Content Menu

● Introduction to Tape and Reel Technology

>> Advantages of Tape and Reel in SMT

● Emerging Innovations in Tape and Reel Technology

>> Next-Generation Systems

>> High-Resolution Vision Inspection

>> Custom Design and Technical Capabilities

>> Enhanced Efficiency and Precision

>> Impact on Diverse Industries

● Challenges and Opportunities

>> Future Directions

>> Integration with Smart Manufacturing

>> Sustainability and Environmental Impact

>> Global Market Trends

● Case Studies: Successful Implementations

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of using tape and reel packaging in SMT?

>> 2. How does next-generation tape and reel technology improve manufacturing processes?

>> 3. What role does custom design play in tape and reel technology for specialized components?

>> 4. How does tape and reel technology impact industries beyond electronics?

>> 5. What are the potential future developments in tape and reel technology?

Tape and reel technology has been a cornerstone in the electronics manufacturing industry, particularly in the realm of Surface Mount Technology (SMT). This packaging method allows for efficient, high-volume production by enabling automated component placement during assembly processes. As the demand for electronic devices continues to grow, innovations in tape and reel technology are crucial for maintaining efficiency, precision, and cost-effectiveness. This article explores the emerging trends and advancements in tape and reel technology, focusing on their impact on SMT and broader manufacturing processes.

Introduction to Tape and Reel Technology

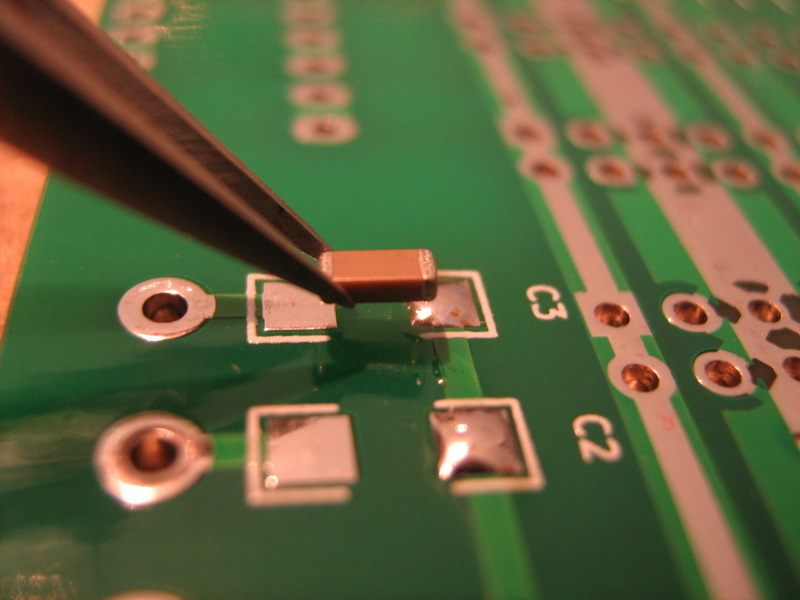

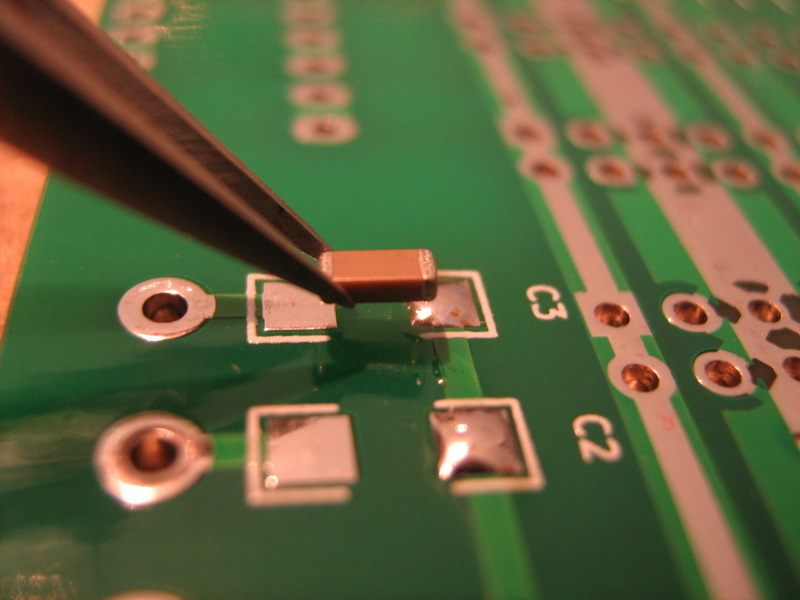

Tape and reel packaging involves mounting components onto a continuous strip of tape, which is then wound onto a reel. This format facilitates automated handling and placement of components during the assembly process, significantly reducing manual labor and increasing production speed. The technology is widely used for SMT components, which require precise placement on printed circuit boards (PCBs).

Advantages of Tape and Reel in SMT

1. Efficiency and Speed: Tape and reel packaging allows for faster setup and component pickup compared to traditional packaging methods like trays or tubes. This is particularly beneficial for high-volume production, where speed and consistency are critical.

2. Cost Savings: By transitioning from manual to automated placement, manufacturers can significantly reduce labor costs. Additionally, the ability to hold a larger quantity of components on a reel compared to trays reduces storage and logistics costs.

