Content Menu

● Understanding SMT and SMD

● Components of an SMT Production Line

● Choosing the Right SMT Production Line

● Top Manufacturers of SMT Equipment

● Benefits of Investing in a Quality SMT Production Line

● Common Challenges in SMT Production

● Future Trends in SMT Technology

● Conclusion

● FAQ

>> 1. What is an SMD?

>> 2. How does an SMT production line work?

>> 3. What are the key components of an SMT line?

>> 4. Why is automation important in SMT?

>> 5. How can I determine the right equipment for my needs?

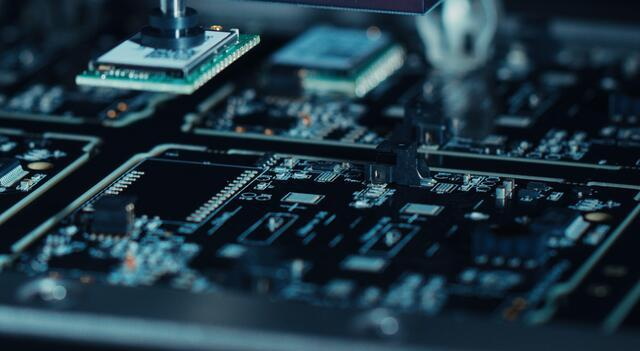

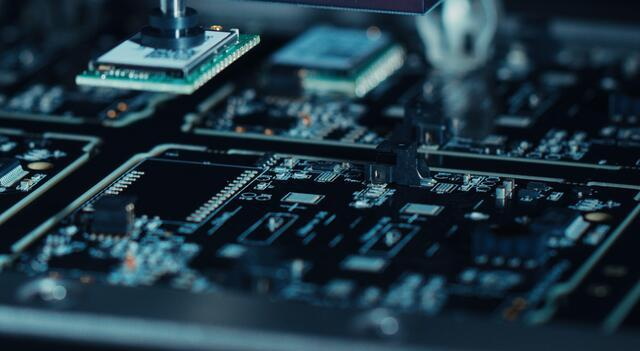

In the fast-paced world of electronics manufacturing, choosing the right Surface Mount Device (SMD) and Surface Mount Technology (SMT) production line is crucial for businesses looking to optimize their assembly processes. This article delves into the essential aspects of SMT production lines, including the types of equipment needed, how to choose the best setup for your business, and the benefits of investing in a quality SMT line.

Understanding SMT and SMD

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). This technology allows for smaller, lighter, and more efficient electronic devices. Surface Mount Devices (SMD) are components designed for this technology, which include resistors, capacitors, and integrated circuits.

The advantages of SMT over traditional through-hole technology include:

- Higher Component Density: SMT allows for more components to be placed on a PCB, leading to smaller device sizes.

- Improved Performance: SMT components have shorter lead lengths, which can enhance performance by reducing inductance and resistance.

- Automated Assembly: SMT processes can be automated, increasing production speed and reducing labor costs.

Components of an SMT Production Line

A complete SMT production line typically consists of several key components:

- Stencil Printer: Used for applying solder paste to the PCB before component placement. The printer ensures that the solder paste is applied accurately to the pads where components will be placed.

- Pick-and-Place Machine: This machine accurately places SMDs onto the soldered pads on the PCB. High-speed machines can place thousands of components per hour, significantly increasing production efficiency.

- Reflow Oven: Used for melting solder paste to create electrical connections between components and the PCB. The reflow oven uses controlled heating profiles to ensure proper soldering without damaging sensitive components.

- Inspection Systems: Automated Optical Inspection (AOI) machines check for placement errors and solder joint quality. These systems are crucial for maintaining high quality in production by identifying defects early in the process.

- Conveyor Systems: These systems transport PCBs between different stages of the assembly process. Efficient conveyor systems help streamline operations and minimize handling time.

Choosing the Right SMT Production Line

When selecting an SMT production line for your business, consider the following factors:

1. Production Volume: Assess your expected production volume. High-volume production may require faster pick-and-place machines and multiple reflow ovens. For lower volumes, a more compact system may suffice.

2. Component Types: Different machines are optimized for various component types. Ensure that your chosen equipment can handle all necessary SMDs. Consider whether you need to work with large components or very small ones, as this will influence your equipment choices.

3. Flexibility and Scalability: Choose a system that can adapt to changing product lines or increased production needs. Modular systems allow for easy upgrades and adjustments as your business grows.

