Content Menu

● Introduction

● Key Features of SMT Soldering Tools

>> Temperature Control

>> Power Output

>> Tip Variety and Quality

>> Ergonomics and Usability

>> Additional Features

● Types of SMT Soldering Tools

>> Soldering Irons

>> Reflow Ovens

>> Hot Air Guns

>> Solder Paste Printers

● How to Choose the Right SMT Soldering Tool

● Conclusion

● Frequently Asked Questions

>> 1. What is the ideal temperature range for SMT soldering?

>> 2. Why is power output important in soldering tools?

>> 3. What additional tools are helpful for SMT soldering?

>> 4. Can beginners use SMT soldering tools?

>> 5. How do I maintain my SMT soldering tools?

Introduction

Surface Mount Technology (SMT) soldering is a critical process in modern electronics manufacturing, allowing for the efficient assembly of compact and high-density circuit boards. As electronics continue to evolve, the demand for reliable and effective SMT soldering tools has increased significantly. Selecting the right SMT soldering tools is essential for achieving high-quality solder joints, minimizing defects, and ensuring the longevity of electronic devices. This article explores the key features to consider when choosing SMT soldering tools, the various types available, and tips for selecting the best tools for your specific needs.

Key Features of SMT Soldering Tools

When evaluating SMT soldering tools, several key features should be prioritized to ensure optimal performance and usability.

Temperature Control

Precise temperature control is paramount in SMT soldering. Different components require specific temperature settings to prevent damage while ensuring effective soldering. High-quality SMT soldering tools provide adjustable temperature settings that can be easily calibrated. Look for tools that offer digital displays for accurate temperature readings and quick adjustments.

Maintaining a consistent temperature during the soldering process is crucial. Fluctuations can lead to cold solder joints or overheating, which can damage sensitive electronic components. Some advanced models come with programmable temperature profiles that allow users to set specific heating cycles tailored to particular components or materials.

Power Output

The power output of a soldering tool directly affects its heating efficiency. Tools with higher power output heat up more quickly and maintain consistent temperatures during operation. This is particularly important for larger components or when working with multiple joints simultaneously. A power output of at least 50 watts is recommended for most SMT applications.

Additionally, some tools feature a power-saving mode that reduces energy consumption during idle periods without compromising performance when in use. This feature not only saves energy but also extends the lifespan of the tool.

Tip Variety and Quality

The quality and variety of soldering tips are crucial for achieving precise results. Different tips are designed for various tasks, such as fine-pitch components or larger pads. High-quality tips made from durable materials ensure longevity and better heat transfer. When selecting SMT soldering tools, consider those that come with a range of interchangeable tips to accommodate diverse soldering tasks.

Some manufacturers offer specialized tips designed for specific applications, such as anti-static tips for sensitive electronic components or chisel tips for broader coverage on larger pads. Investing in a set of high-quality tips can greatly enhance your soldering capabilities.

Ergonomics and Usability

Soldering can often involve extended periods of use, making ergonomics an essential consideration. Tools designed with user comfort in mind will reduce fatigue and improve precision during long sessions. Look for features such as lightweight designs, comfortable grips, and well-balanced structures that allow for easy maneuverability.

Tools with adjustable stands or holders can also enhance usability by keeping the tool accessible while minimizing strain on the user's wrist and hand. Additionally, some models come with built-in anti-static features to protect sensitive components from electrostatic discharge (ESD).

Additional Features

Modern SMT soldering tools may include various additional features that enhance their functionality:

- Vacuum Pickup Tools: Essential for handling small components without damaging them. These tools utilize suction to securely lift and place tiny parts accurately on circuit boards.

- Magnifying Glasses or Microscopes: Useful for inspecting fine details and ensuring proper placement of components. Many advanced models integrate magnification lenses directly into the design for convenience.

- Soldering Stations: Integrated systems that combine multiple functions, including temperature control, tip storage, and power management. These stations often feature multiple ports for connecting various tools simultaneously.

- Built-in Safety Features: Look for tools equipped with automatic shut-off functions that activate after a period of inactivity to prevent overheating and potential accidents.

Types of SMT Soldering Tools

Understanding the different types of SMT soldering tools available can help you choose the right equipment for your projects.

Soldering Irons

Soldering irons are the most common hand-held tools used in SMT soldering. They are versatile and suitable for various applications, from hobbyist projects to professional assembly lines. When selecting a soldering iron, consider its wattage, temperature control capabilities, and tip compatibility.

Some advanced soldering irons incorporate features like rapid heating elements that reach operational temperatures within seconds, enhancing productivity in fast-paced environments.

