Content Menu

● Introduction

● What is an SMT Line?

>> Definition and Role of Surface Mount Technology

● Key Components of an SMT Line

● How Does an SMT Line Function?

● Advantages of SMT Lines

● Applications of SMT Lines

● Challenges in SMT Assembly

● Future Trends in SMT Technology

>> Automation Integration

>> Miniaturization

>> Sustainability Initiatives

>> Advanced Materials Development

>> Customization Capabilities

● Conclusion

● FAQ

>> 1. What is the primary purpose of an SMT line?

>> 2. What are the main machines used in an SMT line?

>> 3. How does a pick-and-place machine work?

>> 4. What are some common challenges faced during SMT assembly?

>> 5. Why is sustainability important in future SMT processes?

● Citations:

Introduction

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the efficient assembly of electronic components onto printed circuit boards (PCBs). SMT line assembling factories are specialized facilities that utilize advanced machinery to automate this process, ensuring high precision and speed. This article explores the workings of an SMT line, its key components, advantages, applications, and more.

What is an SMT Line?

SMT lines are automated systems designed for the assembly of surface mount devices (SMDs) onto PCBs. Unlike traditional through-hole technology, where components are inserted into holes in the PCB, SMT allows components to be mounted directly on the surface. This method enhances production efficiency and reduces the size of electronic devices.

Definition and Role of Surface Mount Technology

Surface Mount Technology involves placing electronic components on the surface of PCBs using solder paste. The process is highly automated and relies on precision machinery to ensure that components are placed accurately and securely. SMT is essential for modern electronics manufacturing, as it supports the production of compact and complex devices.

Key Components of an SMT Line

An SMT line typically consists of several interconnected machines that work together seamlessly. The following are the main components involved in an SMT line:

- SMT Loader: This machine automatically stacks and loads PCBs onto the conveyor belt for processing.

- Stencil Printer: It applies solder paste to the PCB pads using a stencil, ensuring that only the necessary areas are coated.

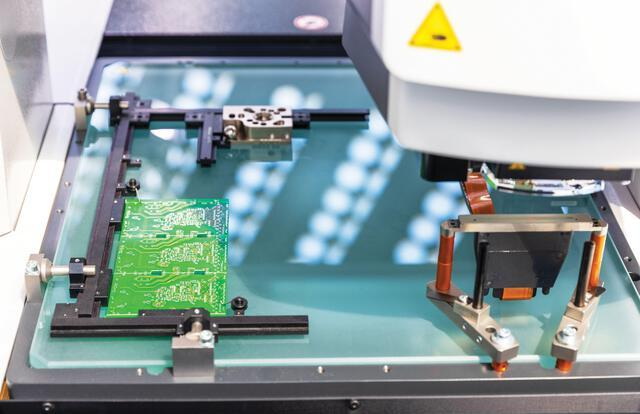

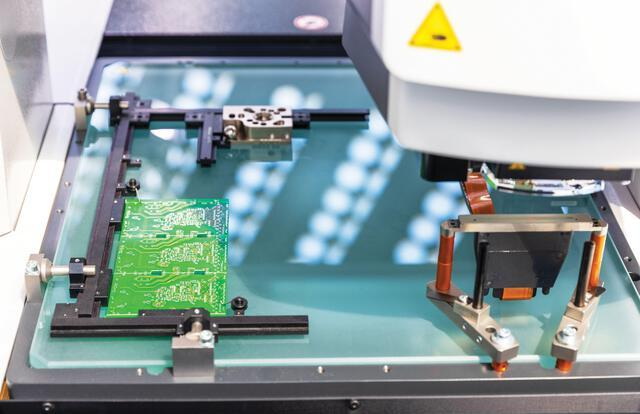

- Pick-and-Place Machine: This machine uses robotics to pick components from reels or trays and place them accurately on the PCB.

- Reflow Oven: It heats the PCB to melt the solder paste, creating strong electrical connections between the components and the board.

- Automated Optical Inspection (AOI): This system inspects the assembled boards for defects or errors in component placement.

- Cleaning Machine: This machine removes excess flux and debris from the PCB and ensures that the PCB is clean and ready for final assembly.

- PCB Transport Systems: These devices ensure safe transport of PCBs between individual machines, maintaining process efficiency.

- Software MES - Traceability: Modern SMT manufacturing companies use software to monitor and control production lines in real-time, optimizing processes and ensuring traceability.

These components work in harmony to streamline the assembly process and improve overall production efficiency.

How Does an SMT Line Function?

