Content Menu

● Introduction to SMT Stencils

>> Key Functions of SMT Stencils

>> Types of SMT Stencils

● Benefits of Using SMT Stencils

● Cheap SMT Stencil Options for Small-Batch Production

>> Mylar SMT Stencils

>> Polyimide SMT Stencils

● Comparison of Cheap SMT Stencil Options

● Choosing the Best Cheap SMT Stencil

● SMT Stencil Materials and Their Properties

>> Stainless Steel

>> Nickel

>> Copper

● SMT Stencil Thickness and Its Impact

● Customization and Design Considerations

● Potential Defects in SMT Stencil Printing

● Conclusion

● FAQs

>> 1. What is the primary function of an SMT stencil?

>> 2. What materials are commonly used for cheap SMT stencils?

>> 3. How do I choose the best cheap SMT stencil for my needs?

>> 4. What are the benefits of using SMT stencils in PCB assembly?

>> 5. Can I use a cheap SMT stencil for high-volume production?

● Citations:

In the realm of electronics manufacturing, Surface Mount Technology (SMT) has become the norm due to its efficiency and cost-effectiveness. A crucial component in this process is the SMT stencil, which ensures precise solder paste application onto printed circuit boards (PCBs). For small-batch production, finding a cheap SMT stencil that balances cost with performance is essential. This article delves into the world of affordable SMT stencils, exploring their types, benefits, and applications, with a focus on cheap SMT stencil options suitable for small-scale manufacturing.

Introduction to SMT Stencils

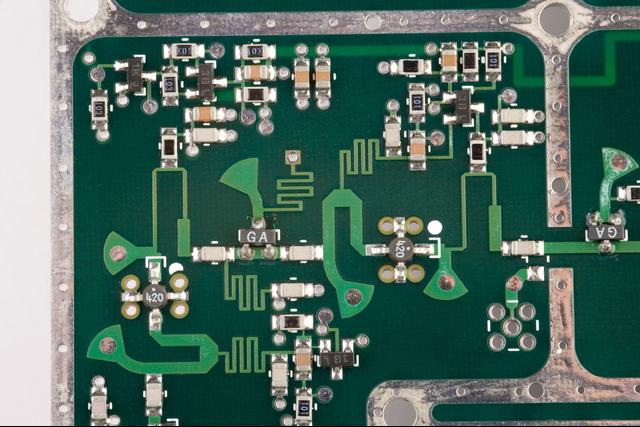

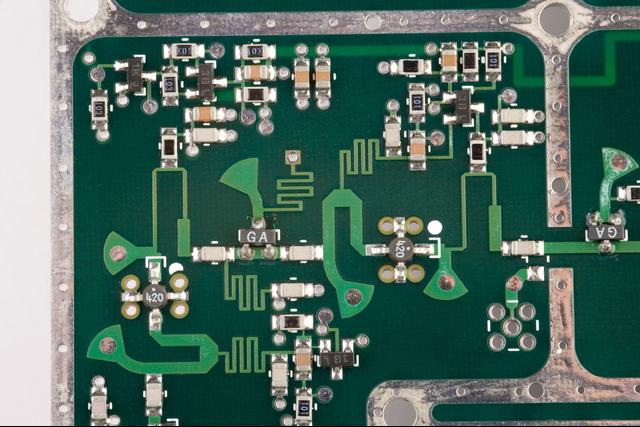

SMT stencils are thin sheets with laser-cut openings that match the component pads on a PCB. They are used to apply solder paste precisely before component placement. The stencil's thickness determines the solder paste volume, ensuring consistent and reliable solder connections. SMT stencils are indispensable for both prototype development and large-scale production due to their ability to streamline the solder paste application process, reduce errors, and enhance product quality.

Key Functions of SMT Stencils

1. Solder Paste Deposition: SMT stencils enable the precise application of solder paste onto PCB pads, ensuring the right amount of solder is used for each component.

2. Consistency: Stencils help maintain consistency in solder paste volume and shape across multiple PCBs, reducing the risk of defects and improving overall product quality.

3. Efficiency: By using SMT stencils, the solder paste application process is automated, saving time and increasing production efficiency compared to manual methods[1].

Types of SMT Stencils

1. Laser-Cut Stencils: These are made from materials like stainless steel or copper and are ideal for prototyping and small production runs. Laser-cut stencils offer high precision and can handle complex designs, making them suitable for fine-pitch applications. However, they are generally more expensive than other types due to the precision cutting process[2].

2. Electroformed Stencils: Made from nickel, these stencils are electroformed onto a mandrel. They offer smooth aperture walls for improved paste release and are suitable for ultra-fine pitch applications. Electroformed stencils are more durable and have a longer lifespan compared to stainless steel stencils[1].

3. Framed vs. Frameless Stencils: Framed stencils are mounted on a frame, providing stability and reusability, making them ideal for high-volume production. Frameless stencils are more economical and suitable for small batches or prototype development[2].

Benefits of Using SMT Stencils

- Precision and Consistency: SMT stencils ensure precise solder paste deposition, reducing defects like bridging or tombstoning.

- Efficiency: They significantly increase the efficiency of the solder paste application process, allowing for simultaneous application to multiple pads.

- Cost-Effectiveness: SMT stencils are reusable, making them cost-effective for both prototype assembly and large-scale production.

- Enhanced Quality: By eliminating manual solder paste application errors, SMT stencils improve the overall quality of PCB assemblies.

Cheap SMT Stencil Options for Small-Batch Production

For small-batch production, cheap SMT stencils made from materials like Mylar or polyimide are attractive options. These stencils are less expensive than stainless steel or nickel stencils but still offer good performance for low-volume manufacturing.