4. Budget Considerations: Balance your budget with your production requirements. Investing in high-quality equipment may lead to lower operational costs in the long run. Analyze total cost of ownership rather than just initial purchase price.

5. Space Constraints: Evaluate your facility's layout to ensure that your chosen production line fits comfortably without hindering workflow. Proper space planning can enhance efficiency and safety within your manufacturing environment.

6. Technological Advancements: Stay informed about new technologies in SMT equipment that can improve efficiency or quality in your production line, such as advanced vision systems or AI-driven optimization tools.

Top Manufacturers of SMT Equipment

Several manufacturers are recognized as leaders in providing high-quality SMT equipment:

- ASM Assembly Systems: Known for their SIPLACE series of pick-and-place machines, offering flexibility and precision suitable for various applications.

- Yamaha Motor IM: Offers advanced high-speed chip shooters with innovative features for complex assemblies, including multi-function capabilities that enhance productivity.

- JUKI Automation Systems: Provides a comprehensive range of modular placement machines suitable for various production needs, known for their reliability and ease of use.

- Panasonic Factory Solutions: Renowned for their precision soldering robots and AOI inspection systems that ensure high-quality assembly processes.

- Mycronic: Specializes in modular lines that adapt easily to different production requirements while maintaining high throughput rates.

Benefits of Investing in a Quality SMT Production Line

Investing in a quality SMT production line offers numerous benefits:

- Increased Efficiency: Automated processes reduce cycle times and improve throughput. By minimizing manual intervention, you can achieve consistent quality and faster turnaround times.

- Cost Savings: Lower labor costs and reduced waste contribute to overall savings on production expenses. Efficient use of materials also minimizes scrap rates during manufacturing.

- Enhanced Quality Control: Advanced inspection systems minimize defects, ensuring high-quality products. Real-time monitoring allows for immediate corrections during the assembly process.

- Scalability: A well-designed SMT line can grow with your business, accommodating new products or increased demand without significant additional investment. This flexibility is essential in responding to market changes quickly.

Common Challenges in SMT Production

While investing in an SMT production line has many benefits, businesses may face challenges such as:

- Component Obsolescence: Rapid advancements in technology can lead to certain components becoming obsolete quickly. Staying updated with industry trends is vital to avoid disruptions in supply chains.

- Training Requirements: Employees must be trained adequately on new equipment and processes to maximize efficiency. Continuous training programs can help mitigate this challenge.

- Maintenance Needs: Regular maintenance is crucial to ensure optimal performance of all machinery involved in the SMT process. Establishing a maintenance schedule can prevent unexpected downtimes.

Future Trends in SMT Technology

As technology evolves, several trends are shaping the future of SMT manufacturing:

- Industry 4.0 Integration: The advent of smart factories involves integrating IoT devices into manufacturing processes, allowing real-time data analysis and improved decision-making capabilities.

- Advanced Robotics: The use of robotics is expanding beyond simple pick-and-place tasks; collaborative robots (cobots) are being employed alongside human workers to enhance productivity without compromising safety.

- Sustainability Practices: There is a growing emphasis on sustainable manufacturing practices within electronics assembly. Companies are looking at ways to reduce waste and energy consumption throughout their operations.

Conclusion

Choosing the best wholesale SMD SMT production line is a critical decision that can significantly impact your business's efficiency and profitability. By understanding your specific needs—such as production volume, component types, budget considerations, space constraints, and technological advancements—you can select an optimal setup that enhances productivity while maintaining high quality. As technology continues to evolve, staying informed about advancements in SMT equipment will also help you remain competitive in this dynamic industry.

FAQ

1. What is an SMD?

SMD stands for Surface Mount Device; it refers to electronic components designed to be mounted directly onto the surface of PCBs using surface mount technology (SMT).

2. How does an SMT production line work?

An SMT production line automates the process of assembling electronic components onto PCBs through several steps: applying solder paste, placing components, reflow soldering, and inspecting finished products.

3. What are the key components of an SMT line?

Key components include stencil printers, pick-and-place machines, reflow ovens, inspection systems (like AOI), and conveyor systems that facilitate movement through each assembly stage.

4. Why is automation important in SMT?

Automation improves efficiency by increasing speed and accuracy while reducing labor costs and minimizing human error during assembly processes.

5. How can I determine the right equipment for my needs?

Assess your production volume, types of components used, flexibility requirements, budget constraints, and available space to choose equipment that meets your specific manufacturing needs effectively.