Content Menu

>> Introduction to NXT Fuji

>> Key Features of the NXT III

>> Applications of NXT Fuji in Modern Manufacturing

>> Comparative Analysis: NXT II vs. NXT III

>> Benefits of Using NXT Fuji Machines

>> Challenges and Considerations

>> Conclusion

>> Frequently Asked Questions

Introduction to NXT Fuji

The NXT Fuji series is renowned for its high-speed pick-and-place machines designed for assembling electronic components onto printed circuit boards (PCBs). The NXT III, the latest iteration, builds upon its predecessor, the NXT II, offering enhanced capabilities that cater to modern manufacturing demands.

NXT Fuji Machine

Key Features of the NXT III

1. Speed and Efficiency

The NXT III is engineered for speed with its advanced H24G high-speed head, achieving up to 37,500 chips per hour (cph). This marks a 44% improvement over the previous model, making it one of the fastest machines in the market today[1][2].

2. Enhanced Placing Accuracy

One of the standout features of the NXT III is its remarkable placing accuracy of ±0.025 mm. This precision is crucial for handling smaller components, such as 0201 mm parts, which are increasingly common in modern electronics[3][4].

3. Modular Design

The modular design allows manufacturers to configure the machine according to their specific production needs. This flexibility means that companies can easily adapt to changing product lines without extensive downtime or reconfiguration[5][6].

4. User-Friendly Interface

The NXT III boasts an intuitive graphical user interface (GUI) combined with a touchscreen panel. This design minimizes operational errors and streamlines the setup process, making it easier for operators to manage complex tasks efficiently[2][3].

5. Advanced Vision Systems

Equipped with a "flying vision" parts camera, the NXT III enhances part recognition and placement accuracy across various component sizes. This technology ensures that even the smallest parts are placed correctly and quickly[1][4].

Applications of NXT Fuji in Modern Manufacturing

The versatility of the NXT Fuji machines makes them suitable for various industries:

- Consumer Electronics: High-density placements are essential for devices like smartphones and tablets.

- Automotive: The precision required for automotive electronics is met by the advanced capabilities of the NXT III.

- Medical Devices: Reliability and accuracy are critical in medical applications, making these machines ideal for such uses.

- LED Lighting: The ability to handle large parts while maintaining precision is beneficial in LED manufacturing.

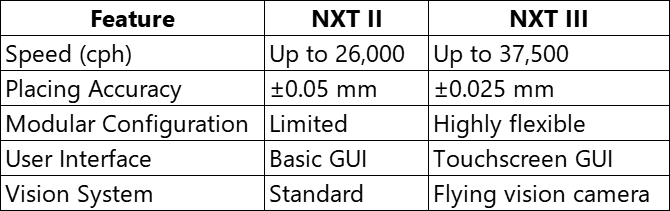

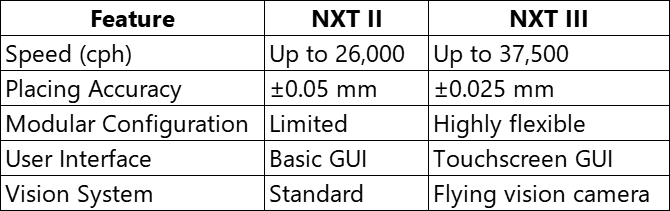

Comparative Analysis: NXT II vs. NXT III

Benefits of Using NXT Fuji Machines

- Increased Productivity: The high-speed capabilities allow manufacturers to increase output without sacrificing quality.

- Reduced Labor Costs: Automation reduces the need for manual intervention, leading to lower labor costs over time.

- Improved Quality Control: Enhanced vision systems and accuracy contribute to fewer defects in produced PCBs.

Challenges and Considerations

While the advancements offered by NXT Fuji machines are substantial, manufacturers must consider:

- Initial Investment Costs: The upfront cost of acquiring advanced machinery can be significant.

- Training Requirements: Operators may need training to effectively utilize new technologies and interfaces.

- Maintenance Needs: Regular maintenance is essential to ensure optimal performance and longevity of equipment.

Conclusion

The NXT Fuji series, especially with its latest model, demonstrates a commitment to innovation in SMT technology. With improved speed, accuracy, and user-friendly features, these machines are setting new standards in electronics manufacturing.

Frequently Asked Questions

1. What is the maximum speed of the NXT III?

- The maximum speed is up to 37,500 chips per hour.

2. What types of components can the NXT III handle?

- It can handle components as small as 0201 mm and larger parts up to 7.5 x 7.5 mm.

3. How does the modular design benefit manufacturers?

- It allows customization based on production needs and facilitates quick changeovers between different product lines.

4. What industries benefit from using NXT Fuji machines?

- Industries such as consumer electronics, automotive, medical devices, and LED lighting benefit significantly.

5. Is training required for operating the NXT III?

- Yes, operators may require training to familiarize themselves with its advanced features and interface.