Content Menu

● Understanding PCB SMT Assembly

>> The SMT Assembly Process

● Factors Affecting PCB SMT Assembly Costs

>> 1. Board Complexity

>> 2. Component Selection

>> 3. Production Volume

>> 4. Turnaround Time

>> 5. Quality Requirements

● Breaking Down the Costs

>> Setup Fees

>> Assembly Costs

>> Material Costs

>> Labor Costs

>> Overhead Costs

>> Testing and Inspection

● Cost-Saving Strategies for PCB SMT Assembly

>> 1. Design for Manufacturability (DFM)

>> 2. Component Selection and Sourcing

>> 3. Optimize Production Volumes

>> 4. Choose the Right Assembly Partner

● Industry Trends Affecting PCB SMT Assembly Costs

>> Automation and Industry 4.0

>> Miniaturization

>> Sustainability Initiatives

● Conclusion

● FAQ

>> 1. What is the average cost per square inch for PCB SMT assembly?

>> 2. How does production volume affect PCB SMT assembly costs?

>> 3. What are the main components of PCB SMT assembly pricing?

>> 4. How can I reduce the cost of PCB SMT assembly services?

>> 5. What future trends might affect PCB SMT assembly costs?

● Citations:

PCB SMT assembly services are a crucial component of modern electronics manufacturing. Surface Mount Technology (SMT) has revolutionized the way electronic components are attached to printed circuit boards (PCBs), offering numerous advantages over traditional through-hole technology. However, one of the most common questions that arise when considering PCB SMT assembly services is the cost. In this comprehensive guide, we will explore the various factors that influence the cost of PCB SMT assembly services and provide insights into pricing structures, cost-saving strategies, and industry trends.

Understanding PCB SMT Assembly

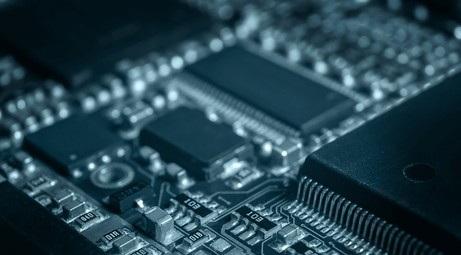

Before delving into the costs associated with PCB SMT assembly services, it's essential to understand what this process entails. SMT assembly involves placing and soldering surface-mount components onto a PCB. This method allows for higher component density, smaller board sizes, and improved performance compared to through-hole technology.

