Content Menu

● Introduction to SMT PCB Carriers

>> Advantages of SMT PCB Carriers

● Innovations in SMT PCB Carriers

>> Advanced Materials and Design

>> Integration with Automation Technologies

>> Customization and Flexibility

● Applications of SMT PCB Carriers

● Benefits of SMT PCB Carriers in Modern Manufacturing

● Future Developments in SMT PCB Carriers

● Integration with PCB Assembly Automation

>> Role of AI and Robotics

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary advantages of using SMT PCB carriers?

>> 2. How do SMT PCB carriers enhance manufacturing efficiency?

>> 3. What role do automation technologies play in SMT PCB carrier development?

>> 4. How do SMT PCB carriers contribute to cost-effectiveness in manufacturing?

>> 5. What future innovations can be expected in SMT PCB carrier technology?

● Citations:

The development of Surface Mount Technology (SMT) PCB carriers is undergoing significant transformations driven by innovative technologies and manufacturing processes. These advancements are crucial for enhancing the efficiency, reliability, and performance of SMT PCB assembly. In this article, we will delve into the key innovations driving the evolution of SMT PCB carriers, exploring their benefits and applications across various industries.

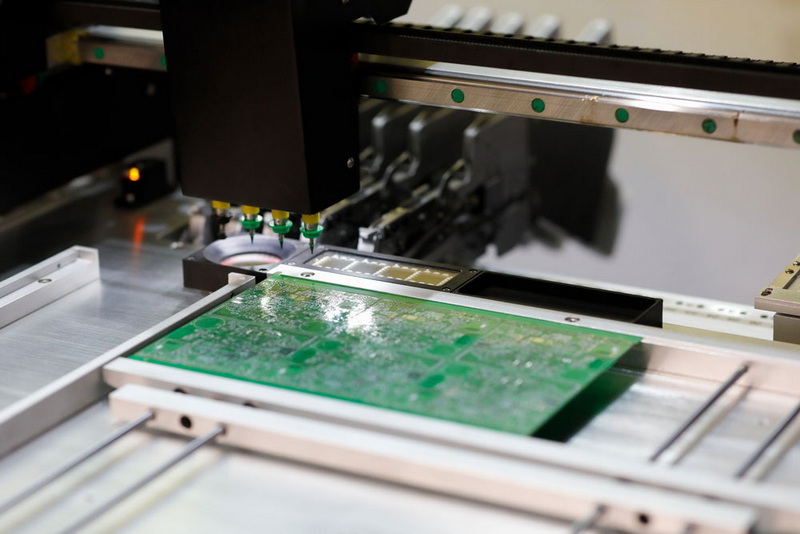

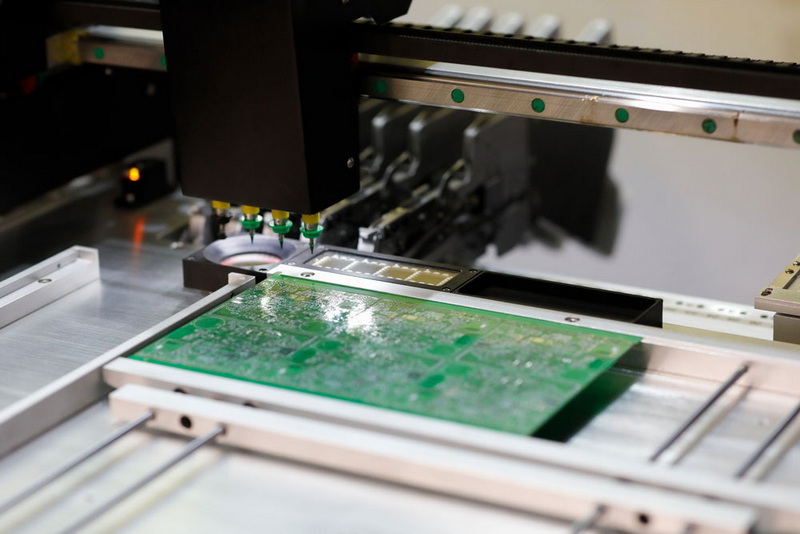

Introduction to SMT PCB Carriers

SMT PCB carriers are specialized tools designed to support and transport printed circuit boards (PCBs) during the assembly process. They play a vital role in ensuring that PCBs are properly aligned and secured, minimizing handling errors and improving overall manufacturing efficiency. The use of SMT PCB carriers is integral to maintaining high-quality production standards in the electronics industry.

