Content Menu

● Understanding SMD AOI Machines

● Key Features to Look for in an SMD AOI Machine

>> 1. High-Resolution Imaging and Multi-Angle Cameras

>> 2. Advanced Image Processing and Defect Recognition Software

>> 3. High-Speed Inspection Capability

>> 4. Multi-Station and Inline Integration

>> 5. User-Friendly Interface and Programming Flexibility

>> 6. Comprehensive Defect Reporting and Data Analysis

>> 7. Compatibility with Various PCB Sizes and Component Types

>> 8. Reliable Lighting and Optics System

>> 9. Robust Mechanical Design and Maintenance Support

● Benefits of Using an SMD AOI Machine

● Conclusion

● FAQ

>> 1. What is the primary function of an SMD AOI machine?

>> 2. How does 3D AOI improve inspection accuracy?

>> 3. Can an SMD AOI machine keep up with high-speed SMT production lines?

>> 4. How does AOI software help in defect detection?

>> 5. Is it possible to integrate AOI machines into existing SMT production lines?

In the fast-evolving electronics manufacturing industry, Surface Mount Device (SMD) Automated Optical Inspection (AOI) machines have become indispensable tools for ensuring product quality and production efficiency. As electronic components shrink and circuit boards become more complex, the demand for precise, fast, and reliable inspection systems grows. This article explores the essential features you should look for in an SMD AOI machine to optimize your SMT (Surface Mount Technology) production line.

Understanding SMD AOI Machines

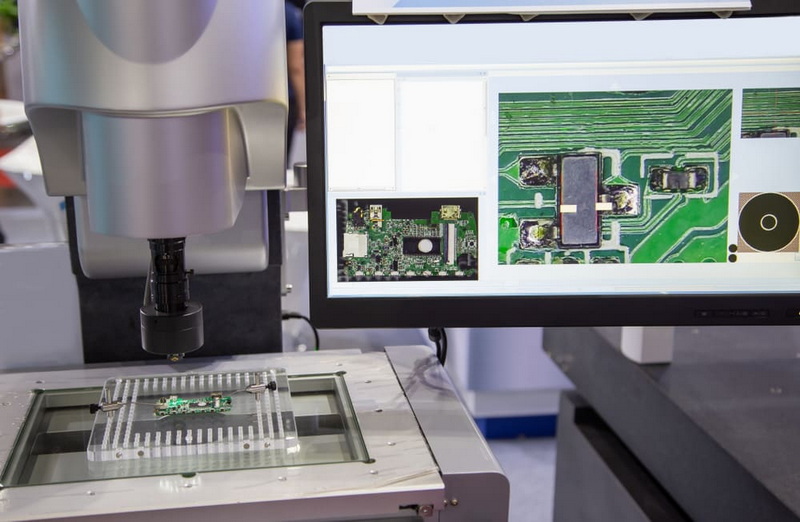

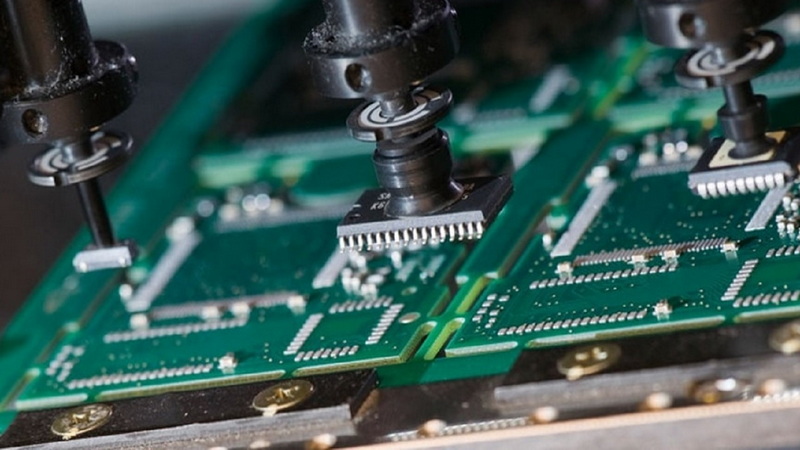

An SMD AOI machine is an automated inspection system that uses high-resolution cameras and advanced image processing algorithms to inspect printed circuit boards (PCBs) during or after the surface mount assembly process. It detects defects such as incorrect component placement, polarity errors, solder joint issues, missing components, and other surface-level faults by comparing real-time images to a digital reference model of the PCB.

