Content Menu

● Introduction to SMT PCB Assembly

>> Advantages of SMT Assembly

● Innovations in SMT PCB Assembly Line Setups

>> Automation Technologies

>>> Impact of Automation

>> Advanced Materials and Techniques

>>> Role of Advanced Materials

>> Inspection Technologies

>>> Benefits of AOI

>> Data Analytics and AI Integration

>>> Impact of Data Analytics

● Prototype Development in SMT PCB Assembly

>> Benefits of SMT in Prototyping

● Setting Up an SMT Factory for PCB Assembly

>> Key Considerations for Setting Up an SMT Factory

● Future Trends in SMT PCB Assembly

>> Emerging Trends

● Conclusion

● FAQs

>> 1. What is the primary advantage of using SMT over THT in PCB assembly?

>> 2. How does automation impact SMT PCB assembly line setups?

>> 3. What role do advanced materials play in SMT assembly?

>> 4. How does AOI contribute to quality control in SMT assembly?

>> 5. What are the benefits of integrating AI and data analytics in SMT assembly?

● Citations:

The field of electronics manufacturing has witnessed significant transformations in recent years, particularly in the realm of Surface Mount Technology (SMT) PCB assembly. Innovations in SMT assembly line setups have not only enhanced efficiency and accuracy but have also paved the way for more sustainable and environmentally conscious manufacturing practices. This article delves into the latest advancements shaping the future of SMT PCB assembly, focusing on automation, advanced materials, inspection technologies, and data analytics.

Introduction to SMT PCB Assembly

SMT assembly has revolutionized the electronics manufacturing industry by allowing components to be mounted directly onto the surface of printed circuit boards (PCBs). This method has replaced traditional through-hole technology (THT) due to its ability to produce smaller, lighter, and more reliable PCBs. The demand for SMT capabilities continues to grow as electronic devices become increasingly complex and compact.

