Content Menu

● Introduction

● What is Surface Mount Technology?

● Advantages of Surface Mount Technology

>> Miniaturization

>> Increased Production Efficiency

>> Enhanced Performance

>> Cost-Effectiveness

>> Flexibility in Design

● Applications of Surface Mount Technology

>> Consumer Electronics

>> Telecommunications

>> Automotive

>> Medical Devices

>> Industrial Equipment

● The Future of Surface Mount Technology

>> Increased Automation

>> Miniaturization of Components

>> Advanced Materials

>> Sustainability

>> Integration with Other Technologies

● Conclusion

● Related Questions

>> 1. What is the difference between Surface Mount Technology and through-hole technology?

>> 2. What are the main advantages of using SMT in electronics manufacturing?

>> 3. In which industries is Surface Mount Technology commonly used?

>> 4. How does SMT contribute to the miniaturization of electronic devices?

>> 5. What trends are shaping the future of Surface Mount Technology?

Introduction

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, enabling the production of smaller, more efficient, and highly reliable electronic devices. This technology allows components to be mounted directly onto the surface of printed circuit boards (PCBs), eliminating the need for through-hole mounting. As a result, SMT has become the standard for modern electronic assembly, facilitating the miniaturization of devices and enhancing production efficiency. In this article, we will explore the fundamentals of SMT, its advantages, applications, and the future of this technology.

What is Surface Mount Technology?

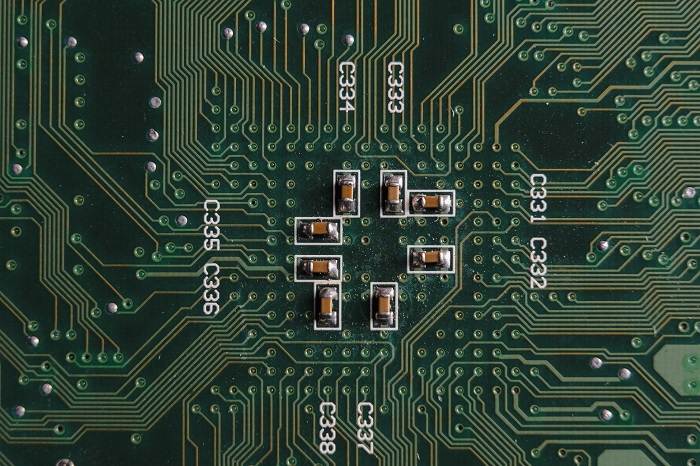

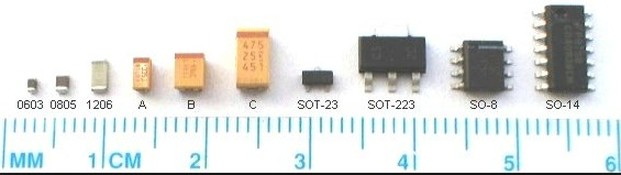

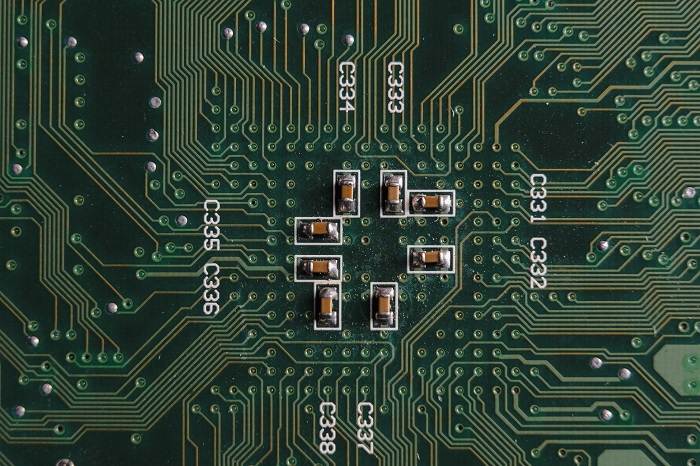

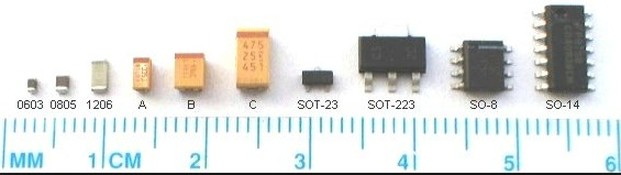

Surface Mount Technology is a method used to mount electronic components directly onto the surface of PCBs. Unlike traditional through-hole technology, where components are inserted into holes drilled in the PCB, SMT components are soldered onto pads on the board's surface. This method allows for a more compact design, as SMT components are generally smaller and lighter than their through-hole counterparts.

The process of SMT involves several key steps, including design, component placement, soldering, and inspection. Each of these steps is crucial to ensuring the reliability and performance of the final product.

Advantages of Surface Mount Technology

Miniaturization

One of the most significant advantages of SMT is the ability to create smaller and lighter electronic devices. As consumer demand for compact gadgets continues to grow, manufacturers are increasingly turning to SMT to meet these needs. The smaller size of SMT components allows for more efficient use of space on PCBs, enabling the design of thinner and lighter devices.