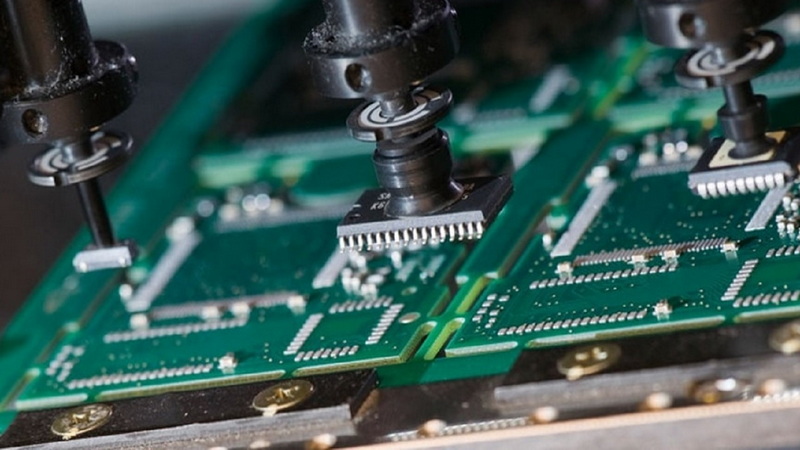

AOI machines replace manual visual inspection, which is slower and prone to human error, providing a faster, more accurate, and consistent quality control method. They are critical in modern SMT lines to maintain high throughput without compromising product quality.

The importance of SMD AOI machines cannot be overstated in today's electronics manufacturing environment. With the increasing miniaturization of components and the complexity of PCB layouts, manual inspection is no longer feasible. AOI machines provide a non-contact, non-destructive method to ensure that every component is correctly placed and soldered, reducing the risk of field failures and costly recalls.

Key Features to Look for in an SMD AOI Machine

1. High-Resolution Imaging and Multi-Angle Cameras

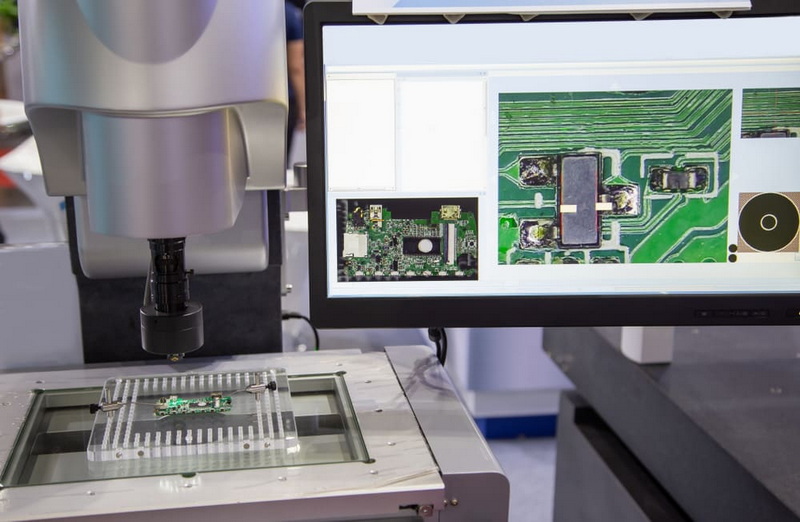

The core of any AOI system is its imaging capability. Look for machines equipped with high-resolution cameras that can capture detailed images of tiny SMD components and solder joints. Multi-angle or 3D imaging capabilities are especially valuable because they allow inspection of hidden or hard-to-see areas, such as underneath components or at solder joint edges, which traditional 2D systems might miss.

High-resolution imaging ensures that even the smallest defects, such as micro-cracks in solder joints or slight misalignments, are detected early. Multi-angle cameras provide a three-dimensional view of the PCB, enabling the system to inspect complex components like Ball Grid Arrays (BGAs) and Quad Flat Packages (QFPs) more effectively.

2. Advanced Image Processing and Defect Recognition Software

The AOI machine should have sophisticated software algorithms capable of accurately analyzing images and identifying a wide range of defects, including:

- Misalignment and incorrect placement

- Polarity errors

- Solder joint defects (insufficient solder, bridging, voids)

- Missing or extra components

- Surface contamination or scratches

The software should also support automatic learning or programming modes, allowing easy setup and adaptation to new PCB designs. Machine learning and artificial intelligence (AI) integration in AOI software are becoming increasingly common, enabling the system to improve defect detection accuracy over time by learning from previous inspections.

