Content Menu

● Understanding the LED SMT PCB Loader

>> Key Components of an LED SMT PCB Loader

>> How It Works

● Efficiency Improvements Brought by LED SMT PCB Loaders

>> 1. Increased Production Speed

>> 2. Enhanced Accuracy and Consistency

>> 3. Reduced Labor Costs

>> 4. Minimized Downtime

>> 5. Versatility in Handling

● Advanced Features of LED SMT PCB Loaders

>> 1. Intelligent Control Systems

>> 2. Multiple Magazine Capacity

>> 3. Adjustable Lifting Distances

>> 4. Integration with IoT and Industry 4.0

>> 5. Enhanced Safety Features

● Impact on LED Manufacturing Industry

>> 1. Increased Production Capacity

>> 2. Improved Product Quality

>> 3. Cost Reduction

>> 4. Enhanced Competitiveness

>> 5. Facilitating Miniaturization

● Case Study: Implementing LED SMT PCB Loader in Production

>> Background

>> Solution

>> Results

● Future Trends in LED SMT PCB Loader Technology

>> 1. AI and Machine Learning Integration

>> 2. Enhanced Connectivity

>> 3. Increased Flexibility

>> 4. Sustainability Features

>> 5. Advanced Vision Systems

● Challenges and Considerations

>> 1. Initial Investment

>> 2. Training Requirements

>> 3. Integration with Existing Systems

>> 4. Maintenance and Downtime

>> 5. Keeping Pace with Technological Advancements

● Conclusion

● FAQ

>> 1. What is the main purpose of an LED SMT PCB loader?

>> 2. How does an LED SMT PCB loader improve manufacturing efficiency?

>> 3. What are the key components of an LED SMT PCB loader?

>> 4. Can LED SMT PCB loaders handle different sizes of PCBs?

>> 5. What future trends can we expect in LED SMT PCB loader technology?

● Citations:

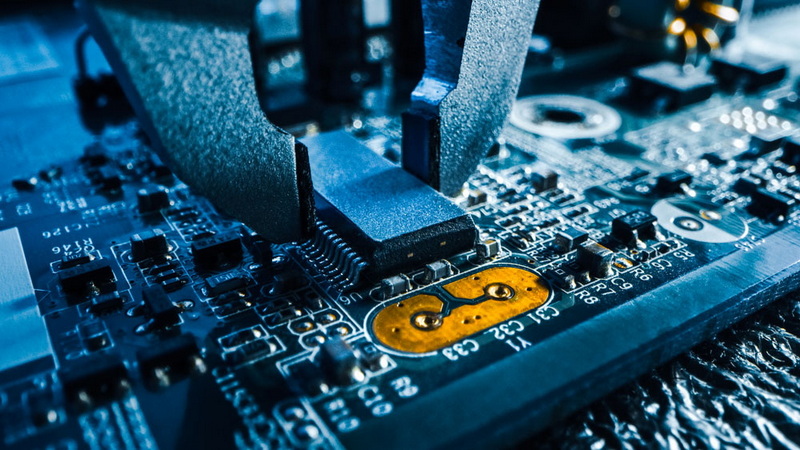

In the rapidly evolving world of electronics manufacturing, efficiency and precision are paramount. One of the key technologies driving these improvements is the LED SMT PCB loader. This sophisticated piece of equipment has revolutionized the way printed circuit boards (PCBs) are handled in the production of light-emitting diode (LED) products. Let's delve into the intricacies of this technology and explore how it enhances manufacturing efficiency.