The operation of an SMT line can be broken down into several key steps:

1. Material Preparation: The process begins with careful inspection of PCBs and electronic components to ensure they meet quality standards.

2. Solder Paste Printing: A stencil printer applies a thin layer of solder paste to specific areas on the PCB where components will be placed.

3. Solder Paste Inspection (SPI): After printing, a SPI system checks for even application and alignment of solder paste.

4. Component Placement: The pick-and-place machine picks up SMDs from their storage reels or trays and places them onto the soldered areas of the PCB with high precision.

5. Reflow Soldering: The assembled board passes through a reflow oven, where controlled heating melts the solder paste, forming reliable connections between components and PCB pads.

6. Automated Optical Inspection (AOI): After soldering, AOI systems inspect the boards for any defects or misalignments.

7. Final Testing: Functional tests may be conducted to ensure that each board operates correctly before packaging.

This systematic approach allows manufacturers to produce high-quality electronic assemblies at a rapid pace while minimizing human error.

Advantages of SMT Lines

The adoption of SMT lines offers numerous benefits over traditional assembly methods:

- Increased Production Speed: SMT lines can assemble thousands of components per hour, making them ideal for high-volume production.

- Enhanced Precision: Automated systems ensure accurate placement of components, improving product quality and consistency.

- Flexibility and Scalability: SMT lines can easily adapt to different component sizes and types, allowing manufacturers to handle various products efficiently.

- Reduced Labor Costs: Automation lowers labor expenses while increasing production capacity without expanding workforce size.

- Higher Quality Control: Integrated inspection systems help detect defects early in the process, ensuring reliable end products.

These advantages make SMT lines essential for modern electronics manufacturing across various industries.

Applications of SMT Lines

SMT lines are widely used in numerous industries due to their efficiency and precision. Some key applications include:

- Consumer Electronics: Smartphones, tablets, and laptops rely heavily on SMT for compact design and functionality.

- Automotive Industry: Modern vehicles incorporate numerous electronic systems that benefit from SMT assembly processes for reliability and performance.

- Telecommunications: Devices such as routers, switches, and communication equipment utilize SMT technology for efficient production.

- Medical Devices: Many medical instruments require precise electronic assemblies that can be effectively produced using SMT lines.

These applications highlight the versatility and importance of SMT technology in today's technological landscape.

Challenges in SMT Assembly

Despite its advantages, SMT assembly comes with challenges that manufacturers must address to maintain efficiency:

- Solder Bridging: This occurs when excess solder creates a bridge between two pads, causing short circuits. Proper stencil design and paste application can mitigate this issue.

- Insufficient Solder Joints: If there is not enough solder during reflow, electrical opens can occur. Ensuring proper solder paste volume is crucial in preventing this defect.

- Non-Wetting Issues: Components may not adhere properly if there are issues with surface preparation or solder quality. Regular maintenance of equipment helps prevent these problems.

- Component Misalignment: Accurate placement is critical; misalignment can lead to functional failures. Utilizing high-resolution cameras in pick-and-place machines improves alignment accuracy significantly.

Addressing these challenges requires continuous monitoring and optimization of processes within an SMT line to enhance yield rates effectively.

Future Trends in SMT Technology

As technology continues to evolve, several trends are shaping the future landscape of SMT:

Automation Integration

Automation technologies are becoming increasingly sophisticated with advancements in robotics. Automated systems can now perform complex tasks more efficiently than ever before. The integration of AI into these systems allows for real-time monitoring and predictive maintenance, further enhancing production capabilities[3][20].

Miniaturization

The demand for smaller electronic devices drives ongoing miniaturization efforts within SMT technology. Manufacturers are developing smaller SMDs that allow for higher component density on PCBs without sacrificing performance[5][12]. This trend is particularly evident in industries like wearables and IoT devices where space is at a premium[10].

Sustainability Initiatives

With growing environmental concerns, there is a push towards sustainable practices within electronics manufacturing. Future SMT processes will likely incorporate eco-friendly materials and practices aimed at reducing waste while maintaining high-quality standards[18][19].

Advanced Materials Development

Innovations in materials used for soldering will enhance reliability while improving performance metrics like thermal conductivity[5][10]. New alloys may provide better performance under varying environmental conditions, which is critical for applications like automotive electronics[10].

Customization Capabilities

As consumer demands shift towards personalized products, flexibility within manufacturing processes will become increasingly important. Future SMT lines will need to accommodate rapid changes in design specifications without significant downtime or resource wastage[8][12].

