Content Menu

● The Evolution of PCB SMT Conveyors

● Current Challenges in PCB Assembly

● Key Innovations Shaping PCB SMT Conveyors

>> 1. Advanced Automation and Robotics Integration

>> 2. Intelligent Conveyor Systems

>> 3. Dual-Lane and Multi-Lane Conveyors

>> 4. Precision Alignment and Positioning

>> 5. Modular and Flexible Conveyor Designs

>> 6. Enhanced Cleanliness and ESD Protection

>> 7. Energy-Efficient and Sustainable Designs

>> 8. Integration of IoT and Data Analytics

>> 9. Advanced Inspection and Quality Control

>> 10. Customizable Conveyor Solutions

● Impact on the Electronics Manufacturing Industry

● Future Outlook

● Conclusion

● FAQ

>> 1. What is the primary function of a PCB SMT conveyor in electronics manufacturing?

>> 2. How are dual-lane and multi-lane conveyors improving PCB production efficiency?

>> 3. What role does IoT play in modern PCB SMT conveyor systems?

>> 4. How are energy-efficient designs being implemented in PCB SMT conveyors?

>> 5. What advancements in inspection and quality control are being integrated into PCB SMT conveyors?

● Citations:

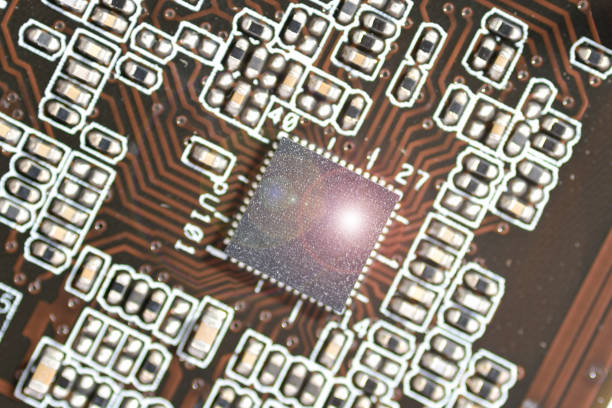

In the rapidly evolving landscape of electronics manufacturing, Surface Mount Technology (SMT) continues to play a pivotal role in the production of printed circuit boards (PCBs). At the heart of this process lies a crucial component: the PCB SMT conveyor. As the industry pushes towards greater efficiency, precision, and automation, innovative developments in conveyor technology are reshaping the future of PCB assembly. This article explores the cutting-edge advancements that are transforming PCB SMT conveyors and their impact on the electronics manufacturing industry.

The Evolution of PCB SMT Conveyors

PCB SMT conveyors have come a long way since their inception. These essential components of the SMT assembly line are responsible for transporting PCBs through various stages of production, from solder paste printing to component placement and reflow soldering. Traditional conveyors have served the industry well, but as demands for higher productivity and quality increase, so does the need for more sophisticated conveyor systems.

Current Challenges in PCB Assembly

Before delving into the innovations, it's crucial to understand the challenges that modern PCB assembly faces:

1. Miniaturization of components

2. Increasing complexity of PCB designs

3. Demand for higher production speeds

4. Need for greater precision and accuracy

5. Flexibility in handling various PCB sizes and shapes

These challenges have spurred the development of innovative solutions in PCB SMT conveyor technology.

Key Innovations Shaping PCB SMT Conveyors

1. Advanced Automation and Robotics Integration

One of the most significant trends in SMT lines is the integration of automation and robotics[10]. Full-auto SMT lines are becoming increasingly prevalent, utilizing robotic arms for precise component placement, soldering, and inspection tasks. This automation extends to PCB SMT conveyors, where robotic systems are being integrated to handle PCB loading, unloading, and transfer between different stages of production.

Benefits:

- Increased productivity and efficiency

- Reduced human error

- Higher-quality PCB assemblies

- Faster turnaround times

2. Intelligent Conveyor Systems

The future of PCB SMT conveyors lies in intelligent systems that can adapt to various production requirements. These smart conveyors incorporate sensors, machine learning algorithms, and real-time data processing to optimize PCB transport.

Features:

- Adaptive speed control based on production flow

- Automatic width adjustment for different PCB sizes

- Predictive maintenance alerts

- Integration with Manufacturing Execution Systems (MES)

3. Dual-Lane and Multi-Lane Conveyors

To meet the demand for increased production capacity, dual-lane and multi-lane conveyor systems are gaining popularity. These systems allow for simultaneous processing of multiple PCBs, significantly boosting throughput.

