Content Menu

● Understanding SMT Solder Paste Stencils

>> Key Characteristics of SMT Solder Paste Stencils

● Innovations Transforming SMT Solder Paste Stencils

>> 1. Nano-Coating Technology

>> 2. Smart Stencils with Embedded Sensors

>> 3. Advanced Laser-Cutting and Fine-Grain Foil Materials

>> 4. Multi-Height and Stepped Apertures

>> 5. Automated Stencil Cleaning and Inspection Systems

>> 6. Dual-Layer Stencil Technology

>> 7. Eco-Friendly and Sustainable Materials

>> 8. Additive Manufacturing and 3D-Printed Stencils

>> 9. Programmable Robotic Stencil Handling

● Impact of Innovations on SMT Manufacturing

● Future Trends in SMT Solder Paste Stencils

● Conclusion

● FAQ

>> 1. What is the primary function of an SMT solder paste stencil?

>> 2. How does nano-coating improve stencil performance?

>> 3. What advantages do smart stencils offer in SMT assembly?

>> 4. Why are multi-height apertures important in stencil design?

>> 5. What role does automation play in the future of SMT solder paste stencil usage?

Surface Mount Technology (SMT) solder paste stencils are indispensable tools in modern electronics manufacturing. They enable the precise deposition of solder paste onto printed circuit boards (PCBs), facilitating the accurate placement and soldering of surface mount devices (SMDs). As electronic devices become increasingly compact, complex, and performance-driven, the demand for higher precision, efficiency, and sustainability in SMT assembly processes has never been greater. This article delves deeply into the latest innovations shaping the future of SMT solder paste stencils, exploring how these advancements are revolutionizing electronics manufacturing and what trends lie ahead.

Understanding SMT Solder Paste Stencils

An SMT solder paste stencil is a thin sheet, usually made from stainless steel, that is laser-cut with apertures matching the PCB pads where solder paste must be applied. The stencil acts as a precise template, allowing solder paste to be deposited only on designated areas, ensuring accurate component placement and reliable solder joints. The quality and design of the stencil directly influence the solder paste volume, print accuracy, and ultimately the quality of the assembled PCB.

Key Characteristics of SMT Solder Paste Stencils

- Material: Stainless steel is the industry standard due to its durability, corrosion resistance, and ability to be laser-cut with high precision. Some applications use Mylar or other polymer films for prototyping or low-volume runs.

- Thickness: Typically ranges from 0.005″ (127 microns) to 0.007″ (178 microns). Thicker stencils deposit more solder paste, which is necessary for larger components, while thinner stencils are used for fine-pitch components.

- Aperture Design: Apertures are laser-cut to match PCB pad layouts but are often scaled down by about 10% to optimize solder paste volume and reduce bridging.

- Standards: IPC 7525 provides guidelines for stencil design, including aperture sizing, thickness, and material selection.

These fundamental characteristics form the baseline for ongoing innovations that improve stencil performance and manufacturing outcomes.

Innovations Transforming SMT Solder Paste Stencils

1. Nano-Coating Technology

One of the most impactful recent innovations is the application of nano-coatings on stencil surfaces. These ultra-thin, hydrophobic coatings create a non-stick surface that repels solder paste, preventing it from adhering to the stencil foil. This results in:

- Improved Paste Release: Solder paste cleanly transfers from the stencil to the PCB pads, reducing defects such as bridging and smearing.

- Reduced Cleaning Frequency: Since paste does not stick to the stencil, cleaning intervals can be extended, increasing uptime.

- Longer Stencil Life: Less mechanical cleaning reduces wear and tear on the stencil.

- Consistent Print Volume: Enhanced paste release leads to more repeatable solder paste deposits, critical for fine-pitch and ultra-fine-pitch components.

Nano-coatings are typically applied using advanced chemical vapor deposition or plasma-enhanced processes, ensuring uniform coverage and durability.

2. Smart Stencils with Embedded Sensors

The integration of smart technology into SMT solder paste stencils is revolutionizing process control. These smart stencils embed micro-sensors that monitor critical parameters such as:

- Pressure: Ensures consistent squeegee force during printing.

