Content Menu

● Understanding SMT Assembly Basics

>> The SMT Assembly Process

● Factors Influencing SMT Assembly Costs

>> Board Complexity and Size

>> Component Selection

>> Production Volume

>> Assembly Technology

>> Turnaround Time

● Breaking Down the Average Cost

>> Cost Per Component

>> Cost Per Square Inch

>> Setup and Non-Recurring Engineering (NRE) Costs

● Regional Cost Variations

>> US-Based Assembly

>> Offshore Assembly

● Cost Optimization Strategies

>> Design for Manufacturability (DFM)

>> Component Selection and Standardization

>> Volume Planning

>> Balancing Automation and Manual Assembly

● The Impact of Technology Advancements on Costs

>> Increased Automation

>> Miniaturization

>> Industry 4.0 and Smart Manufacturing

● Quality Considerations in PCB SMT Assembly

>> Inspection and Testing

>> Certifications and Standards

>> Rework and Repair Capabilities

● Environmental and Regulatory Factors

>> RoHS Compliance

>> Environmental Certifications

● Future Trends in PCB SMT Assembly Costs

>> Artificial Intelligence and Machine Learning

>> Additive Manufacturing

>> Sustainability Initiatives

● Conclusion

● FAQ

>> 1. How does production volume affect PCB SMT assembly costs?

>> 2. What role does component selection play in SMT assembly pricing?

>> 3. How do regional differences impact PCB SMT assembly costs?

>> 4. What are the cost implications of different SMT assembly technologies?

>> 5. How do quality assurance measures affect SMT assembly costs?

● Citations:

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, offering significant advantages in terms of miniaturization, efficiency, and cost-effectiveness. As businesses and individuals seek to understand the financial implications of PCB SMT assembly, it's crucial to delve into the factors that influence the average cost and explore the nuances of pcb smt quotes. This comprehensive analysis will provide insights into the various aspects of SMT assembly costs, helping you make informed decisions for your electronics projects.

Understanding SMT Assembly Basics

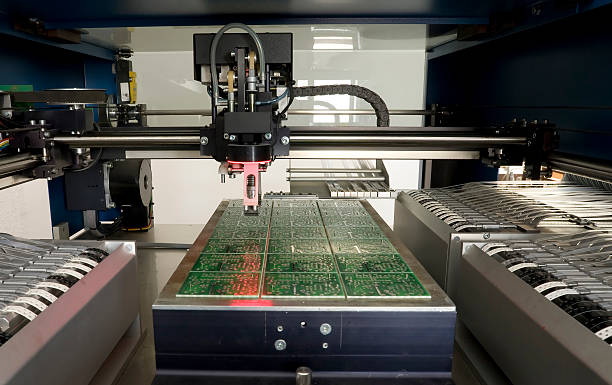

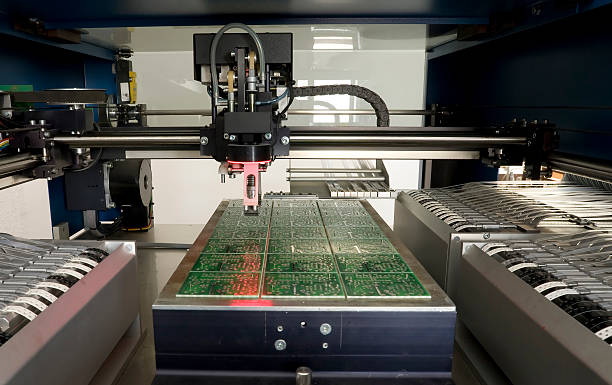

Before we dive into the cost analysis, it's essential to understand what SMT assembly entails. Surface Mount Technology involves placing and soldering electronic components directly onto the surface of a printed circuit board (PCB). This method contrasts with through-hole technology, where component leads are inserted through holes in the board[1].

The SMT Assembly Process

The SMT assembly process typically includes the following steps:

1. Solder paste application

2. Component placement

3. Reflow soldering

4. Inspection and quality control

Each of these steps contributes to the overall cost of SMT assembly, and understanding them is crucial when evaluating pcb smt quotes[2].

Factors Influencing SMT Assembly Costs

Several factors play a role in determining the cost of PCB SMT assembly. Let's explore these in detail to gain a comprehensive understanding of what influences pcb smt quotes.

Board Complexity and Size

The complexity and size of the PCB are significant cost determinants. More complex boards with multiple layers and higher component density require more sophisticated assembly techniques and equipment, which can increase costs. Similarly, larger boards generally cost more to assemble due to increased material and handling requirements[3].

Component Selection

The type and quantity of components used in a PCB design directly impact the assembly cost. Surface mount devices (SMDs) come in various sizes and types, each with its own cost implications. For instance, ball grid array (BGA) components are typically more expensive to place and require specialized equipment for inspection[4].