Advantages of SMT Assembly

1. Compact Design: SMT enables the production of smaller PCBs, which are ideal for modern electronic devices.

2. Increased Reliability: Direct surface mounting reduces the risk of component failure due to wire breakage.

3. Faster Production: Automated SMT lines can assemble components at a much faster rate than manual THT methods.

Innovations in SMT PCB Assembly Line Setups

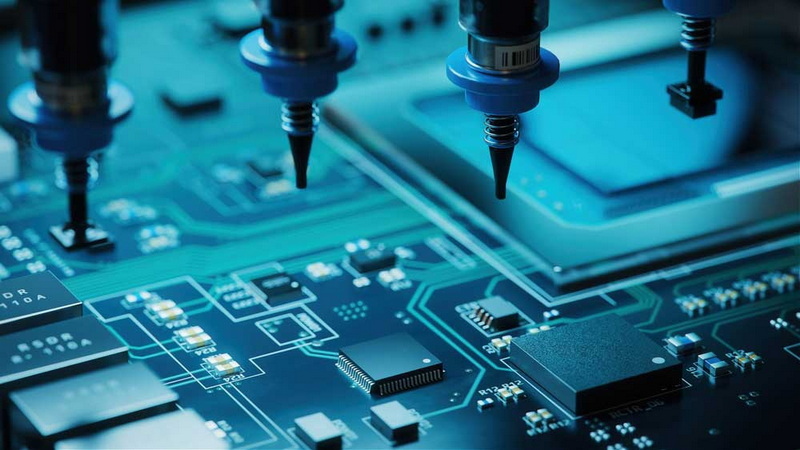

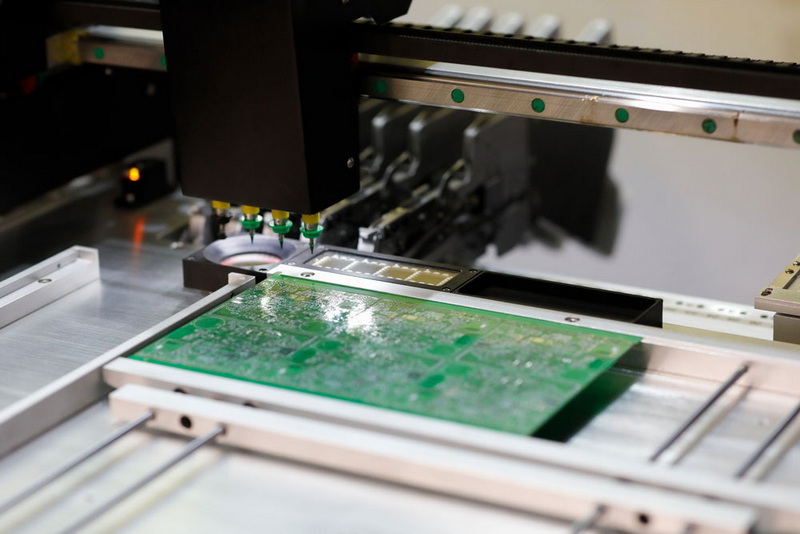

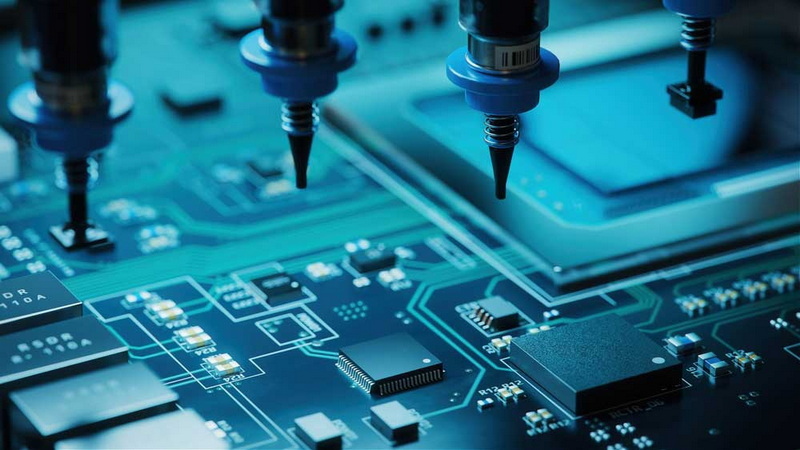

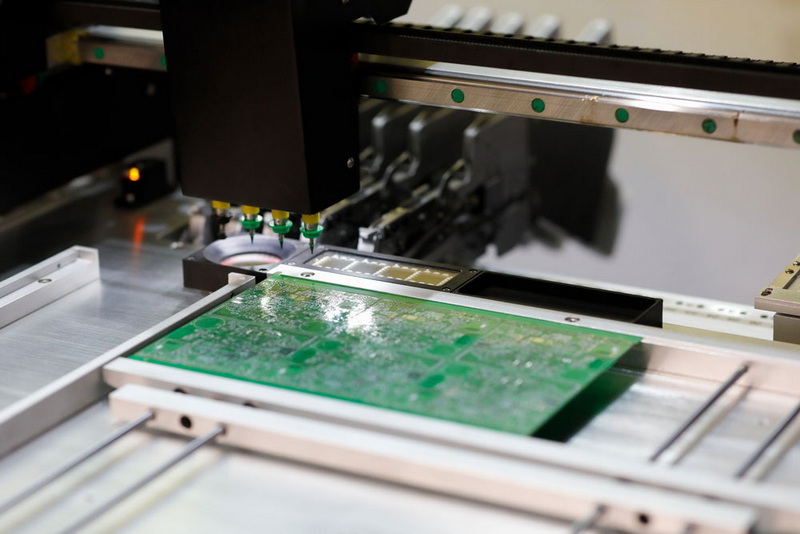

Automation Technologies

Automation is a key driver of innovation in SMT assembly. Advanced pick-and-place machines equipped with vision alignment technology ensure precise component placement, reducing errors and increasing throughput. Robotics and AI-powered systems further enhance production rates and streamline workflows, allowing for real-time monitoring and adjustments during the assembly process.

Impact of Automation

- Streamlined Production: Automation reduces manual labor, minimizing human error and increasing production speed.