- Temperature: Monitors stencil and paste temperature to prevent defects caused by thermal variations.

- Paste Volume: Detects paste thickness and uniformity in real-time.

This data is transmitted to manufacturing execution systems (MES) or quality control software, enabling:

- Real-Time Adjustments: Operators can fine-tune printing parameters immediately.

- Predictive Maintenance: Early detection of stencil wear or damage prevents defects.

- Process Optimization: Data analytics improve overall yield and reduce scrap.

Smart stencils represent a leap forward in Industry 4.0 integration for SMT assembly lines.

3. Advanced Laser-Cutting and Fine-Grain Foil Materials

Laser cutting technology has advanced significantly, enabling the production of finer, more uniform apertures with smoother walls. This precision cutting is enhanced by the use of fine-grain stainless steel foils, which offer:

- Cleaner Apertures: Reduced burrs and rough edges minimize solder paste smearing.

- Improved Paste Transfer Efficiency: Smooth aperture walls facilitate better paste release.

- Greater Aperture Consistency: Critical for high-volume production and fine-pitch components.

Additionally, laser welding techniques allow the fabrication of dual-thickness or stepped stencils, which provide variable solder paste volumes on a single stencil, accommodating mixed component sizes.

4. Multi-Height and Stepped Apertures

The development of multi-height or stepped apertures addresses the challenge of heterogeneous PCB assemblies, where components of varying sizes and pitch require different solder paste volumes. These apertures feature:

- Stepped Geometry: Different aperture heights control the volume of solder paste deposited.

- Improved Solder Joint Quality: Ensures optimal paste volume for each component, reducing defects like tombstoning or insufficient solder.

- Single Stencil Versatility: Eliminates the need for multiple stencils or complex printing steps.

This innovation is particularly valuable in automotive, medical, and IoT applications where PCBs often combine large connectors with ultra-fine-pitch ICs.

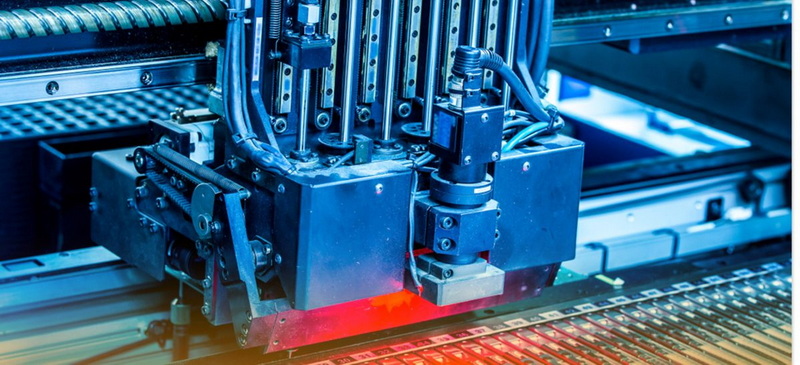

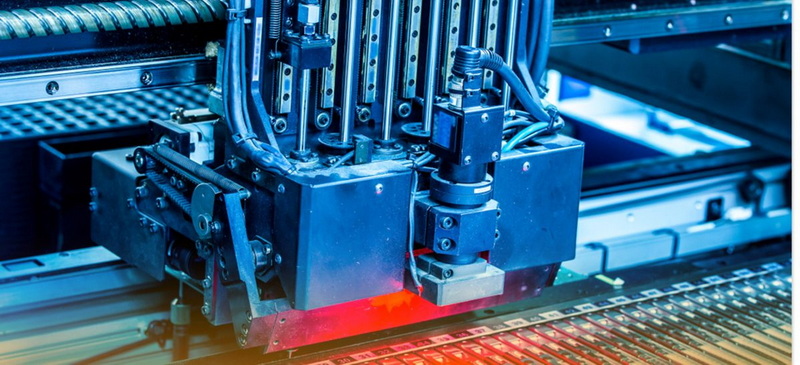

5. Automated Stencil Cleaning and Inspection Systems

Maintaining stencil cleanliness is vital for consistent solder paste printing. Innovations in automated cleaning and inspection include:

- Under-Stencil Cleaning Systems: Use brushes, ultrasonic waves, or solvents to remove paste residues without removing the stencil from the printer.

