Content Menu

● Introduction

● Understanding SMT

>> Key Characteristics of SMT

● Components of an SMT Line

>> 1. Solder Paste Printer

>> 2. Pick and Place Machine

>> 3. Reflow Oven

>> 4. Inspection Systems

>> 5. Conveyor Systems

● The SMT Assembly Process

>> Step 1: Solder Paste Application

>> Step 2: Component Placement

>> Step 3: Reflow Soldering

>> Step 4: Inspection

>> Step 5: Final Assembly and Testing

● Advantages of Using an SMT Line

● Challenges Faced by SMT Lines

● Innovations Shaping SMT Lines

>> Automation and Robotics

>> AI Integration

>> Sustainability Initiatives

>> Microassembly Techniques

● The Future of SMT Lines

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology?

>> 2. What are the main components of an SMT line?

>> 3. How does an SMT assembly process work?

>> 4. What are some advantages of using an SMT line?

>> 5. What challenges do manufacturers face with SMT lines?

● Citations:

Introduction

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the efficient assembly of electronic components onto printed circuit boards (PCBs). An SMT line is a critical part of this process, serving as a dedicated production line where various operations are performed to assemble electronic devices. This article will explore what an SMT line is, its components, processes, advantages, challenges, and its significance in modern electronics manufacturing.

Understanding SMT

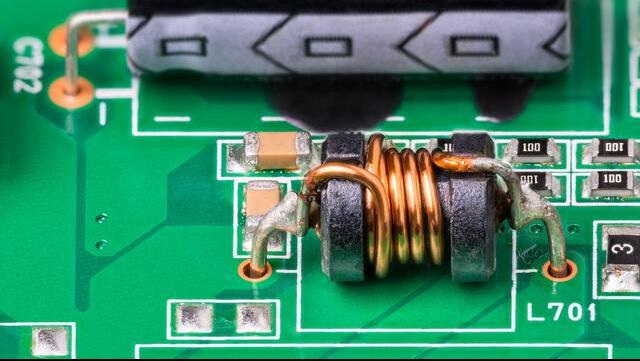

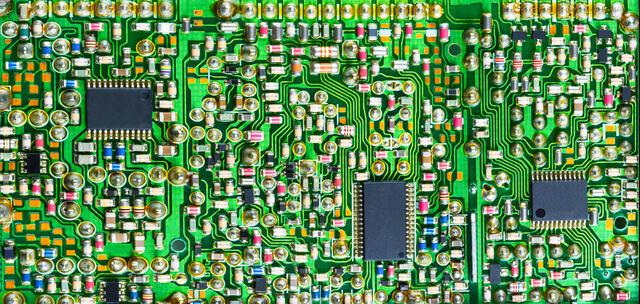

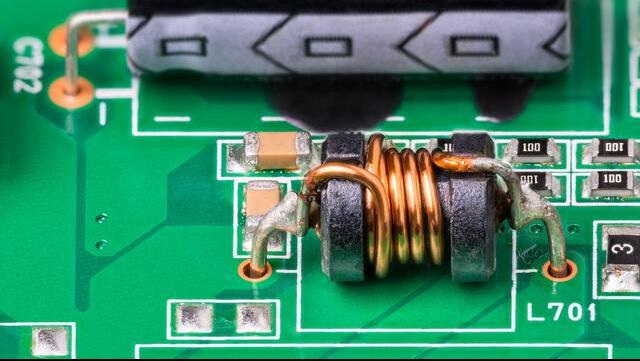

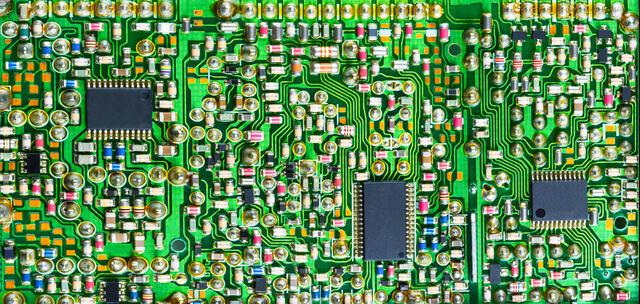

Before delving into the specifics of an SMT line, it is essential to understand what Surface Mount Technology entails. SMT is a method used to mount electronic components directly onto the surface of PCBs. Unlike traditional through-hole technology, where components are inserted into holes drilled in the PCB, SMT allows for a more compact design and higher component density.

