufacturing practices.

- Rising investments in research and development aimed at improving stencil materials and designs.

Latest Market Trends and Technological Advancements

The PCB SMT stencil market is witnessing a surge in demand, primarily driven by the increasing complexity of electronic devices and the need for high-precision manufacturing processes. According to a recent report, the electroform SMT stencil market is projected to grow from USD 7.5 billion in 2023 to USD 13.72 billion by 2031, with a CAGR of 13.59%. This growth is attributed to the rising demand for miniaturized electronics and advancements in manufacturing technologies.

Innovations in Stencil Manufacturing

Recent innovations in stencil manufacturing, such as laser cutting and chemical etching, have significantly improved the quality and efficiency of SMT stencils. Laser-cut stencils are particularly valued for their rapid prototyping capabilities and adaptability to different solder paste types and thicknesses. Additionally, the introduction of nano-coatings has enhanced the performance of stencils by improving solder paste release and reducing adhesion, which is crucial for high-density interconnections.

Case Studies and Best Practices

1. Production of Step Stencils: A case study by LPKF highlights the development of step stencils that allow for precise solder paste application on components with varying heights. This innovation has streamlined the production process, reducing time and costs associated with traditional methods.

2. Best Practices in PCB Stencil Usage: Effective practices include regular cleaning and maintenance of stencils, proper storage to prevent damage, and accurate alignment during the printing process. These practices ensure consistent quality and reliability in solder paste application.

Advantages of Using PCB Stencils

Integrating SMT stencils into PCB assembly offers several benefits:

- Precision Deposition: SMT stencils ensure precise and uniform solder paste deposition on PCB pads, minimizing solder bridging and ensuring consistent solder joint quality.

- Enhanced Efficiency: Stencils streamline the PCB assembly process by enabling simultaneous solder paste application across multiple PCBs, reducing assembly time.

- Flexibility and Adaptability: Modern SMT stencil technologies adapt to diverse PCB designs and component configurations, accommodating fine-pitch components without compromising quality.

- Environmental Considerations: SMT stencils contribute to sustainability by optimizing resource use and reducing material waste through improved efficiency.

Future Trends in SMT Stencil Technology

The evolution of SMT stencil technology continues to drive innovation:

Nano-coatings and Surface Treatments

Advanced nano-coatings improve solder paste release characteristics while reducing adhesion issues during printing processes. These coatings enhance print quality significantly while extending stencil life by requiring less frequent cleaning.

Additive Manufacturing

3D printing technology enables custom-designed SMT stencils with intricate geometries tailored specifically for unique PCB layouts or component configurations. This flexibility supports rapid prototyping efforts while accommodating innovative designs that require specialized stencil solutions.

Conclusion

In conclusion, the PCB SMT stencil market is experiencing significant growth driven by technological advancements, increasing demand for miniaturized electronics, and a shift towards sustainable manufacturing practices. As manufacturers adapt to these changes, they will continue to seek innovative solutions that enhance production efficiency while meeting stringent quality standards.

FAQ

1. What are PCB SMT stencils used for?

PCB SMT stencils are used to apply solder paste accurately onto printed circuit boards before surface-mounted components are placed.

2. What materials are commonly used for SMT stencils?

SMT stencils are typically made from stainless steel or polymer materials due to their durability and ability to provide precise solder paste deposition.

3. How does automation impact the use of SMT stencils?

Automation enhances the efficiency and accuracy of solder paste application by reducing human error through automated printing systems that increase production speed.

4. What trends are influencing the PCB SMT stencil market?

Key trends include miniaturization of electronics, technological advancements in stencil production methods like laser cutting or electroforming, sustainability initiatives promoting eco-friendly practices, as well as customization demands from manufacturers seeking flexible solutions tailored to their needs.

5. What is the projected growth rate for the PCB SMT stencil market?

The global market size for PCB SMT stencils is projected to grow at a CAGR of 7.4%, reaching approximately USD 590.9 million by 2030.

Citations:

[1] https://www.verifiedmarketresearch.com/product/electroform-smt-stencil-market/

[2] https://jlcpcb.com/blog/guide-to-smt-stencils-in-pcb-assembly

[3] https://www.lpkfusa.com/case-studies/smt-stencil

[4] https://www.hemeixinpcb.com/company/news/what-is-a-pcb-stencil.html

[5] https://www.pcbdirectory.com/news/pcb-solder-paste-stencil-market-to-witness-steady-growth-driven-by-electronics-and-miniaturization-trends

[6] https://www.oem-pcb.com/news/what-new-technologies-are-transforming-the-pcb-83439618.html

[7] https://www.ipc.org/system/files/technical_resource/E2&S27_01.pdf

[8] https://www.elepcb.com/blog/pcb-stencil-smt-assembly/

[9] https://reports.valuates.com/market-reports/QYRE-Auto-5T13633/pcb-smt-stencils-global

[10] https://www.stentech.com/company/cvd-treatment-for-smt-stencils

[11] https://www.circuitinsight.com/pdf/SAMP_based_stencil_nano_coatings_ipc.pdf

[12] https://www.ednasia.com/top-12-incredible-techniques-to-control-the-quality-of-pcb-smt-assembly/

[13] https://smttoday.com/2024/09/13/stentech-wins-prestigious-2024-mexico-technology-award-for-innovative-stencil-surface-treatment/

[14] https://www.pcbasic.com/blog/pcb_stencils_key_to_high-quality.html

[15] https://www.technotronix.us/pcbblog/top-trends-in-printed-circuit-board-manufacturing-for-2024/

[16] https://www.linkedin.com/pulse/smt-stencils-market-innovations-trends-analysis-2024-2031-xhyrf/

[17] https://pmarketresearch.com/product/worldwide-pcb-surface-mount-technology-smt-solder-paste-stencil-market-research-2024-by-type-application-participants-and-countries-forecast-to-2030/

[18] https://www.linkedin.com/pulse/global-pcb-smt-stencils-market-impact-ai-automation-p4fgf/

[19] https://hilelectronic.com/blog-pcb-stencil/

[20] https://fourtec.com/blog-post/best-practices-for-monitoring-environmental-conditions-in-smt-lines/

[21] https://www.techspray.com/preventing-pcb-misprints-with-optimized-stencil-cleaning-process

[22] https://www.giiresearch.com/report/infi1625963-global-pcb-solder-paste-stencil-market.html

[23] https://www.multi-circuit-boards.eu/en/pcb-design-aid/smd-stencils.html