Content Menu

● Understanding PCB Loader SMT Machines

>> Key Features of PCB Loader SMT Machines

● How PCB Loader SMT Machines Work

>> 1. PCB Storage

>> 2. PCB Separation

>> 3. Alignment

>> 4. Transfer

>> 5. Cycle Repetition

● Benefits of Using PCB Loader SMT Machines

>> Increased Productivity

>> Enhanced Accuracy

>> Reduced Labor Costs

>> Consistent Performance

>> Flexibility

● Key Components of PCB Loader SMT Machines

>> 1. Frame and Structure

>> 2. PLC Control System

>> 3. User Interface

>> 4. Conveyor System

>> 5. Safety Features

● Integration with SMT Production Lines

● Advancements in PCB Loader SMT Machine Technology

>> 1. Enhanced Vision Systems

>> 2. IoT Integration

>> 3. Increased Speed and Capacity

>> 4. Improved User Interfaces

● Choosing the Right PCB Loader SMT Machine

● Conclusion

● FAQ

>> 1. What is the main function of a PCB Loader SMT Machine?

>> 2. How does a PCB Loader SMT Machine improve production efficiency?

>> 3. What types of PCBs can be handled by a PCB Loader SMT Machine?

>> 4. How does a PCB Loader SMT Machine integrate with other equipment in the production line?

>> 5. What maintenance is required for a PCB Loader SMT Machine?

● Citations:

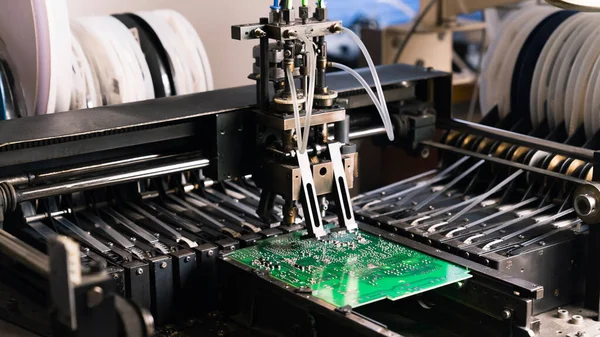

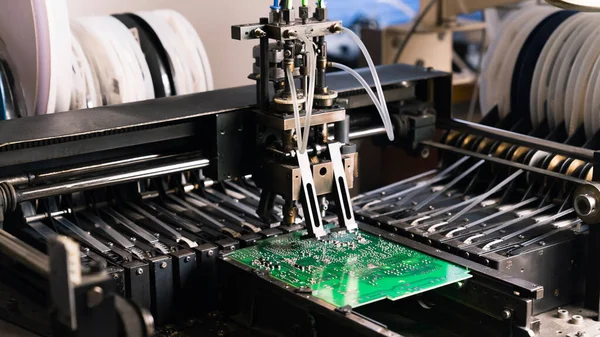

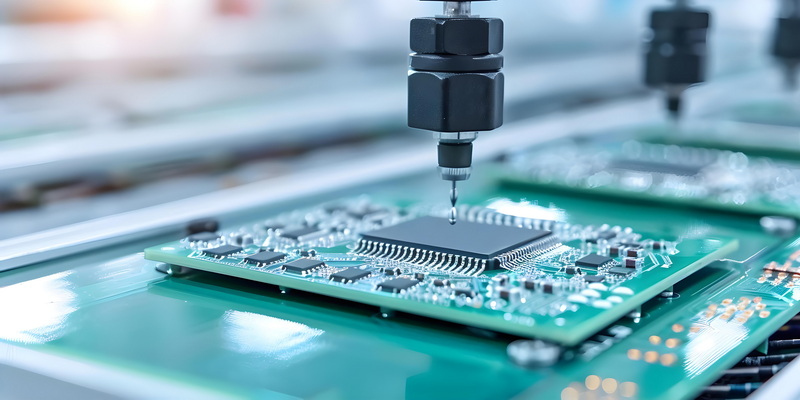

In the world of electronics manufacturing, efficiency and precision are paramount. One of the key components in achieving these goals is the PCB Loader SMT Machine. This sophisticated piece of equipment plays a crucial role in the Surface Mount Technology (SMT) production line, streamlining the process of loading Printed Circuit Boards (PCBs) for component placement and soldering.