Conclusion

In summary, SMT line assembling factories play a crucial role in modern electronics manufacturing by automating the assembly process of surface mount devices onto printed circuit boards. The integration of advanced machinery enhances production speed, precision, flexibility, and overall quality control. As technology continues to advance with trends like automation integration, miniaturization efforts, sustainability initiatives, advanced materials development, and customization capabilities, SMT lines will remain pivotal in meeting growing demands across various industries while driving innovation in electronic device design and functionality.

FAQ

1. What is the primary purpose of an SMT line?

The primary purpose of an SMT line is to automate the assembly of electronic components onto PCBs with high precision and efficiency.

2. What are the main machines used in an SMT line?

The main machines used in an SMT line include stencil printers, pick-and-place machines, reflow ovens, automated inspection systems (AOI), cleaning machines, and transport systems for PCBs.

3. How does a pick-and-place machine work?

A pick-and-place machine uses robotics to pick components from reels or trays based on programmed coordinates and places them accurately onto pre-applied solder paste on PCBs.

4. What are some common challenges faced during SMT assembly?

Common challenges include solder bridging (short circuits), insufficient solder joints (electrical opens), non-wetting issues (poor adhesion), component misalignment during placement, among others.

5. Why is sustainability important in future SMT processes?

Sustainability is essential due to increasing environmental concerns; future processes will focus on reducing waste through eco-friendly materials while maintaining high-quality standards necessary for modern electronics manufacturing.

Citations:

[1] https://www.allsmt.com/SMT-line-concept-assembly-manufacturing-production-Assembly

[2] https://levisonenterprises.com/5-advantages-to-using-smt/

[3] https://www.mycronic.com/product-areas/pcb-assembly/news-and-press-releases/news/ten-key-smt-trends-you-need-to-know/

[4] https://jhdpcb.com/blog/efficient-smt-assembly/

[5] https://www.marketsandmarketsblog.com/future-of-surface-mount-technology-paving-the-way-for-compact-electronics.html

[6] https://www.pcbasic.com/blog/smt_production_line.html

[7] https://www.blackfox.com/7-benefits-of-surface-mount-technology-smt/

[8] https://finestpcb.com/smt-assembly/

[9] https://fctassembly.wordpress.com/technical-resources/technical-papers/smt-assembly-challenges-and-proven-solutions-for-improving-yields/

[10] https://www.smtfactory.com/SMT-Technology-in-Automotive-Electronics-Prospects-and-Future-Trends-id64370127.html

[11] https://minearc.com/what-is-an-smt-line/

[12] https://vectorbluehub.com/smt-assembly

[13] https://www.atmwa.com.au/new-trends-in-pcb-assembly-what-to-expect-in-2023/

[14] https://blog.intraratio.com/revolutionizing-smt-manufacturing-amidst-economic-challenges

[15] https://www.globenewswire.com/news-release/2024/10/14/2962707/28124/en/Surface-Mount-Technology-Equipment-SMT-Market-to-Surge-to-8-32-Billion-by-2028-Global-Long-term-Forecast-to-2033.html

[16] https://www.wevolver.com/article/smt-process

[17] https://www.pcbelec.com/smt-advantages-and-disadvantages.html

[18] https://www.pcbcart.com/article/content/smt-assembly-development-trend.html

[19] https://www.vse.com/blog/2022/03/15/8-common-smt-placement-issues-and-solutions/

[20] https://www.rhsmt.com/news/smt-industrys-future-trends-the-impact-of-ai-and-automation/

[21] https://www.pcbonline.com/blog/smt-manufacturing-process.html

[22] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[23] https://smt.fuji.co.jp/en/topics/2858

[24] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[25] https://www.linkedin.com/pulse/smt-most-advanced-technology-future-devices-adrif

[26] https://mermarinc.com/2022/12/24/smt-line/

[27] https://www.sonicmfg.com/what-are-the-advantages-of-surface-mount-technology-in-pcba/

[28] https://www.linkedin.com/pulse/surface-mount-technology-smt-assembly-line-market-dynamics-ulqle/

[29] https://www.pcbjhy.com/blog/pros-and-cons-of-smt-pcb-assembly/

[30] https://www.renishaw.com/resourcecentre/tw/download/feature-article-why-future-smt-placement-needs-absolute-encoder-feedback--84260

[31] https://www.linkedin.com/pulse/ins-outs-setting-up-smt-factory-prototype-pcb-assembly-yljdc

[32] https://www.linkedin.com/pulse/advantages-smt-manufacturing-practical-cost-effective-nyn3c

[33] https://www.linkedin.com/pulse/optimization-challenges-smt-component-9zfsc