Content Menu

● Introduction to SMT Stencil Thickness

>> Common SMT Stencil Thicknesses

● Factors Influencing SMT Stencil Thickness Selection

● Calculating Stencil Thickness

>> Aspect Ratio Calculation

>> Area Ratio Calculation

● Special Considerations for Fine-Pitch Components

>> Stepped Stencils

● Impact of Stencil Thickness on PCB Assembly Quality

● Stencil Materials and Manufacturing Processes

>> Laser Cutting

>> Chemical Etching

● Conclusion

● FAQs

>> 1. What is the typical range of SMT stencil thicknesses?

>> 2. How does component size affect SMT stencil thickness selection?

>> 3. What is the role of aspect ratio in stencil thickness selection?

>> 4. How does the type of solder paste influence stencil thickness?

>> 5. What are the benefits and drawbacks of using stepped stencils?

● Citations:

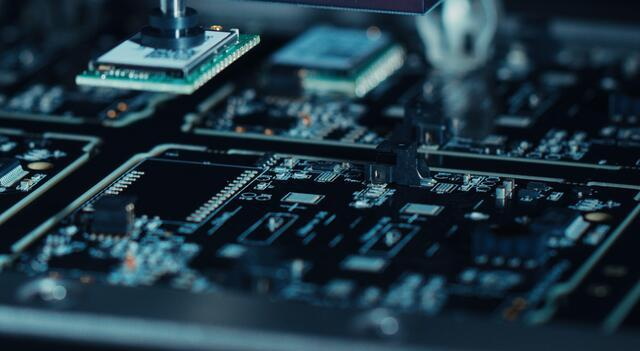

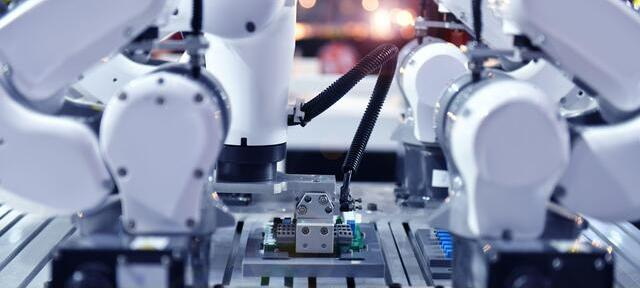

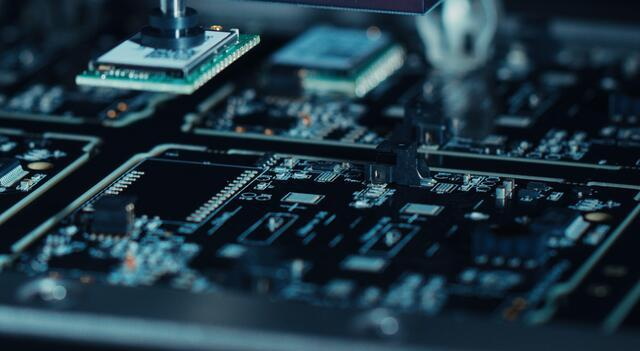

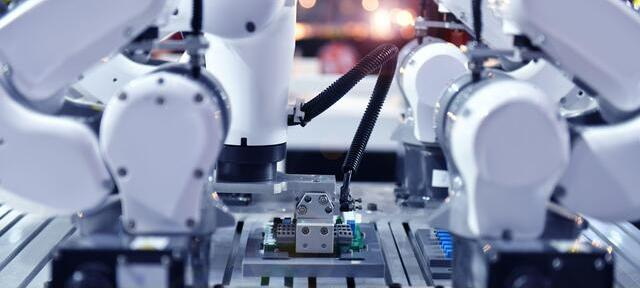

The selection of the appropriate SMT (Surface Mount Technology) stencil thickness is a critical factor in ensuring the quality and reliability of printed circuit boards (PCBs). SMT stencils are used to apply solder paste onto PCB pads, and their thickness directly affects the volume of solder paste deposited, which in turn influences the solder joint quality. In this article, we will explore the key factors that influence the selection of SMT stencil thickness and discuss how these factors impact PCB assembly.

