Content Menu

● Understanding Reflow Soldering

● The Importance of Reflow Soldering in SMT

● Stages of the Reflow Soldering Process

>> 1. Preheat Stage

>> 2. Soak Stage

>> 3. Reflow Stage

>> 4. Cooling Stage

>> Factors Influencing Reflow Soldering Quality

>> Common Defects in Reflow Soldering

● Conclusion

● Related Questions

>> 1. What are some common defects associated with reflow soldering?

>> 2. How does temperature affect the reflow process?

>> 3. What materials are typically used in solder paste?

>> 4. Why is nitrogen used in some reflow processes?

>> 5. How often should reflow ovens be calibrated?

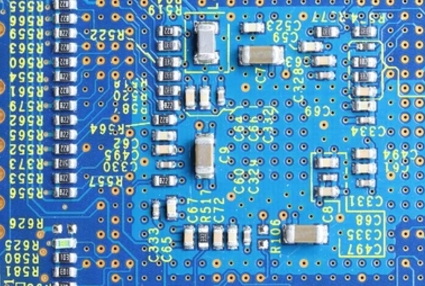

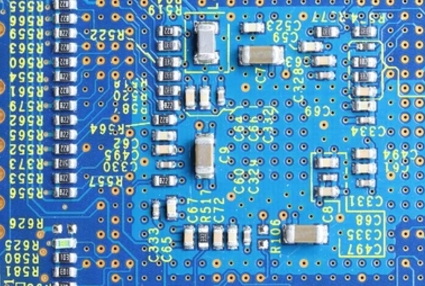

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by allowing for more compact and efficient designs. One of the most critical processes in SMT is reflow soldering, which is essential for creating reliable electrical connections between surface mount devices (SMDs) and printed circuit boards (PCBs). This article will provide an in-depth look at the reflow soldering process, its stages, and its significance in SMT.

Understanding Reflow Soldering

Reflow soldering is a technique that involves the application of solder paste to the pads of a PCB, followed by the placement of SMDs on these pads. The assembly is then heated in a controlled environment, causing the solder to melt and create permanent connections between the components and the board. This process is crucial for ensuring the performance and reliability of electronic devices.

The Importance of Reflow Soldering in SMT

Reflow soldering is favored in SMT due to several advantages:

- Higher Component Density: SMT allows for smaller components to be placed closer together, maximizing space on PCBs.

- Reduced Manufacturing Costs: The automated nature of reflow soldering reduces labor costs and increases production efficiency.

- Improved Performance: Properly executed reflow soldering results in strong and reliable solder joints, which are essential for device longevity.

Stages of the Reflow Soldering Process

The reflow soldering process can be divided into four main stages: preheat, soak, reflow, and cooling. Each stage plays a vital role in ensuring that the solder joints are formed correctly without damaging the components or PCB.

1. Preheat Stage

During the preheat stage, the entire assembly is gradually heated to a specified temperature. This stage is crucial for several reasons:

- Evaporation of Solvents: The preheat phase allows volatile solvents in the solder paste to evaporate. If these solvents are not removed, they can lead to defects during the reflow process.

- Temperature Uniformity: Gradually raising the temperature ensures that all components reach a uniform temperature, reducing thermal shock risks.

The typical temperature rise during this phase should not exceed 2°C per second to avoid damaging sensitive components.

2. Soak Stage

Following preheating, the assembly enters the soak stage. This phase typically lasts between 60 to 120 seconds and serves several purposes:

- Activation of Flux: The flux within the solder paste becomes active during this stage, helping to clean oxidation from component leads and pads.

- Thermal Equilibrium: The soak stage aims to achieve thermal equilibrium across all components, which is essential for consistent reflow.

If temperatures are too high during this phase, it can lead to issues such as solder spattering or oxidation of the pads.

3. Reflow Stage

The reflow stage is where the actual melting of solder occurs. Key points about this stage include:

- Temperature Control: The temperature must be carefully controlled to ensure it exceeds the melting point of the solder paste but does not damage any components. Typically, this temperature is maintained at 20-40°C above the melting point of the solder alloy used.

- Time Above Liquidus (TAL): This refers to how long the solder remains above its melting point. A TAL of 30 to 60 seconds is generally recommended to ensure proper wetting and bonding between surfaces.

Exceeding this time can lead to brittle joints or thermal damage to components.

4. Cooling Stage

After reflow, controlled cooling is essential for solidifying the solder joints. Cooling rates typically range from 2°C to 4°C per second. Proper cooling helps:

- Prevent Thermal Shock: Rapid cooling can cause stress fractures in both components and PCB materials.

- Enhance Joint Quality: Controlled cooling promotes a fine grain structure in solder joints, improving their strength and reliability.

Factors Influencing Reflow Soldering Quality

Several factors can affect the quality of reflow soldering:

- Solder Paste Quality: The composition and freshness of solder paste play a critical role in achieving good wetting and bonding.

- PCB Design: Proper layout designs with appropriate pad sizes and spacings facilitate better heat distribution during reflow.

- Equipment Calibration: Regular calibration of reflow ovens ensures that temperature profiles are accurate and consistent throughout production runs.

Common Defects in Reflow Soldering

Despite careful control over the process, defects can still occur during reflow soldering. Some common issues include:

- Cold Joints: These occur when solder does not melt properly due to insufficient heat, leading to poor electrical connections.

- Solder Balls: Small balls of solder that form on surfaces can result from excessive spattering during heating or improper paste application.

- Voiding: Air trapped under a joint can create voids that weaken connections; controlling soak times helps mitigate this issue.

Conclusion

Reflow soldering is a vital process within Surface Mount Technology that ensures reliable connections between electronic components and PCBs. By understanding each stage of this process—from preheating through cooling—manufacturers can optimize their SMT assembly lines for better performance and reduced defect rates. As technology continues to advance, mastering reflow soldering will remain crucial for producing high-quality electronic devices that meet consumer demands for reliability and efficiency.

Related Questions

1. What are some common defects associated with reflow soldering?

Common defects include cold joints, solder balls, and voiding, often caused by improper temperature control or paste application.

2. How does temperature affect the reflow process?

Temperature must be carefully controlled; too high can damage components while too low may prevent proper melting of solder paste.

3. What materials are typically used in solder paste?

Solder paste usually consists of a mixture of metal alloys like tin-lead or lead-free alloys combined with flux agents for effective adhesion.

4. Why is nitrogen used in some reflow processes?

Nitrogen environments reduce oxidation during reflow, improving wettability and overall joint quality by preventing defects related to oxidized surfaces.

5. How often should reflow ovens be calibrated?

Reflow ovens should be calibrated regularly—typically at least once every few months or before significant production runs—to ensure accurate temperature profiles.