Content Menu

● Introduction to SMT PCB Assembly

>> Key Steps in SMT Assembly

● Essential Equipment for SMT PCB Assembly Line Setup

>> 1. Solder Paste Printing Machine

>> 2. Pick-and-Place Machine

>> 3. Reflow Oven

>> 4. SPI Machine

>> 5. AOI Machine

>> 6. Conveyor System

>> 7. Docking Station

>> 8. SMT Loader and Unloader

● Additional Equipment for Enhanced Quality and Efficiency

>> 1. X-Ray Inspection Machine

>> 2. In-Circuit Test (ICT) Fixture

>> 3. Functional Test Machine

>> 4. Steel Mesh Laser Cutting Machine

● Planning and Setup Considerations

● Innovations in SMT Technology

>> Role of AI in SMT Assembly

● Best Practices for SMT Assembly

>> Optimizing PCB Design

>> Streamlining the Assembly Process

● Advanced SMT Line Equipment

>> Role of 3D Printing in SMT

>> Impact of AI on Quality Control

● Future Trends in SMT Assembly

● Conclusion

● FAQs

>> 1. What is the primary function of a pick-and-place machine in an SMT assembly line?

>> 2. Why is solder paste inspection (SPI) important in the SMT assembly process?

>> 3. What role does an AOI machine play in the SMT assembly line?

>> 4. How does a reflow oven contribute to the SMT assembly process?

>> 5. What are the benefits of using SMT technology over traditional through-hole technology?

● Citations:

Setting up a successful SMT (Surface Mount Technology) PCB assembly line requires careful planning and the right equipment. SMT technology has revolutionized the electronics manufacturing industry by enabling the production of smaller, more reliable, and cost-effective electronic devices. In this article, we will explore the essential equipment needed for an efficient SMT PCB assembly line setup.

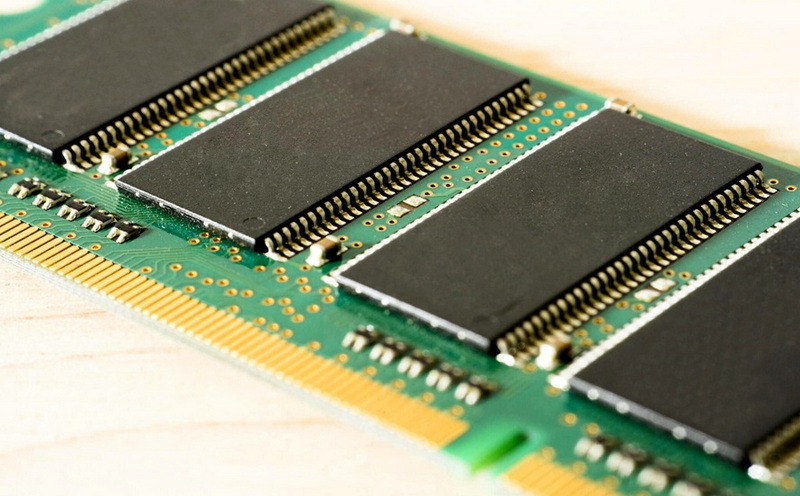

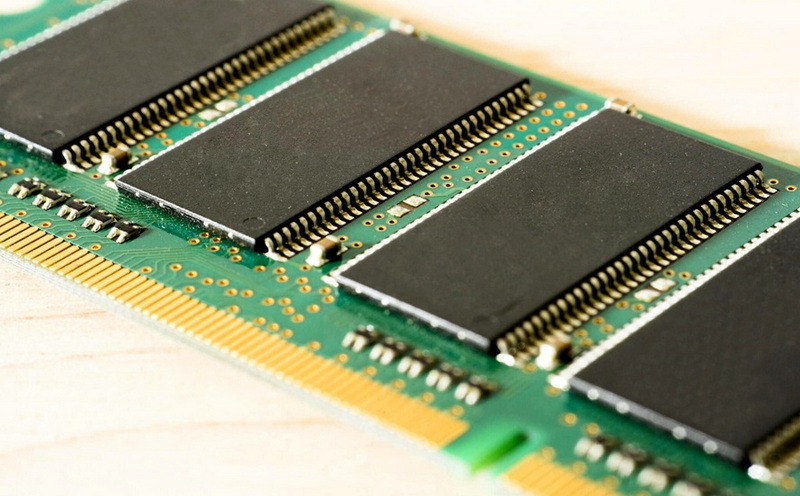

Introduction to SMT PCB Assembly

SMT assembly involves mounting electronic components directly onto the surface of a printed circuit board (PCB). This method is preferred over traditional through-hole technology due to its ability to increase component density, reduce size, and enhance reliability. The process involves several key steps, including solder paste printing, component placement, reflow soldering, and inspection.

