Content Menu

● Introduction to SMT Reel Dispensers

>> Role of SMT Reel Dispensers in Electronics Manufacturing

● Innovations in SMT Reel Dispensers

● Technological Trends in SMT Machines

● Impact of Emerging Trends on SMT Reel Dispensers

>> Miniaturization and Component Handling

>> Automation and Efficiency

● Integration with Manufacturing Systems

● Sustainability and Environmental Considerations

● Challenges and Opportunities

● Conclusion

● FAQ

>> 1. What are the primary benefits of using SMT reel dispensers in electronics manufacturing?

>> 2. How does MIMO technology improve SMT reel dispenser efficiency?

>> 3. What role does AI and ML play in enhancing SMT reel dispensers?

>> 4. What are some future trends in SMT component reels?

>> 5. How do high-density storage solutions benefit SMT reel dispensers?

● Citations:

The future of SMT reel dispensers is being shaped by a series of innovative technologies and trends that aim to enhance efficiency, precision, and sustainability in electronics manufacturing. As the demand for miniaturized and complex electronic devices continues to grow, the role of SMT reel dispensers in managing and dispensing components becomes increasingly critical. This article explores the key innovations and technological advancements that are transforming the landscape of SMT reel dispensers.

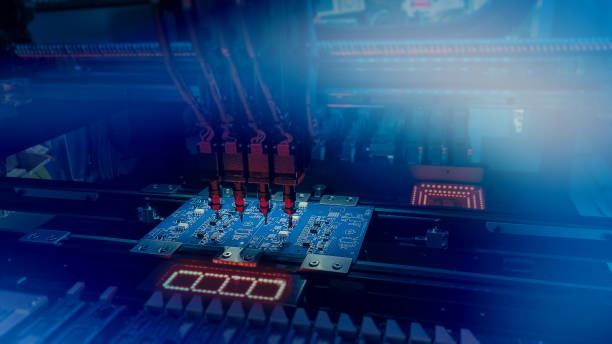

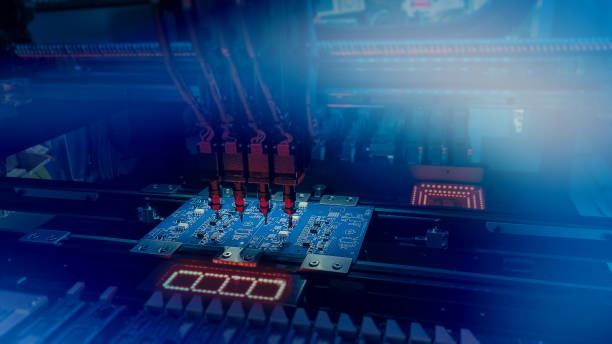

Introduction to SMT Reel Dispensers

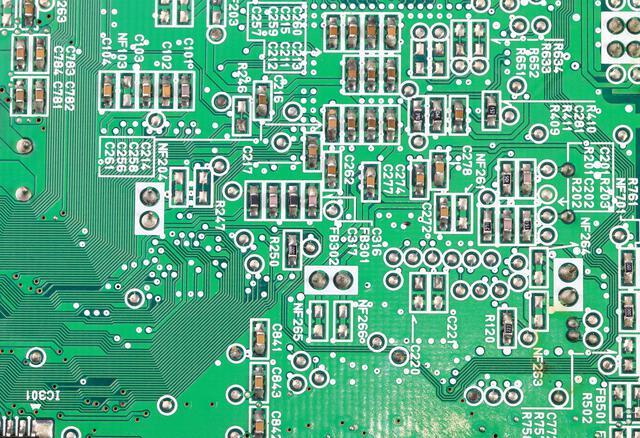

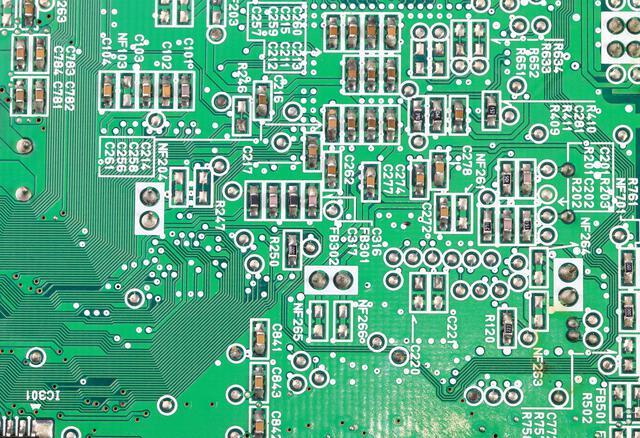

SMT reel dispensers are essential components in the surface mount technology (SMT) assembly process. They are used to store and dispense surface mount components, such as resistors, capacitors, and integrated circuits, onto printed circuit boards (PCBs). The efficiency and accuracy of these dispensers directly impact the quality and speed of electronic device production.