3. High-Speed Inspection Capability

In high-volume SMT production, speed is critical. The AOI machine must keep pace with fast assembly lines, inspecting hundreds or thousands of components per minute without sacrificing accuracy. High-speed AOI systems enable real-time defect detection and immediate feedback to upstream processes, reducing defect propagation and rework costs.

Speed is not just about the camera's frame rate but also the processing power of the software and the efficiency of the mechanical handling system. A well-designed SMD AOI machine balances speed and accuracy to ensure that no defects are missed while maintaining production throughput.

4. Multi-Station and Inline Integration

Modern AOI machines often support multi-station setups, where several inspection points along the production line are controlled by a single system. This integration reduces equipment complexity and improves data management. Inline AOI systems that can inspect PCBs at various stages (post-placement, post-soldering, final inspection) provide comprehensive quality control throughout the SMT process.

Inline integration allows manufacturers to catch defects as early as possible, preventing defective boards from moving further down the line. This early detection reduces waste and rework, saving time and money. Additionally, multi-station AOI systems can share data and provide a holistic view of the production quality, enabling better process control.

5. User-Friendly Interface and Programming Flexibility

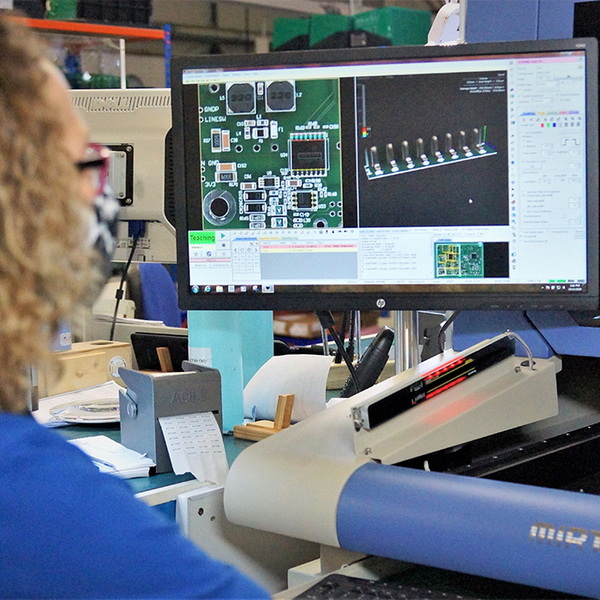

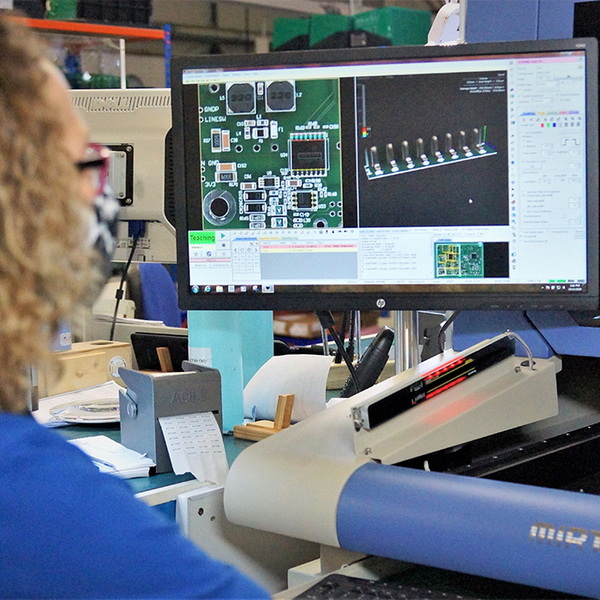

Ease of use is essential for efficient operation. The AOI machine should offer intuitive user interfaces, manual and automatic programming modes, and the ability to import CAD data for quick setup. This flexibility reduces downtime and training requirements, enabling operators to quickly adapt to new products or changes in production.

A graphical user interface (GUI) with drag-and-drop programming, real-time image display, and easy defect classification tools can significantly improve operator productivity. Some advanced AOI machines also offer remote access and cloud-based data management, allowing engineers to monitor and adjust inspection parameters from anywhere.