Advantages of SMT PCB Carriers

1. Reduced Setup Time: SMT PCB carriers streamline the assembly process by reducing the time required for setup and preparation. This efficiency is crucial in high-volume production environments where time is of the essence.

2. Minimized Board Warping: By providing a stable and secure platform for PCBs, carriers help prevent warping and damage during the assembly process. This is particularly important for ensuring the structural integrity of the PCB.

3. Elimination of Unnecessary Handling: SMT PCB carriers reduce the need for manual handling of PCBs, which decreases the risk of human error and damage to the boards. This automated approach enhances consistency and reliability in production.

4. Cost Savings: The use of SMT PCB carriers eliminates expensive hand masking and labor costs associated with manual handling and processing. This cost-effectiveness is a significant advantage in competitive manufacturing environments.

5. Standardized Process Repetition: Carriers ensure that the assembly process is standardized, allowing for consistent results across different production batches. This consistency is vital for maintaining quality control standards.

Innovations in SMT PCB Carriers

Advanced Materials and Design

Recent innovations in SMT PCB carriers involve the use of advanced materials and designs that enhance their performance and durability. For instance, high-temperature semi-conductive composite materials are used to manufacture carriers that can withstand the thermal stresses encountered during the assembly process. These materials ensure that the carriers maintain their structural integrity and precision alignment capabilities even under extreme conditions.

Durostone, a heavy-duty glass fiber reinforced plastic, is commonly used for making reflow carriers due to its excellent mechanical and thermal properties. It offers extreme strength and dimensional stability, allowing carriers to be reused over 20,000 times under high temperatures[2]. Other materials like FR4 (without copper) and aluminum alloy are also utilized based on specific requirements[8].

