Content Menu

● Understanding SMT Nozzles

>> Types of SMT Nozzles

● Key Factors in Selecting an SMT Nozzle

>> 1. Component Type and Size

>> 2. Nozzle Shape

>> 3. Material

>> 4. Precision Requirements

● Advantages of High-Precision SMT Nozzle Selection

● Applications of SMT Nozzles

● Maintenance of SMT Nozzles

● Innovations in SMT Nozzle Technology

>> 1. Smart Nozzle Technology

>> 2. Modular Nozzle Systems

>> 3. Advanced Coatings

● Challenges in SMT Soldering

>> 1. Component Variability

>> 2. Solder Paste Consistency

>> 3. Environmental Factors

● Conclusion

● FAQ

>> 1. What is an SMT nozzle?

>> 2. How do I choose the right size of SMT nozzle?

>> 3. What materials are commonly used for SMT nozzles?

>> 4. Why are wettable nozzles preferred for high precision?

>> 5. How often should I maintain my SMT nozzles?

● Citations:

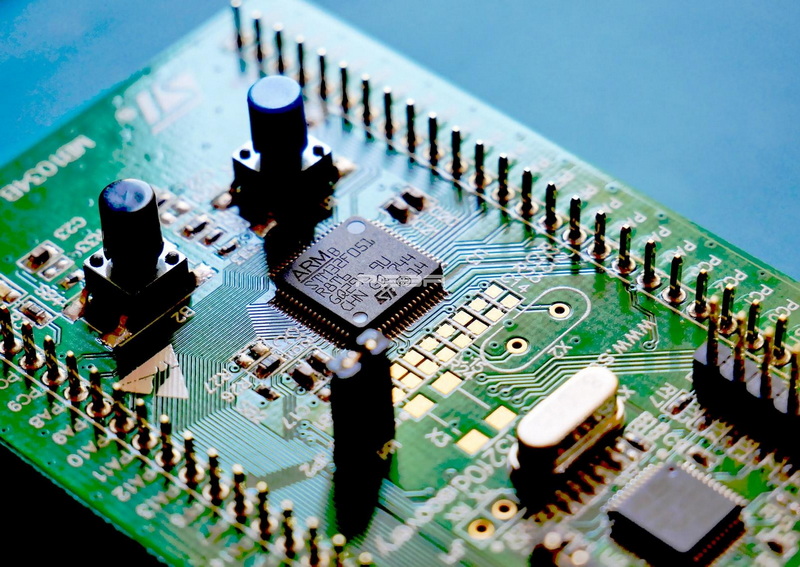

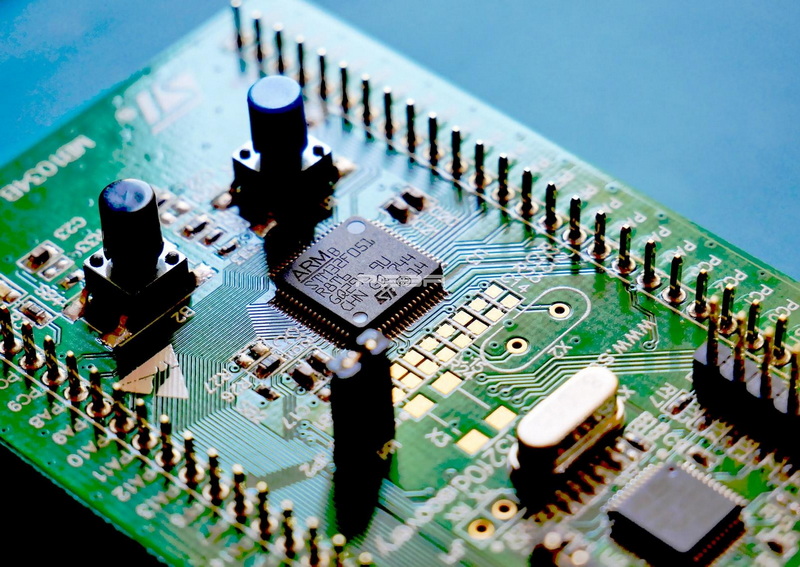

In the world of surface mount technology (SMT), the choice of nozzle is critical for achieving high precision in soldering applications. SMT nozzles play a vital role in the pick-and-place process, where components are accurately positioned on printed circuit boards (PCBs). This article explores the different types of SMT nozzles, their applications, and how to select the best nozzle for high-precision soldering.

Understanding SMT Nozzles

SMT nozzles are specialized tools used in automated soldering processes. They are designed to pick up and place SMT components onto PCBs with precision. The effectiveness of an SMT nozzle can significantly impact the quality of solder joints, making it essential to choose the right type based on specific requirements.

