Content Menu

● Introduction

● Understanding SMT Technology

>> Key Components of SMT

● The SMT Production Process

● Advantages of SMT Production Lines

● Challenges in SMT Production

● Future Trends in SMT Production Lines

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. What are some advantages of using SMT?

>> 3. What challenges does SMT face?

>> 4. How does an SMT production line work?

>> 5. What is the future of SMT production lines?

Introduction

Surface Mount Technology (SMT) production lines are essential in the manufacturing of electronic components and printed circuit boards (PCBs). This technology has revolutionized the electronics industry, allowing for more compact designs, increased production efficiency, and greater reliability. In this article, we will explore the components, processes, advantages, challenges, and future trends of SMT production lines.

Understanding SMT Technology

Surface Mount Technology is a method for producing electronic circuits in which components are mounted directly onto the surface of PCBs. This contrasts with older technologies, such as through-hole technology, where components are inserted into holes drilled in the circuit board.

Key Components of SMT

1. Surface Mount Devices (SMDs): These are the components used in SMT, including resistors, capacitors, integrated circuits (ICs), and diodes. SMDs are designed to be soldered onto the surface of PCBs.

2. Printed Circuit Boards (PCBs): The substrate on which SMDs are mounted. PCBs can be single-sided, double-sided, or multi-layered.

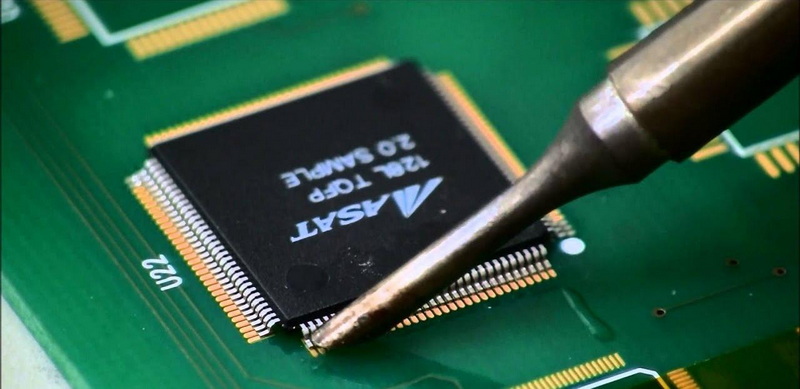

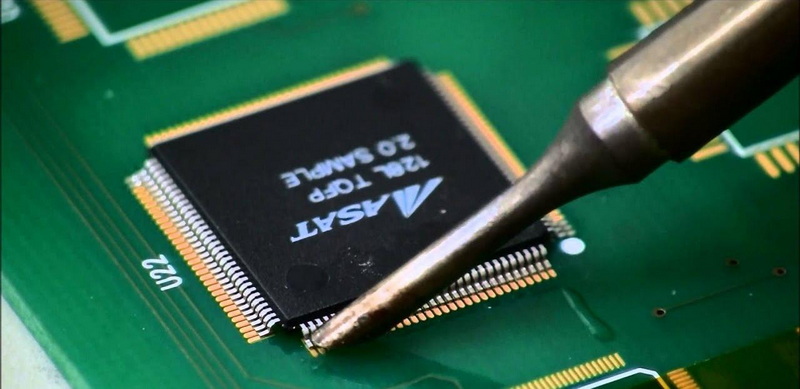

3. Solder Paste: A mixture of tiny solder balls and flux used to attach SMDs to PCBs during the soldering process.

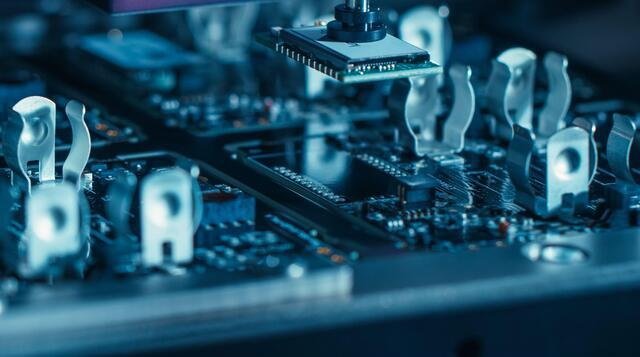

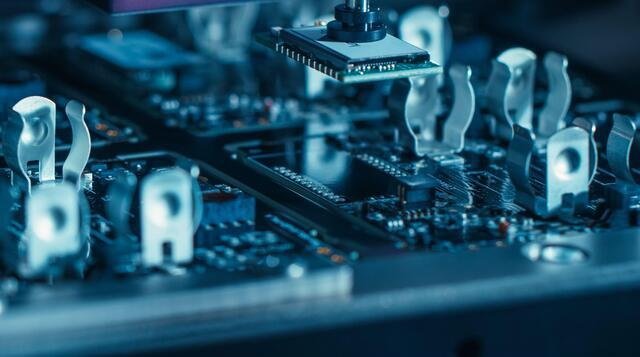

4. Pick and Place Machines: Automated machines that pick up SMDs from a feeder and place them accurately onto the PCB.

5. Reflow Ovens: Equipment used to heat the solder paste, causing it to melt and form a solid connection between the SMDs and the PCB.