Key Characteristics of SMT

- Miniaturization: SMT enables the use of smaller components, leading to more compact electronic devices.

- Higher Density: Components can be placed closer together on the PCB, increasing functionality without enlarging the device size.

- Automated Assembly: SMT is highly compatible with automated assembly processes, reducing labor costs and production times.

Components of an SMT Line

An SMT line consists of several key components that work together to ensure efficient production. These include:

1. Solder Paste Printer

The solder paste printer applies solder paste to the PCB in precise locations where components will be placed. This step is crucial as it ensures reliable electrical connections.

2. Pick and Place Machine

This machine is responsible for picking up surface mount components from their packaging and placing them onto the PCB. Advanced pick and place machines can handle various component sizes and shapes with high accuracy.

3. Reflow Oven

After components are placed on the PCB, they must be soldered in place. The reflow oven heats the PCB to melt the solder paste, creating strong electrical connections between the components and the board.

4. Inspection Systems

Quality control is vital in electronics manufacturing. Automated optical inspection (AOI) systems check for defects in solder joints and component placement before and after reflow.

5. Conveyor Systems

These systems transport PCBs between different stages of production, ensuring smooth operation across the entire SMT line.

The SMT Assembly Process

The assembly process on an SMT line involves several steps that must be executed with precision for optimal results:

Step 1: Solder Paste Application

The process begins with applying solder paste onto the PCB using a stencil or screen printing method. Accurate paste application is critical for ensuring proper solder joints.

Step 2: Component Placement

Once the solder paste is applied, the pick and place machine picks up components from feeders and places them onto the designated pads on the PCB.

Step 3: Reflow Soldering

After placement, the PCB moves into a reflow oven, where it undergoes a temperature profile that melts the solder paste. This step solidifies connections between components and pads.

Step 4: Inspection

Post-reflow inspection is conducted using AOI systems to identify any defects in component placement or solder joints. This step helps catch errors early in the process.

Step 5: Final Assembly and Testing

After inspection, additional processes such as wave soldering (for through-hole components), conformal coating, or final testing may occur before packaging the finished product.

Advantages of Using an SMT Line

Implementing an SMT line offers numerous advantages for electronics manufacturers:

- Increased Production Speed: Automation reduces assembly time significantly compared to manual methods.

- Cost Efficiency: Lower labor costs and reduced material waste contribute to overall cost savings.

- Improved Reliability: Automated processes minimize human error, leading to higher quality products.

- Flexibility: Modern SMT lines can quickly adapt to different product designs without extensive reconfiguration.

- Better Electrical Performance: Shorter signal paths reduce lead inductance and capacitance, enhancing performance at high frequencies[1][2].

Challenges Faced by SMT Lines

While there are many benefits to using an SMT line, manufacturers also face challenges:

- Initial Setup Costs: The investment required for machinery and training can be substantial.

- Complexity of Processes: Maintaining quality control throughout various stages can be challenging due to increased complexity.

- Component Availability: Sourcing high-quality components can sometimes lead to delays in production schedules.

- Sensitivity of Components: SMT components are often more sensitive to thermal stress and electrostatic discharge (ESD), which can damage them during handling[4].

Innovations Shaping SMT Lines

The landscape of SMT lines is continually evolving due to technological advancements. Some notable innovations include:

Automation and Robotics

Automation has become a cornerstone of modern SMT lines. Robotic arms are now utilized for precise component placement, soldering, and inspection tasks. This automation not only boosts productivity but also reduces human error—leading to higher-quality PCB assemblies[3].

