Content Menu

● Introduction

● Understanding PCB Making Machines

>> Types of PCB Making Machines

● The Role of PCB Making Machines in SMT Production

>> SMT Process Overview

>> Advanced SMT Techniques

● Advantages of Using PCB Making Machines in SMT Production

● Key Features of Modern PCB Making Machines

>> 1. Computer Numerical Control (CNC)

>> 2. Vision Systems

>> 3. Multi-Layer Capability

>> 4. Automatic Tool Changing

>> 5. Software Integration

>> 6. Real-Time Monitoring and Data Analytics

>> 7. Modular Design

● The Impact of PCB Making Machines on Electronics Manufacturing

>> Miniaturization of Devices

>> Increased Functionality

>> Improved Reliability

>> Faster Time-to-Market

>> Customization and Prototyping

● Challenges and Considerations

● Future Trends in PCB Making Machines and SMT Production

>> 1. Industry 4.0 Integration

>> 2. Artificial Intelligence and Machine Learning

>> 3. Eco-Friendly Production

>> 4. Flexible Manufacturing

>> 5. 3D Printed Electronics

>> 6. Nanotechnology Integration

>> 7. Augmented Reality (AR) Assisted Maintenance

● Conclusion

● FAQ

>> 1. What are the main types of PCB making machines used in SMT production?

>> 2. How do PCB making machines improve the efficiency of SMT production?

>> 3. What are the key considerations when choosing a PCB making machine for SMT production?

>> 4. How has the evolution of PCB making machines impacted the electronics industry?

>> 5. What are the future trends in PCB making machines for SMT production?

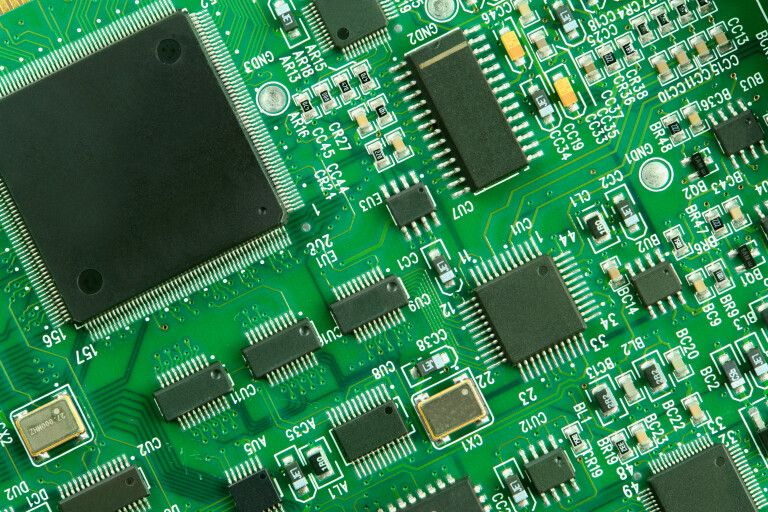

Introduction

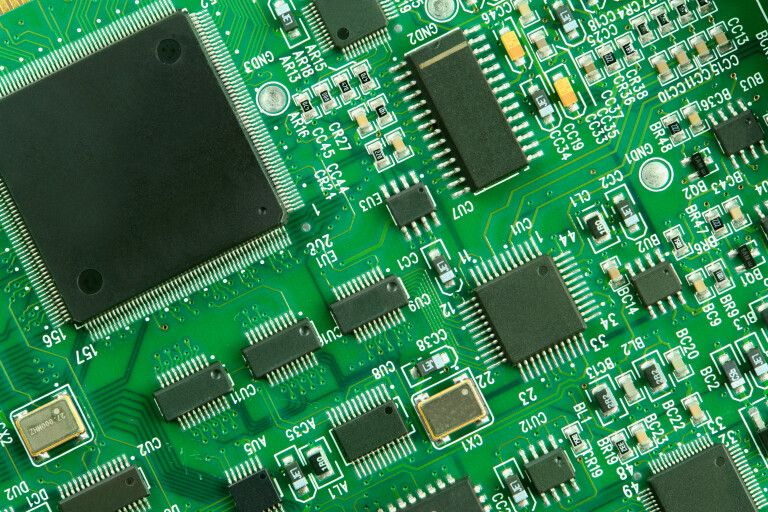

Printed Circuit Boards (PCBs) are the backbone of modern electronics, serving as the foundation for countless devices we use daily. The production of these essential components has been revolutionized by the introduction of PCB making machines and Surface Mount Technology (SMT) production techniques. This article will explore the intricacies of PCB making machines, their role in SMT production, and how they have transformed the electronics manufacturing industry.