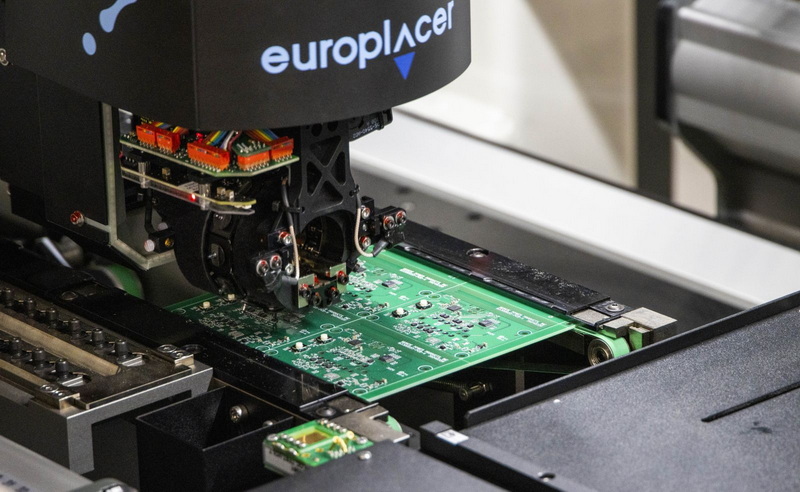

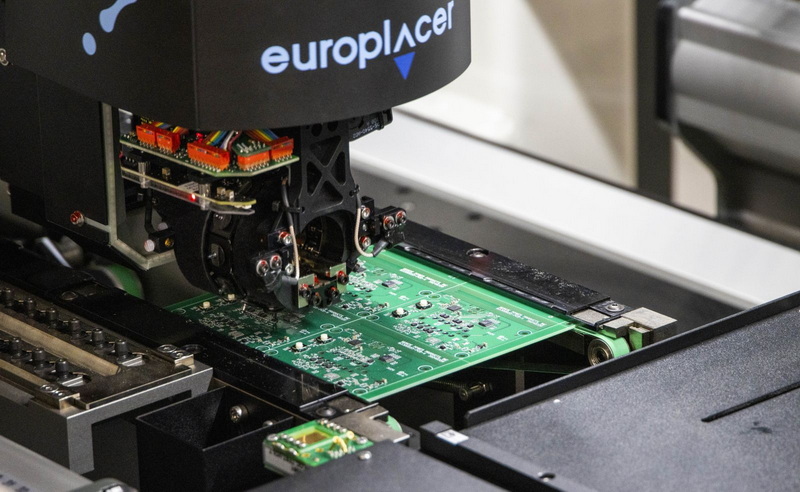

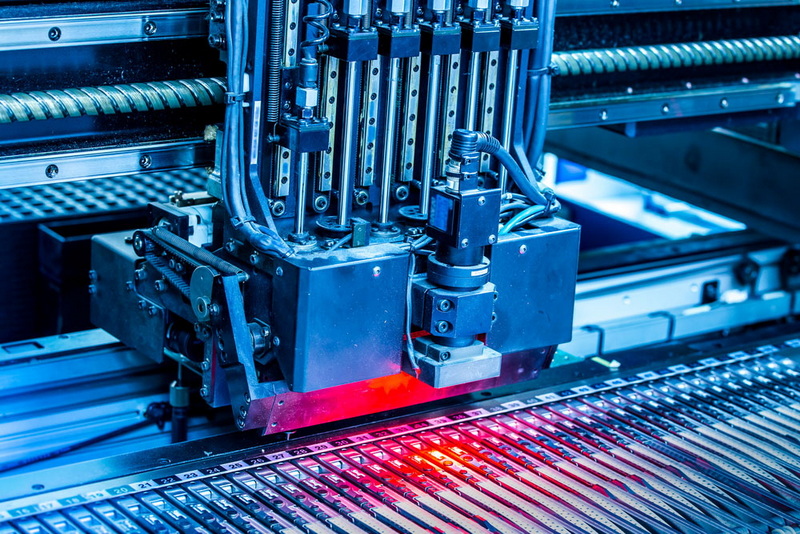

The SMT Assembly Process

The PCB SMT assembly process typically includes the following steps:

1. PCB preparation

2. Solder paste printing

3. Component placement

4. Reflow soldering

5. Inspection and quality control

Each of these steps contributes to the overall cost of the assembly service, and understanding them can help in estimating expenses more accurately.

Factors Affecting PCB SMT Assembly Costs

Several factors influence the cost of PCB SMT assembly services. Let's examine these in detail:

1. Board Complexity

The complexity of the PCB design is a significant cost driver. More complex boards with higher component density, multiple layers, or advanced features like blind and buried vias will generally cost more to assemble. This is due to the increased time and precision required during the assembly process[1].

2. Component Selection

The type and quantity of components used in the PCB design directly impact the assembly cost. Some factors to consider include:

- Component availability

- Special handling requirements for sensitive components

- The mix of SMT and through-hole components (if any)

- Use of BGA or other complex package types

3. Production Volume

The number of PCBs to be assembled plays a crucial role in determining the cost per unit. Generally, larger production runs benefit from economies of scale, resulting in lower per-unit costs. For example:

- Low-volume production (1-10 units) may cost $50-$200 per unit

- High-volume production (10,000+ units) can reduce costs to $2-$20 per unit[4]

4. Turnaround Time

Faster turnaround times often come at a premium. Rush orders or expedited services will increase the overall cost of PCB SMT assembly services. Planning ahead and allowing for standard lead times can help reduce expenses.