Key Steps in SMT Assembly

1. Solder Paste Printing: This is the first step in the SMT assembly process. A solder paste printer applies solder paste onto the PCB pads using a stencil. The solder paste acts as a temporary adhesive to hold components in place before soldering.

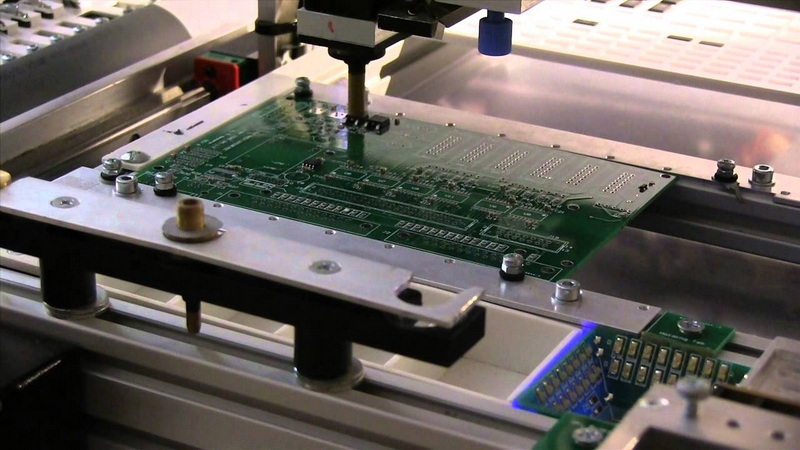

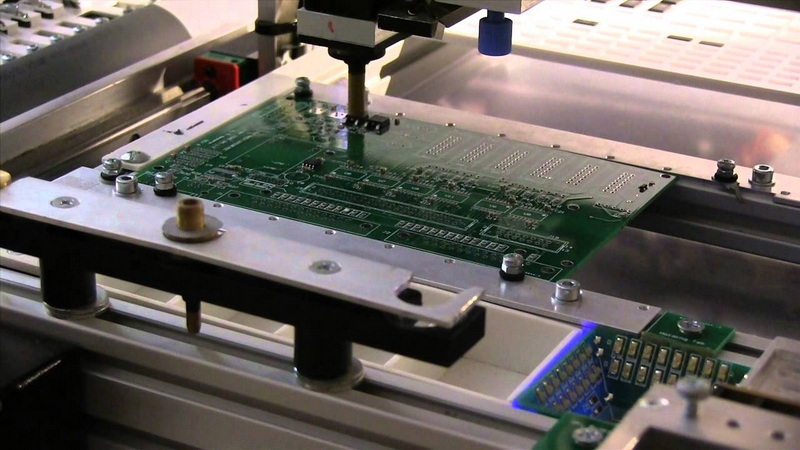

2. Component Placement: Pick-and-place machines are used to accurately place surface mount devices (SMDs) onto the solder paste on the PCB. These machines can handle a wide range of component sizes and types.

3. Reflow Soldering: After component placement, the PCB is passed through a reflow oven. The oven heats the solder paste to melt and form permanent solder joints between the components and the PCB.

4. Inspection: Automated Optical Inspection (AOI) and Solder Paste Inspection (SPI) machines are used to detect defects such as misaligned components, insufficient solder paste, or soldering defects.

Essential Equipment for SMT PCB Assembly Line Setup

1. Solder Paste Printing Machine

The solder paste printing machine is crucial for applying solder paste onto the PCB pads. It uses a stencil to ensure precise application, which is essential for reliable solder joints.