6. Comprehensive Defect Reporting and Data Analysis

A good SMD AOI machine provides detailed defect reports and analytics, helping manufacturers identify recurring issues and optimize their processes. Real-time feedback and trend analysis allow for proactive adjustments, improving yield and reducing waste.

Defect data can be categorized by type, location, frequency, and severity, enabling root cause analysis. Integration with Manufacturing Execution Systems (MES) and Statistical Process Control (SPC) software further enhances process control and continuous improvement initiatives.

7. Compatibility with Various PCB Sizes and Component Types

The AOI system should accommodate a wide range of PCB sizes and component packages, including fine-pitch ICs, QFPs, BGAs, and tiny passive components. This versatility ensures the machine remains useful as product designs evolve.

Adjustable fixtures, flexible conveyor systems, and adaptable inspection algorithms allow the AOI machine to handle different board dimensions and component densities without extensive reconfiguration. This flexibility is especially important for contract manufacturers and companies with diverse product lines.

8. Reliable Lighting and Optics System

Consistent and adjustable lighting is crucial for capturing clear images. Look for AOI machines with advanced lighting systems that minimize shadows and reflections, enhancing defect detection accuracy.

Different lighting techniques, such as coaxial, ring, and dark-field illumination, can highlight various defect types. The ability to adjust lighting parameters dynamically during inspection improves the detection of subtle defects like solder voids or component discoloration.

9. Robust Mechanical Design and Maintenance Support

An often-overlooked feature is the mechanical reliability of the AOI machine. Look for systems built with durable materials and precision components to ensure long-term stability and minimal downtime.

Additionally, consider the availability of technical support, training, and maintenance services from the manufacturer. Regular calibration and preventive maintenance are essential to maintain inspection accuracy over time.

Benefits of Using an SMD AOI Machine

- Improved Quality and Reliability: Detects defects early, ensuring only high-quality PCBs proceed to the next stage or shipment. This reduces the risk of field failures and enhances customer satisfaction.

- Increased Production Efficiency: High-speed inspection reduces bottlenecks and allows faster throughput, enabling manufacturers to meet tight delivery schedules.

- Cost Savings: Early defect detection minimizes costly rework, scrap, and returns, significantly lowering production costs.

- Consistent Inspection: Eliminates variability and fatigue associated with manual inspection, providing uniform quality control across shifts and operators.

- Process Optimization: Data analytics help identify root causes and improve manufacturing processes, leading to continuous quality improvement and higher yields.

- Traceability and Compliance: Detailed inspection records support traceability requirements and compliance with industry standards such as IPC and ISO.

Conclusion

Choosing the right SMD AOI machine is critical for maintaining high quality and efficiency in SMT production. Key features to prioritize include high-resolution multi-angle imaging, advanced defect recognition software, high-speed inspection capabilities, multi-station integration, user-friendly interfaces, comprehensive reporting, and compatibility with diverse PCB and component types. Additionally, reliable lighting, robust mechanical design, and strong manufacturer support are essential for long-term success.

Investing in a capable SMD AOI machine not only enhances product quality but also reduces costs and supports continuous process improvement, making it an essential asset in modern electronics manufacturing. As technology advances, integrating AI and machine learning into AOI systems will further improve defect detection accuracy and adaptability, ensuring manufacturers stay competitive in a demanding market.

FAQ

1. What is the primary function of an SMD AOI machine?

An SMD AOI machine inspects surface-mounted components on PCBs to detect defects such as misplacement, polarity errors, solder joint issues, and missing components by comparing images to a digital reference.

2. How does 3D AOI improve inspection accuracy?

3D AOI uses multi-angle cameras to capture images from different perspectives, allowing it to detect hidden defects under components or at solder joint edges that 2D AOI might miss.

3. Can an SMD AOI machine keep up with high-speed SMT production lines?

Yes, modern SMD AOI machines are designed for high-speed inspection, capable of processing hundreds to thousands of components per minute, matching the pace of fast SMT lines.

4. How does AOI software help in defect detection?

AOI software uses advanced image processing algorithms to analyze captured images, identify deviations from the standard, and classify defects, enabling accurate and automated inspection.

5. Is it possible to integrate AOI machines into existing SMT production lines?

Yes, many AOI machines support inline integration and multi-station setups, allowing seamless incorporation into various stages of the SMT process for comprehensive quality control.