Content Menu

● Introduction to SMT PCB Container Design

>> Role of SMT in PCB Assembly

● Innovations in SMT PCB Container Design

● Impact of Innovations on SMT PCB Container Design

● Applications of SMT PCB Containers

● Future of SMT PCB Container Design

● Challenges and Opportunities

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of using SMT in PCB assembly?

>> 2. How does miniaturization impact SMT PCB container design?

>> 3. What role does automation play in SMT PCB assembly?

>> 4. How does sustainability influence SMT PCB container design?

>> 5. What are some common applications of SMT PCB containers?

The landscape of Surface Mount Technology (SMT) PCB container design is undergoing significant transformations, driven by advancements in materials, automation, and sustainability. As electronic devices become increasingly complex and compact, the need for innovative SMT PCB container designs has never been more pressing. This article explores the emerging trends and innovations in SMT PCB container design, highlighting how these developments are shaping the future of electronics manufacturing.

Introduction to SMT PCB Container Design

SMT PCB containers are critical components in the assembly and protection of electronic devices. They house the PCBs, ensuring they are shielded from environmental factors such as dust, moisture, and physical stress. Traditional container designs have focused on functionality and durability, but modern innovations are pushing beyond these boundaries, incorporating advanced materials, miniaturization techniques, and sustainable practices.

Role of SMT in PCB Assembly

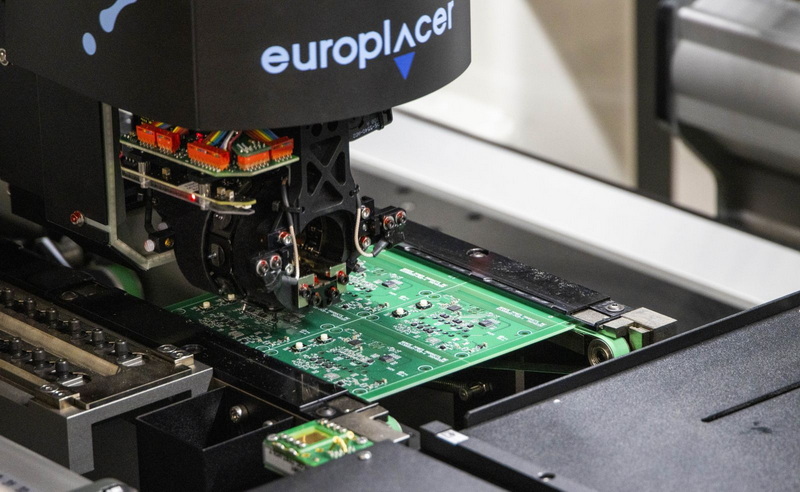

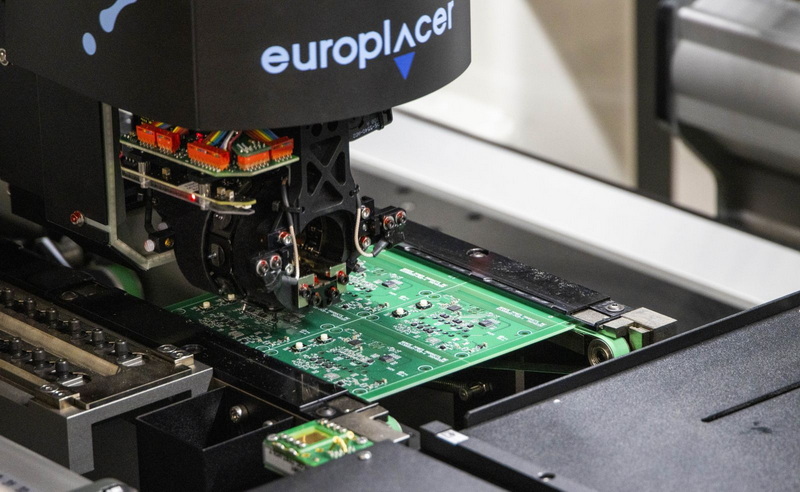

SMT is a widely adopted method for PCB assembly due to its ability to mount components directly onto the PCB surface, enhancing component density and reducing the size and weight of electronic devices. This technology has become indispensable in various industries, including consumer electronics, automotive, medical devices, and aerospace. The efficiency and precision of SMT allow for the production of complex electronic systems with high reliability and performance.