Types of SMT Nozzles

1. Standard Nozzles: These are the most common types used in pick-and-place machines. They come in various shapes and sizes, including round, square, and V-shaped openings.

2. Custom Nozzles: Custom-designed nozzles are tailored to specific components or applications. They can be created to accommodate unusual shapes or sizes that standard nozzles cannot handle.

3. Wettable Nozzles: These nozzles provide enhanced accuracy due to their design, which allows solder to flow evenly around the nozzle's surface. They are particularly effective for densely populated boards where components are in close proximity.

4. Jet Nozzles: Jet nozzles deliver a high volume of solder through a tapered tip, guiding solder roll-off in one direction. This design is beneficial for applications requiring fast and efficient soldering.

5. Vacuum Nozzles: Utilizing vacuum pressure, these nozzles securely hold components during transport and placement, ensuring minimal movement and maximum accuracy.

Key Factors in Selecting an SMT Nozzle

When selecting an SMT nozzle for high-precision soldering, several factors must be considered:

1. Component Type and Size

Different components require different nozzle specifications. For example:

- 0805 Components: Typically use CN065 nozzles.

- 0603 Components: Generally require CN040 nozzles.

Choosing the correct size ensures that the nozzle can securely grip the component without causing damage.

2. Nozzle Shape

The shape of the nozzle affects its ability to pick up and place components accurately. Common shapes include:

- Round Holes: Ideal for standard components.

- Square Holes: Better suited for flat or rectangular components.

- V-Shaped: Useful for components with edges or corners.

3. Material

The material of the nozzle influences its durability and performance:

- Plastic Nozzles: Suitable for sticky materials but have a shorter lifespan.

- Tungsten Steel Nozzles: Durable but may require maintenance as they can discolor over time.

- Ceramic Nozzles: Never discolor but are brittle and can break easily.

- Diamond Steel Nozzles: Extremely durable but more expensive.

4. Precision Requirements

For high-precision applications, wettable nozzles are often preferred due to their ability to minimize oxidation and provide better control over solder flow.

Advantages of High-Precision SMT Nozzle Selection

Selecting the right SMT nozzle can lead to numerous benefits:

- Improved Accuracy: High-quality nozzles ensure that components are placed accurately, reducing defects such as tombstoning or solder bridging.

- Enhanced Production Efficiency: The right nozzle can speed up the assembly process by allowing faster pick-and-place operations without compromising quality.

- Reduced Downtime: Using durable materials reduces wear and tear on equipment, leading to less frequent replacements and maintenance.

Applications of SMT Nozzles

SMT nozzles find applications across various industries due to their versatility:

- Consumer Electronics: In devices like smartphones and tablets, precise placement of tiny components is crucial for functionality.

- Automotive Industry: High-reliability components used in vehicles require accurate soldering to ensure safety and performance.

- Medical Devices: Components in medical instruments must be placed with extreme precision to meet stringent regulatory standards.

Maintenance of SMT Nozzles

Proper maintenance is crucial for ensuring that SMT nozzles perform optimally over time. Here are some best practices:

- Regularly clean nozzles to prevent clogging from solder residue.

- Inspect for wear and replace damaged or worn-out nozzles promptly.

- Store nozzles properly to avoid physical damage when not in use.

Innovations in SMT Nozzle Technology

The field of SMT nozzle technology continues to evolve with advancements aimed at improving efficiency and precision:

1. Smart Nozzle Technology

Emerging technologies have introduced smart nozzles equipped with sensors that monitor performance in real-time. These sensors can detect issues such as clogs or misalignment, allowing for immediate corrective actions.

2. Modular Nozzle Systems

Modular systems allow manufacturers to quickly change out nozzles based on production needs without requiring extensive downtime or recalibration of machines. This flexibility enhances productivity on assembly lines where various component sizes are used.

3. Advanced Coatings

Innovative coatings applied to nozzle surfaces can reduce friction and enhance solder release properties, leading to improved performance during high-speed operations.