Understanding PCB Loader SMT Machines

A PCB Loader SMT Machine, also known as an SMT PCB Loader or Automatic PCB Loader, is a specialized device designed to automate the process of loading PCBs onto the SMT production line[1]. These machines are essential in modern electronics manufacturing, where high-volume production and consistent quality are required.

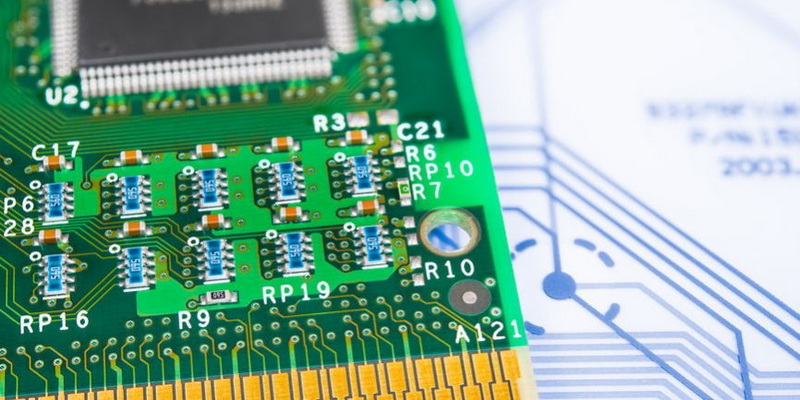

Key Features of PCB Loader SMT Machines

1. Automation: PCB Loader SMT Machines eliminate the need for manual loading, significantly reducing human error and increasing production speed[3].

2. Precision: These machines are equipped with advanced alignment systems to ensure accurate placement of PCBs onto the conveyor belt[1].

3. Efficiency: By automating the loading process, these machines can handle multiple PCBs simultaneously, greatly improving production efficiency[3].

4. Versatility: Most PCB Loader SMT Machines can accommodate various PCB sizes and types, making them suitable for diverse manufacturing needs[3].

5. Integration: These loaders are designed to seamlessly integrate with other components of the SMT production line, such as stencil printers and pick-and-place machines[2].

How PCB Loader SMT Machines Work

The operation of a PCB Loader SMT Machine involves several key steps:

1. PCB Storage

PCBs are typically stored in magazines or stacks within the loader. The machine is designed to hold a significant number of PCBs, often with a stack height of up to 250mm[4].

2. PCB Separation

The loader uses a mechanism, often involving vacuum suction or mechanical grippers, to separate individual PCBs from the stack[9].

3. Alignment

Once separated, the PCB is precisely aligned using sensors or vision systems to ensure it is correctly positioned for the next stage of production[1].

4. Transfer

The aligned PCB is then transferred onto the conveyor belt of the SMT production line. This transfer is typically done using a combination of motorized rollers and pneumatic systems[6].

5. Cycle Repetition

After successfully loading a PCB, the machine repeats the process, continuously feeding PCBs into the production line. The cycle time for loading a single PCB is typically around 6 seconds[4].

Benefits of Using PCB Loader SMT Machines

Incorporating PCB Loader SMT Machines into the production line offers numerous advantages:

Increased Productivity

By automating the loading process, these machines significantly reduce the time required to feed PCBs into the production line. This automation allows for continuous operation, minimizing downtime and maximizing output[3].

Enhanced Accuracy

Manual loading of PCBs can lead to misalignment and potential damage. PCB Loader SMT Machines use precise mechanisms to ensure each board is correctly positioned, reducing errors and improving overall product quality[1].

Reduced Labor Costs

Automating the PCB loading process reduces the need for manual labor, allowing manufacturers to allocate human resources to more complex tasks. This not only cuts down on labor costs but also minimizes the risk of repetitive strain injuries associated with manual loading[3].