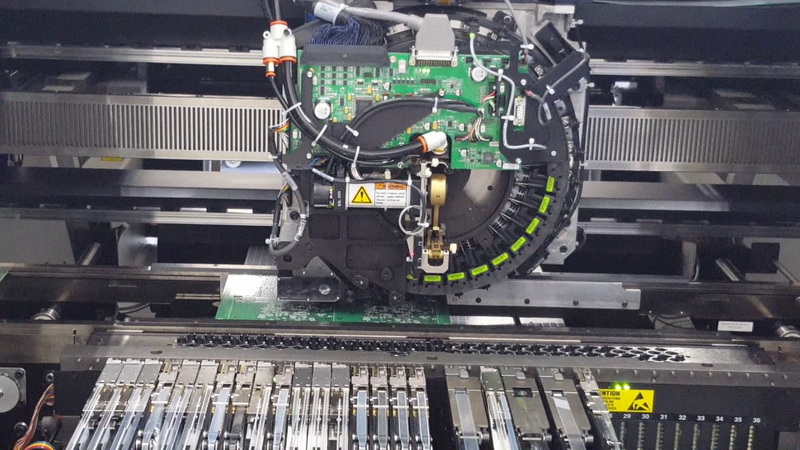

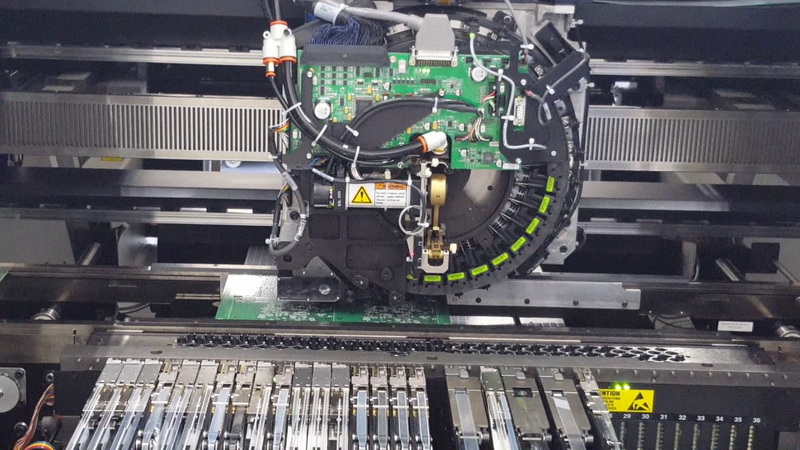

Integration with Automation Technologies

The integration of SMT PCB carriers with automation technologies is another significant innovation. Automated assembly lines equipped with machine vision systems and robotic arms can precisely align and place components on PCBs held by carriers. This integration enhances production speed and accuracy, reducing the likelihood of defects and improving overall product quality.

AI-powered automation is transforming the PCB assembly process by enabling real-time defect detection, predictive maintenance, and autonomous process adjustments. These technologies facilitate increased productivity and decreased waste, making them essential for modern manufacturing environments[1][4].

Customization and Flexibility

Modern SMT PCB carriers are designed to be highly customizable, allowing manufacturers to tailor them to specific production needs. This flexibility is crucial for accommodating diverse PCB sizes and shapes, ensuring that each board is properly supported and aligned during assembly. Custom-engineered carriers can also be optimized for specific soldering processes, such as wave soldering or reflow soldering, further enhancing their versatility.

The design of SMT carriers often involves the use of tapered tooling pins and flush-mounted pushers to secure PCBs during the assembly process. These mechanisms help maintain board flatness and prevent warping, especially for thinner substrates[2].

Applications of SMT PCB Carriers

SMT PCB carriers are widely used across various industries where electronic devices are manufactured. Some of the key applications include:

- Consumer Electronics: Smartphones, laptops, and wearable devices rely heavily on SMT PCB assembly. Carriers play a crucial role in ensuring the precision and reliability of these compact and complex electronic systems.

- Automotive Electronics: Advanced driver-assistance systems (ADAS), infotainment systems, and engine control units (ECUs) require high-quality PCBs assembled using SMT techniques. SMT PCB carriers are essential for maintaining the integrity and performance of these critical automotive components.

- Medical Devices: Diagnostic tools, portable monitors, and imaging systems benefit from the compact and reliable PCBs produced using SMT assembly. The precision and consistency provided by SMT PCB carriers are vital for ensuring the reliability of medical devices.

Benefits of SMT PCB Carriers in Modern Manufacturing

The advantages of SMT PCB carriers are multifaceted, contributing significantly to modern manufacturing processes:

1. Enhanced Efficiency: By streamlining the assembly process and reducing manual handling, SMT PCB carriers increase production efficiency and throughput.

2. Improved Quality Control: The use of carriers minimizes defects and ensures consistent quality across different production batches, which is critical for maintaining high standards in the electronics industry.

3. Cost-Effectiveness: The elimination of unnecessary handling and labor-intensive processes reduces production costs, making SMT PCB carriers a cost-effective solution for manufacturers.

4. Flexibility and Customization: The ability to customize carriers for specific PCB designs and assembly processes allows manufacturers to adapt to diverse production requirements, enhancing their flexibility in responding to market demands.

Future Developments in SMT PCB Carriers

As technology continues to evolve, future developments in SMT PCB carriers are expected to focus on further integrating automation and AI technologies. This integration will enable real-time monitoring and adjustments during the assembly process, enhancing precision and speed without compromising quality. Additionally, advancements in materials science will lead to the development of more durable and versatile carrier designs, capable of withstanding increasingly complex assembly processes.

The trend towards Industry 4.0 and smart manufacturing initiatives will also influence the design of SMT PCB carriers, emphasizing modularity and flexibility to accommodate diverse production needs. Sustainability will become a key factor, with manufacturers focusing on energy-efficient and environmentally friendly carrier designs[1][4].

