Content Menu

● Understanding SMD Assembly Machines and Their Role

>> What Is an All-in-One SMD Assembly Machine?

● Factors Influencing Production Costs in SMT Assembly

● How SMD Assembly Machines Reduce Production Costs

>> 1. Labor Cost Reduction

>> 2. Increased Throughput and Efficiency

>> 3. Improved Quality and Reduced Rework

>> 4. Lower Overhead and Space Requirements

>> 5. Scalability and Flexibility

● Cost Considerations: SMD Assembly Machine All-in-One Price

>> Return on Investment (ROI)

● Additional Benefits of Using an SMD Assembly Machine

>> Enhanced Process Control and Data Collection

>> Environmental and Safety Advantages

>> Competitive Advantage

● Challenges and Limitations

● Conclusion

● FAQ

>> 1. What is the typical price range for an SMD assembly machine all in one price?

>> 2. How does an SMD assembly machine reduce labor costs?

>> 3. Is an all-in-one SMD assembly machine suitable for small production runs?

>> 4. What factors affect the total cost of SMT assembly besides the machine price?

>> 5. How long does it take to see a return on investment from an SMD assembly machine?

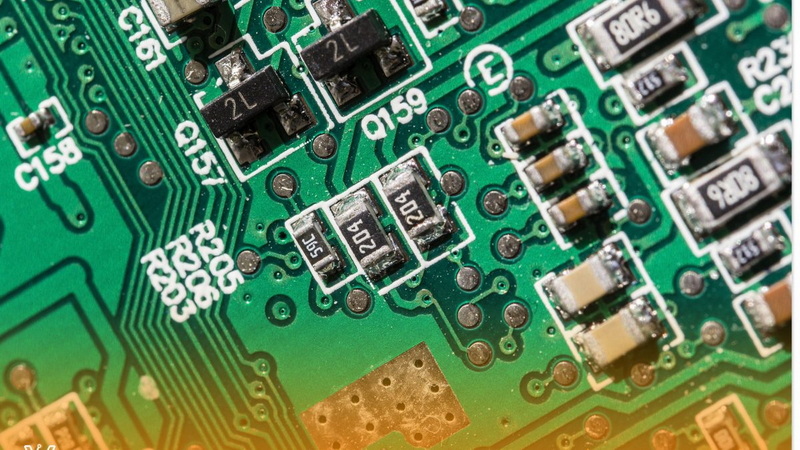

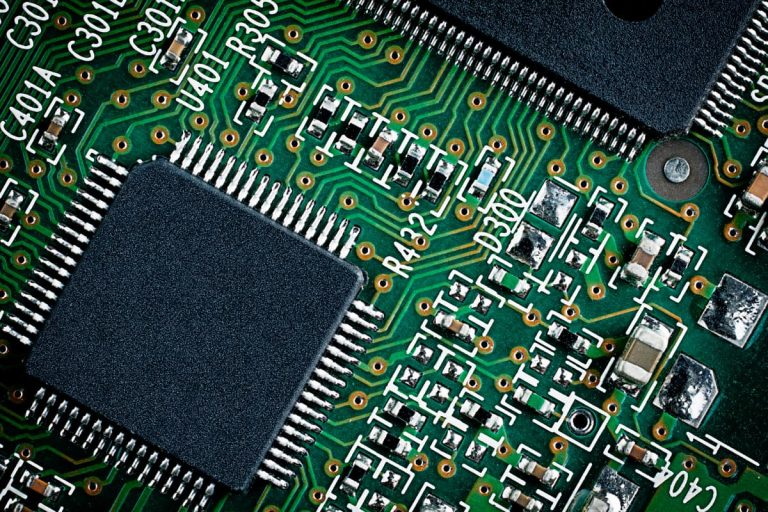

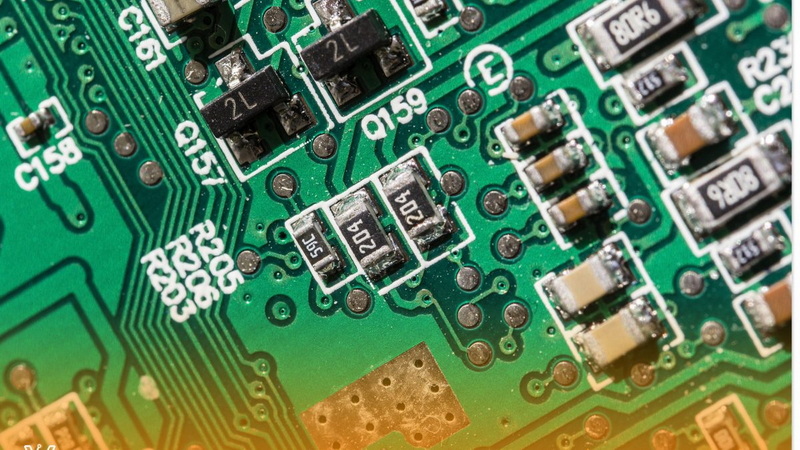

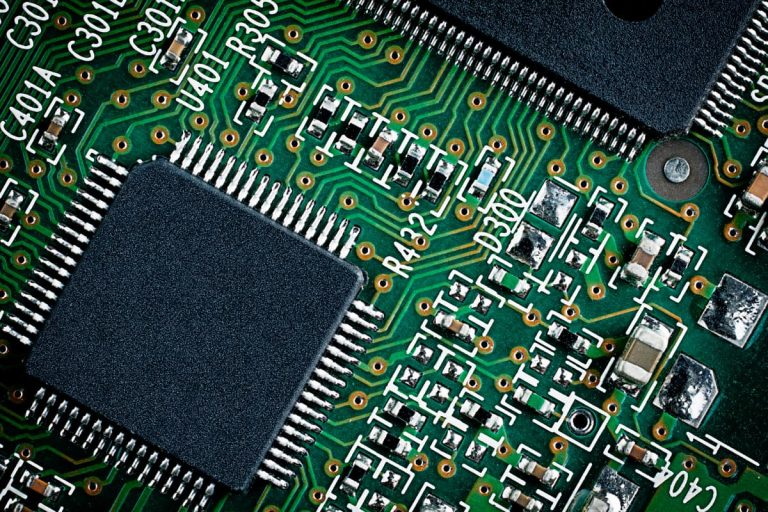

In the rapidly evolving electronics manufacturing industry, cost efficiency is a critical factor for competitiveness and profitability. Surface Mount Device (SMD) assembling machines, integral to Surface Mount Technology (SMT) assembly lines, have revolutionized the way printed circuit boards (PCBs) are produced. This article explores whether investing in an SMD assembly machine can help reduce production costs, analyzing the factors involved, the pricing of all-in-one SMD assembly machines, and the overall impact on manufacturing economics.

Understanding SMD Assembly Machines and Their Role

SMD assembly machines are automated systems designed to place surface mount components onto PCBs with high precision and speed. These machines are part of a broader SMT assembly line that typically includes solder paste printing, component placement, and reflow soldering. The automation provided by SMD assembly machines reduces manual labor, increases throughput, and improves assembly accuracy.

What Is an All-in-One SMD Assembly Machine?

An all-in-one SMD assembly machine integrates multiple functions such as solder paste printing, component placement, and sometimes reflow soldering into a single compact unit. This integration can be particularly beneficial for small to medium-sized production runs or prototyping, where space and budget constraints exist. By combining these processes, manufacturers can streamline their workflow, reduce equipment footprint, and simplify training and maintenance.

Factors Influencing Production Costs in SMT Assembly