- In-Line Inspection: Optical and laser-based systems detect aperture wear, damage, or clogging in real-time.

- Automated Alerts: Notify operators of maintenance needs before defects occur.

These systems reduce downtime, labor costs, and scrap rates, improving overall line efficiency.

6. Dual-Layer Stencil Technology

Dual-layer stencils enable simultaneous printing of solder paste and adhesive materials, streamlining assembly processes for components that require both. Benefits include:

- Reduced Handling Steps: Combining two printing processes into one saves time.

- Improved Alignment: Ensures precise registration between solder paste and adhesive deposits.

- Higher Throughput: Speeds up production cycles, especially for complex assemblies.

This technology is gaining traction in applications such as LED packaging and advanced sensor modules.

7. Eco-Friendly and Sustainable Materials

Environmental sustainability is a growing priority in electronics manufacturing. Innovations include:

- Lead-Free and Low-Toxicity Solder Pastes: Compliant with RoHS and other regulations.

- Recyclable Stainless Steel Foils: Designed for reuse or recycling at end-of-life.

- Biodegradable Polymer Stencils: For prototyping and low-volume production, reducing plastic waste.

- Green Manufacturing Processes: Reduced chemical usage and energy consumption in stencil fabrication.

These efforts align with global initiatives to reduce the environmental impact of electronics production.

8. Additive Manufacturing and 3D-Printed Stencils

Additive manufacturing, including 3D printing, is emerging as a flexible method to produce complex stencil geometries that are difficult or impossible to achieve with traditional laser cutting. Advantages include:

- Rapid Prototyping: Quick turnaround for new designs.

- Complex Multi-Level Apertures: Tailored to specific component layouts.

- Cost-Effective Low-Volume Production: Avoids expensive tooling for small runs.

While still in early stages, 3D-printed stencils hold promise for customized and highly specialized SMT assembly.

