Content Menu

● Introduction

● Understanding SMT Reels

>> Key Features of SMT Reels

● The Role of SMT Reel Holders

>> 1. Efficient Storage

>> 2. Component Protection

>> 3. Inventory Management

>> 4. Improved Workflow

● Types of SMT Reel Holders

>> 1. Static Reel Holders

>> 2. Mobile Reel Holders

>> 3. Automated Reel Holders

>> 4. Smart Reel Holders

● How SMT Reel Holders Work

>> 1. Reel Loading

>> 2. Component Identification

>> 3. Reel Dispensing

>> 4. Feeder Integration

>> 5. Inventory Tracking

● Benefits of Using SMT Reel Holders

>> 1. Increased Efficiency

>> 2. Improved Accuracy

>> 3. Enhanced Component Protection

>> 4. Better Inventory Control

>> 5. Space Optimization

● Considerations When Choosing an SMT Reel Holder

>> 1. Production Volume

>> 2. Component Variety

>> 3. Integration Capabilities

>> 4. ESD Protection

>> 5. Scalability

● Maintenance and Best Practices

>> 1. Regular Cleaning

>> 2. Periodic Inspection

>> 3. Proper Loading

>> 4. Environmental Control

>> 5. Software Updates

● Future Trends in SMT Reel Holder Technology

>> 1. AI-Powered Inventory Management

>> 2. IoT Connectivity

>> 3. Augmented Reality Integration

>> 4. Sustainable Materials

● Conclusion

● Frequently Asked Questions

>> 1. What are the main types of SMT reel holders available?

>> 2. How do SMT reel holders contribute to improved efficiency in electronics manufacturing?

>> 3. What features should I look for when choosing an SMT reel holder?

>> 4. How do automated SMT reel holders differ from manual ones?

>> 5. What maintenance is required for SMT reel holders?

● Citations:

Introduction

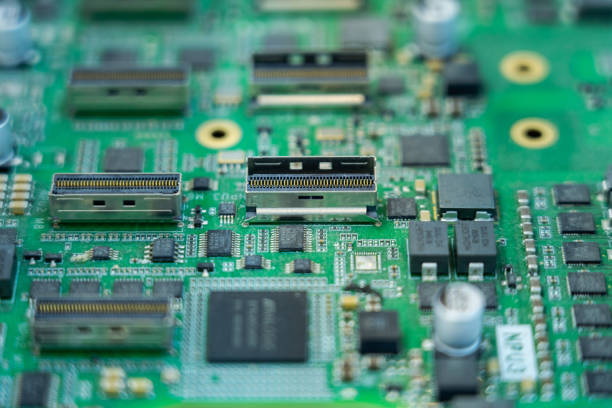

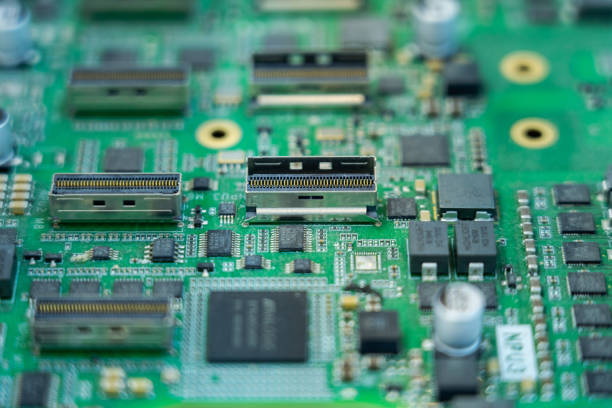

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, enabling the production of smaller, more complex, and highly efficient electronic devices. At the heart of this technology lies a crucial component: the SMT reel holder. This essential tool plays a vital role in the storage, organization, and dispensing of electronic components during the SMT assembly process. In this comprehensive article, we will explore the intricacies of SMT reel holders, their functionality, and their significance in modern electronics manufacturing.