Production Volume

Production volume plays a crucial role in determining the average cost per unit. Generally, higher volumes lead to lower per-unit costs due to economies of scale. When requesting pcb smt quotes, it's important to specify your production volume as it significantly influences pricing[1].

Assembly Technology

The choice between automated and manual assembly processes affects costs. While automated assembly is more efficient for large-scale production, it requires significant upfront investment in equipment. Manual assembly might be more cost-effective for small batches or prototypes but becomes less economical as volume increases[2].

Turnaround Time

Faster turnaround times often come at a premium. If you need your PCBs assembled quickly, you may incur additional costs for expedited service. This is an important consideration when evaluating pcb smt quotes[4].

Breaking Down the Average Cost

While the average cost of PCB SMT assembly can vary widely depending on the factors mentioned above, it's helpful to have a general understanding of cost ranges. Based on industry data and pcb smt quotes, we can provide some ballpark figures.

Cost Per Component

On average, the assembly cost per SMT component ranges from $0.02 to $0.05. However, this can vary based on the complexity of the component and the assembly process required[4].

Cost Per Square Inch

Another metric used in pcb smt quotes is the cost per square inch of the PCB. This typically falls between $0.02 and $0.05 per square inch, but can be higher for more complex boards or lower for large-volume orders[4].

Setup and Non-Recurring Engineering (NRE) Costs

When evaluating pcb smt quotes, it's important to consider one-time costs such as setup fees and NRE charges. These can range from $200 to $500 or more, depending on the complexity of the project and the assembly house[7].

Regional Cost Variations

The location of the assembly service can significantly impact costs. While many companies offer services with a US presence, assembly may actually occur in various global locations, affecting pricing.

US-Based Assembly

Assembly in the United States generally comes at a premium due to higher labor costs. However, it may offer advantages in terms of quality control, intellectual property protection, and faster turnaround times[7].

Offshore Assembly

Countries like China often offer lower assembly costs. Some estimates suggest that assembly in China can be priced at around $0.00333 per pad or termination for SMD components. However, this comes with considerations such as longer lead times and potential communication challenges[7].

Cost Optimization Strategies

To get the most value from your pcb smt quotes, consider implementing these cost optimization strategies:

Design for Manufacturability (DFM)

Optimizing your PCB design for manufacturability can significantly reduce assembly costs. This includes considerations such as component placement, trace routing, and pad design[3].

Component Selection and Standardization

Choosing readily available, standard components can help reduce costs. Additionally, standardizing components across different projects can lead to volume discounts[4].

Volume Planning

Planning for higher production volumes, even if spread out over time, can help secure better pricing in pcb smt quotes. Many assembly houses offer price breaks at certain volume thresholds[1].

Balancing Automation and Manual Assembly

For some projects, a hybrid approach using both automated and manual assembly techniques can optimize costs while maintaining quality[2].

The Impact of Technology Advancements on Costs

As SMT technology continues to evolve, it's impacting assembly costs in various ways:

Increased Automation

Advancements in pick-and-place machines and other automated assembly equipment are improving efficiency and reducing labor costs, particularly for high-volume production[2].

Miniaturization

The trend towards smaller components and denser PCB designs is driving changes in assembly techniques and equipment, which can affect costs[1].

Industry 4.0 and Smart Manufacturing

The integration of data analytics, IoT, and AI in the manufacturing process is improving efficiency and yield rates, potentially leading to cost reductions in the long term[2].

Quality Considerations in PCB SMT Assembly

While cost is a crucial factor, it's essential to balance it with quality considerations when evaluating pcb smt quotes:

Inspection and Testing

Rigorous inspection and testing processes, while adding to the overall cost, are crucial for ensuring the reliability and functionality of the assembled PCBs[2].

Certifications and Standards

Assembly houses with industry certifications (e.g., ISO 9001, IPC standards) may charge higher rates but offer assurances of quality and consistency[4].

Rework and Repair Capabilities

Consider the assembly house's capabilities for rework and repair, as these can impact the overall cost and quality of the final product[7].

Environmental and Regulatory Factors

Environmental regulations and compliance requirements can influence SMT assembly costs:

RoHS Compliance

The need for lead-free soldering to comply with RoHS (Restriction of Hazardous Substances) regulations can impact material costs and process requirements[1].

Environmental Certifications

Assembly houses with environmental certifications may have higher operating costs, which can be reflected in their pcb smt quotes[4].

Future Trends in PCB SMT Assembly Costs

Looking ahead, several trends are likely to influence the cost landscape of PCB SMT assembly:

Artificial Intelligence and Machine Learning

The integration of AI and ML in assembly processes is expected to improve efficiency and reduce costs over time[2].

Additive Manufacturing

Advancements in 3D printing technology may impact certain aspects of PCB manufacturing and assembly, potentially offering cost savings for specific applications[3].

Sustainability Initiatives

Increasing focus on sustainable manufacturing practices may introduce new costs but could also lead to long-term savings through improved efficiency and waste reduction[4].