Understanding the LED SMT PCB Loader

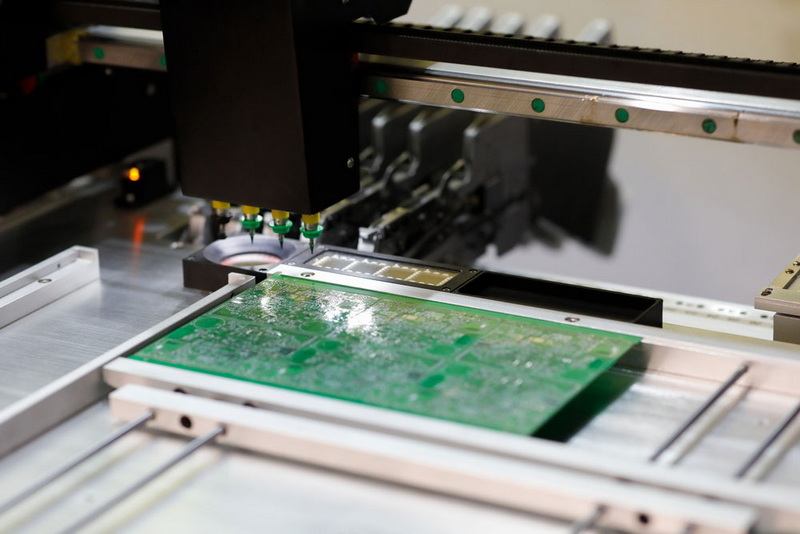

The LED SMT PCB loader is a specialized machine designed to automate the process of loading PCBs into surface mount technology (SMT) production lines[1]. It's a critical component in the manufacturing of LED products, which are increasingly prevalent in various applications, from lighting to displays.

Key Components of an LED SMT PCB Loader

1. Magazine System: This component holds stacks of PCBs ready for loading.

2. Lifting Mechanism: Typically uses a screw rod driven by an electric-brake motor to lift PCBs[7].

3. Conveyor System: Transports PCBs from the magazine to the production line.

4. Control System: Often employs a programmable logic controller (PLC) for precise operation[4].

5. Sensors: Detect PCB presence and ensure proper alignment.

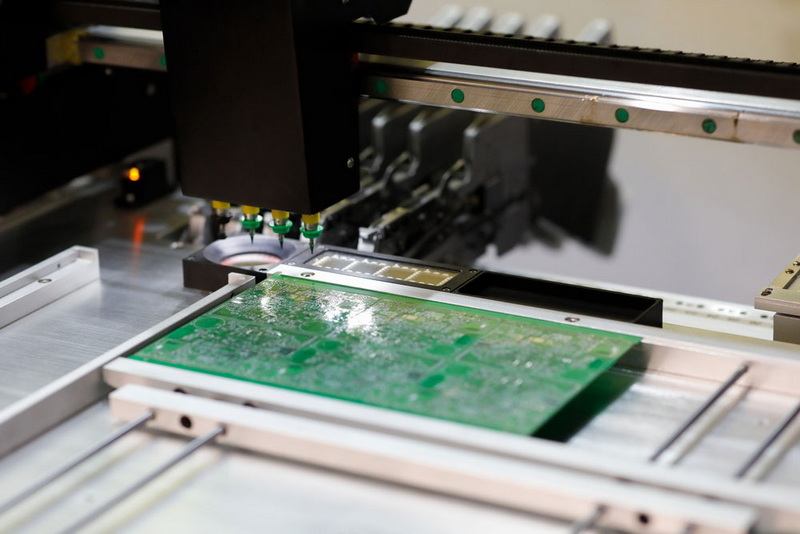

How It Works

The LED SMT PCB loader operates through a series of coordinated steps:

1. PCBs are stacked in magazines, which are loaded into the machine.

2. The lifting mechanism raises the stack of PCBs to the appropriate height.

3. A vacuum system or mechanical arm picks up the topmost PCB.

4. The PCB is then precisely placed onto the conveyor system.

5. The conveyor transports the PCB to the next stage of the SMT process.

This process repeats continuously, ensuring a steady supply of PCBs to the production line.

Efficiency Improvements Brought by LED SMT PCB Loaders

The introduction of LED SMT PCB loaders has significantly enhanced manufacturing efficiency in several ways:

1. Increased Production Speed

By automating the PCB loading process, these machines dramatically increase the speed at which PCBs can be fed into the production line[5]. This reduction in loading time translates directly to higher production rates.