Introduction to SMT Stencil Thickness

SMT stencils are typically made from stainless steel or other materials and come in various thicknesses, ranging from 0.05 mm to 0.30 mm. The choice of stencil thickness depends on several factors, including the type and size of components, the pitch between components, and the desired solder joint profile.

Common SMT Stencil Thicknesses

Common thicknesses for solder paste stencils are between 0.05 mm and 0.15 mm, while thicker stencils (0.18 mm to 0.30 mm) are often used for adhesives or special applications. For example, components like 0201 and 0402 require thinner stencils (around 0.10 mm to 0.12 mm), while larger components such as QFPs and BGAs may use thicker stencils (0.13 mm to 0.15 mm) to ensure sufficient solder paste volume for robust solder joints[1][2].

Factors Influencing SMT Stencil Thickness Selection

Several factors are crucial when determining the appropriate SMT stencil thickness:

1. Component Size and Pitch: Smaller components with finer pitches require thinner stencils to ensure precise solder paste deposition. For instance, 0201 components typically use a stencil thickness of 0.10 mm to 0.12 mm, while 0402 components may use 0.10 mm to 0.12 mm as well. Larger components, such as those with pitches greater than 1 mm, can use thicker stencils to accommodate more solder paste[1][4].

2. Solder Paste Type and Viscosity: The type and viscosity of solder paste can affect how well it releases from the stencil. Thicker pastes may require slightly thicker stencils to ensure adequate release, while thinner pastes may work well with thinner stencils[4].

3. PCB Pad Size and Shape: The size and shape of PCB pads influence the aperture size on the stencil, which in turn affects the solder paste volume. Apertures should be slightly larger than the pad to accommodate paste shrinkage during reflow. For larger components requiring more solder paste, the aperture area may be increased by 10% to 20%[1].

4. Desired Solder Joint Profile: The desired solder joint profile, including the height and volume of solder, influences the choice of stencil thickness. Thicker stencils deposit more solder paste, which can be beneficial for components requiring robust solder joints but may lead to solder bridging on fine-pitch components[2][3].

5. Aspect Ratio and Area Ratio: The aspect ratio (aperture width/thickness) and area ratio (aperture area/aperture wall area) are important parameters. An aspect ratio greater than 1.5 and an area ratio greater than 0.66 are recommended to ensure smooth solder paste release and prevent bridging[3][4].

Calculating Stencil Thickness

Calculations for stencil thickness often involve the aspect ratio and area ratio. The aspect ratio ensures that the stencil can release solder paste effectively without leaving residue, while the area ratio helps in maintaining the right amount of solder paste on the PCB pads.

Aspect Ratio Calculation

The aspect ratio is calculated as the width of the aperture divided by the thickness of the stencil (W/T). A minimum aspect ratio of 1.5 is recommended to ensure reliable solder paste release.

Area Ratio Calculation

The area ratio is calculated as the surface area of the aperture divided by the surface area of the aperture walls. A minimum area ratio of 0.66 is recommended for reliable solder paste deposition.

Special Considerations for Fine-Pitch Components

Fine-pitch components, such as BGAs with small ball pitches, require precise solder paste deposition to prevent solder bridging. Thinner stencils are often used for these components to ensure accurate paste placement. For example, components like 01005s may require stencil thicknesses as low as 0.075 mm to maintain the necessary area ratio for good paste transfer efficiency[5].

Stepped Stencils

For PCBs with both fine-pitch and larger components, stepped stencils can be used. These stencils have varying thicknesses in different areas to accommodate different component types. However, stepped stencils increase manufacturing complexity and cost. The maximum step difference is typically limited to 0.05 mm to ensure smooth paste release and prevent paste retention[4][7].

Impact of Stencil Thickness on PCB Assembly Quality

The thickness of the SMT stencil significantly impacts the quality of PCB assembly. Thicker stencils provide more solder paste, which can be beneficial for components requiring robust solder joints but may lead to solder bridging on fine-pitch components. Conversely, thinner stencils offer better precision for fine-pitch components but may result in insufficient solder paste for larger components[2][3].