5. Quality Requirements

The level of quality control and testing required can significantly impact costs. More stringent quality standards, additional inspections, or specialized testing procedures will increase the overall expense but may be necessary for certain applications or industries.

Breaking Down the Costs

To better understand the pricing structure of PCB SMT assembly services, let's break down the costs into different categories:

Setup Fees

Most PCB assembly services charge a one-time setup fee for each new project. This fee typically covers:

- Programming of the SMT assembly line

- Production of SMT stencils

- Initial machine configuration and calibration

For example, JLCPCB charges a setup fee of $8.00 for their SMT assembly service[1].

Assembly Costs

The core assembly cost is usually calculated on a per-joint basis. This includes:

- SMT Assembly: Approximately $0.0017 per joint

- Manual Assembly (if required): Around $0.0173 per joint[1]

Material Costs

Material costs encompass:

- PCB substrate

- Solder paste

- Any specialized materials required for the assembly

These costs can vary widely depending on the specific requirements of the project.

Labor Costs

Labor costs are a significant component of PCB SMT assembly pricing. These can range from:

- $15-$30 per hour for standard SMT assembly

- $20-$50 per hour for specialized or prototype assembly[4]

Overhead Costs

Overhead costs typically account for 20% to 40% of the total assembly cost. These include:

- Facility rent

- Utilities

- Equipment maintenance and depreciation[4]

Testing and Inspection

Quality assurance is crucial in PCB assembly. Costs for testing and inspection can include:

- Basic functional testing: $0.10-$2 per board

- More advanced testing methods (e.g., X-ray inspection for BGAs)[4]

Cost-Saving Strategies for PCB SMT Assembly

While PCB SMT assembly services can be a significant expense, there are several strategies to optimize costs without compromising quality:

1. Design for Manufacturability (DFM)

Implementing DFM principles during the PCB design phase can significantly reduce assembly costs. This includes:

- Optimizing component placement for efficient assembly

- Standardizing component packages where possible

- Minimizing the use of mixed technologies (SMT and through-hole)

2. Component Selection and Sourcing

Careful component selection can lead to cost savings:

- Use readily available, standard components when possible

- Consider alternative components with similar specifications but lower costs

- Leverage the assembly service provider's component sourcing capabilities

3. Optimize Production Volumes

Finding the right balance in production volume can lead to cost efficiencies:

- Consider grouping multiple small orders into a larger batch

- Evaluate the trade-offs between inventory costs and production run size

4. Choose the Right Assembly Partner

Selecting an appropriate PCB SMT assembly service provider is crucial:

- Compare quotes from multiple providers

- Consider the provider's expertise, equipment, and quality control processes

- Look for providers offering value-added services that align with your needs

Industry Trends Affecting PCB SMT Assembly Costs

Several trends in the electronics manufacturing industry are influencing the cost of PCB SMT assembly services:

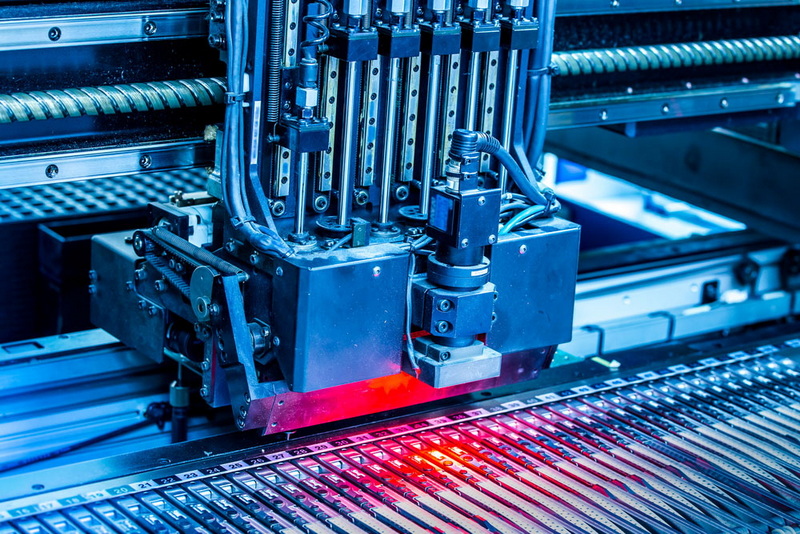

Automation and Industry 4.0

Increased automation in SMT assembly lines is leading to improved efficiency and potentially lower costs. Industry 4.0 technologies, such as IoT-enabled equipment and data analytics, are optimizing production processes and reducing errors.

