Content Menu

● Introduction to SMT Adhesives

>> Types of SMT Adhesives

● Emerging Innovations in SMT Adhesives

>> 1. Environmentally Friendly Adhesives

>> 2. Lead-Free and RoHS-Compliant Adhesives

>> 3. Advanced Formulations for High-Speed Manufacturing

>> 4. Integration with Emerging Technologies

>> 5. Transient Liquid Phase Sintering (TLPS) Solder Pastes

● Applications of SMT Adhesives

● Challenges and Future Prospects

>> Technological Advancements

>> Sustainability Initiatives

>> Market Expansion

● Conclusion

● FAQs

>> 1. What is the primary function of SMT adhesives in PCB assembly?

>> 2. What types of SMT adhesives are commonly used?

>> 3. Why are environmentally friendly SMT adhesives becoming more important?

>> 4. How do advancements in SMT adhesives support high-speed manufacturing?

>> 5. What role do TLPS solder pastes play in SMT manufacturing?

● Citations:

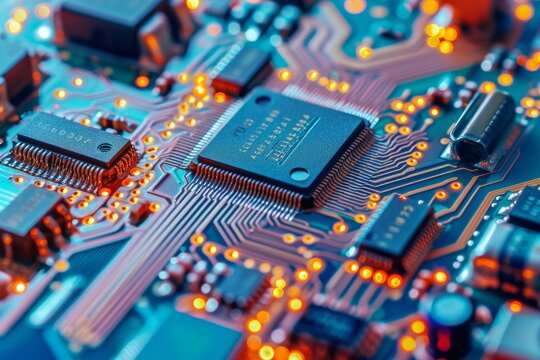

The field of Surface Mount Technology (SMT) adhesives has witnessed significant advancements in recent years, driven by the increasing demand for more efficient, reliable, and sustainable electronics manufacturing processes. SMT adhesives play a crucial role in securing components onto printed circuit boards (PCBs), ensuring the durability and performance of electronic devices. This article explores the emerging innovations in SMT adhesive technology, focusing on their applications, benefits, and future prospects.

Introduction to SMT Adhesives

SMT adhesives are essential in the assembly of surface mount devices (SMDs) onto PCBs. They provide mechanical support, prevent component movement during the soldering process, and enhance the overall reliability of electronic assemblies. The choice of SMT adhesive depends on factors such as curing time, viscosity, thermal resistance, and compatibility with the PCB and component materials.

Types of SMT Adhesives

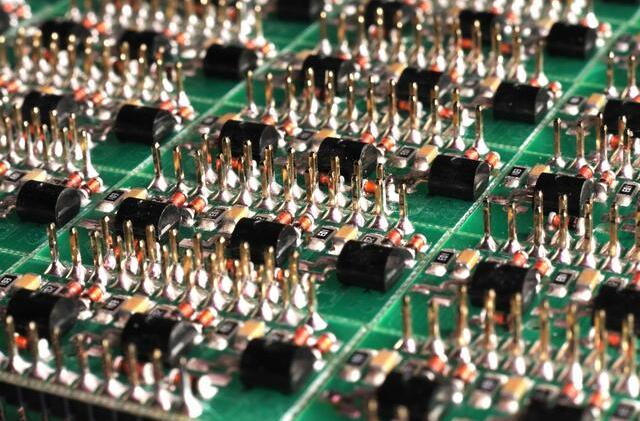

1. Epoxy Adhesives: Known for their high strength and thermal resistance, epoxy adhesives are widely used in SMT applications. They offer excellent mechanical properties and are often customized with additives to enhance adhesion and flexibility.

2. Acrylic Adhesives: These adhesives provide a balance of strength and flexibility, making them suitable for various applications. They are available in both clear and opaque versions and offer good resistance to heat and chemicals.

3. Silicone Adhesives: Flexible and resistant to heat and chemicals, silicone adhesives are ideal for applications where vibration or thermal stress is a concern.

4. Urethane Adhesives: Similar to silicone adhesives, urethane adhesives offer flexibility and resistance to heat and chemicals, making them suitable for applications requiring a flexible bond.

