Content Menu

● Understanding SMT and Its Importance

● Key Elements of an Efficient SMT Line Layout

>> 1. Flow of Materials

>> 2. Machine Placement

>> 3. Ergonomics

>> 4. Standardization of Procedures

>> 5. Technology Integration

● Optimizing PCB Design for SMT Assembly

>> 1. Component Placement

>> 2. Orientation Consistency

>> 3. Single-Sided Components

>> 4. Spacing Guidelines

● Common Challenges in SMT Line Layout

● Continuous Improvement Strategies

● Advanced Techniques for Efficiency

>> 1. Investing in Automation

>> 2. Implementing Lean Manufacturing Practices

>> 3. Regular Training Programs

>> 4. Data Analytics for Process Monitoring

● Quality Control Measures

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How does component placement affect SMT efficiency?

>> 3. What role does inspection play in an SMT line?

>> 4. Why is ergonomics important in an SMT line?

>> 5. What are some common challenges faced in SMT assembly?

● Citations:

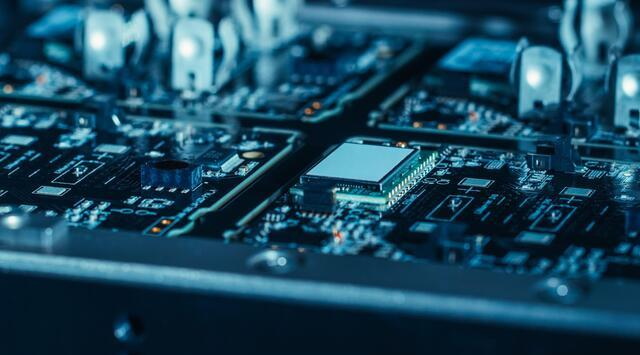

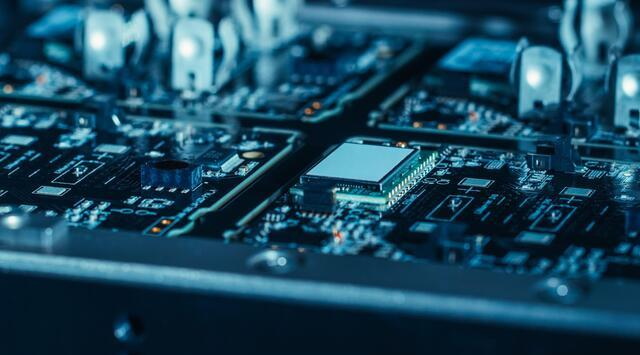

In the rapidly evolving world of electronics manufacturing, optimizing the layout of Surface Mount Technology (SMT) lines is crucial for achieving maximum efficiency in Printed Circuit Board Assembly (PCBA). This article explores the best practices for designing an efficient SMT line layout, focusing on various elements that contribute to enhanced productivity, reduced costs, and improved quality.

Understanding SMT and Its Importance

Surface Mount Technology (SMT) involves placing electronic components directly onto the surface of a printed circuit board (PCB). This method has revolutionized PCB assembly due to its ability to accommodate smaller components, increase component density, and enhance manufacturing efficiency. The SMT process typically includes several stages:

- Solder Paste Printing: Applying solder paste onto PCB pads.