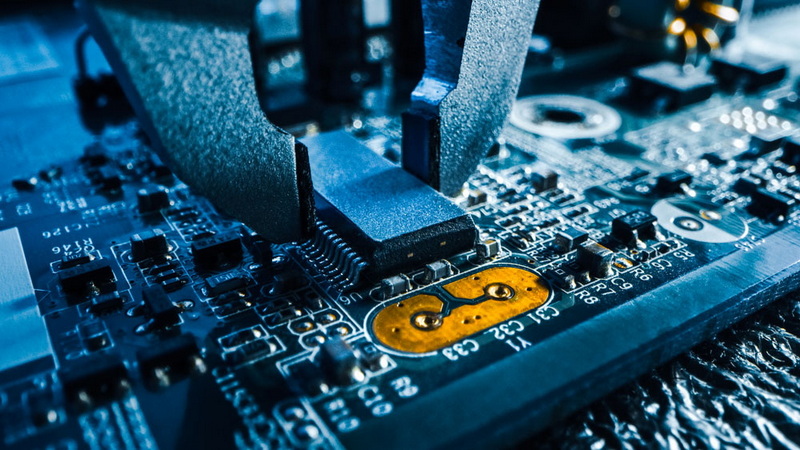

2. Enhanced Accuracy and Consistency

Manual loading of PCBs can lead to inconsistencies and potential damage. LED SMT PCB loaders ensure each board is handled with precision, reducing the likelihood of defects and improving overall product quality[5].

3. Reduced Labor Costs

Automating the loading process reduces the need for manual labor, allowing manufacturers to allocate human resources to more complex tasks. This not only cuts costs but also minimizes the risk of repetitive strain injuries associated with manual loading.

4. Minimized Downtime

LED SMT PCB loaders can operate continuously without breaks, unlike human operators. This continuous operation minimizes production line stoppages, leading to increased overall efficiency.

5. Versatility in Handling

Modern LED SMT PCB loaders can handle a variety of PCB sizes and thicknesses, making them versatile tools in production lines that manufacture different types of LED products[5].

Advanced Features of LED SMT PCB Loaders

As technology advances, LED SMT PCB loaders are incorporating more sophisticated features to further enhance efficiency:

1. Intelligent Control Systems

Many loaders now use advanced PLC systems with color man-machine interfaces, allowing for easy operation and real-time monitoring of the loading process[4].

2. Multiple Magazine Capacity

Some loaders can accommodate multiple magazines simultaneously, reducing the frequency of magazine changes and further minimizing downtime[7].

3. Adjustable Lifting Distances

To accommodate different PCB thicknesses, many loaders offer adjustable lifting distances, typically ranging from 10mm to 50mm[7].

4. Integration with IoT and Industry 4.0

The latest LED SMT PCB loaders are being designed with connectivity in mind, allowing them to communicate with other equipment in the assembly line and contribute to a more integrated, data-driven manufacturing process[2].

5. Enhanced Safety Features

Modern loaders incorporate various safety mechanisms, including acoustic and optical alarm systems, to alert operators of any issues promptly[4].

Impact on LED Manufacturing Industry

The adoption of LED SMT PCB loaders has had a profound impact on the LED manufacturing industry:

1. Increased Production Capacity

With faster and more efficient PCB loading, manufacturers can significantly increase their production capacity without necessarily expanding their physical footprint.

2. Improved Product Quality

The precision and consistency offered by automated loaders have led to a reduction in defects and an overall improvement in product quality.

3. Cost Reduction

While the initial investment in an LED SMT PCB loader may be significant, the long-term cost savings in terms of reduced labor, lower defect rates, and increased production efficiency often result in a rapid return on investment.

4. Enhanced Competitiveness

Manufacturers who adopt this technology gain a competitive edge in terms of production speed, quality, and cost-effectiveness.