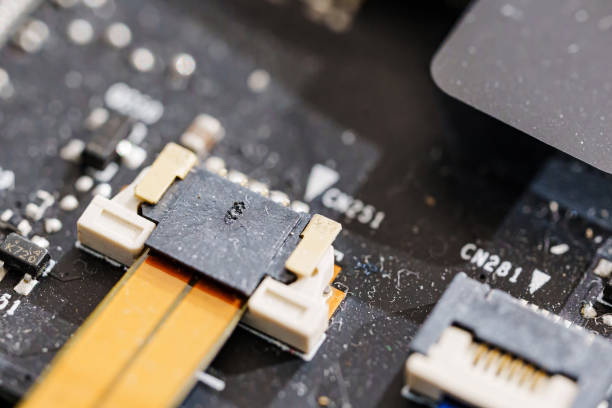

Understanding SMT Reels

Before delving into the specifics of SMT reel holders, it's important to understand what SMT reels are and their purpose in the manufacturing process. SMT reels are spools used to hold and dispense electronic components such as resistors, capacitors, and integrated circuits[1]. These reels are typically made of plastic or cardboard and come in various sizes to accommodate different component types and quantities.

Key Features of SMT Reels

SMT reels are designed with several key features to ensure efficient component storage and dispensing:

1. Reel diameter: The outer diameter of the reel, usually measured in millimeters.

2. Reel width: The width of the reel, also measured in millimeters.

3. Reel hole size: The size of the central hole, typically measured in inches.

4. Reel thickness: The thickness of the reel material.

5. Component pockets: Small compartments along the reel's circumference that hold individual components.

The Role of SMT Reel Holders

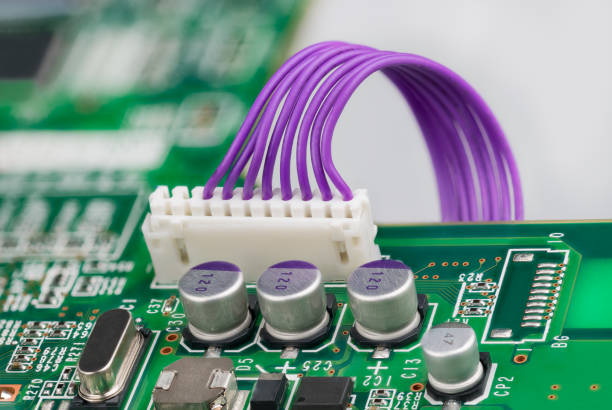

SMT reel holders are specialized storage and dispensing systems designed to accommodate multiple SMT reels. These holders serve several critical functions in the SMT assembly process:

1. Efficient Storage

SMT reel holders provide a compact and organized storage solution for multiple reels. This efficient storage system allows manufacturers to maximize space utilization in their production facilities while keeping components readily accessible.

2. Component Protection

By securely holding SMT reels, these holders protect sensitive electronic components from damage due to mishandling, dust, and electrostatic discharge (ESD). Many SMT reel holders are equipped with ESD-protective materials to safeguard components from static electricity[1].

3. Inventory Management

SMT reel holders often incorporate features that facilitate inventory tracking and management. This can include barcode scanning capabilities, RFID technology, or integration with inventory management software.

4. Improved Workflow

By organizing reels in a logical and accessible manner, SMT reel holders contribute to a smoother workflow in the assembly process. Operators can quickly locate and retrieve the required components, reducing production downtime.

Types of SMT Reel Holders

There are several types of SMT reel holders available in the market, each designed to meet specific manufacturing needs:

1. Static Reel Holders

Static reel holders are fixed storage systems that provide a stable platform for storing SMT reels. These holders are typically used in smaller production environments or for storing less frequently used components.

2. Mobile Reel Holders

Mobile reel holders are equipped with wheels, allowing for easy transportation of multiple reels around the production floor. These holders are particularly useful in larger manufacturing facilities where components need to be moved between different assembly lines.

3. Automated Reel Holders

Automated reel holders represent the cutting edge of SMT reel storage technology. These systems incorporate robotics and software control to automatically retrieve and dispense reels as needed. Automated holders can significantly improve efficiency and reduce human error in high-volume production environments.

4. Smart Reel Holders

Smart reel holders, also known as intelligent reel storage systems, utilize advanced technologies such as RFID tracking, real-time inventory management, and integration with Manufacturing Execution Systems (MES). These holders provide real-time data on component usage, stock levels, and even predictive maintenance alerts[4].