Innovations in SMT PCB Container Design

Several key innovations are transforming the field of SMT PCB container design:

1. Advanced Materials: The use of high-conductivity substrates and low-temperature solder is becoming more prevalent, enhancing the durability and performance of PCBs. Additionally, the integration of flexible substrates allows for more versatile and compact designs, suitable for applications where space is limited. These materials also improve thermal management, reducing heat-related failures and enhancing overall system reliability.

2. Miniaturization: Advances in High-Density Interconnect (HDI) technology enable the creation of PCBs with higher layer densities, allowing for more complex circuits in smaller spaces. This miniaturization trend is crucial for modern electronic devices that require increased functionality without compromising size. HDI PCBs support higher signal speeds and reduce electromagnetic interference, making them ideal for high-speed applications.

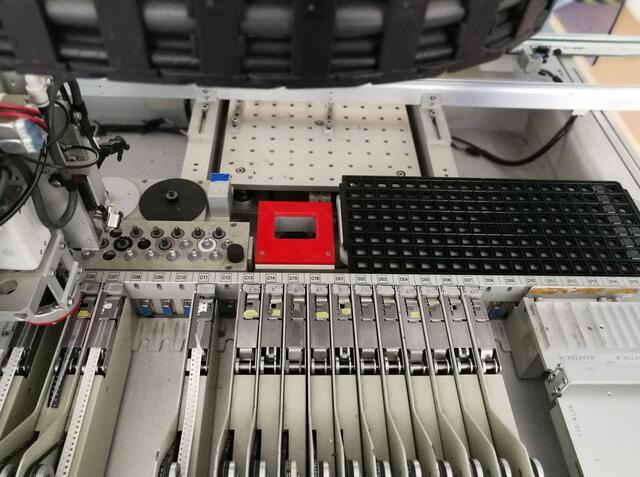

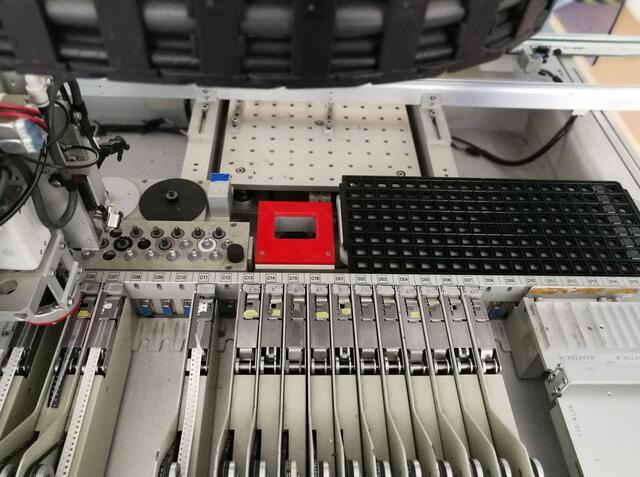

3. Automation and Robotics: The integration of intelligent automation and robotics in SMT assembly processes has significantly improved production efficiency and accuracy. Real-time monitoring systems provide instant feedback, reducing defects and ensuring high-quality outputs. Automated systems can also handle complex tasks such as component placement and soldering with precision, further enhancing production efficiency.

4. Sustainability: There is a growing emphasis on sustainable manufacturing practices, including the use of 3D printing for custom components, which reduces material waste and supports environmental goals. This shift towards sustainability is not only beneficial for the environment but also enhances the competitive edge of manufacturers by reducing costs associated with waste disposal and material sourcing.

5. Data Analytics and Predictive Maintenance: The application of data analytics in SMT PCB assembly facilitates real-time monitoring and predictive maintenance, making production processes more proactive and efficient. By analyzing production data, manufacturers can identify potential issues before they occur, reducing downtime and improving overall productivity.