Increased Production Efficiency

SMT allows for automated assembly processes, which significantly increases production efficiency. Automated pick-and-place machines can quickly and accurately place components on PCBs, reducing labor costs and minimizing human error. This automation also leads to faster production times, allowing manufacturers to meet tight deadlines and respond to market demands more effectively.

Enhanced Performance

SMT components typically have shorter lead lengths, which reduces the inductance and resistance in the circuit. This results in improved electrical performance, making SMT ideal for high-frequency applications. Additionally, the soldering process used in SMT creates a more reliable connection between components and the PCB, enhancing the overall durability of the device.

Cost-Effectiveness

While the initial setup costs for SMT can be higher due to the need for specialized equipment, the long-term savings are significant. The reduced labor costs, increased production speed, and lower material waste associated with SMT make it a cost-effective solution for manufacturers. Furthermore, the ability to produce smaller devices can lead to savings in shipping and storage costs.

Flexibility in Design

SMT offers greater flexibility in PCB design compared to through-hole technology. Designers can place components more freely on the board, allowing for innovative layouts and configurations. This flexibility is particularly beneficial for complex circuits that require a high density of components.

Applications of Surface Mount Technology

Surface Mount Technology is widely used across various industries, including consumer electronics, telecommunications, automotive, and medical devices. Here are some notable applications:

Consumer Electronics

SMT is prevalent in the production of consumer electronics such as smartphones, tablets, and laptops. The demand for compact and lightweight devices has driven manufacturers to adopt SMT for its miniaturization capabilities.

Telecommunications

In the telecommunications industry, SMT is used to produce high-frequency components such as antennas, filters, and amplifiers. The enhanced performance and reliability of SMT components make them ideal for these applications.

Automotive

The automotive industry has embraced SMT for its ability to produce reliable and compact electronic systems. Modern vehicles are equipped with numerous electronic components, including sensors, control units, and infotainment systems, all of which benefit from SMT.

Medical Devices

In the medical field, SMT is used to manufacture devices such as pacemakers, diagnostic equipment, and monitoring systems. The reliability and compactness of SMT components are critical in ensuring the safety and effectiveness of these devices.

Industrial Equipment

SMT is also utilized in industrial equipment, where it is used to produce control systems, sensors, and automation devices. The durability and performance of SMT components are essential in demanding industrial environments.

The Future of Surface Mount Technology

As technology continues to evolve, so too does Surface Mount Technology. The future of SMT is likely to be shaped by several trends:

Increased Automation

The trend towards automation in manufacturing is expected to continue, with more advanced pick-and-place machines and soldering techniques being developed. This will further enhance production efficiency and reduce costs.

Miniaturization of Components

As the demand for smaller devices grows, manufacturers will continue to innovate in the design and production of SMT components. This will lead to even smaller and more efficient components, enabling the creation of ultra-compact devices.

Advanced Materials

The development of new materials for SMT components and PCBs will play a crucial role in the future of this technology. Advanced materials can improve performance, reduce costs, and enhance the reliability of electronic devices.

Sustainability

Sustainability is becoming increasingly important in manufacturing. The electronics industry is likely to focus on developing environmentally friendly materials and processes for SMT, reducing waste and energy consumption.

Integration with Other Technologies

The integration of SMT with other technologies, such as flexible electronics and IoT (Internet of Things), will open up new possibilities for innovation. This will enable the development of smart devices that are more efficient and capable of advanced functionalities.

Conclusion

Surface Mount Technology has transformed the electronics manufacturing landscape, offering numerous advantages such as miniaturization, increased production efficiency, and enhanced performance. Its applications span various industries, from consumer electronics to medical devices, highlighting its versatility and importance. As technology continues to advance, SMT is poised to evolve further, driven by trends such as increased automation, miniaturization, and sustainability. The future of SMT looks promising, with exciting developments on the horizon that will continue to shape the way we design and manufacture electronic devices.

Related Questions

1. What is the difference between Surface Mount Technology and through-hole technology?

Surface Mount Technology (SMT) involves mounting components directly onto the surface of PCBs, while through-hole technology requires components to be inserted into holes drilled in the PCB. SMT allows for smaller and lighter designs, whereas through-hole technology is often used for larger components.

2. What are the main advantages of using SMT in electronics manufacturing?

The main advantages of SMT include miniaturization of devices, increased production efficiency through automation, enhanced electrical performance, cost-effectiveness, and greater flexibility in PCB design.

3. In which industries is Surface Mount Technology commonly used?

SMT is commonly used in various industries, including consumer electronics, telecommunications, automotive, medical devices, and industrial equipment.

4. How does SMT contribute to the miniaturization of electronic devices?

SMT allows for the use of smaller components that can be placed more densely on PCBs, enabling the design of thinner and lighter devices that meet consumer demand for compact electronics.

5. What trends are shaping the future of Surface Mount Technology?

Trends shaping the future of SMT include increased automation in manufacturing, continued miniaturization of components, the development of advanced materials, a focus on sustainability, and integration with other technologies like IoT.