Consistent Performance

Unlike human operators who may tire or lose focus over time, PCB Loader SMT Machines maintain consistent performance throughout the production cycle. This consistency leads to more reliable output and fewer variations in product quality[3].

Flexibility

Many PCB Loader SMT Machines are designed to handle a variety of PCB sizes and types. This flexibility allows manufacturers to switch between different products without significant downtime for machine reconfiguration[3].

Key Components of PCB Loader SMT Machines

To understand how these machines function, it's important to examine their key components:

1. Frame and Structure

PCB Loader SMT Machines are typically constructed using high-strength materials such as steel plates and aviation-grade aluminum profiles. This robust construction ensures stability and longevity, even under continuous operation[10].

2. PLC Control System

The Programmable Logic Controller (PLC) is the brain of the PCB Loader SMT Machine. It manages all operations, from PCB separation to transfer, ensuring precise timing and coordination[4].

3. User Interface

Most modern PCB Loader SMT Machines feature a touch screen interface for easy operation and monitoring. This interface allows operators to adjust settings, monitor performance, and troubleshoot issues[10].

4. Conveyor System

The conveyor system, often featuring ESD (Electrostatic Discharge) belts, is responsible for moving PCBs from the loader onto the main production line[10].

5. Safety Features

To protect both operators and PCBs, these machines often include safety features such as emergency stop buttons, safety door locks, and enclosed designs[10].

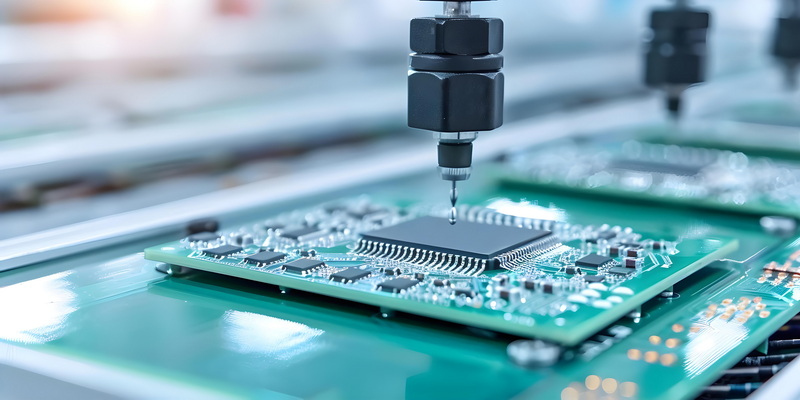

Integration with SMT Production Lines

PCB Loader SMT Machines are designed to seamlessly integrate with other components of the SMT production line. They typically feature standard SMEMA (Surface Mount Equipment Manufacturers Association) interfaces, allowing for easy connection with downstream equipment such as solder paste printers and pick-and-place machines[10].

This integration is crucial for maintaining a smooth and efficient production flow. The loader must be synchronized with the rest of the line to ensure a steady supply of PCBs without causing bottlenecks or delays.

Advancements in PCB Loader SMT Machine Technology

As with many aspects of electronics manufacturing, PCB Loader SMT Machines are continually evolving. Some recent advancements include:

1. Enhanced Vision Systems

Advanced vision systems are being incorporated to improve alignment accuracy and detect defects in PCBs before they enter the production line[3].

2. IoT Integration

Some newer models are equipped with IoT capabilities, allowing for remote monitoring, predictive maintenance, and integration with factory management systems[3].

3. Increased Speed and Capacity

Manufacturers are developing loaders with faster cycle times and larger PCB stack capacities to meet the demands of high-volume production[4].

4. Improved User Interfaces

Touch screen interfaces are becoming more sophisticated, offering more detailed diagnostics and easier programming options[10].

Choosing the Right PCB Loader SMT Machine

Selecting the appropriate PCB Loader SMT Machine for a production line requires careful consideration of several factors:

1. Production Volume: The loader's capacity and speed should match the overall production volume of the line.

2. PCB Specifications: Ensure the loader can accommodate the size range and thickness of the PCBs being produced.

3. Integration Capabilities: The loader should be compatible with existing equipment and easily integrated into the production line.