Conclusion

The average cost of PCB SMT assembly is a complex interplay of various factors, including board complexity, component selection, production volume, and geographic location. While general estimates can provide a starting point, obtaining detailed pcb smt quotes from reputable assembly houses is crucial for accurate budgeting.

As technology continues to advance and market demands evolve, the landscape of SMT assembly costs is likely to change. Staying informed about industry trends, optimizing designs for manufacturability, and carefully evaluating pcb smt quotes will be key to managing costs effectively while maintaining quality.

Ultimately, the goal is to find the sweet spot between cost, quality, and performance that best meets the needs of your specific project. By understanding the factors that influence SMT assembly costs and leveraging strategies for optimization, you can make informed decisions that balance budget constraints with product requirements.

FAQ

1. How does production volume affect PCB SMT assembly costs?

Production volume significantly impacts PCB SMT assembly costs due to economies of scale. Higher volumes generally lead to lower per-unit costs as fixed costs are spread across more units. For example, setup costs and programming time for pick-and-place machines remain relatively constant regardless of volume. When production increases, these fixed costs are distributed over more units, reducing the cost per board. Additionally, larger orders often qualify for bulk discounts on components and materials. However, it's important to note that the relationship between volume and cost is not always linear, and there may be threshold points where significant cost reductions occur[1][4].

2. What role does component selection play in SMT assembly pricing?

Component selection is a crucial factor in SMT assembly pricing. The type, size, and complexity of components directly impact assembly costs. For instance, smaller components like 0201 or 01005 resistors and capacitors require more precise placement equipment and may increase assembly time. Similarly, complex components like BGAs or QFNs often require specialized equipment for placement and inspection, which can drive up costs. The availability of components also plays a role; using readily available, standard components can help reduce costs compared to specialized or custom parts. When evaluating pcb smt quotes, it's essential to consider how your component choices affect the overall assembly cost[4][7].

3. How do regional differences impact PCB SMT assembly costs?

Regional differences can significantly impact PCB SMT assembly costs due to variations in labor rates, operational costs, and regulatory environments. For example, assembly in countries like China or India often offers lower costs due to reduced labor expenses. However, these savings may be offset by longer lead times, potential communication challenges, and increased shipping costs. In contrast, assembly in the United States or Western Europe typically comes at a premium but may offer advantages in terms of quality control, intellectual property protection, and faster turnaround times. When considering pcb smt quotes from different regions, it's important to factor in these trade-offs and evaluate the total cost of ownership, including potential hidden costs related to quality issues or supply chain disruptions[7].

4. What are the cost implications of different SMT assembly technologies?

Different SMT assembly technologies can have varying cost implications. Automated assembly using advanced pick-and-place machines offers high efficiency and precision, making it cost-effective for large-scale production. However, the initial investment in such equipment is substantial, which can impact pricing for smaller runs. Manual or semi-automated assembly might be more cost-effective for low-volume production or prototyping but becomes less economical as volume increases. Additionally, specialized technologies like vapor phase soldering or selective soldering can offer benefits for certain applications but may come at a higher cost. When evaluating pcb smt quotes, consider how the proposed assembly technology aligns with your project requirements and production volume[2][4].

5. How do quality assurance measures affect SMT assembly costs?

Quality assurance measures play a crucial role in SMT assembly and can significantly impact costs. Processes such as automated optical inspection (AOI), X-ray inspection for BGAs, and in-circuit testing (ICT) add to the overall assembly cost but are often essential for ensuring product reliability. More rigorous quality control measures may increase upfront costs but can lead to long-term savings by reducing the likelihood of field failures and returns. The level of quality assurance required often depends on the application; for instance, medical or aerospace applications typically require more stringent (and costly) quality control measures compared to consumer electronics. When reviewing pcb smt quotes, it's important to understand the quality assurance processes included and how they align with your product requirements and industry standards[2][4].

Citations:

[1] https://www.7pcb.com/blog/surface-mount-smt-assembly-cost-china

[2] https://www.pcbonline.com/blog/smt-manufacturing-process.html

[3] https://resources.pcb.cadence.com/blog/2023-10-factors-in-pcb-fabrication-cost-estimation

[4] https://aaloktronix.com/how-much-does-it-cost-to-get-a-pcb-assembled-the-ultimate-guide/

[5] https://jhdpcb.com/pcb-assembly/smt-assembly/

[6] https://hackaday.io/page/11900-costing-assembly-service-for-my-pcb

[7] https://electronics.stackexchange.com/questions/30671/estimating-assembly-cost

[8] https://www.protoexpress.com/kb/pcb-assembly-process-overview/

[9] https://hackaday.io/project/184378-jlcpcb-smt-assembly-service-complete-guide/details

[10] https://www.candorind.com/blog/how-much-does-pcb-assembly-cost/

[11] https://www.fs-pcba.com/smt-process-flow/