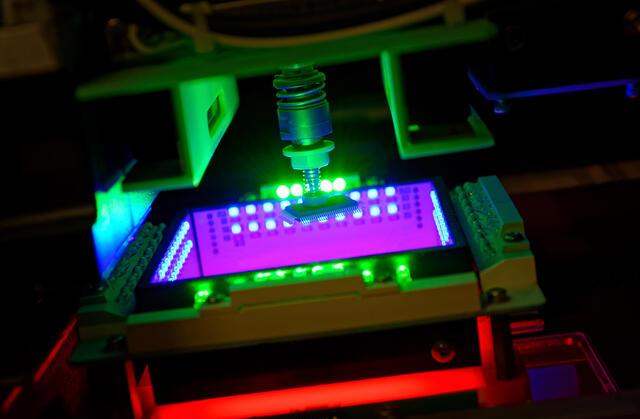

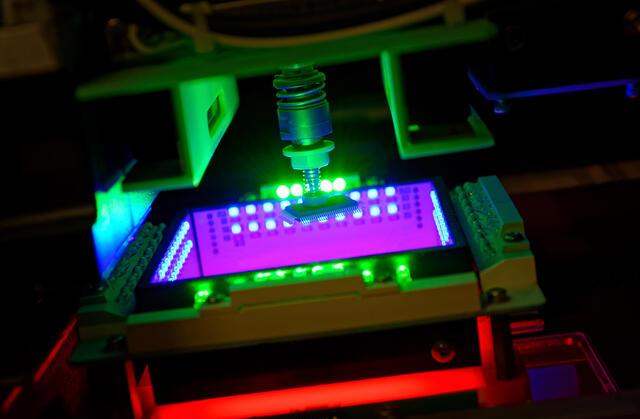

Reflow Ovens

Reflow ovens are essential in automated SMT assembly processes. They provide uniform heating to melt solder paste on multiple components simultaneously, ensuring consistent solder joints across a board. Reflow ovens vary in size and complexity; choose one that fits your production volume and specific requirements.

Advanced reflow ovens come equipped with programmable profiles that allow users to customize heating cycles based on different materials or component types, ensuring optimal results every time.

Hot Air Guns

Hot air guns are versatile tools ideal for reworking or desoldering small components. They use heated air to melt solder without direct contact with the component, reducing the risk of damage. Hot air guns are particularly useful for surface-mounted devices (SMDs) with fine pitch or when working with sensitive components.

Many hot air guns come with adjustable airflow settings, allowing users to control the intensity of airflow based on their specific needs—this feature is particularly useful when working with delicate components that could be dislodged by excessive force.

Solder Paste Printers

For those involved in high-volume production, solder paste printers are invaluable tools that apply precise amounts of solder paste onto circuit boards before component placement. These printers ensure uniform coverage and minimize waste while maximizing efficiency in the assembly process.

Automated models can significantly increase throughput by allowing multiple boards to be printed simultaneously while maintaining high accuracy levels.

How to Choose the Right SMT Soldering Tool

Selecting the right SMT soldering tool involves considering several factors:

- Project Requirements: Assess the types of components you will be working with and their specific requirements regarding heat and precision. For example, if you frequently work with fine-pitch ICs, investing in high-quality hot air rework stations might be beneficial.

- Budget: High-quality tools can vary significantly in price. Determine your budget while considering long-term investments in durable equipment that will withstand regular use without compromising performance.

- User Experience: If you are new to SMT soldering, consider starting with beginner-friendly tools that offer intuitive controls and safety features. Many manufacturers provide starter kits that include essential tools along with instructional materials.

- Brand Reputation: Research reputable brands known for producing reliable SMT soldering tools backed by good customer support. Reading reviews from other users can provide valuable insights into product reliability and performance.

- Maintenance Needs: Consider how easy it is to maintain your chosen tools. Some models may require more frequent cleaning or part replacements than others; understanding these requirements can help you make an informed decision regarding long-term usability.

Conclusion

Choosing the right SMT soldering tools is vital for achieving high-quality results in electronics manufacturing. By focusing on key features such as temperature control, power output, tip variety, ergonomics, and additional functionalities, you can select tools that meet your specific needs effectively. Whether you are a hobbyist or a professional technician, investing in quality SMT soldering equipment will enhance your productivity and ensure successful project outcomes.

In summary, understanding the various types of SMT soldering tools available—such as soldering irons, reflow ovens, hot air guns, and paste printers—will help you make informed decisions based on your project requirements and budget constraints. By prioritizing quality features and ergonomics while considering maintenance needs and brand reputation, you can equip yourself with reliable tools that will serve you well over time.

Frequently Asked Questions

1. What is the ideal temperature range for SMT soldering?

Typically between 350-400°C; however, this can vary depending on the components being used and the type of solder.

2. Why is power output important in soldering tools?

Higher power output allows for faster heating times and better efficiency during the soldering process.

3. What additional tools are helpful for SMT soldering?

Useful additional tools include magnifying glasses or microscopes for inspection, vacuum pickup tools for handling small components, and advanced soldering stations.

4. Can beginners use SMT soldering tools?

Yes! With proper guidance and practice, beginners can effectively learn to use these tools successfully.

5. How do I maintain my SMT soldering tools?

Regular cleaning, proper storage practices, and following manufacturer guidelines will help ensure your tools remain in good condition over time.