4. Flexibility: Consider whether the loader can handle different types of PCBs if production needs are likely to change.

5. Maintenance and Support: Look for machines with good reliability records and readily available support and spare parts.

Conclusion

PCB Loader SMT Machines are indispensable components of modern electronics manufacturing. By automating the PCB loading process, these machines significantly enhance production efficiency, accuracy, and consistency. As technology continues to advance, we can expect to see even more sophisticated PCB Loader SMT Machines with improved speed, precision, and integration capabilities.

For manufacturers looking to optimize their SMT production lines, investing in a high-quality PCB Loader SMT Machine is a crucial step towards achieving higher productivity and maintaining a competitive edge in the fast-paced world of electronics manufacturing.

FAQ

1. What is the main function of a PCB Loader SMT Machine?

The main function of a PCB Loader SMT Machine is to automatically load PCBs onto the SMT production line. It takes PCBs from a magazine or stack and transfers them onto the conveyor belt of the next machine in the production line, such as a solder paste printer or pick-and-place machine[1][2].

2. How does a PCB Loader SMT Machine improve production efficiency?

A PCB Loader SMT Machine improves production efficiency by automating the PCB loading process. It can handle multiple PCBs simultaneously, operates faster than manual loading, reduces human error, and allows for continuous operation. This automation leads to increased production speed, reduced downtime, and more consistent output quality[3].

3. What types of PCBs can be handled by a PCB Loader SMT Machine?

Most PCB Loader SMT Machines are designed to handle a variety of PCB sizes and types. Typically, they can accommodate PCBs with dimensions ranging from 50mm x 50mm to 400mm x 350mm, and thicknesses from 0.6mm to 2mm. However, specific capabilities can vary between different models and manufacturers[4].

4. How does a PCB Loader SMT Machine integrate with other equipment in the production line?

PCB Loader SMT Machines are designed to integrate seamlessly with other components of the SMT production line. They usually feature standard SMEMA interfaces, allowing for easy connection with downstream equipment. The loader's operation is synchronized with the rest of the line to ensure a steady supply of PCBs without causing bottlenecks or delays[10].

5. What maintenance is required for a PCB Loader SMT Machine?

Regular maintenance for a PCB Loader SMT Machine typically includes cleaning of the conveyor belts and vacuum systems, checking and tightening of mechanical components, lubrication of moving parts, and calibration of sensors and alignment systems. It's also important to regularly update the machine's software and conduct preventive maintenance as recommended by the manufacturer to ensure optimal performance and longevity[3].

Citations:

[1] https://www.hayawin.com/product-fixture-loading-unloading-machine.html

[2] https://www.zjyingxing.com/info/the-function-of-smt-loader-69563920.html

[3] https://www.hct-smt.com/blog/boost-your-pcb-production-with-smt-automatic-loader-machines

[4] https://cnsmtline.com/pcb-magazine-loader/

[5] https://www.smtsite.com/resources/pcb-loader-unloader-improve-efficiency-and-accuracy.html

[6] https://www.zjyingxing.com/info/what-is-the-role-of-loader-and-unloader-in-the-96545010.html

[7] https://www.smtmachine.eu/i-c-t-pcb-magazine-loader-and-smt-unloader/

[8] https://baike.baidu.com/item/%E7%94%B5%E5%AD%90%E7%BB%84%E8%A3%85%E6%8A%80%E6%9C%AF%E4%B8%93%E4%B8%9A%E8%8B%B1%E8%AF%AD/12086345

[9] https://www.sunzontech.com/product/ld-250m-sz-automatic-loader/

[10] https://www.hayawin.com/product-vacuum-loader.html

[11] https://www.smtfactory.com/smt-pcb-magazine-loader-and-unloader-for-smt-production-line.html

[12] https://www.smtneoden.com/news/definition-and-working-principle-of-smt-machine/