3. Precision and Reliability: SMT components are characterized by their high density and small size, making precise placement essential. Tape and reel packaging supports this requirement by ensuring components are accurately positioned on the PCB.

Emerging Innovations in Tape and Reel Technology

Next-Generation Systems

Recent advancements in tape and reel technology include the development of next-generation systems designed to meet the demands of high-speed, high-volume manufacturing. These systems incorporate advanced device handling methods and high-performance vision inspection technology. The latter provides improved accuracy and repeatability, ensuring that components are inspected with precision, which is crucial for maintaining high yields and reducing downtime.

High-Resolution Vision Inspection

Traditional camera-based vision systems have limitations in terms of accuracy and repeatability, often not meeting the stringent inspection requirements of modern packages. Next-generation tape and reel systems address this by utilizing high-resolution vision technology, advanced optics, and sophisticated imaging software. This enables the reliable inspection of devices with an accuracy and repeatability of 7.5 microns, significantly enhancing the reliability of the manufacturing process.

Custom Design and Technical Capabilities

The evolution of tape and reel technology also involves custom design processes tailored to specific manufacturing needs. This includes the development of specialized carrier tapes for handling fragile components, such as bare die, which require precise protection and handling to prevent damage during the assembly process.

Enhanced Efficiency and Precision

Innovations in tape and reel packaging for SMD components focus on enhancing efficiency and precision. By integrating cutting-edge technology with meticulous attention to detail, manufacturers can safeguard the integrity of delicate components while streamlining the assembly process. This approach sets new benchmarks for efficiency and reliability in electronic production.

Impact on Diverse Industries

Tape and reel technology is not limited to electronics; it has transformed industries such as automotive and medical manufacturing by improving automation, efficiency, and precision. The ability to adapt this technology to various applications underscores its versatility and potential for future growth.

Challenges and Opportunities

Despite the advancements, there are challenges associated with adopting tape and reel technology, particularly for manufacturers considering significant investments in new equipment. However, by transitioning to tape and reel packaging, companies can often avoid costly investments in tray modules for SMD lines, which can exceed $100,000.

Future Directions

The future of tape and reel technology will likely involve further integration with advanced manufacturing techniques, such as 3D printing and robotics, to enhance precision and speed. Additionally, the development of more robust and precise carrier tapes will be crucial for handling emerging technologies like stacked die and wafer-level packaging.

Integration with Smart Manufacturing

The integration of tape and reel technology with smart manufacturing systems is another area of innovation. By leveraging IoT and AI technologies, manufacturers can optimize production workflows, predict maintenance needs, and improve quality control. This integration enables real-time monitoring and adjustments, further enhancing efficiency and reducing waste.

Sustainability and Environmental Impact

As industries move towards more sustainable practices, tape and reel technology is evolving to reduce environmental impact. This includes the development of eco-friendly packaging materials and processes that minimize waste. By adopting sustainable practices, manufacturers can not only reduce their environmental footprint but also comply with increasingly stringent regulations.

Global Market Trends

The global market for tape and reel technology is expected to grow significantly due to increasing demand from the electronics and automotive sectors. Emerging markets in Asia and Latin America are driving this growth, as local manufacturers invest in modernizing their production lines to meet global standards.

Case Studies: Successful Implementations

Several companies have successfully implemented tape and reel technology to enhance their manufacturing processes. For instance, a leading automotive electronics manufacturer in Europe reported a 30% increase in production efficiency after transitioning to tape and reel packaging for their SMT components. Similarly, a medical device manufacturer in the U.S. saw a significant reduction in defect rates by leveraging advanced vision inspection systems integrated into their tape and reel lines.

Conclusion

Innovations in tape and reel technology are pivotal for maintaining competitiveness in the electronics manufacturing sector. By embracing advancements in vision inspection, custom design capabilities, and efficiency enhancements, manufacturers can optimize their production processes. As demand for electronic devices continues to rise, the role of tape and reel technology in facilitating high-volume, precise manufacturing will only grow more critical. The integration of this technology with smart manufacturing and sustainable practices will further enhance its impact across diverse industries.

Frequently Asked Questions

1. What are the primary benefits of using tape and reel packaging in SMT?

Tape and reel packaging offers several benefits in SMT, including increased efficiency, reduced labor costs, and improved precision in component placement. It allows for faster setup and component pickup compared to traditional packaging methods.

2. How does next-generation tape and reel technology improve manufacturing processes?

Next-generation systems enhance manufacturing by incorporating advanced device handling and high-performance vision inspection. This improves accuracy, reduces downtime, and increases overall yields.

3. What role does custom design play in tape and reel technology for specialized components?

Custom design is crucial for handling specialized components like bare die. It involves creating carrier tapes with high precision to protect fragile components and ensure their integrity during assembly.

4. How does tape and reel technology impact industries beyond electronics?

Tape and reel technology has transformed industries such as automotive and medical manufacturing by improving automation, efficiency, and precision. Its adaptability to various applications highlights its potential for future growth.

5. What are the potential future developments in tape and reel technology?

Future developments will likely include further integration with advanced manufacturing techniques like 3D printing and robotics. There will also be a focus on developing more robust and precise carrier tapes for emerging technologies.