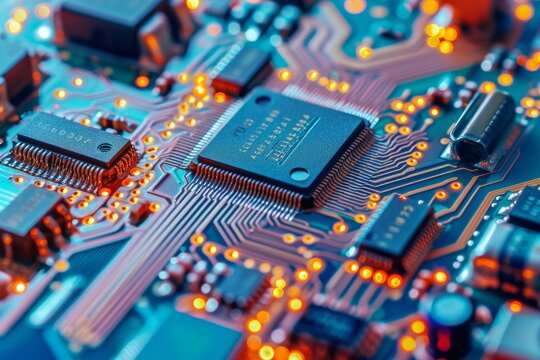

Emerging Innovations in SMT Adhesives

1. Environmentally Friendly Adhesives

The electronics industry is shifting towards more sustainable practices, including the development of environmentally friendly SMT adhesives. These adhesives are designed to reduce volatile organic compound (VOC) emissions, use renewable materials, and minimize waste, aligning with regulatory standards such as RoHS compliance. Water-based and bio-based adhesives are gaining traction, offering a safer alternative without compromising on adhesion strength[2][5].

2. Lead-Free and RoHS-Compliant Adhesives

In response to environmental regulations, there is a growing demand for lead-free and RoHS-compliant SMT adhesives. These adhesives not only meet stringent environmental standards but also maintain high performance in challenging environments.

3. Advanced Formulations for High-Speed Manufacturing

The increasing adoption of automation in electronics manufacturing has led to the development of SMT adhesives with precise dispensing characteristics and fast curing times. These adhesives are crucial for maintaining efficiency and product quality in high-speed assembly lines. Heraeus Electronics offers one-component, thermo-setting, solvent-free adhesives with high-green strength, ideal for high-speed production processes[3].

4. Integration with Emerging Technologies

The rollout of 5G technology and the growth of IoT devices are driving the demand for advanced SMT adhesives that can support faster data transmission and improved performance. This includes adhesives with enhanced thermal stability and mechanical strength to ensure reliability in demanding applications[7].

5. Transient Liquid Phase Sintering (TLPS) Solder Pastes

Recent breakthroughs include the development of SAC-based TLPS solder pastes, such as SMT-8120 by AI Technology, Inc. These pastes eliminate the need for SMT adhesives in double-sided PCB manufacturing by forming sintered interconnections during the first soldering cycle. This innovation simplifies assembly, reduces costs, and enhances design flexibility[1][4].

Applications of SMT Adhesives

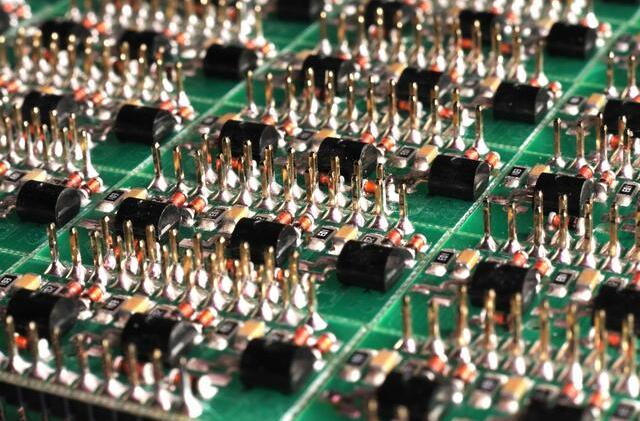

SMT adhesives are used across various industries, including:

- Automotive: Critical in the assembly of engine management systems, transmission controllers, and safety systems like ABS and ESP. The automotive sector is also driving the demand for lightweight and strong bonding solutions, aligning with the trend towards electric vehicles (EVs)[3][5].

- Consumer Electronics: Essential for smartphones, laptops, and wearables, where miniaturization and reliability are key. The increasing complexity of electronic devices necessitates adhesives that provide precise application and excellent thermal stability[2][3].