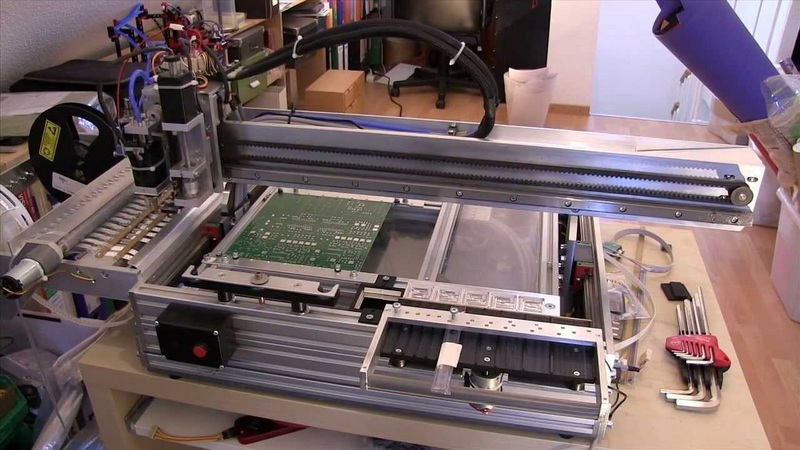

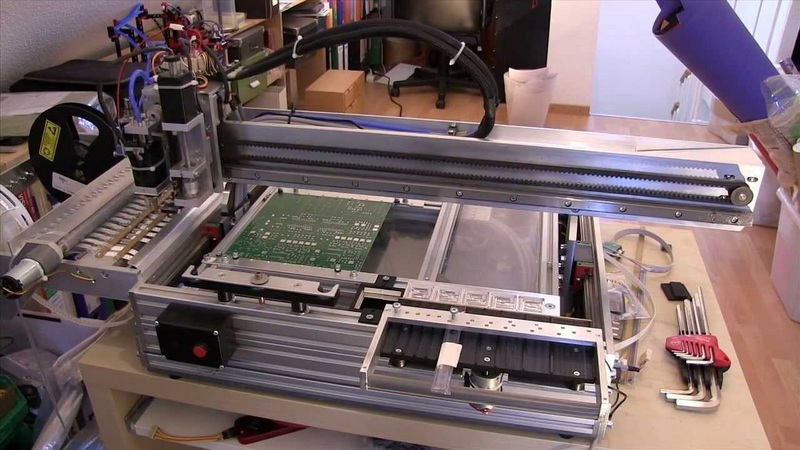

2. Pick-and-Place Machine

Pick-and-place machines are the heart of any SMT assembly line. They accurately place components onto the PCB, ensuring high-speed and high-precision placement.

3. Reflow Oven

The reflow oven is used for soldering components to the PCB. It provides a controlled heating environment to ensure strong and reliable connections.

4. SPI Machine

SPI machines inspect the solder paste after printing to ensure it meets quality standards. This step helps prevent defects that could lead to rework or failures.

5. AOI Machine

AOI machines inspect the PCBs after reflow soldering to detect any soldering defects or component misalignments. They are essential for maintaining high-quality output.

6. Conveyor System

A conveyor system connects different machines in the SMT line, ensuring continuous production flow and efficient material handling.

7. Docking Station

Docking stations facilitate the transfer of PCBs between machines, enhancing workflow efficiency and reducing downtime.

8. SMT Loader and Unloader

These machines automate the loading and unloading of PCBs onto the assembly line, reducing manual handling and improving efficiency.

Additional Equipment for Enhanced Quality and Efficiency

1. X-Ray Inspection Machine

X-ray inspection machines are used to detect internal defects in solder joints, especially in complex components like BGAs (Ball Grid Arrays).

2. In-Circuit Test (ICT) Fixture

ICT fixtures test the electrical performance of PCBs to ensure they function as intended.

3. Functional Test Machine

Functional test machines simulate real-world conditions to verify the PCB's functionality before shipping.

4. Steel Mesh Laser Cutting Machine

This machine creates high-precision stencils for solder paste application, ensuring accurate solder paste deposition.

Planning and Setup Considerations

Setting up an SMT PCB assembly line involves several key considerations:

- Assess Production Requirements: Determine the volume of production and the types of components to be used.

- Choose the Right Equipment: Ensure compatibility with components and PCBs.

- Layout Design: Arrange equipment to maximize efficiency and minimize bottlenecks.

- Software Integration: Configure software for seamless operation across different machines.

- Testing and Calibration: Conduct thorough tests to ensure all equipment functions correctly.

Innovations in SMT Technology

Recent advancements in SMT technology include the integration of 3D printing, which allows for the creation of complex and customized PCB structures. This innovation enables the design and production of flexible and curved PCBs, providing enhanced design flexibility for applications where traditional flat boards are insufficient. Additionally, advanced robotics and automation have become integral to modern PCB assembly lines, enhancing precision and consistency by minimizing human errors.

Role of AI in SMT Assembly

Artificial Intelligence (AI) is increasingly being used in SMT assembly to optimize the manufacturing process. AI algorithms analyze extensive datasets to predict potential defects, powering automated inspection systems that identify soldering issues and component misplacements with high accuracy. This proactive approach ensures that only flawless PCBs proceed to the final product stage, contributing to elevated quality control standards.

Best Practices for SMT Assembly

Optimizing PCB Design

Optimizing PCB design for SMT involves several key strategies:

- Component Placement: Strategically position components to minimize signal path lengths and reduce potential signal loss and interference.

- Pad Design: Ensure pads accommodate component leads while optimizing solder joint formation.

- Substrate Material: Choose materials that support thermal management and performance, such as FR-4 or polyimide for high-performance applications.

- Design for Manufacturability: Consider assembly processes when designing PCBs to ensure efficient production.

Streamlining the Assembly Process

Streamlining the assembly process involves implementing automated assembly lines, which enhance precision and speed. Automated pick-and-place machines and optical inspection systems are crucial for minimizing human error and identifying defects early in the process. Additionally, optimizing solder paste application through well-maintained stencil printing processes ensures reliable solder joints.