How SMT Reel Holders Work

The functionality of SMT reel holders can vary depending on their type and level of sophistication. However, the basic working principle remains consistent across most systems:

1. Reel Loading

Operators load SMT reels onto the holder, ensuring that each reel is securely positioned. Many holders feature adjustable dividers or slots to accommodate reels of different sizes.

2. Component Identification

In more advanced systems, the holder may use barcode scanning or RFID technology to identify and log the components on each reel. This information is then integrated into the inventory management system.

3. Reel Dispensing

When components are needed for production, the appropriate reel is retrieved from the holder. In manual systems, this is done by an operator. In automated systems, robotic arms or conveyor mechanisms may handle the retrieval process.

4. Feeder Integration

Once retrieved, the reel is typically loaded onto an SMT feeder, which then supplies components to the placement machine during the assembly process.

5. Inventory Tracking

As components are used, many SMT reel holders can track usage and update inventory levels in real-time. This feature is particularly important for maintaining accurate stock counts and triggering reorder alerts when supplies run low.

Benefits of Using SMT Reel Holders

The implementation of SMT reel holders in electronics manufacturing offers numerous benefits:

1. Increased Efficiency

By organizing components and streamlining the retrieval process, SMT reel holders can significantly reduce the time spent searching for and handling reels. This increased efficiency can lead to higher production rates and reduced labor costs.

2. Improved Accuracy

Proper storage and organization of SMT reels reduce the likelihood of component mix-ups or incorrect reel selection. This improved accuracy can lead to fewer assembly errors and higher product quality.

3. Enhanced Component Protection

SMT reel holders provide a controlled environment for storing sensitive electronic components, protecting them from physical damage, contamination, and electrostatic discharge.

4. Better Inventory Control

Advanced SMT reel holders with integrated inventory management features allow manufacturers to maintain accurate stock levels, reduce waste, and optimize component ordering.

5. Space Optimization

By providing a compact and organized storage solution, SMT reel holders help manufacturers make the most of their available space, which is particularly valuable in facilities with limited floor area.

Considerations When Choosing an SMT Reel Holder

When selecting an SMT reel holder for a manufacturing facility, several factors should be considered:

1. Production Volume

The size and type of SMT reel holder should be appropriate for the production volume. High-volume manufacturers may benefit from larger, automated systems, while smaller operations might find manual holders more suitable.

2. Component Variety

The holder should be able to accommodate the range of reel sizes and types used in production. Adjustable or modular systems offer greater flexibility in this regard.

3. Integration Capabilities

For manufacturers looking to optimize their processes, choosing a holder that can integrate with existing inventory management and production control systems is crucial.

4. ESD Protection

Ensure that the chosen holder provides adequate ESD protection to safeguard sensitive components from static electricity damage.

5. Scalability

Consider future production needs and choose a system that can be easily expanded or upgraded as requirements change.

Maintenance and Best Practices

To ensure optimal performance and longevity of SMT reel holders, proper maintenance and adherence to best practices are essential:

1. Regular Cleaning

Keep the holder clean and free from dust and debris, which can contaminate components or interfere with moving parts in automated systems.

2. Periodic Inspection

Regularly inspect the holder for signs of wear or damage, particularly in areas that experience frequent contact or movement.

3. Proper Loading

Train operators on the correct method for loading and unloading reels to prevent damage to both the components and the holder itself.

4. Environmental Control

Maintain appropriate temperature and humidity levels in the storage area to protect components from environmental damage.

5. Software Updates

For smart or automated systems, ensure that software and firmware are kept up to date to benefit from the latest features and security enhancements.

Future Trends in SMT Reel Holder Technology

As electronics manufacturing continues to evolve, so too does the technology behind SMT reel holders. Some emerging trends include:

1. AI-Powered Inventory Management

Artificial intelligence and machine learning algorithms are being integrated into SMT reel holders to predict component usage patterns and optimize inventory levels.