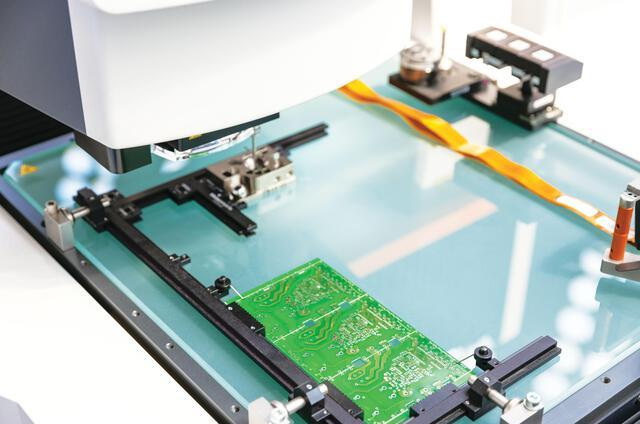

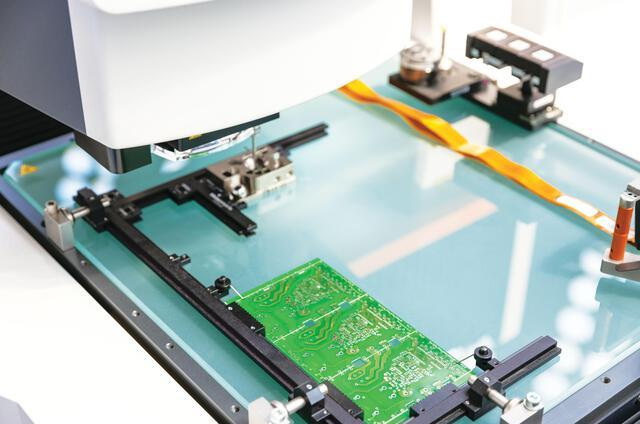

- Component Placement: Using pick-and-place machines to position components accurately.

- Reflow Soldering: Melting solder to create electrical connections.

- Inspection: Ensuring that components are placed correctly and that solder joints are reliable.

Key Elements of an Efficient SMT Line Layout

To maximize efficiency in an SMT line, several factors must be considered:

1. Flow of Materials

The layout should facilitate a smooth flow of materials from one stage to another. This involves arranging equipment in a linear fashion, minimizing backtracking and unnecessary movement. A well-organized flow reduces cycle times and enhances overall productivity.

2. Machine Placement

Strategically placing machines is vital for minimizing handling time and ensuring quick transitions between processes. Key considerations include:

- Proximity: Place machines that interact closely next to each other (e.g., solder paste printer next to the pick-and-place machine).

- Accessibility: Ensure that operators can easily access machines for maintenance and troubleshooting.

3. Ergonomics

Operator comfort is essential for maintaining high productivity levels. Workstations should be designed with ergonomics in mind, reducing strain and enhancing efficiency. Features such as adjustable heights and proper lighting can significantly improve operator performance.

4. Standardization of Procedures

Implementing standardized operating procedures (SOPs) ensures consistency across the production line. This includes:

- Detailed Work Instructions: Providing clear guidelines for each stage of the process.

- Quality Checkpoints: Establishing quality control measures at various stages to catch defects early.

5. Technology Integration

Embracing advanced technologies can further optimize SMT line efficiency:

- Automated Optical Inspection (AOI): Utilizing AOI systems for real-time inspection helps identify defects quickly, reducing rework costs.

- Predictive Maintenance: Implementing machine learning algorithms can predict equipment failures before they occur, minimizing downtime.

Optimizing PCB Design for SMT Assembly

An efficient SMT line starts with effective PCB design. Here are some best practices:

1. Component Placement

Proper component placement minimizes routing complexity and improves signal integrity by reducing trace lengths between related components. Grouping similar components together reduces the need for complex routing and enhances signal integrity.

2. Orientation Consistency

Keeping all components oriented in the same direction simplifies the pick-and-place process and reduces errors during assembly. A good rule of thumb is to orient similar components in the same direction, ensuring a more efficient soldering process.

3. Single-Sided Components

Where possible, design PCBs with components on one side only. This simplifies assembly and increases yield by reducing potential misalignment issues during placement.

4. Spacing Guidelines

Maintaining adequate spacing between components is critical to avoid solder bridging and ensure proper solder paste application. Recommended spacing includes:

- At least 40 mils between homogeneous components.

- At least 100 mils between each component and the edge of the PCB[1][4].

Common Challenges in SMT Line Layout

Despite best efforts, challenges may arise that can hinder efficiency:

- Bottlenecks: Identifying stages where delays occur is crucial for optimizing flow.

- Defects: Regular inspection and maintenance are necessary to prevent defects from impacting production quality.

Continuous Improvement Strategies

To maintain an efficient SMT line layout over time, manufacturers should adopt continuous improvement strategies:

- Lean Manufacturing Principles: Implementing lean practices helps identify wasteful activities and streamline processes.

- Feedback Loops: Regularly soliciting feedback from operators can provide insights into potential improvements in layout and processes.

Advanced Techniques for Efficiency

To further enhance the efficiency of your SMT line, consider implementing these advanced techniques:

1. Investing in Automation

Automation plays a pivotal role in improving efficiency within SMT lines. Automated systems such as high-speed pick-and-place machines can place thousands of components per hour, significantly reducing assembly time while ensuring consistent accuracy[9][10]. Robotic soldering ensures uniform application of solder to each joint, maintaining consistent quality across batches[9].