Advantages:

- Higher production capacity

- Efficient use of floor space

- Flexibility in handling different product mixes

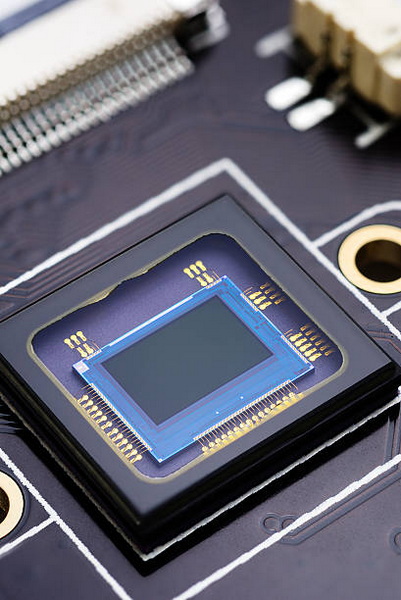

4. Precision Alignment and Positioning

As components become smaller and PCB designs more complex, the need for precise alignment during transport is critical. Innovative conveyor systems now incorporate advanced alignment mechanisms to ensure accurate positioning of PCBs at each production stage.

Technologies used:

- Laser alignment systems

- High-precision servo motors

- Computer vision for real-time position correction

5. Modular and Flexible Conveyor Designs

The electronics industry demands flexibility, and PCB SMT conveyors are evolving to meet this need. Modular conveyor designs allow for easy reconfiguration of production lines, enabling manufacturers to adapt quickly to changing product requirements.

Benefits:

- Reduced downtime during line changeovers

- Customizable production layouts

- Scalability for future expansion

6. Enhanced Cleanliness and ESD Protection

As PCBs become more sensitive to contamination and electrostatic discharge (ESD), conveyor systems are being designed with enhanced cleanliness and ESD protection features.

Innovations:

- Anti-static conveyor belts and components

- Integrated ionization systems

- Enclosed conveyor designs to minimize dust exposure

7. Energy-Efficient and Sustainable Designs

With a growing focus on sustainability in manufacturing, PCB SMT conveyor manufacturers are developing energy-efficient systems that reduce power consumption and environmental impact.

Features:

- Low-power motors and drive systems

- Regenerative braking to recapture energy

- Use of recyclable materials in conveyor construction

8. Integration of IoT and Data Analytics

The Internet of Things (IoT) is making its way into PCB SMT conveyors, enabling real-time monitoring and data collection. This integration allows for advanced analytics and predictive maintenance, reducing downtime and optimizing conveyor performance.

Capabilities:

- Remote monitoring and control

- Performance analytics and reporting

- Integration with factory-wide data systems

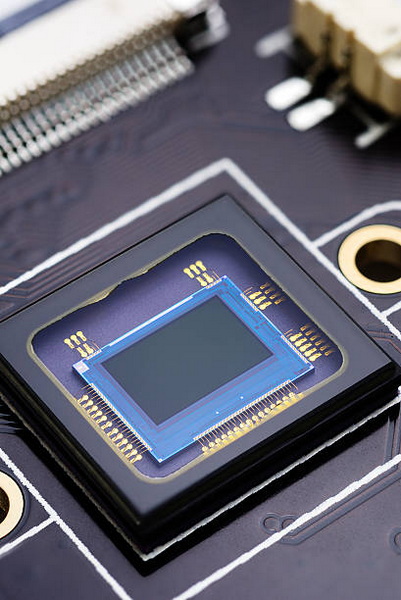

9. Advanced Inspection and Quality Control

Innovative PCB SMT conveyors are incorporating advanced inspection technologies directly into the transport system. This integration allows for continuous quality monitoring throughout the production process.

Technologies:

- Inline optical inspection

- X-ray inspection for hidden solder joints

- Automated defect detection and classification

10. Customizable Conveyor Solutions

Recognizing that one size does not fit all in PCB assembly, manufacturers are offering increasingly customizable conveyor solutions. These systems can be tailored to specific production requirements, PCB sizes, and factory layouts.

Customization options:

- Adjustable conveyor lengths and widths

- Interchangeable conveyor modules

- Custom integration with existing equipment

Impact on the Electronics Manufacturing Industry

The innovations in PCB SMT conveyors are having a profound impact on the electronics manufacturing industry:

1. Increased Productivity: Advanced conveyor systems are enabling higher throughput and faster production cycles, meeting the growing demand for electronic devices.

2. Improved Quality: Precision alignment, integrated inspection, and reduced human intervention are leading to higher quality PCB assemblies with fewer defects.

3. Greater Flexibility: Modular and customizable conveyor systems allow manufacturers to adapt quickly to changing market demands and product variations.

4. Cost Reduction: While initial investments in advanced conveyor technology may be higher, the long-term benefits in terms of increased efficiency and reduced errors lead to significant cost savings.

5. Enhanced Competitiveness: Manufacturers adopting these innovative conveyor systems gain a competitive edge in the market, able to offer faster turnaround times and higher quality products.

Future Outlook

The future of PCB SMT conveyors looks promising, with continued innovation on the horizon. We can expect to see:

- Further integration of artificial intelligence for autonomous conveyor operation

- Development of ultra-high-speed conveyor systems for next-generation electronics production

- Increased focus on sustainability, with conveyor systems designed for minimal environmental impact

- Enhanced integration with other SMT line components for seamless, end-to-end automation

As the global surface mount technology market is projected to grow from USD 5.8 billion in 2023 to reach USD 8.4 billion by 2028[11], the demand for advanced PCB SMT conveyors will continue to rise. This growth will drive further innovation and investment in conveyor technology, shaping the future of electronics manufacturing.