AI Integration

Artificial intelligence (AI) is revolutionizing how SMT lines operate by enabling predictive maintenance and real-time optimization of production processes. AI-powered systems analyze vast amounts of data in real-time, identifying potential issues before they escalate[5]. This intelligent automation enhances decision-making capabilities and drives continuous improvement in operations.

Sustainability Initiatives

As environmental concerns grow, sustainability has become a crucial focus in electronics manufacturing. Manufacturers are adopting eco-friendly practices such as using lead-free soldering materials and implementing energy-efficient processes[3]. The development of recyclable materials contributes to a more sustainable future for the industry.

Microassembly Techniques

With advancements in technology, microassembly techniques are becoming increasingly important in SMT lines. These techniques allow for smaller components to be assembled with precision, enabling even more compact electronic devices[9].

The Future of SMT Lines

As technology continues to advance, so too will SMT lines. Trends such as Industry 4.0 are influencing how these lines operate—integrating IoT devices for real-time monitoring and data collection enhances efficiency and predictive maintenance capabilities[10].

Moreover, developments in materials science may lead to new types of solder pastes and components that further improve performance and reliability in electronic devices. The focus on shorter production cycles necessitates flexibility in equipment design to accommodate rapid changes in product specifications[10].

Conclusion

In conclusion, an SMT line plays a pivotal role in modern electronics manufacturing by facilitating efficient assembly processes that meet consumer demands for smaller, more reliable devices. Understanding its components, processes, advantages, challenges, and innovations provides valuable insight into how electronics are produced today. As technology evolves alongside sustainability initiatives and automation trends, SMT lines will continue to shape the future of electronic device manufacturing while addressing industry challenges head-on.

FAQ

1. What is Surface Mount Technology?

Surface Mount Technology (SMT) is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs), allowing for more compact designs compared to traditional through-hole methods.

2. What are the main components of an SMT line?

The main components include a solder paste printer, pick and place machine, reflow oven, inspection systems (such as AOI), and conveyor systems that facilitate movement between different stages of production.

3. How does an SMT assembly process work?

The assembly process involves applying solder paste on PCBs, placing components using automated machines, reflow soldering them in an oven, inspecting for defects, and conducting any final assembly or testing before packaging.

4. What are some advantages of using an SMT line?

Advantages include increased production speed due to automation, cost efficiency from reduced labor costs and material waste, improved reliability through minimized human error, and flexibility in adapting to different product designs.

5. What challenges do manufacturers face with SMT lines?

Challenges include high initial setup costs for machinery and training, complexity in maintaining quality control throughout various stages of production, potential delays due to sourcing high-quality components, and sensitivity issues related to component handling[4].

Citations:

[1] https://www.raypcb.com/surface-mount-technology/

[2] https://vectorbluehub.com/smt-assembly

[3] https://www.smtfactory.com/Future-Trends-in-SMT-Lines-Innovations-Shaping-The-Electronics-Manufacturing-Industry-id44863586.html

[4] https://www.linkedin.com/advice/1/what-benefits-challenges-using-surface-mount-technology

[5] https://www.swfuliusmt.com/2024/07/12/understanding-smt-lines-the-backbone-of-modern-electronics-manufacturing/

[6] https://www.mpe-electronics.co.uk/2024/10/22/advantages-and-disadvantages-of-surface-mount-technology

[7] https://smt.fuji.co.jp/en/topics/2858

[8] https://www.viasion.com/blog/common-challenges-in-smt-assembly-and-solutions/

[9] https://www.unmannedsystemstechnology.com/feature/mpl-explains-the-evolution-of-smt-technology/

[10] https://www.mycronic.com/product-areas/pcb-assembly/news-and-press-releases/news/ten-key-smt-trends-you-need-to-know/