Understanding PCB Making Machines

PCB making machines are sophisticated pieces of equipment designed to automate and streamline the process of manufacturing printed circuit boards. These machines are capable of handling various stages of PCB production, from design implementation to the final assembly of components.

Types of PCB Making Machines

There are several types of PCB making machines, each specializing in different aspects of the manufacturing process:

1. CNC Drilling Machines: These machines create precise holes in the PCB substrate for component leads and vias.

2. Exposure Units: Used to transfer the circuit design onto the photoresist-coated PCB.

3. Etching Machines: Remove unwanted copper from the board, leaving only the desired circuit patterns.

4. Solder Mask Applicators: Apply a protective layer to the PCB, preventing solder from bridging between connections.

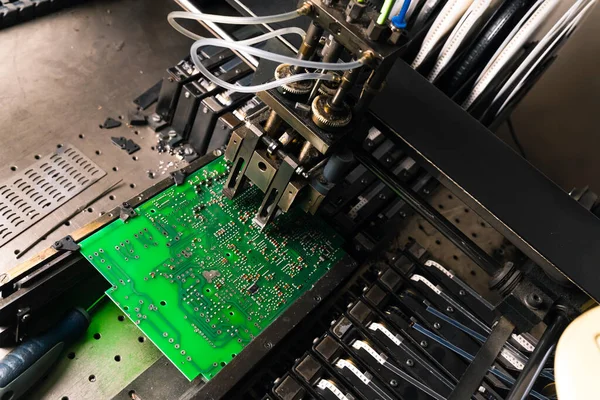

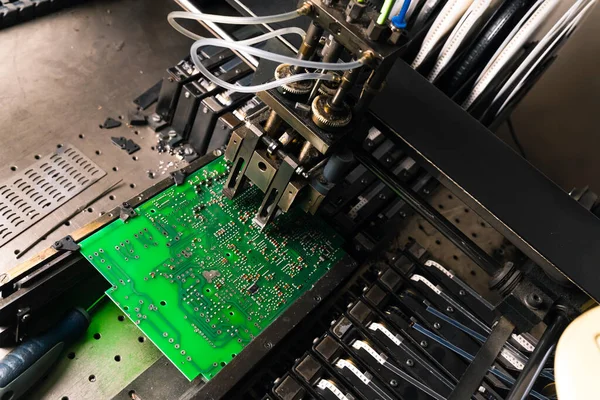

5. Pick and Place Machines: Essential for SMT production, these machines accurately place components onto the PCB.

The Role of PCB Making Machines in SMT Production

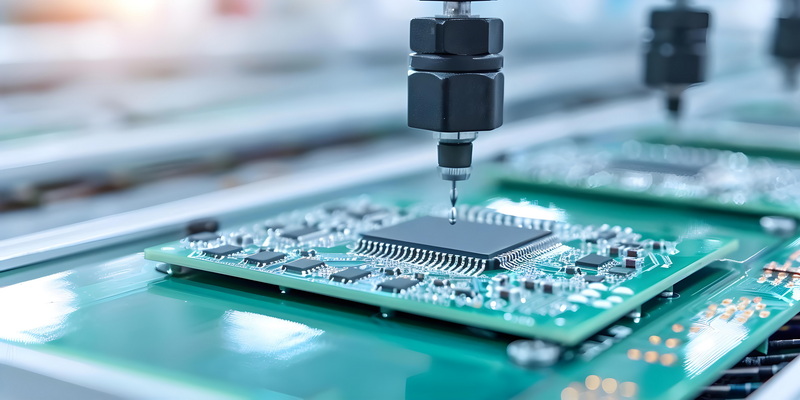

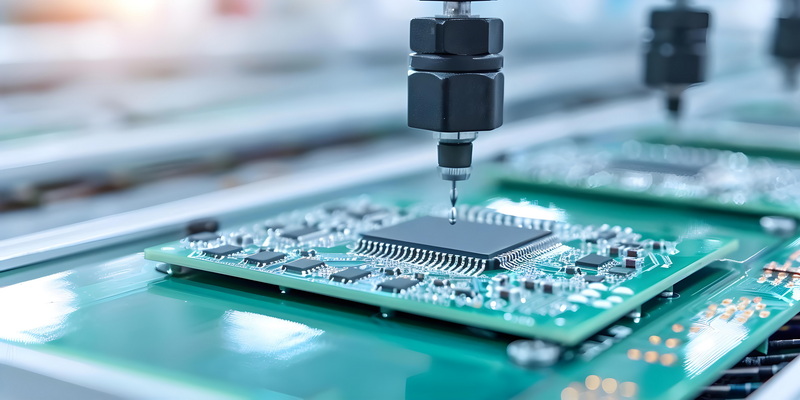

Surface Mount Technology (SMT) has become the standard for modern PCB assembly due to its efficiency and ability to work with smaller components. PCB making machines play a crucial role in the SMT production process.

SMT Process Overview

1. Solder Paste Printing: A PCB making machine known as a stencil printer applies solder paste to the board's surface.

2. Component Placement: Pick and place machines, a type of PCB making machine, accurately position SMT components onto the board.

3. Reflow Soldering: The PCB passes through a reflow oven, melting the solder paste and securing the components.

4. Inspection: Automated optical inspection (AOI) machines check for defects or misalignments.

5. Testing: Electrical testing ensures the PCB functions as intended.

Advanced SMT Techniques

In addition to the basic SMT process, advanced PCB making machines incorporate cutting-edge techniques to enhance production:

1. 3D Solder Paste Inspection: This technology uses laser scanning to measure the volume and height of solder paste deposits, ensuring optimal solder joint formation.

2. Component Traceability: Modern pick and place machines can track individual components throughout the assembly process, improving quality control and facilitating recalls if necessary.

3. Inline X-ray Inspection: Some PCB making machines integrate X-ray inspection capabilities to detect hidden defects in solder joints, particularly useful for ball grid array (BGA) components.

Advantages of Using PCB Making Machines in SMT Production

The integration of PCB making machines in SMT production offers numerous benefits:

1. Increased Precision: Machines can place components with accuracy impossible to achieve manually.