Impact of Innovations on SMT PCB Container Design

These innovations have profound implications for SMT PCB container design:

- Compact Designs: With the ability to pack more components into smaller spaces, SMT PCB containers can be designed to be more compact, reducing overall device size and weight. This compactness is particularly beneficial in consumer electronics, where portability and aesthetics are key selling points.

- Enhanced Durability: The use of advanced materials and manufacturing techniques ensures that SMT PCB containers are more robust and reliable, capable of withstanding harsh environmental conditions. This durability is critical in industries such as aerospace and automotive, where electronic systems must operate under extreme conditions.

- Sustainability: The integration of sustainable practices in container design aligns with broader environmental goals, reducing waste and promoting eco-friendly manufacturing processes. Sustainable materials and production methods not only reduce environmental impact but also appeal to consumers who prioritize eco-friendliness.

Applications of SMT PCB Containers

SMT PCB containers are crucial in a wide range of industries:

- Consumer Electronics: Essential for devices like smartphones and laptops, where compactness and reliability are paramount. SMT PCB containers protect these devices from environmental stressors, ensuring consistent performance and longevity.

- Automotive: Used in critical automotive systems, requiring high durability and performance. Automotive electronics must withstand extreme temperatures and vibrations, making robust SMT PCB containers indispensable.

- Medical Devices: Vital for medical equipment, where precision and reliability are critical. SMT PCB containers in medical devices ensure that electronic systems operate flawlessly, even in high-stress environments.

- Aerospace and Defense: Plays a key role in systems requiring high reliability and resistance to extreme conditions. Aerospace electronics must operate under intense stress, including extreme temperatures and radiation, making durable SMT PCB containers essential.

Future of SMT PCB Container Design

As technology continues to evolve, we can expect further advancements in SMT PCB container design. The integration of AI and IoT technologies will likely enhance automation and real-time monitoring capabilities, while advancements in materials science will lead to even more durable and sustainable designs. Additionally, the adoption of modular design principles will allow for easier customization and upgradeability of electronic devices, further extending the lifespan of SMT PCB containers.

Challenges and Opportunities

Despite the numerous innovations, there are challenges to be addressed. One of the primary challenges is balancing miniaturization with thermal management, as smaller devices can generate significant heat relative to their size. Another challenge is ensuring that sustainable practices do not compromise performance or increase costs. However, these challenges also present opportunities for innovation, driving research into new materials and manufacturing techniques that can meet these demands.

Conclusion

Innovations in SMT PCB container design are revolutionizing the electronics manufacturing industry by enhancing efficiency, sustainability, and product reliability. As consumer demand for smaller, more powerful devices continues to grow, the importance of these advancements will only increase. By embracing cutting-edge technologies and sustainable practices, manufacturers can not only improve their products but also contribute to a more environmentally conscious future.

Frequently Asked Questions

1. What are the primary benefits of using SMT in PCB assembly?

SMT offers several key benefits, including increased component density, smaller form factors, and cost-efficient production. It also allows for the use of smaller and lighter components, reducing the overall size and weight of electronic devices.

2. How does miniaturization impact SMT PCB container design?

Miniaturization enables the creation of more compact PCBs, which in turn allows for smaller SMT PCB containers. This trend is driven by advancements in HDI technology and precision placement techniques, enhancing signal integrity and reducing device size.

3. What role does automation play in SMT PCB assembly?

Automation significantly improves production efficiency and accuracy in SMT assembly. It streamlines workflows, minimizes human error, and enables real-time monitoring, ensuring high-quality outputs and reducing turnaround times.

4. How does sustainability influence SMT PCB container design?

Sustainability is increasingly important in SMT PCB container design, with a focus on reducing material waste and promoting eco-friendly manufacturing practices. Techniques like 3D printing for custom components support these goals by minimizing excess materials.

5. What are some common applications of SMT PCB containers?

SMT PCB containers are used across various industries, including consumer electronics, automotive, medical devices, aerospace, and telecommunications. They provide critical protection and housing for PCBs in these applications, ensuring device reliability and performance.