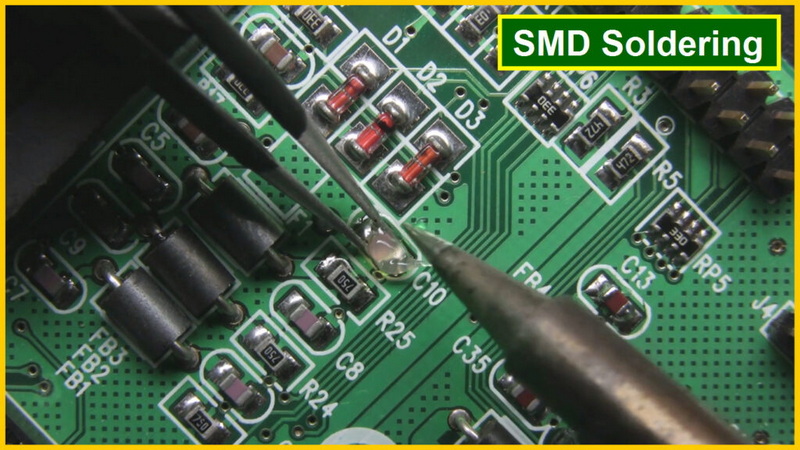

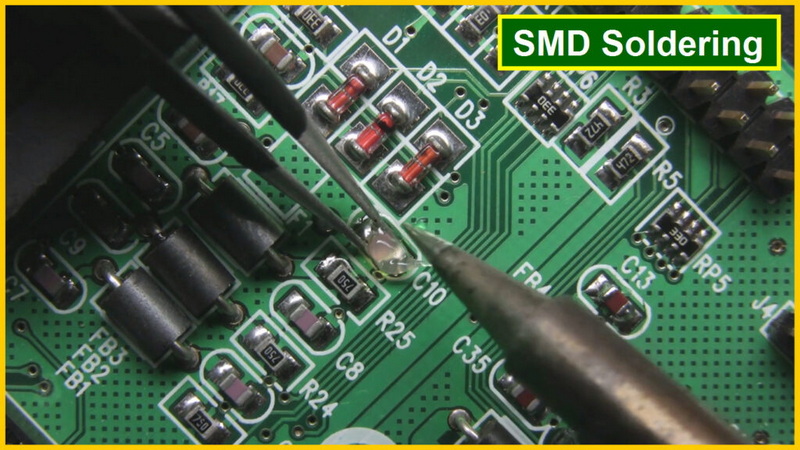

Challenges in SMT Soldering

While selecting the right nozzle is vital, several challenges may still arise during the soldering process:

1. Component Variability

Variations in component size and shape can lead to difficulties in achieving consistent placement accuracy. Using adjustable or custom nozzles can help mitigate this issue.

2. Solder Paste Consistency

The viscosity and composition of solder paste can affect how well it flows through the nozzle during application. Ensuring that paste consistency is maintained is critical for achieving reliable joints.

3. Environmental Factors

Humidity and temperature fluctuations can impact soldering quality by affecting both component properties and solder paste behavior. Maintaining stable environmental conditions is essential for optimal results.

Conclusion

Choosing the best SMT nozzle for high-precision soldering is essential for achieving optimal performance in electronic manufacturing processes. By considering factors such as component type, nozzle shape, material, and precision requirements, manufacturers can enhance their production efficiency while minimizing defects. Regular maintenance further ensures that these critical tools remain effective throughout their operational life. As technology advances, innovations such as smart nozzles and modular systems will continue to shape the future of SMT processes, driving improvements in both speed and accuracy.

FAQ

1. What is an SMT nozzle?

An SMT nozzle is a specialized tool used in surface mount technology to pick up and place electronic components onto printed circuit boards with precision.

2. How do I choose the right size of SMT nozzle?

The right size of SMT nozzle depends on the dimensions of the component being placed. Standard sizes correspond to specific component types (e.g., CN065 for 0805 components).

3. What materials are commonly used for SMT nozzles?

Common materials include plastic (for sticky surfaces), tungsten steel (for durability), ceramic (for non-discoloration), and diamond steel (for extreme durability).

4. Why are wettable nozzles preferred for high precision?

Wettable nozzles provide better control over solder flow and minimize oxidation during the soldering process, making them ideal for densely populated boards.

5. How often should I maintain my SMT nozzles?

Regular maintenance should be performed based on usage frequency; however, a good practice is to inspect and clean them after every production run to ensure optimal performance.

Citations:

[1] https://www.ddmnovastar.com/smt-selecting-a-selective-soldering-system

[2] https://www.rchelicopterfun.com/t12-soldering-station.html

[3] https://www.swtechnology.com.sg/product/smt-nozzle-all-smt-machine-model-copy-nozzle-quality/

[4] https://iconnect007.com/index.php/article/52613/smt-preventive-maintenance-stop-5-major-problems-with-pick-and-place-nozzles/52616

[5] https://www.viasion.com/blog/smt-assembly-explained-an-introductory-guide-for-beginners/

[6] https://rework.co.uk/blog/in-depth-guide-to-surface-mount-technology/

[7] https://www.itechsmt.com/products/itech-high-quality-smt-nozzle-for-pick-and-place-machine

[8] https://www.tomshardware.com/best-picks/best-soldering-irons

[9] https://www.tronstol.com/selection-and-function-of-pick-and-place-nozzle.html

[10] https://www.neodensmt.com/news/do-you-know-the-function-and-choice-for-smt-no-39242403.html