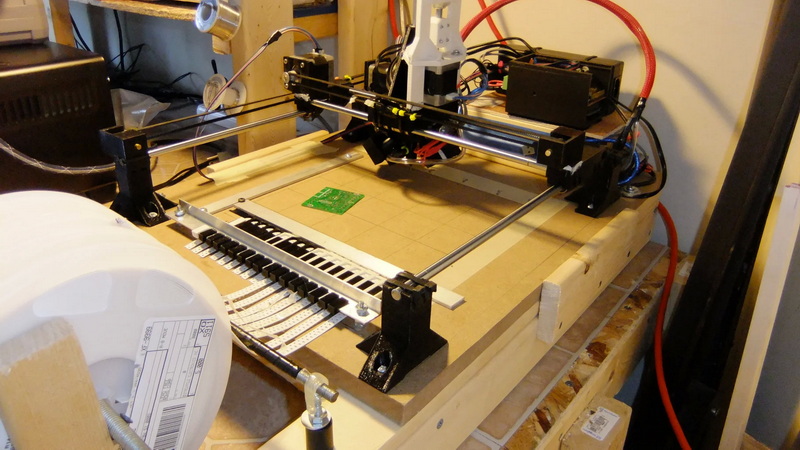

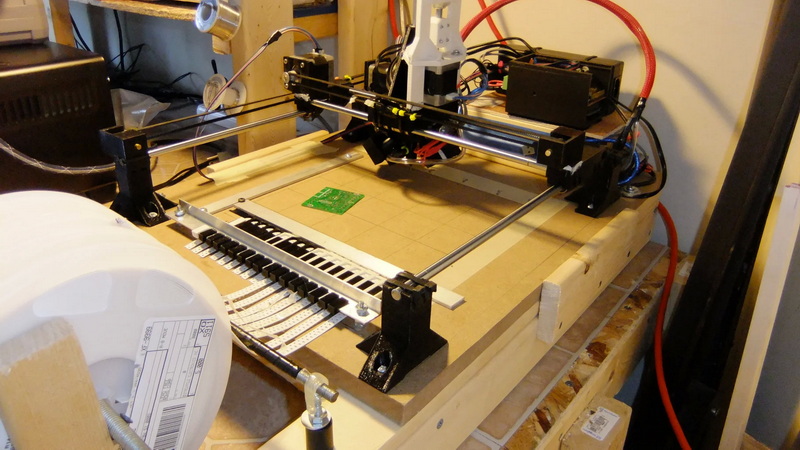

9. Programmable Robotic Stencil Handling

Automation extends beyond stencil fabrication to robotic handling systems that:

- Automate Stencil Changeover: Reducing manual labor and setup time.

- Ensure Precise Positioning: Enhancing print repeatability.

- Support High-Mix Manufacturing: Quickly switch between different PCB designs.

Robotic systems improve line flexibility and throughput, essential for modern electronics manufacturers facing diverse product portfolios.

Impact of Innovations on SMT Manufacturing

The integration of these innovations in SMT solder paste stencil technology leads to several tangible benefits:

- Improved Print Quality: Enhanced aperture precision, nano-coatings, and smart monitoring reduce defects such as bridging, insufficient paste, and misalignment.

- Higher Throughput: Automated cleaning, robotic handling, and dual-layer printing accelerate production cycles.

- Cost Efficiency: Longer stencil lifespans, reduced scrap rates, and optimized paste usage lower operational costs.

- Environmental Compliance: Use of sustainable materials and processes aligns with global environmental standards.

- Adaptability: Advanced stencil designs and smart technologies support the assembly of increasingly miniaturized and complex PCBs, meeting the demands of emerging markets like IoT, 5G, automotive, and medical devices.

Future Trends in SMT Solder Paste Stencils

Looking ahead, the SMT solder paste stencil market is expected to continue evolving with:

- AI-Driven Design Optimization: Artificial intelligence and machine learning will automate aperture design, optimizing solder paste volume and print quality based on PCB layout and component data.

- Enhanced Smart Stencil Capabilities: Integration with cloud-based analytics for predictive maintenance and process control.

- Expansion of Additive Manufacturing: Wider adoption of 3D printing for customized stencil solutions, especially in prototyping and low-volume production.

- Sustainability Focus: Development of new eco-friendly materials and processes to meet stricter environmental regulations.

- Ultra-Fine-Pitch Compatibility: Innovations to support the printing of solder paste for components with pitches below 0.3 mm, driven by miniaturization trends.

Conclusion

Innovations in SMT solder paste stencil technology are pivotal in advancing electronics manufacturing to meet the challenges of modern device complexity, miniaturization, and sustainability. From nano-coatings and smart stencils to advanced laser cutting and eco-friendly materials, these developments enhance print quality, efficiency, and environmental responsibility. As the industry embraces these technologies, manufacturers will be better equipped to produce high-quality, reliable PCBs for a wide range of applications, driving growth and competitiveness in the global electronics market.

FAQ

1. What is the primary function of an SMT solder paste stencil?

An SMT solder paste stencil precisely deposits solder paste onto PCB pads through laser-cut apertures, enabling accurate placement and soldering of surface mount components.

2. How does nano-coating improve stencil performance?

Nano-coating creates a hydrophobic surface on the stencil that repels solder paste, reducing sticking and bridging defects, improving print consistency, and decreasing cleaning frequency.

3. What advantages do smart stencils offer in SMT assembly?

Smart stencils with embedded sensors provide real-time monitoring of printing parameters, enabling immediate adjustments, better quality control, longer stencil life, and reduced defects.

4. Why are multi-height apertures important in stencil design?

Multi-height or stepped apertures allow precise control of solder paste volume for different component sizes on the same PCB, improving solder joint quality in heterogeneous assemblies.

5. What role does automation play in the future of SMT solder paste stencil usage?

Automation in stencil cleaning, inspection, and robotic handling increases production efficiency, reduces manual labor, minimizes downtime, and supports high-mix manufacturing flexibility.