To evaluate how an SMD assembly machine affects production costs, it is essential to understand the key cost drivers in SMT assembly:

- Material Costs: Includes the PCB substrate, components, solder paste, and other consumables.

- Labor Costs: Costs related to manual assembly, machine setup, programming, and quality control.

- Equipment Costs: Purchase price, maintenance, depreciation, and operating expenses of assembly machines.

- Design Complexity: More complex PCBs require more precise and time-consuming assembly processes.

- Production Volume: Higher volumes typically reduce per-unit costs due to economies of scale.

- Testing and Quality Assurance: Costs associated with inspection, functional testing, and rework.

Each of these factors interacts with the others, and the introduction of an SMD assembly machine can influence many of them simultaneously.

How SMD Assembly Machines Reduce Production Costs

1. Labor Cost Reduction

Automating component placement with an SMD assembly machine significantly reduces the need for manual labor. Labor costs, which can range from $15 to $50 per hour depending on skill level and complexity, are a major part of total assembly costs. By minimizing human intervention, companies can lower labor expenses and reduce errors caused by manual handling.

Manual assembly is not only labor-intensive but also prone to human error, which can lead to defective products and costly rework. SMD assembly machines ensure consistent placement accuracy, reducing the likelihood of defects and the associated labor costs for troubleshooting and repair.

2. Increased Throughput and Efficiency

SMD assembly machines operate at high speeds, placing hundreds to thousands of components per hour with consistent accuracy. This increased throughput shortens production cycles, enabling faster time-to-market and better utilization of resources. Higher efficiency also means less downtime and fewer bottlenecks in the assembly line.

For example, a mid-range all-in-one SMD assembly machine can place components at speeds exceeding 20,000 components per hour, far surpassing manual assembly rates. This speed advantage allows manufacturers to meet tight deadlines and scale production without proportional increases in labor or overhead.

3. Improved Quality and Reduced Rework

Automated placement reduces the risk of misalignment and soldering defects, which are common in manual assembly. Improved quality leads to fewer defective boards, reducing costs related to rework, scrap, and warranty claims. This quality improvement is crucial for maintaining customer satisfaction and brand reputation.

SMD assembly machines often come equipped with vision systems that verify component placement in real-time, catching errors before they propagate down the line. This proactive quality control reduces waste and improves yield, directly impacting the bottom line.