2. Implementing Lean Manufacturing Practices

Lean principles focus on eliminating waste throughout the production process. Techniques such as Kanban systems help manage inventory effectively while visual management tools ensure that workstations remain organized and efficient[10].

3. Regular Training Programs

Continuous training for operators enhances their skills in equipment operation, troubleshooting, and maintenance, contributing to smoother production flows and reduced error rates[10].

4. Data Analytics for Process Monitoring

Utilizing data analytics allows manufacturers to monitor production processes in real-time, identifying bottlenecks or inefficiencies quickly[6]. This proactive approach enables timely interventions that can enhance overall productivity.

Quality Control Measures

Quality control is integral to maintaining high standards throughout the SMT assembly process:

- Implement Automated Optical Inspection (AOI) systems that utilize high-resolution cameras to inspect PCBs for defects swiftly[9].

- Establish regular quality checkpoints within the production line to ensure adherence to standards at every stage.

Conclusion

An efficient SMT line layout is essential for maximizing productivity in PCB assembly. By focusing on material flow, machine placement, ergonomics, standardization, technology integration, and effective PCB design, manufacturers can significantly enhance their production capabilities while minimizing costs and defects. Continuous improvement strategies will ensure that these efficiencies are maintained over time, adapting to changes in technology and market demands.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used in electronics manufacturing where components are mounted directly onto the surface of a printed circuit board (PCB), allowing for higher component density and reduced manufacturing costs compared to traditional through-hole technology.

2. How does component placement affect SMT efficiency?

Proper component placement minimizes routing complexity and improves signal integrity by reducing trace lengths between related components. It also facilitates faster assembly processes by grouping similar components together.

3. What role does inspection play in an SMT line?

Inspection is critical in an SMT line as it ensures that components are placed correctly and that solder joints are reliable. Automated Optical Inspection (AOI) systems help identify defects early in the process, reducing rework costs.

4. Why is ergonomics important in an SMT line?

Ergonomics enhances operator comfort and efficiency by reducing physical strain during repetitive tasks. A well-designed workstation can lead to higher productivity levels and lower error rates.

5. What are some common challenges faced in SMT assembly?

Common challenges include bottlenecks in production flow, defects due to misalignment or insufficient solder joints, and maintaining consistent quality throughout the assembly process.

Citations:

[1] https://www.proto-electronics.com/blog/best-rules-for-pcb-components-placement

[2] https://www.smtfactory.com/Perfecting-Your-SMT-Line-Layout-for-Efficiency-id47017676.html

[3] https://pcbtrace.com/techniques-to-streamline-and-optimize-pcb-assembly/

[4] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[5] https://www.smtfactory.com/Optimizing-Efficiency-Strategies-for-A-Smooth-SMT-Line-Production-Process-id47463586.html

[6] https://www.pcbx.com/article/How-to-Increase-Efficiency-in-PCB-Assembly-Manufacturing

[7] https://wellerpcb.com/pcb-layout-guidelines-for-smt-assembly-process-limits

[8] https://jhdpcb.com/blog/efficient-smt-assembly/

[9] https://profabelectronics.com/posts/how-automated-pcb-assembly-improves-efficiency/

[10] https://www.mtek.co.uk/streamlining-pcb-assembling-processes-enhancing-efficiency-and-quality

[11] https://resources.altium.com/p/pcb-layout-guidelines

[12] https://www.mtsc-solution.com/blog/116-optimizing-efficiency-the-full-smt-line-in-shaping-your-future

[13] https://www.pcbelec.com/10-tips-to-improve-pcb-design-for-manufacturability.html

[14] https://forum.kicad.info/t/pcb-layout-strategy/51620

[15] https://www.linkedin.com/pulse/rapid-smt-assembly-improving-efficiency-surface-oerzc

[16] https://kicthermal.com/article-paper/maximizing-efficiency-in-pcb-assembly/

[17] https://www.protoexpress.com/blog/tips-pcb-design-for-assembly/

[18] https://www.andwinpcb.com/optimizing-pcb-and-assembly-processes-for-enhanced-efficiency/

[19] https://www.911eda.com/news/importance-planning-ahead-pcb-assembly/

[20] https://www.raypcb.com/line-efficiency/

[21] https://resources.pcb.cadence.com/blog/2020-how-to-optimize-pcb-design-for-smt-assembly-process-flow