Integration with PCB Assembly Automation

The integration of SMT PCB carriers with automated PCB assembly processes is crucial for enhancing efficiency and quality. Automated systems, including CNC routing machines for depaneling and conveyor systems for material movement, ensure a streamlined manufacturing process. These systems reduce manual handling, minimize the risk of damage, and optimize production logistics[3].

Role of AI and Robotics

AI-powered automated optical inspection (AOI) and robotic soldering are transforming PCB assembly trends by enabling faster production, fewer errors, and higher efficiency. AI-driven analytics optimize workflows, reducing waste and improving quality control. The integration of robotics and advanced vision systems improves the overall flexibility and accuracy of SMT placement, allowing for the efficient handling of components with varying sizes and shapes[1][4].

Conclusion

In conclusion, the development of SMT PCB carriers is driven by innovations in materials, design, and automation technologies. These advancements have significantly enhanced the efficiency, reliability, and performance of SMT PCB assembly processes. As the electronics industry continues to evolve, the role of SMT PCB carriers will remain crucial in supporting the production of compact, complex, and high-performance electronic devices.

Frequently Asked Questions

1. What are the primary advantages of using SMT PCB carriers?

- The primary advantages include reduced setup time, minimized board warping, elimination of unnecessary handling, cost savings, and standardized process repetition.

2. How do SMT PCB carriers enhance manufacturing efficiency?

- SMT PCB carriers enhance efficiency by streamlining the assembly process, reducing manual handling, and ensuring consistent alignment and support of PCBs during production.

3. What role do automation technologies play in SMT PCB carrier development?

- Automation technologies, such as machine vision systems and robotic arms, are integrated with SMT PCB carriers to enhance precision and speed during assembly, reducing defects and improving product quality.

4. How do SMT PCB carriers contribute to cost-effectiveness in manufacturing?

- SMT PCB carriers contribute to cost-effectiveness by eliminating expensive hand masking and labor costs associated with manual handling and processing, thereby reducing overall production expenses.

5. What future innovations can be expected in SMT PCB carrier technology?

- Future innovations are expected to focus on integrating AI technologies for real-time monitoring and adjustments, along with advancements in materials science to develop more durable and versatile carrier designs.

Citations:

[1] https://www.datainsightsmarket.com/reports/pcb-smt-machines-55637

[2] https://madpcb.com/reflow-carrier/

[3] https://develop-llc.com/insights/guide-to-pcb-assembly-automation/

[4] https://novaenginc.com/future-of-circuit-board-assembly/

[5] https://www.pcbunlimited.com/smt-carriers

[6] https://www.sealevel.com/smt-line

[7] https://highpcb.com/top-5-emerging-trends-in-pcb-technology-for-2025/

[8] https://smartsmttools.com/how-to-order-a-suitable-smt-carrier-to-highly-improve-your-smt-process-efficiency%EF%BC%9F/

[9] https://versae.com/smt-assembly-faq/

[10] https://www.allsmt.com/electronic-manufacturing-innovations-2025

[11] https://www.stentech.com/products/solder-pallet/surface-mount-process-carriers

[12] https://iconnect007.com/article/141778/designers-notebook-pcb-design-and-ipccfx-for-assembly-automation/141775/pcb

[13] https://asselems.com/en/key-trends-in-the-electronics-manufacturing-industry-for-2025

[14] https://www.stencilsunlimited.com/surface-mount-carriers

[15] https://blog.isa.org/the-opportunities-and-obstacles-in-using-automation-for-pcb-assembly

[16] https://southelectronicpcb.com/top-pcb-manufacturers-for-advanced-packaging-in-2025/

[17] https://www.nordson.com/en/divisions/electronics-solutions/your-process/industries/pcb-and-smt-assembly

[18] https://www.festo.com/us/en/e/solutions/industries/electronics-industry/pcb-assembly-id_7025/

[19] https://www.newschannelnebraska.com/story/52586034/smt-machine-market-2025-2033-manufacturers-new-entrants-growth-and-scope

[20] https://www.teknek.com/sectors/advanced-electronic-manufacturing-smt/