- Enhanced Precision: Machines can place components with near-perfect accuracy, improving overall product quality.

Advanced Materials and Techniques

New materials such as low-temperature solder and high-conductivity substrates are being integrated into SMT assembly. These materials enhance the durability and performance of PCBs, allowing them to withstand harsh environmental conditions. Additionally, techniques like vapor phase soldering and conformal coating improve the reliability and longevity of electronic products.

Role of Advanced Materials

- Durability: New materials ensure that PCBs can operate effectively in challenging environments.

- Performance: High-conductivity substrates improve signal integrity and reduce signal loss.

Inspection Technologies

Advanced inspection technologies, such as Automated Optical Inspection (AOI) systems, play a crucial role in maintaining rigorous quality control standards. These systems use machine vision to detect defects early in the production process, reducing waste and improving yield rates. AOI systems are essential for ensuring that every PCB meets stringent industry standards for performance and reliability.

Benefits of AOI

- Early Defect Detection: AOI systems identify issues before they become major problems, saving time and resources.

- Improved Yield Rates: By reducing defects, AOI systems help increase the number of usable PCBs produced.

Data Analytics and AI Integration

The integration of data analytics and AI in SMT assembly facilitates real-time monitoring and predictive maintenance. AI algorithms can analyze production data to detect anomalies, optimize workflows, and predict equipment failures. This proactive approach minimizes downtime and enhances overall production efficiency.

Impact of Data Analytics

- Predictive Maintenance: AI can predict when maintenance is needed, reducing unexpected downtime.

- Workflow Optimization: Data analytics help optimize production processes, improving efficiency and reducing waste.

Prototype Development in SMT PCB Assembly

Prototyping is a critical phase in the development of new PCB designs. SMT assembly lines are often used for prototyping due to their ability to quickly produce small batches of PCBs with high accuracy. This allows engineers to test and validate designs before moving to full-scale production.

Benefits of SMT in Prototyping

- Rapid Prototyping: SMT lines can produce prototypes quickly, enabling faster design iteration and validation.

- Cost-Effective: Prototyping with SMT reduces costs by minimizing material waste and production time.

Setting Up an SMT Factory for PCB Assembly

Establishing an SMT factory requires careful planning and investment. Key considerations include facility design, equipment selection, and workforce training. The layout of the factory should optimize production workflows, and equipment should be chosen based on production volume and budget constraints.

Key Considerations for Setting Up an SMT Factory

1. Facility Location: Accessibility and local regulations are crucial factors.

2. Equipment Selection: Choose machinery that fits production needs and budget.

3. Workforce Training: Ensure that staff are trained to operate advanced equipment efficiently.

Future Trends in SMT PCB Assembly

As technology continues to evolve, SMT assembly will play a pivotal role in meeting the demands of modern electronics manufacturing. Trends such as the integration of 5G technology, flexible PCBs, and sustainable practices will shape the future of the industry.

Emerging Trends

- 5G Integration: PCBs will need to support high-speed data transfer requirements.

- Flexible PCBs: Increasing demand for wearable and IoT devices.

- Sustainability: Focus on eco-friendly materials and processes.

Conclusion

Innovations in SMT PCB assembly line setups are transforming the electronics manufacturing landscape by enhancing efficiency, accuracy, and sustainability. As the industry continues to evolve, embracing automation, advanced materials, inspection technologies, and data analytics will be crucial for manufacturers seeking to remain competitive. The integration of these technologies not only improves production processes but also paves the way for a more environmentally conscious manufacturing model.

FAQs

1. What is the primary advantage of using SMT over THT in PCB assembly?

- The primary advantage of SMT is its ability to produce smaller, lighter, and more reliable PCBs by mounting components directly onto the surface of the board, which enhances compactness and reduces the risk of wire breakage.

2. How does automation impact SMT PCB assembly line setups?

- Automation significantly enhances production speed and accuracy by minimizing human error and allowing for real-time monitoring and adjustments during the assembly process.

3. What role do advanced materials play in SMT assembly?

- Advanced materials like low-temperature solder and high-conductivity substrates improve the durability and performance of PCBs, enabling them to operate effectively in challenging environments.