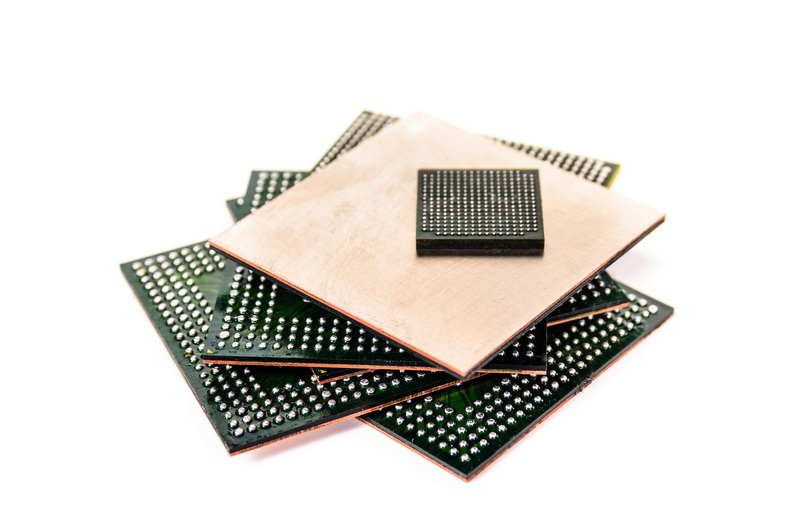

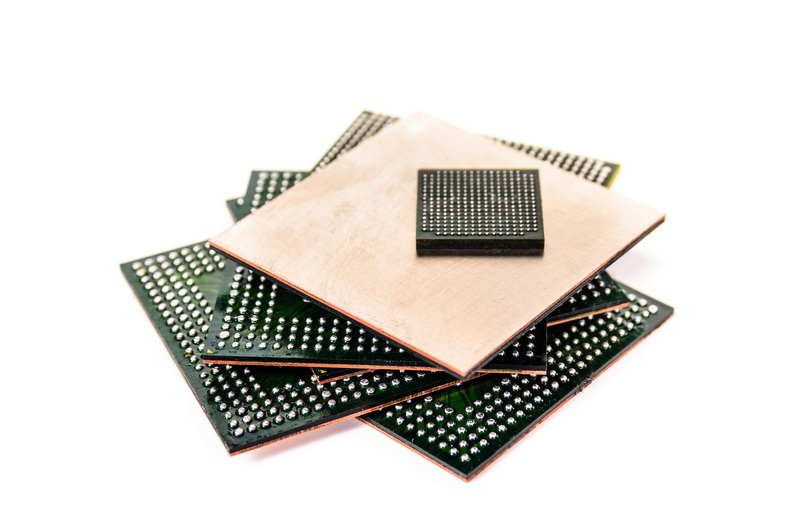

5. Facilitating Miniaturization

As LED products continue to shrink in size, the precision offered by automated loaders becomes increasingly crucial in handling smaller, more delicate PCBs.

Case Study: Implementing LED SMT PCB Loader in Production

To illustrate the real-world impact of LED SMT PCB loaders, let's consider a case study of a leading LED manufacturer:

Background

A major LED lighting manufacturer was facing challenges with their manual PCB loading process. They were experiencing inconsistencies in production speed, quality issues due to mishandling, and rising labor costs.

Solution

The company invested in a state-of-the-art LED SMT PCB loader, integrating it into their existing SMT production line.

Results

After implementing the LED SMT PCB loader, the company observed:

1. A 40% increase in production speed

2. A 30% reduction in PCB-related defects

3. Labor cost savings of approximately 25%

4. Improved consistency in product quality

5. Enhanced ability to handle rush orders due to increased production flexibility

This case study demonstrates the tangible benefits that LED SMT PCB loaders can bring to manufacturing operations.

Future Trends in LED SMT PCB Loader Technology

As we look to the future, several trends are emerging in LED SMT PCB loader technology:

1. AI and Machine Learning Integration

Future loaders may incorporate AI algorithms to optimize loading patterns, predict maintenance needs, and adapt to different PCB types automatically.

2. Enhanced Connectivity

With the growth of Industry 4.0, LED SMT PCB loaders will likely become more integrated with other production line equipment, allowing for seamless data exchange and process optimization[2].

3. Increased Flexibility

As product lifecycles shorten and customization becomes more common, loaders will need to be increasingly flexible, capable of handling a wider variety of PCB types and sizes without significant retooling.

4. Sustainability Features

Future loaders may incorporate energy-saving features and use more sustainable materials in their construction, aligning with growing environmental concerns in manufacturing.

5. Advanced Vision Systems

The integration of sophisticated vision systems could allow loaders to perform quality checks on PCBs as they are being loaded, further streamlining the production process.

Challenges and Considerations

While LED SMT PCB loaders offer numerous benefits, there are also challenges to consider:

1. Initial Investment

The upfront cost of purchasing and installing an LED SMT PCB loader can be significant, which may be a barrier for smaller manufacturers.