Role of SMT Reel Dispensers in Electronics Manufacturing

- Automation and Efficiency: SMT reel dispensers enable automated assembly processes, significantly increasing production speed and reducing manual errors. Advanced dispensers can handle multiple reels simultaneously, streamlining material handling and kitting processes.

- Component Protection: These dispensers protect components from damage and environmental factors like moisture and static electricity, ensuring that components remain viable for assembly.

- Inventory Management: By accurately tracking component quantities, SMT reel dispensers facilitate better inventory management, allowing manufacturers to optimize stock levels and reduce waste.

Innovations in SMT Reel Dispensers

Several innovations are currently shaping the future of SMT reel dispensers:

1. Artificial Intelligence (AI) and Machine Learning (ML): The integration of AI and ML into SMT reel dispensers enhances their ability to detect anomalies, predict maintenance needs, and optimize dispensing processes. This results in improved efficiency and reduced downtime.

2. Multi-Input Multi-Output (MIMO) Technology: MIMO systems allow for the simultaneous handling of multiple reels, significantly increasing throughput and reducing operator dependency. This technology revolutionizes the storage and retrieval process by automating material handling tasks.

3. Smart Reels and RFID Integration: Future SMT reel dispensers may incorporate smart reels with RFID tags to enhance inventory tracking and traceability. This technology enables real-time monitoring of component usage and storage conditions, further optimizing production workflows.

4. Eco-Friendly Materials: There is a growing focus on using eco-friendly materials for reel and tape construction to reduce environmental impact. This shift towards sustainability is expected to become a key feature of future SMT reel dispensers.

5. High-Density Storage Solutions: Innovations in storage solutions, such as those offered by Inovaxe and TDI International, provide high-density storage options that maximize space efficiency while maintaining component integrity. These solutions are crucial for managing large inventories of components.

Technological Trends in SMT Machines

The broader SMT machine industry is also experiencing significant technological advancements that impact SMT reel dispensers:

1. Intelligentization and Automation: SMT machines are becoming more intelligent and automated, leveraging technologies like AI, ML, and IoT to enhance production efficiency and quality.

2. High Precision and Speed: Future SMT machines will focus on achieving higher placement precision and speed, driven by advanced visual recognition systems and precision mechanical structures.

3. Multifunctionality and Integration: There is a trend towards multifunctional SMT machines capable of handling various component types, improving flexibility and adaptability in production lines.

4. Flexible Production: With the rise of multi-variety and small-batch production models, SMT machines need to be highly flexible to quickly adapt to changing product requirements.

5. Green and Environmental Protection: The industry is moving towards more sustainable practices, including the use of environmentally friendly materials and energy-efficient designs.

Impact of Emerging Trends on SMT Reel Dispensers

Emerging trends in the SMT industry, such as miniaturization and automation, are driving the need for more sophisticated SMT reel dispensers. The integration of AI and IoT technologies into these systems is revolutionizing inventory management by providing real-time tracking and predictive analytics, which help optimize production cycles and reduce downtime.

Miniaturization and Component Handling

As electronic devices become more sophisticated and compact, the demand for smaller components increases. SMT reel dispensers must adapt to handle these miniaturized components efficiently, ensuring precise placement and minimizing errors.

Automation and Efficiency

Automation is a key driver in the SMT industry, with SMT reel dispensers playing a crucial role in streamlining production processes. By automating material handling and dispensing, manufacturers can significantly reduce production time and enhance product quality.

Integration with Manufacturing Systems

Advanced SMT reel dispensers are designed to integrate seamlessly with various manufacturing systems, including Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP), and Automated Guided Vehicles (AGVs). This integration enhances automation and efficiency by enabling seamless data exchange and workflow automation, which is critical for maintaining operational agility and competitiveness.

Sustainability and Environmental Considerations

The emphasis on sustainability in the electronics sector is driving innovations in SMT reel dispensers. Manufacturers are adopting eco-friendly practices to minimize environmental impact, such as optimizing space, reducing waste, and utilizing energy-efficient technologies. These sustainable practices not only reduce the carbon footprint of manufacturing operations but also align with global environmental goals.