2. Higher Production Rates: Automated processes significantly speed up manufacturing times.

3. Consistency: Machine-driven production ensures uniform quality across large batches.

4. Miniaturization: SMT and PCB making machines enable the creation of smaller, more complex circuits.

5. Cost-Effectiveness: Despite initial investment, automation reduces labor costs and material waste in the long run.

6. Flexibility: Modern PCB making machines can quickly adapt to different board designs and component types, allowing for efficient small-batch production.

7. Enhanced Quality Control: Integrated inspection systems catch defects early in the production process, reducing waste and improving overall quality.

Key Features of Modern PCB Making Machines

Today's PCB making machines are equipped with advanced features that enhance their performance and versatility:

1. Computer Numerical Control (CNC)

CNC technology allows for precise control of machine operations, ensuring accuracy in drilling, cutting, and component placement.

2. Vision Systems

Integrated cameras and image processing software enable machines to align components and inspect for quality with high precision.

3. Multi-Layer Capability

Advanced PCB making machines can handle the production of multi-layer boards, essential for complex electronic devices.

4. Automatic Tool Changing

This feature allows machines to switch between different tools without manual intervention, increasing efficiency.

5. Software Integration

Modern machines integrate with CAD/CAM software, streamlining the transition from design to production.

6. Real-Time Monitoring and Data Analytics

PCB making machines now incorporate sensors and data collection systems that provide real-time insights into production metrics, enabling proactive maintenance and process optimization.

7. Modular Design

Many PCB making machines feature modular construction, allowing manufacturers to easily upgrade or reconfigure their production lines as needs change.

The Impact of PCB Making Machines on Electronics Manufacturing

The adoption of PCB making machines and SMT production has had a profound impact on the electronics industry:

Miniaturization of Devices

By enabling the use of smaller components and more compact layouts, PCB making machines have contributed to the trend of device miniaturization.

Increased Functionality

The precision of PCB making machines allows for more components to be packed into a smaller area, increasing the functionality of electronic devices.

Improved Reliability

Automated production reduces human error, leading to more reliable and consistent PCB assemblies.

Faster Time-to-Market

The speed and efficiency of PCB making machines have significantly reduced production times, allowing companies to bring products to market faster.

Customization and Prototyping

Advanced PCB making machines have made it easier for manufacturers to produce small batches of custom PCBs, facilitating rapid prototyping and innovation in product development.