Stencil Materials and Manufacturing Processes

SMT stencils are typically made from stainless steel, with fine-grain stainless steel being preferred for high-precision applications due to its smoother aperture walls. Other materials like nickel are used in high-temperature environments. The manufacturing process, such as laser cutting or chemical etching, affects the surface finish and accuracy of the stencil apertures[6][7].

Laser Cutting

Laser cutting is the most common method for creating stencil apertures due to its precision and ability to handle complex designs. It is ideal for fine-pitch components and ensures smooth aperture walls, which are crucial for efficient solder paste release[6].

Chemical Etching

Chemical etching is an alternative process that involves using a photoresist mask and chemical solution to create apertures. While less precise than laser cutting, it can be cost-effective for larger apertures or thicker stencils[6].

Conclusion

Selecting the appropriate SMT stencil thickness is crucial for achieving high-quality PCB assemblies. Factors such as component size, solder paste type, and desired solder joint profile all influence the choice of stencil thickness. By understanding these factors and applying guidelines such as aspect and area ratios, manufacturers can optimize their PCB assembly processes to ensure reliable and efficient production.

FAQs

1. What is the typical range of SMT stencil thicknesses?

Typical SMT stencil thicknesses range from 0.10 mm to 0.20 mm, with thinner stencils used for fine-pitch components and thicker stencils for larger components. For solder paste stencils, common thicknesses are between 0.05 mm and 0.15 mm[1][8].

2. How does component size affect SMT stencil thickness selection?

Smaller components with finer pitches require thinner stencils to ensure precise solder paste deposition. For example, 0201 components typically use a stencil thickness of 0.10 mm to 0.12 mm, while larger components may use thicker stencils[1][4].

3. What is the role of aspect ratio in stencil thickness selection?

The aspect ratio ensures that the stencil can release solder paste effectively without leaving residue. A minimum aspect ratio of 1.5 is recommended to ensure reliable solder paste release[3][4].

4. How does the type of solder paste influence stencil thickness?

The type and viscosity of solder paste can affect how well it releases from the stencil. Thicker pastes may require slightly thicker stencils to ensure adequate release, while thinner pastes may work well with thinner stencils[4].

5. What are the benefits and drawbacks of using stepped stencils?

Stepped stencils allow for varying thicknesses to accommodate different component types but increase manufacturing complexity and cost. They are beneficial for PCBs with both fine-pitch and larger components, enabling precise solder paste deposition for each component type[4][7].

Citations:

[1] https://jlcpcb.com/blog/how-to-choose-a-smt-stencil

[2] https://rigidflexpcb.org/smt-stencil-why-you-need-one/

[3] https://www.stencils.co.uk/wp-content/uploads/2021/07/Tecan-stencils-handbook_WEB_compressed.pdf

[4] https://mpe.researchmfg.com/stencil-thickness-aperture/

[5] https://www.circuitinsight.com/pdf/stencil_print_options_for_small_components_ipc.pdf

[6] https://pcbpit.com/smt-stencil-a-comprehensive-guide/

[7] https://www.ipc.org/system/files/technical_resource/E38&S12-02%20-%20Chrys%20Shea.pdf

[8] https://smartsmttools.com/thicknessofsmtstencils/

[9] https://www.surfacemountprocess.com/a-guide-to-effective-stencil-design.html

[10] https://smtnet.com/library/files/upload/Best-Stencil-SMT.pdf

[11] https://www.protoexpress.com/kb/solder-paste/

[12] https://www.globalwellpcba.com/how-to-choose-a-smt-stencil/

[13] https://www.elepcb.com/blog/pcb-stencil-smt-assembly/

[14] https://electronics.stackexchange.com/questions/214248/solder-paste-stencil-application

[15] https://www.circuitinsight.com/pdf/choosing_right_stencil_smta.pdf

[16] https://www.protoexpress.com/kb/smd-stencils-overview/

[17] https://www.indium.com/blog/stencil-printing-for-smt-assembly-success-part-2-print-metrics.php

[18] https://www.linkedin.com/pulse/smt-stencil-preparation-tips-tricks-design-software-alex-akulin-z2aif

[19] https://rushpcb.com/factors-affecting-print-quality-of-smt-solder-paste/

[20] https://electronics.stackexchange.com/questions/369667/solder-paste-stencil