Miniaturization

The trend towards smaller, more compact electronic devices is driving the need for more advanced SMT assembly techniques. While this can increase costs in the short term, it's also pushing innovation in assembly processes.

Sustainability Initiatives

Growing emphasis on sustainable manufacturing practices may impact assembly costs. While some eco-friendly materials or processes may be more expensive initially, they could lead to long-term cost savings and improved market positioning.

Conclusion

The cost of PCB SMT assembly services is influenced by a complex interplay of factors, including board complexity, component selection, production volume, and quality requirements. While prices can vary significantly based on these factors, understanding the cost structure and implementing cost-saving strategies can help optimize expenses without compromising quality.

As the electronics manufacturing industry continues to evolve, staying informed about the latest trends and technologies in PCB SMT assembly will be crucial for managing costs effectively. By carefully considering all aspects of the assembly process and choosing the right partners, businesses can ensure they receive high-quality PCB SMT assembly services at competitive prices.

FAQ

1. What is the average cost per square inch for PCB SMT assembly?

The typical cost of PCB SMT assembly ranges from $0.02 to $0.05 per square inch. However, this can vary based on factors such as design complexity, component selection, and production volume[10].

2. How does production volume affect PCB SMT assembly costs?

Production volume significantly impacts assembly costs. Larger volumes generally result in lower per-unit costs due to economies of scale. For example, a production run of 1-10 units might cost $50-$200 per unit, while a run of 10,000+ units could reduce costs to $2-$20 per unit[4].

3. What are the main components of PCB SMT assembly pricing?

The main components of PCB SMT assembly pricing include setup fees, assembly costs (per joint), material costs, labor costs, overhead costs, and testing/inspection fees. Setup fees can be around $8.00, while SMT assembly might cost about $0.0017 per joint[1][4].

4. How can I reduce the cost of PCB SMT assembly services?

To reduce costs, consider implementing Design for Manufacturability (DFM) principles, optimizing component selection and sourcing, finding the right production volume, and choosing an appropriate assembly partner. Additionally, planning for standard lead times rather than rush orders can help reduce expenses.

5. What future trends might affect PCB SMT assembly costs?

Future trends that may impact PCB SMT assembly costs include increased automation and Industry 4.0 technologies, ongoing miniaturization of electronic components, and growing emphasis on sustainable manufacturing practices. These trends could potentially lead to improved efficiency and long-term cost savings in PCB assembly processes.

Citations:

[1] https://jlcpcb.com/help/article/pcb-assembly-faqs

[2] https://www.pcbonline.com/blog/smt-manufacturing-process.html

[3] https://hackaday.io/project/184378-jlcpcb-smt-assembly-service-complete-guide

[4] https://www.pcbasic.com/blog/PCB_Assembly_Cost.html

[5] https://jhdpcb.com/pcb-assembly/smt-assembly/

[6] https://fliphtml5.com/ppflo/mvfu/Complete_and_Complementary_Range_of_PCB_Assembly_Services_and_Solutions/

[7] https://assemteceurope.com/en/orders/pricing

[8] https://www.pgftech.com/smt-assembly-process/

[9] https://hackaday.io/project/184378-jlcpcb-smt-assembly-service-complete-guide/details

[10] https://aaloktronix.com/how-much-does-it-cost-to-get-a-pcb-assembled-the-ultimate-guide/

[11] https://baike.baidu.com/item/%E7%94%B5%E5%AD%90%E7%BB%84%E8%A3%85%E6%8A%80%E6%9C%AF%E4%B8%93%E4%B8%9A%E8%8B%B1%E8%AF%AD/12086345