Challenges and Considerations

While PCB making machines offer numerous advantages, there are challenges to consider:

1. Initial Investment: High-quality PCB making machines can be expensive, requiring significant upfront capital.

2. Maintenance and Training: Regular maintenance and skilled operators are necessary to keep machines running efficiently.

3. Rapid Technological Advancements: The fast pace of technological change can make machines obsolete quickly.

4. Environmental Concerns: Proper disposal of chemicals and materials used in PCB production is crucial.

5. Supply Chain Dependencies: The complexity of PCB making machines often means reliance on specialized components and materials, which can be affected by supply chain disruptions.

6. Energy Consumption: Advanced PCB making machines can be energy-intensive, necessitating considerations for power management and efficiency.

Future Trends in PCB Making Machines and SMT Production

The future of PCB making machines and SMT production looks promising, with several emerging trends:

1. Industry 4.0 Integration

PCB making machines are becoming increasingly connected, with IoT capabilities for real-time monitoring and predictive maintenance.

2. Artificial Intelligence and Machine Learning

AI algorithms are being integrated into PCB making machines to optimize production processes and improve quality control.

3. Eco-Friendly Production

Manufacturers are developing more environmentally friendly PCB making machines and processes to reduce the industry's ecological footprint.

4. Flexible Manufacturing

PCB making machines are evolving to handle a wider variety of board types and sizes, allowing for more versatile production lines.

5. 3D Printed Electronics

Advancements in 3D printing technology are being incorporated into PCB making machines, opening up new possibilities for circuit design and production.

6. Nanotechnology Integration

The integration of nanotechnology in PCB making machines is expected to enable the production of even smaller and more efficient electronic components.

7. Augmented Reality (AR) Assisted Maintenance

AR technology is being developed to assist technicians in maintaining and repairing complex PCB making machines, reducing downtime and improving efficiency.

Conclusion

PCB making machines have revolutionized the electronics manufacturing industry, particularly in the realm of SMT production. These sophisticated devices have enabled the creation of smaller, more complex, and more reliable electronic components, driving innovation across various sectors. As technology continues to advance, PCB making machines will undoubtedly evolve, further enhancing their capabilities and efficiency.

The integration of PCB making machines in SMT production has not only improved the quality and consistency of PCBs but has also significantly reduced production times and costs. This has allowed manufacturers to meet the ever-increasing demand for electronic devices while maintaining high standards of quality and reliability.

As we look to the future, the continued development of PCB making machines will play a crucial role in shaping the electronics industry. From the integration of AI and IoT technologies to the adoption of more sustainable manufacturing practices, these machines will continue to be at the forefront of innovation in electronics production. The ongoing advancements in PCB making machines promise to unlock new possibilities in electronic design and functionality, paving the way for the next generation of smart devices and technologies.

FAQ

1. What are the main types of PCB making machines used in SMT production?

The main types of PCB making machines used in SMT production include:

- Solder paste printers

- Pick and place machines

- Reflow ovens

- Automated optical inspection (AOI) machines

- Wave soldering machines (for through-hole components)

2. How do PCB making machines improve the efficiency of SMT production?

PCB making machines improve SMT production efficiency by:

- Increasing production speed and throughput

- Enhancing accuracy and precision in component placement

- Reducing human error and inconsistencies

- Enabling the handling of smaller and more complex components

- Automating quality control processes

3. What are the key considerations when choosing a PCB making machine for SMT production?

When selecting a PCB making machine for SMT production, consider:

- Production volume requirements

- Types of components to be handled

- Board size and complexity capabilities

- Integration with existing systems

- Maintenance and support availability

- Cost and return on investment

4. How has the evolution of PCB making machines impacted the electronics industry?

The evolution of PCB making machines has impacted the electronics industry by:

- Enabling the production of smaller and more complex devices

- Increasing production speeds and reducing time-to-market

- Improving overall product quality and reliability

- Reducing manufacturing costs through automation

- Facilitating the development of new technologies and applications

5. What are the future trends in PCB making machines for SMT production?

Future trends in PCB making machines for SMT production include:

- Integration of AI and machine learning for process optimization

- Implementation of Industry 4.0 principles for smart manufacturing

- Development of more environmentally friendly production processes

- Increased flexibility to handle a wider range of board types and components

- Advancements in 3D printed electronics integration