4. How does AOI contribute to quality control in SMT assembly?

- AOI systems use machine vision to detect defects early in the production process, reducing waste and improving yield rates by ensuring that every PCB meets stringent industry standards.

5. What are the benefits of integrating AI and data analytics in SMT assembly?

- AI and data analytics facilitate predictive maintenance, optimize workflows, and enhance overall production efficiency by analyzing production data to detect anomalies and predict equipment failures.

Citations:

[1] https://www.andwinpcb.com/innovations-in-smt-assembly-for-enhanced-circuit-board-production/

[2] https://www.andwinpcb.com/advancements-in-smt-assembly-for-modern-electronics-production/

[3] https://www.manncorp.com/pages/smt-assembly-lines

[4] https://www.pcbonline.com/blog/pcba-prototyping.html

[5] https://www.pcbasic.com/blog/smt_production_line.html

[6] https://www.linkedin.com/pulse/2025-future-pcb-pcba-trends-daisy-jiang-rmiyc

[7] https://rootsems.com/future-of-electronics-manufacturing-emerging-trends-in-2025/

[8] https://www.linkedin.com/pulse/ins-outs-setting-up-smt-factory-prototype-pcb-assembly-yljdc

[9] https://coaxinc.com/services/prototyping/

[10] https://www.kinghelm.net/industry-news/2025-The-Future-of-PCB-PCBA-Trends.html

[11] https://www.allsmt.com/SMT-line-concept-assembly-manufacturing-production-Assembly

[12] https://www.mycronic.com/product-areas/pcb-assembly/news-events-pcb-assembly/live-events/southern-manufacturing-2025/

[13] https://www.andwinpcb.com/revolutionizing-modern-manufacturing-the-rise-of-smt-assembly-techniques/

[14] https://www.sakicorp.com/en/news/newsrelease/3915/

[15] https://www.thebusinessresearchcompany.com/report/surface-mount-technology-smt-equipment-global-market-report

[16] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[17] https://www.youtube.com/watch?v=_0E9IbXmpnQ

[18] https://www.mycronic.com/product-areas/pcb-assembly/smt/

[19] https://www.wevolver.com/article/quick-turn-pcb-everything-you-need-to-know

[20] https://smt.asmpt.com/en/news-center/press/seamless-program-changeovers-now-also-across-setups/

[21] https://www.pcbpower.us/blog/top-trends-pcb-assembly

[22] https://www.smtfactory.com/Essential-Steps-for-SMT-Production-Line-Setup-id49117676.html

[23] https://www.tronstol.com/smt-assembly/prototype-smt-line/

[24] https://sfmpcb.com/pcb-assemblies/prototype-pcb-assembly/

[25] https://ventureoutsource.com/contract-manufacturing/setting-up-electronics-manufacturing-smt-pcb-assembly-lines/

[26] https://forums.adafruit.com/viewtopic.php?t=31465

[27] https://www.eevblog.com/forum/manufacture/jlc-pcb-prototype-assembly-incredibly-cheap/

[28] https://www.pcbcart.com/article/content/smt-process-to-cost-reduction.html

[29] https://www.pcbelec.com/pcb_assembly_defects.html

[30] https://www.protoexpress.com/kb/smt-assembly/

[31] https://www.viasion.com/blog/smt-pcb-assembly-process-8-basic-steps/

[32] https://www.nexpcb.com/blog/layout-design-for-printed-circuit-board-assembly

[33] https://www.hemeixinpcb.com/company/news/what-is-the-smt-assembly-process.html

[34] https://vectorbluehub.com/smt-assembly

[35] https://novaenginc.com/future-of-circuit-board-assembly/

[36] https://www.odyssey-oei.com/pcb-assembly-process/surface-mount-technology-smt.html

[37] https://jlcpcb.com/blog/design-process-of-a-surface-mount-pcb

[38] https://electronics.stackexchange.com/questions/174082/making-prototypes-with-high-speed-smd-components

[39] https://www.pcbway.com/pcb-assembly.html