2. Training Requirements

Operators need to be trained to use and maintain these sophisticated machines effectively, which requires time and resources.

3. Integration with Existing Systems

Incorporating a new loader into an existing production line may require adjustments to other equipment or processes.

4. Maintenance and Downtime

While these machines can increase overall uptime, when they do require maintenance, the entire production line may be affected.

5. Keeping Pace with Technological Advancements

As loader technology continues to evolve rapidly, manufacturers may face pressure to upgrade their equipment frequently to stay competitive.

Conclusion

The LED SMT PCB loader represents a significant advancement in electronics manufacturing technology. By automating the PCB loading process, these machines have dramatically improved efficiency, accuracy, and consistency in LED production lines. They have enabled manufacturers to increase production speeds, reduce labor costs, and improve product quality.

As we look to the future, LED SMT PCB loaders are likely to become even more sophisticated, incorporating AI, enhanced connectivity, and advanced vision systems. While challenges such as initial investment and integration exist, the benefits of these machines far outweigh the drawbacks for many manufacturers.

For companies in the LED industry, investing in LED SMT PCB loader technology is not just about improving current operations; it's about preparing for a future where automation, precision, and efficiency will be key to remaining competitive in a rapidly evolving market.

FAQ

1. What is the main purpose of an LED SMT PCB loader?

The main purpose of an LED SMT PCB loader is to automate the process of loading printed circuit boards (PCBs) into surface mount technology (SMT) production lines for LED manufacturing. It enhances efficiency by increasing speed, improving accuracy, and reducing labor costs in the PCB assembly process[1].

2. How does an LED SMT PCB loader improve manufacturing efficiency?

An LED SMT PCB loader improves manufacturing efficiency by:

- Increasing production speed through automated loading

- Enhancing accuracy and consistency in PCB placement

- Reducing labor costs and the risk of human error

- Minimizing production line downtime

- Handling a variety of PCB sizes and thicknesses, offering versatility in production[5]

3. What are the key components of an LED SMT PCB loader?

The key components of an LED SMT PCB loader typically include:

- A magazine system for holding PCBs

- A lifting mechanism (often using a screw rod and electric-brake motor)

- A conveyor system for transporting PCBs

- A control system (usually a PLC)

- Sensors for detecting PCB presence and alignment[4][7]

4. Can LED SMT PCB loaders handle different sizes of PCBs?

Yes, modern LED SMT PCB loaders are designed to handle a variety of PCB sizes and thicknesses. Many loaders offer adjustable lifting distances, typically ranging from 10mm to 50mm, to accommodate different PCB specifications. This versatility makes them suitable for production lines that manufacture different types of LED products[5][7].

5. What future trends can we expect in LED SMT PCB loader technology?

Future trends in LED SMT PCB loader technology may include:

- Integration of AI and machine learning for optimized loading and predictive maintenance

- Enhanced connectivity with other production line equipment as part of Industry 4.0

- Increased flexibility to handle a wider variety of PCB types without retooling

- Incorporation of sustainability features and energy-saving mechanisms

- Advanced vision systems for real-time quality checks during the loading process[2]

Citations:

[1] https://ko.hct-smt.com/blog/led-smd-pcb-loader--enhancing-efficiency-and-automation-in-manufacturing-processes

[2] https://www.hct-smt.com/blog/maximizing-efficiency-with-the-smd-pcb-loader-set--a-comprehensive-guide

[3] https://www.cgtrader.com/free-3d-models/industrial/industrial-machine/smt-solutions-for-led-pcb-assembly-pick-and-place-machine

[4] https://www.smtmountingmachine.com/quality-14247222-plc-led-light-production-line-vacuum-loader-pcb-loader-machine

[5] https://www.hct-smt.com/blog/the-ultimate-guide-to-led-smd-pcb-loaders--everything-you-need-to-know

[6] https://www.ti.com.cn/cn/lit/ug/zhcu582/zhcu582.pdf?ts=1730994493738

[7] https://www.flason-smt.com/product/SMT-PCB-Loader.html

[8] https://www.zjyingxing.com/info/what-are-the-ways-to-improve-the-efficiency-of-88896111.html