2. IoT Connectivity

Internet of Things (IoT) technology is enabling SMT reel holders to communicate with other manufacturing equipment and systems, creating a more connected and efficient production environment.

3. Augmented Reality Integration

Some manufacturers are exploring the use of augmented reality (AR) to assist operators in locating and retrieving specific reels, potentially reducing errors and improving efficiency.

4. Sustainable Materials

As environmental concerns grow, there is a trend towards developing SMT reel holders using more sustainable and recyclable materials.

Conclusion

SMT reel holders play a crucial role in modern electronics manufacturing, providing an efficient, organized, and protective storage solution for the myriad of components used in surface mount technology. From simple static holders to advanced automated systems, these tools contribute significantly to the streamlining of production processes, improvement of inventory management, and enhancement of overall manufacturing efficiency.

As technology continues to advance, SMT reel holders are likely to become even more sophisticated, incorporating features such as AI-powered predictive maintenance, enhanced IoT connectivity, and augmented reality assistance. By staying informed about these developments and carefully selecting the right SMT reel holder for their specific needs, electronics manufacturers can position themselves to meet the challenges of increasingly complex and demanding production requirements.

Frequently Asked Questions

1. What are the main types of SMT reel holders available?

The main types of SMT reel holders include:

1. Static reel holders

2. Mobile reel holders

3. Automated reel holders

4. Smart reel holders with advanced features like RFID tracking and real-time inventory management

Each type is designed to meet different manufacturing needs and production volumes.

2. How do SMT reel holders contribute to improved efficiency in electronics manufacturing?

SMT reel holders improve efficiency by:

1. Organizing components for easy access

2. Reducing time spent searching for specific reels

3. Minimizing handling errors and component mix-ups

4. Facilitating quick reel changes during production

5. Enabling better inventory management and stock control

These factors combined lead to smoother workflows and increased production rates.

3. What features should I look for when choosing an SMT reel holder?

When selecting an SMT reel holder, consider the following features:

1. Capacity and size appropriate for your production volume

2. Adjustability to accommodate different reel sizes

3. ESD protection to safeguard sensitive components

4. Integration capabilities with existing inventory systems

5. Durability and ease of maintenance

6. Potential for future scalability or upgrades

The ideal features will depend on your specific manufacturing requirements and future growth plans.

4. How do automated SMT reel holders differ from manual ones?

Automated SMT reel holders differ from manual ones in several ways:

1. They use robotic systems to retrieve and dispense reels without human intervention

2. They often incorporate advanced inventory tracking and management features

3. They can integrate with other automated manufacturing systems for seamless operation

4. They typically have higher initial costs but can offer greater efficiency and accuracy in high-volume production environments

5. They require less manual labor but may need more specialized maintenance and technical support

The choice between automated and manual holders depends on factors such as production volume, budget, and desired level of automation.

5. What maintenance is required for SMT reel holders?

Proper maintenance of SMT reel holders typically includes:

1. Regular cleaning to remove dust and debris

2. Periodic inspection for wear and damage

3. Lubrication of moving parts in automated systems

4. Software updates for smart or automated holders

5. Calibration of any integrated measurement or sensing components

6. Replacement of worn parts as needed

Following the manufacturer's maintenance guidelines is crucial for ensuring the longevity and optimal performance of your SMT reel holder.

Citations:

[1] https://global.neotel.tech/2023/01/05/what-is-smt-reel-storage-solution/

[2] https://www.neotel-technology.de/what-is-smt-reel-storage-solution/

[3] https://patents.google.com/patent/CN108910627A/zh

[4] https://global.neotel.tech/2022/07/22/how-smt-smart-rack-work/

[5] https://global.neotel.tech/2022/02/24/5-things-you-must-know-about-smt-reel/

[6] https://patents.google.com/patent/CN101595823A/zh

[7] https://www.zjyingxing.com/info/what-is-the-function-of-the-feeder-in-the-smt-83821364.html

[8] https://www.reddit.com/r/AskElectronics/comments/11mspyt/storing_smt_reels/

[9] https://www.cambridgeinternational.org/Images/520575-june-2022-examiner-report.pdf

[10] https://patents.google.com/patent/WO2017016320A1/zh