Conclusion

The innovations shaping the future of PCB SMT conveyors are transforming the electronics manufacturing landscape. From advanced automation and intelligent systems to modular designs and IoT integration, these developments are addressing the industry's challenges head-on. As PCB assembly becomes increasingly complex and demanding, the role of innovative conveyor technology in ensuring efficiency, quality, and flexibility cannot be overstated.

Manufacturers who embrace these advancements in PCB SMT conveyors will be well-positioned to meet the evolving demands of the electronics market, producing high-quality PCBs with greater speed and precision than ever before. As we look to the future, it's clear that the continued evolution of PCB SMT conveyor technology will play a crucial role in driving the electronics industry forward, enabling the production of the next generation of electronic devices that will shape our world.

FAQ

1. What is the primary function of a PCB SMT conveyor in electronics manufacturing?

A PCB SMT conveyor is a critical component in the Surface Mount Technology (SMT) assembly line, responsible for transporting Printed Circuit Boards (PCBs) through various stages of production. It ensures smooth and efficient movement of PCBs from one process to another, such as from the solder paste printing stage to component placement and then to the reflow soldering process. The conveyor system plays a crucial role in maintaining production flow, ensuring precise positioning of PCBs, and contributing to the overall efficiency and quality of the assembly process.

2. How are dual-lane and multi-lane conveyors improving PCB production efficiency?

Dual-lane and multi-lane conveyor systems are significantly enhancing PCB production efficiency by allowing simultaneous processing of multiple PCBs. This innovation enables manufacturers to increase their production capacity without necessarily expanding their factory floor space. By processing two or more PCBs side by side, these systems can effectively double or triple the throughput of a single production line. Additionally, they offer flexibility in handling different product mixes, allowing manufacturers to run various PCB types or sizes concurrently, thus optimizing production schedules and reducing changeover times.

3. What role does IoT play in modern PCB SMT conveyor systems?

The Internet of Things (IoT) is revolutionizing PCB SMT conveyor systems by enabling real-time monitoring, data collection, and advanced analytics. IoT integration allows for remote monitoring and control of conveyor operations, providing manufacturers with instant access to performance metrics and system status. This capability facilitates predictive maintenance, reducing unexpected downtime and optimizing conveyor performance. Furthermore, IoT enables the integration of conveyor data with factory-wide information systems, contributing to comprehensive production analytics and supporting data-driven decision-making processes in manufacturing operations.

4. How are energy-efficient designs being implemented in PCB SMT conveyors?

Energy-efficient designs in PCB SMT conveyors are being implemented through various innovative approaches. Manufacturers are incorporating low-power motors and drive systems that consume less electricity while maintaining optimal performance. Some advanced conveyor systems feature regenerative braking technology, which recaptures energy during deceleration and feeds it back into the system, further reducing overall power consumption. Additionally, the use of lightweight and recyclable materials in conveyor construction not only reduces the energy required for operation but also contributes to sustainability efforts in manufacturing. These energy-efficient designs help reduce operational costs and minimize the environmental impact of PCB production processes.

5. What advancements in inspection and quality control are being integrated into PCB SMT conveyors?

PCB SMT conveyors are increasingly incorporating advanced inspection and quality control technologies directly into the transport system. This integration allows for continuous monitoring and inspection of PCBs throughout the production process. Some of the key advancements include inline optical inspection systems that can detect surface defects, component misalignments, or solder paste issues in real-time. X-ray inspection capabilities are being added to identify hidden solder joint problems, especially crucial for ball grid array (BGA) components. Furthermore, automated defect detection and classification systems, powered by machine learning algorithms, are enhancing the accuracy and speed of quality control processes. These integrated inspection technologies help identify and address quality issues early in the production cycle, reducing waste and improving overall product quality.

Citations:

[1] https://arshon.com/blog/smt-assembly-how-surface-mount-technology-simplifies-pcb-production/

[2] https://cnsmtline.com/smt-conveyor/

[3] https://www.smtfactory.com/Introduction-of-types-of-SMT-conveyor-id60011807.html

[4] https://www.youtube.com/watch?v=tR3s8gTdnmg

[5] https://patents.google.com/patent/WO2016165636A1/en

[6] https://www.xlin-smt.com/news/the-future-development-trend-of-smt-placement-machine/

[7] https://www.zjyingxing.com/info/what-does-conveyor-do-in-the-smt-line-96523854.html

[8] https://www.grandviewresearch.com/industry-analysis/surface-mount-technology-market-report

[9] https://www.morequip.com/product/SMT-PCB-Conveyor.html

[10] https://www.smtfactory.com/Future-Trends-in-SMT-Lines-Innovations-Shaping-The-Electronics-Manufacturing-Industry-id44863586.html

[11] https://www.marketsandmarkets.com/Market-Reports/surface-mount-technology-market-99662691.html