Advanced SMT Line Equipment

Advanced SMT line equipment significantly boosts manufacturing efficiency. With high-speed pick-and-place machines and precise solder paste printers, manufacturers can produce more units in less time. This increased throughput translates to higher productivity and profitability. Moreover, integrating advanced inspection systems like AOI and X-ray inspection ensures that only high-quality products leave the production line.

Role of 3D Printing in SMT

The integration of 3D printing technology into PCB assembly processes has opened new possibilities for creating intricate and customized structures. This technology enables the fabrication of three-dimensional circuitry, allowing for the design and production of complex PCB layouts that cannot be achieved with traditional flat boards. Additionally, 3D printing accelerates rapid prototyping, minimizing the time-to-market for innovative electronic products.

Impact of AI on Quality Control

AI plays a pivotal role in enhancing quality control in SMT assembly. By analyzing extensive datasets, AI algorithms can predict potential defects and optimize inspection processes. Machine learning models power automated inspection systems that identify soldering issues and component misplacements with unparalleled accuracy. This proactive approach ensures that only flawless PCBs make their way into the final product, contributing to elevated quality control standards.

Future Trends in SMT Assembly

As technology continues to evolve, future trends in SMT assembly are likely to focus on further miniaturization, increased automation, and the integration of emerging technologies like AI and 3D printing. These advancements will enable the production of even more complex and reliable electronic devices, meeting the growing demands for smaller, lighter, and more efficient electronics.

Conclusion

A successful SMT PCB assembly line setup requires a combination of essential equipment and careful planning. By understanding the role of each machine and ensuring they are properly integrated, manufacturers can achieve high-quality output and efficient production processes. The integration of advanced technologies such as 3D printing and AI further enhances the capabilities of SMT assembly lines, enabling the production of complex and reliable electronic devices.

FAQs

1. What is the primary function of a pick-and-place machine in an SMT assembly line?

The primary function of a pick-and-place machine is to accurately place surface mount devices (SMDs) onto the solder paste on the PCB. These machines are crucial for high-speed and high-precision component placement.

2. Why is solder paste inspection (SPI) important in the SMT assembly process?

SPI is important because it checks the quality of solder paste application before component placement. This step helps prevent defects related to solder paste, such as insufficient volume or misalignment, which can lead to rework or failures.

3. What role does an AOI machine play in the SMT assembly line?

An AOI machine inspects PCBs after reflow soldering to detect defects such as solder bridges, insufficient solder, or misaligned components. It ensures that only high-quality PCBs proceed to the next stages of production.

4. How does a reflow oven contribute to the SMT assembly process?

A reflow oven melts the solder paste to form permanent solder joints between components and the PCB. It provides a controlled heating environment to ensure strong and reliable connections.

5. What are the benefits of using SMT technology over traditional through-hole technology?

SMT technology offers several benefits, including higher component density, smaller size, lower cost, and improved reliability. It also allows for faster production and better electromagnetic compatibility (EMC) performance.

Citations:

[1] https://www.smtfactory.com/Elevate-Your-Manufacturing-with-Advanced-SMT-Line-Equipment-id46017676.html

[2] https://www.linkedin.com/pulse/latest-advancements-pcb-assembly-technologies-whats-new-2024-xo2qf

[3] https://vohrum.com/from-concept-to-completion-best-practices-in-smt-design-assembly-and-testing-for-high-performance-pcbs/

[4] https://www.itechsmt.com/blogs/news/smt-equipment-list-for-your-new-smt-manufacturing

[5] https://www.wevolver.com/article/what-is-smt

[6] https://www.hayawin.com/news-how-do-you-handle-pcbs-in-smt-production-line.html

[7] https://www.greencircuits.com/pcb-assembly-capabilities-and-equipment/

[8] https://riversideintegratedsolutions.com/n/pcb-assembly-surface-mount-technology/

[9] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[10] https://www.pcbunlimited.com/t/smt-equipment

[11] https://morepcb.com/smt/

[12] https://www.electronicspecifier.com/news/surface-mount-technology-best-practice-guide

[13] https://www.mycronic.com/product-areas/pcb-assembly/smt/

[14] https://www.pcbjhy.com/blog/pros-and-cons-of-smt-pcb-assembly/

[15] https://www.viasion.com/blog/smt-pcb-assembly-process-8-basic-steps/

[16] https://www.creativehitech.com/capabilities/pcb-assembly-equipment/

[17] https://www.raypcb.com/surface-mount-technology/

[18] https://asselems.com/en/best-practices-in-smt-assembly

[19] https://www.smtmachine.eu/top-5-smt-line-of-2024-advanced-smt-solutions/

[20] https://blog.matric.com/what-is-smt-assembly