6. Inspection Equipment: Tools such as Automated Optical Inspection (AOI) systems that check for defects in solder joints and component placement.

The SMT Production Process

The SMT production line consists of several key stages:

1. Solder Paste Application: Solder paste is applied to the PCB using a stencil or screen printing method. This ensures that the right amount of paste is deposited on each pad where an SMD will be placed.

2. Component Placement: The pick and place machine picks up the SMDs from their respective feeders and places them onto the solder paste on the PCB with high precision.

3. Reflow Soldering: The assembled PCBs are passed through a reflow oven where they are heated to a temperature that melts the solder paste, creating strong electrical connections between the components and the PCB.

4. Cooling: After reflow soldering, PCBs are cooled down to solidify the solder joints.

5. Inspection and Testing: The finished assemblies undergo inspection using AOI systems to detect any defects in component placement or solder joints. Functional testing may also be performed to ensure that each assembly works correctly.

6. Packaging: Once inspected and tested, the PCBs are packaged for shipment or further assembly into final products.

Advantages of SMT Production Lines

SMT production lines offer several advantages over traditional manufacturing methods:

- Higher Component Density: SMT allows for more components to be placed on a smaller area of a PCB due to their smaller size compared to through-hole components.

- Improved Performance: Shorter lead lengths in SMT reduce inductance and resistance, leading to better electrical performance.

- Automated Production: The use of automated machines increases production speed and reduces labor costs while improving consistency in quality.

- Flexibility: SMT production lines can easily adapt to changes in product design or volume by reprogramming machines or changing tooling setups.

- Reduced Manufacturing Costs: Overall costs can be lower due to reduced material waste, less manual labor, and faster production times.

Challenges in SMT Production

Despite its many advantages, SMT production lines also face challenges:

- Complexity of Design: Designing PCBs for SMT requires careful consideration of component placement and thermal management due to higher component densities.

- Soldering Issues: Problems such as cold solder joints or insufficient solder can occur if not properly managed during reflow soldering.

- Component Handling: SMDs can be sensitive to electrostatic discharge (ESD), requiring careful handling procedures to avoid damage.

- Inspection Requirements: The need for precise inspection increases as component densities rise, necessitating advanced inspection technologies that can be costly.

Future Trends in SMT Production Lines

As technology evolves, SMT production lines are expected to undergo significant changes:

- Increased Automation: The trend toward Industry 4.0 will lead to more fully automated production lines with enhanced data analytics capabilities for real-time monitoring and quality control.

- Miniaturization: As electronic devices continue to shrink in size, there will be a growing demand for even smaller SMDs and more compact PCB designs.

- Advanced Materials: New materials for PCBs and solder pastes will emerge that improve performance characteristics such as thermal conductivity and reliability under harsh conditions.

- Sustainability Practices: There will be an increasing focus on environmentally friendly practices within SMT production lines, including waste reduction strategies and energy-efficient processes.

- Integration with Other Technologies: The integration of SMT with other manufacturing technologies like additive manufacturing (3D printing) will create new opportunities for innovation in electronics design and production.

Conclusion

SMT production lines play a crucial role in modern electronics manufacturing by enabling high-density assembly of components on PCBs with improved performance and efficiency. While there are challenges associated with this technology, its advantages far outweigh them, making it an essential part of the electronics industry today. As we look towards the future, advancements in automation, materials science, sustainability practices, and integration with other technologies promise exciting developments that will shape how electronic devices are produced.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used in electronics manufacturing where components are mounted directly onto the surface of printed circuit boards (PCBs), allowing for more compact designs compared to traditional through-hole methods.

2. What are some advantages of using SMT?

Some advantages include higher component density on PCBs, improved electrical performance due to shorter lead lengths, increased automation leading to lower labor costs, flexibility in adapting to design changes, and reduced overall manufacturing costs.

3. What challenges does SMT face?

Challenges include design complexity requiring careful planning for component placement, potential soldering issues like cold joints or insufficient solder, handling sensitivity of components to electrostatic discharge (ESD), and increased inspection requirements due to higher component densities.

4. How does an SMT production line work?

An SMT production line typically involves several stages including solder paste application on PCBs, automated placement of components using pick-and-place machines, reflow soldering in ovens, cooling processes, inspection using automated systems, and final packaging for shipment or further assembly.

5. What is the future of SMT production lines?

The future trends include increased automation driven by Industry 4.0 principles, miniaturization of components and PCBs, development of advanced materials for better performance and reliability, sustainability practices aimed at reducing environmental impact, and integration with other manufacturing technologies like additive manufacturing.