Challenges and Opportunities

While innovations in SMT reel dispensers offer numerous benefits, there are challenges to address:

- Component Sensitivity: Many SMT components are sensitive to moisture and static electricity, requiring careful handling and storage.

- Alignment and Placement Accuracy: Ensuring proper alignment of components on reels is critical to prevent pickup errors during assembly.

- Efficient Reel Management: Frequent reel changes can lead to downtime unless managed efficiently, highlighting the need for automated reel handling systems.

Despite these challenges, the future of SMT reel dispensers looks promising, with opportunities for increased automation, sustainability, and precision.

Conclusion

Innovations in SMT reel dispensers are transforming the electronics manufacturing landscape by enhancing efficiency, precision, and sustainability. As technology continues to evolve, we can expect SMT reel dispensers to play an increasingly critical role in meeting the demands of modern electronics production.

FAQ

1. What are the primary benefits of using SMT reel dispensers in electronics manufacturing?

- The primary benefits include automation, increased production speed, reduced manual errors, and better inventory management. SMT reel dispensers protect components from environmental factors and facilitate efficient material handling.

2. How does MIMO technology improve SMT reel dispenser efficiency?

- MIMO technology allows for the simultaneous handling of multiple reels, significantly increasing throughput and reducing operator dependency. This results in streamlined material handling and kitting processes.

3. What role does AI and ML play in enhancing SMT reel dispensers?

- AI and ML enhance the ability of SMT reel dispensers to detect anomalies, predict maintenance needs, and optimize dispensing processes. This leads to improved efficiency and reduced downtime.

4. What are some future trends in SMT component reels?

- Future trends include the integration of RFID for better inventory tracking, the use of eco-friendly materials, and advancements in automation to minimize human intervention.

5. How do high-density storage solutions benefit SMT reel dispensers?

- High-density storage solutions maximize space efficiency while maintaining component integrity. They provide efficient use of storage space and ensure components are readily available for production.

Citations:

[1] https://www.dataweek.co.za/24082r

[2] https://www.linkedin.com/pulse/future-surface-mount-technology-smt-industry-key-trends-p-virkhe-zxnyf

[3] https://www.hwgcsmt.com/news/new-technological-trends-in-the-smt-machine-in-84515003.html

[4] https://smttoday.com/2025/02/20/inovaxe-to-unveil-smart-storage-technologies-at-apex/

[5] https://www.gssmt-parts.com/what-innovations-are-emerging-in-smt-reel-shelving-technology.html

[6] https://www.cognitivemarketresearch.com/articles/surface-mount-technology-smt-market-trends-and-future-opportunities

[7] https://www.prnewswire.com/apac/news-releases/productronica-china-to-delve-into-the-unlimited-possibilities-of-electronic-manufacturing-in-march-2025-302383181.html

[8] https://www.dafton-smt.com/news/development-forecast-of-smt-processing-80656963.html

[9] https://blog.tbrc.info/2025/02/surface-mount-technology-equipment-market/

[10] https://essemtec.com/en/

[11] https://www.consegicbusinessintelligence.com/surface-mount-technology-equipment-market

[12] https://www.dafton-smt.com/news/analysis-of-smt-requirements-and-development-78032961.html

[13] https://smtnet.com/news/index.cfm?fuseaction=see_company_news&company_id=51236

[14] https://www.thebusinessresearchcompany.com/report/surface-mount-technology-smt-equipment-global-market-report

[15] https://www.rhsmt.com/news/smt-industrys-future-trends-the-impact-of-ai-and-automation/

[16] https://www.allsmt.com/electronic-manufacturing-innovations-2025

[17] https://markwideresearch.com/surface-mount-technology-equipment-market/

[18] https://m.smt11.com/blog/SMT-Field/SMT-Process-Status-and-Future-Development-Trends-2023.html

[19] https://www.globalsmt.net/trade-show-news/smartsol-technologies-to-exhibit-at-apex-2025-showcasing-cutting-edge-smt-and-test-technologies-with-leading-partners/

[20] https://pmarketresearch.com/product/worldwide-intravenous-injection-equipment-market-research-2024-by-type-application-participants-and-countries-forecast-to-2030/worldwide-smt-machine-market-research-2024-by-type-application-participants-and-countries-forecast-to-2030