Mylar SMT Stencils

Mylar stencils are made from thin plastic sheets (typically 3-mil or 4-mil) and are cut using a low-power CO2 laser. They are an economical alternative to metal stencils and are suitable for prototyping and low-volume runs. Mylar stencils are frameless and do not include a squeegee or solder paste. The cost starts at around $25 for up to 4 square inches of apertures.

Polyimide SMT Stencils

Polyimide stencils, such as StencilQuik™, are flexible and come with a high-temperature adhesive covered by a release liner. They serve as both a stencil and an alignment device, making them ideal for manual printing of solder paste onto PCBs. These stencils are designed to work with stencil tensioning systems and are suitable for prototyping and low-volume production.

Comparison of Cheap SMT Stencil Options

| Stencil Type | Material | Cost | Suitability |

| Mylar Stencil | Mylar | $25+ | Prototyping, Low-Volume |

| Polyimide Stencil | Polyimide | Varies | Prototyping, Low-Volume |

| Stainless Steel | Stainless Steel | Higher | High-Volume Production |

Choosing the Best Cheap SMT Stencil

When selecting a cheap SMT stencil for small-batch production, consider the following factors:

- Material: Mylar or polyimide stencils are more affordable than stainless steel but may lack durability.

- Precision: Ensure the stencil can handle the pitch of your components.

- Ease of Use: Frameless stencils are simpler to manage for small batches.

- Cost: Balance cost with performance needs.

SMT Stencil Materials and Their Properties

Stainless Steel

Stainless steel is the most common material used for SMT stencils. It offers several advantages:

- Durability and Long Lifespan: Stainless steel stencils are highly durable and can withstand repeated use without significant wear.

- Compatibility: They are compatible with most solder pastes and cleaning agents, making them versatile in various manufacturing environments.

- Dimensional Stability: Stainless steel maintains its shape well, ensuring consistent solder paste application over time[1].

Nickel

Nickel stencils, particularly electroformed nickel stencils, are gaining popularity due to their unique properties:

- Smooth Aperture Walls: Nickel stencils have smooth walls, which improve solder paste release and reduce defects.

- High Durability: They are more resistant to wear than stainless steel stencils, making them suitable for high-volume production.

- Ultra-Fine Pitch Applications: Nickel stencils are ideal for components with very small pitches, such as BGAs and uBGAs[1].

Copper

Copper stencils offer better electrical conductivity, which can enhance production efficiency. However, they are less common due to higher costs and lower durability compared to stainless steel[2].

SMT Stencil Thickness and Its Impact

The thickness of an SMT stencil is crucial as it determines the amount of solder paste applied to the PCB pads. Thicker stencils result in more solder paste being deposited, while thinner stencils are used for fine-pitch components where less solder is required. Common thicknesses range from 0.004 inches to 0.007 inches, with the choice depending on the specific PCB design and component density[2].

Customization and Design Considerations

SMT stencils can be highly customized to accommodate various PCB designs, including single- or multi-layered boards and complex components like BGAs and QFNs. When designing a stencil, it's essential to consider the pad size and spacing on the PCB. For components requiring more solder paste, the pad opening on the stencil can be increased by 10% to 20%. Conversely, for fine-pitch components, the opening may need to be reduced to prevent excessive solder paste application[2][3].

Potential Defects in SMT Stencil Printing

Despite the benefits of SMT stencils, several defects can occur during the printing process:

- Misaligned Prints: This happens when the stencil is not properly aligned with the PCB, leading to solder paste being applied to incorrect locations.

- Erroneous Printing: Incorrect squeegee pressure or speed can result in uneven or incomplete paste deposits.

- Fiducial Misalignment: Misalignment between the fiducials on the PCB and the stencil can cause inaccurate paste placement[3].

Conclusion

In conclusion, for small-batch production, cheap SMT stencils made from Mylar or polyimide offer a cost-effective solution without compromising on performance. These stencils are ideal for prototyping and low-volume manufacturing, providing precision and efficiency in solder paste application. While they may not match the durability of stainless steel stencils, they are well-suited for small-scale electronics manufacturing needs.

FAQs

1. What is the primary function of an SMT stencil?

An SMT stencil is used to apply solder paste precisely onto the pads of a PCB, ensuring consistent and reliable solder connections during component placement.

2. What materials are commonly used for cheap SMT stencils?

Common materials for cheap SMT stencils include Mylar and polyimide. These materials are less expensive than stainless steel or nickel but still provide good performance for low-volume manufacturing.

3. How do I choose the best cheap SMT stencil for my needs?

When choosing a cheap SMT stencil, consider factors such as material, precision, ease of use, and cost. Ensure the stencil can handle the pitch of your components and is suitable for your production volume.

4. What are the benefits of using SMT stencils in PCB assembly?

SMT stencils offer several benefits, including precise solder paste deposition, increased efficiency, cost-effectiveness, and enhanced product quality. They reduce errors and improve the overall assembly process.

5. Can I use a cheap SMT stencil for high-volume production?

While cheap SMT stencils are suitable for small-batch production, they may not be ideal for high-volume manufacturing due to durability concerns. Stainless steel stencils are generally preferred for large-scale production due to their durability and reusability.

Citations:

[1] https://rigidflexpcb.org/comprehensive-guide-to-smt-stencils/

[2] https://jlcpcb.com/blog/how-to-choose-a-smt-stencil

[3] https://www.applepcb.com/smt-stencil

[4] https://www.thomasnet.com/suppliers/usa/smt-stencils-80451305

[5] https://www.venture-mfg.com/what-is-a-pcb-stencil/

[6] https://www.stencilsunlimited.com/t/smt-stencils

[7] https://www.pololu.com/product/446

[8] https://forum.kicad.info/t/cheap-stencils-where-to-get/5630