- Healthcare: Used in medical devices for improved diagnostics and treatment procedures. The reliability and durability of these devices are paramount, making high-quality SMT adhesives indispensable.

Challenges and Future Prospects

Despite the advancements, the SMT adhesives market faces challenges such as regulatory hurdles and the need for continuous innovation to meet evolving consumer demands. However, the outlook remains positive, with growth driven by technological advancements and expanding applications across industries. The integration of smart manufacturing technologies, including IoT and AI, is revolutionizing the production and application of SMT adhesives, enabling real-time monitoring and optimization of adhesive processes[2][5].

Technological Advancements

The integration of nanotechnology into SMT adhesives is enhancing their performance characteristics. By incorporating nanoparticles, manufacturers are creating adhesives that boast superior thermal conductivity and mechanical strength. This innovation is particularly crucial for high-power electronic devices, where efficient heat dissipation is essential[2].

Sustainability Initiatives

Sustainability efforts are driving demand for low-VOC and bio-based adhesives that meet stricter environmental standards without compromising performance. Companies are investing in research to create adhesives that are free from harmful solvents and align with consumer preferences for greener products[2][5].

Market Expansion

The growth of emerging markets contributes significantly to the expansion of the SMT adhesives sector. Regions such as Asia-Pacific are witnessing a surge in electronics manufacturing, driven by rising disposable incomes and increasing consumer demand for electronic goods[2].

Conclusion

Innovations in SMT adhesive technology are transforming the electronics manufacturing landscape by offering more efficient, sustainable, and reliable solutions. As the industry continues to evolve, the demand for advanced SMT adhesives will grow, driven by emerging technologies and the need for environmentally friendly practices. Understanding these trends is crucial for manufacturers seeking to capitalize on the opportunities presented by this rapidly changing market.

FAQs

1. What is the primary function of SMT adhesives in PCB assembly?

SMT adhesives primarily serve to secure components onto PCBs during the manufacturing process, ensuring they remain in place until soldered. This prevents movement and misalignment, enhancing the reliability and durability of electronic devices.

2. What types of SMT adhesives are commonly used?

Common types include epoxy, acrylic, silicone, and urethane adhesives, each offering unique properties such as strength, flexibility, and thermal resistance.

3. Why are environmentally friendly SMT adhesives becoming more important?

The shift towards environmentally friendly adhesives is driven by regulatory requirements and consumer demand for sustainable products. These adhesives reduce VOC emissions and waste, aligning with global environmental standards.

4. How do advancements in SMT adhesives support high-speed manufacturing?

Advanced SMT adhesives are formulated to have precise dispensing characteristics and fast curing times, which are essential for maintaining efficiency and product quality in automated assembly lines.

5. What role do TLPS solder pastes play in SMT manufacturing?

TLPS solder pastes, like SMT-8120, eliminate the need for SMT adhesives in double-sided PCB assembly by forming secure interconnections during the first soldering cycle, simplifying the manufacturing process and reducing costs.

Citations:

[1] https://www.aitechnology.com/wp-content/uploads/EINPresswire-791360701-ai-technology-launches-a-novel-sac-based-tlps-solder-paste-for-adhesive-free-smt-components-mounting-on-2-sided-pcbs.pdf

[2] https://pmarketresearch.com/product/worldwide-smt-adhesives-market-research-2024-by-type-application-participants-and-countries-forecast-to-2030/

[3] https://www.heraeus-electronics.com/en/products-and-solutions/adhesives/smt-adhesives/

[4] https://www.roi-nj.com/2025/03/07/tech/ai-technology-creates-new-sac-based-tlps-solder-paste/

[5] https://www.usp-research.com/insights/blogs/adhesives-and-sealants-market-trends-for-2025/

[6] https://www.in-adhesives.com/pdf/2025/in-adhesives2025_Abstracts_Day1.pdf

[7] https://www.linkedin.com/pulse/smt-adhesives-market-size-2025-unlocking-potential-pam1f/

[8] https://www.fortunebusinessinsights.com/temporary-bonding-adhesive-market-111464