4. Lower Overhead and Space Requirements

All-in-one SMD assembly machines combine multiple processes into a single unit, saving factory floor space and reducing overhead costs such as rent, utilities, and maintenance. This compactness is especially advantageous for small manufacturers or startups with limited space and capital.

By consolidating equipment, companies can reduce the complexity of their production lines, which also simplifies maintenance and reduces the need for specialized operators. This streamlined approach can lead to lower indirect costs and faster changeovers between production runs.

5. Scalability and Flexibility

Modern SMD assembly machines can be programmed for different PCB designs and component types, allowing manufacturers to adapt quickly to changing product requirements without significant additional costs. This flexibility supports small batch production and prototyping, which can be cost-prohibitive with manual assembly.

The ability to quickly switch between product variants without extensive retooling or retraining is a significant advantage in industries where product lifecycles are short and customization is common. This adaptability helps manufacturers respond to market demands efficiently while controlling costs.

Cost Considerations: SMD Assembly Machine All-in-One Price

The price of an all-in-one SMD assembly machine varies widely depending on features, speed, precision, and brand. Typical price ranges include:

| Machine Type | Price Range (USD) |

| Entry-level desktop machines | $2,000 - $10,000 |

| Mid-range all-in-one machines | $20,000 - $60,000 |

| High-end fully automated lines | $150,000 - $180,000+ |

Entry-level machines are suitable for prototyping and small runs, while mid-range and high-end machines support larger volumes and more complex assemblies.

Return on Investment (ROI)

While the initial investment in an SMD assembly machine can be substantial, the reduction in labor costs, improved quality, and increased throughput often lead to a favorable ROI within a few years. Companies must consider their production volume, product complexity, and labor costs to determine the payback period.

For example, a manufacturer producing 10,000 units per month with high labor costs may recover the cost of a mid-range all-in-one SMD assembly machine within 12 to 18 months due to savings in labor and rework. Conversely, a small-scale producer with low volume might find the ROI period longer, making outsourcing a more viable option.

Additional Benefits of Using an SMD Assembly Machine

Enhanced Process Control and Data Collection

Many modern SMD assembly machines come equipped with software that tracks production data, component usage, and machine performance. This data can be analyzed to optimize processes, reduce waste, and improve scheduling, further lowering production costs.

Environmental and Safety Advantages

Automating assembly reduces human exposure to solder paste and other chemicals, improving workplace safety. Additionally, precise material usage reduces waste, contributing to more environmentally friendly manufacturing practices and potential cost savings in material procurement.

Competitive Advantage

Investing in advanced SMD assembly technology can position a manufacturer as a leader in quality and efficiency. This competitive edge can attract more customers, enable premium pricing, and open new market opportunities.

Challenges and Limitations

Despite the benefits, some challenges exist:

- High Initial Capital: The upfront cost can be prohibitive for very small manufacturers.

- Setup and Programming Complexity: Skilled technicians are required to program and maintain the machines.

- Maintenance and Downtime: Machines require regular maintenance to avoid costly downtime.

- Not Always Cost-Effective for Very Low Volumes: For extremely small batches, outsourcing assembly may be more economical.

Manufacturers must weigh these challenges against the potential cost savings and operational improvements to make an informed decision.

Conclusion

An SMD assembly machine, especially an all-in-one model, can significantly reduce production costs by lowering labor expenses, increasing throughput, improving quality, and reducing overhead. While the initial investment is considerable, the long-term savings and efficiency gains often justify the cost for manufacturers with moderate to high production volumes. Careful analysis of production needs, volume, and budget is essential to determine if investing in an SMD assembly machine is the right choice for your business.

By integrating an all-in-one SMD assembly machine into your production line, you can streamline operations, enhance product quality, and ultimately improve your bottom line. Whether you are a startup looking to scale or an established manufacturer aiming to optimize costs, the right SMD assembly machine can be a game-changer.

FAQ

1. What is the typical price range for an SMD assembly machine all in one price?

The price for all-in-one SMD assembly machines ranges from about $2,000 for entry-level desktop models to over $150,000 for high-end fully automated lines, with mid-range machines costing between $20,000 and $60,000.

2. How does an SMD assembly machine reduce labor costs?

By automating the placement of components on PCBs, SMD assembly machines reduce the need for manual labor, which can cost $15 to $50 per hour, thereby lowering overall labor expenses and minimizing human error.

3. Is an all-in-one SMD assembly machine suitable for small production runs?

Yes, all-in-one machines are particularly beneficial for small to medium production runs and prototyping because they combine multiple processes in a compact unit, saving space and reducing setup time.

4. What factors affect the total cost of SMT assembly besides the machine price?

Other factors include material costs (PCB and components), labor, design complexity, testing, quality assurance, and overhead costs such as facility rent and utilities.

5. How long does it take to see a return on investment from an SMD assembly machine?

The ROI depends on production volume and cost savings but typically ranges from a few months to a few years, with higher volumes and complex assemblies accelerating payback.