Content Menu

● Understanding the Role of an SMT Line Operator

● Key Responsibilities

● Skills Required

● Educational Requirements

● Work Environment

● Career Advancement Opportunities

● Challenges Faced by SMT Line Operators

● The Importance of Quality Control

● The Role of Technology in SMT Operations

● Material Management Challenges

● Conclusion

● FAQs

>> 1. What qualifications do I need to become an SMT line operator?

>> 2. What are the primary responsibilities of an SMT line operator?

>> 3. Is prior experience necessary for this role?

>> 4. What skills are essential for success as an SMT line operator?

>> 5. What career advancement opportunities exist for SMT line operators?

● Citations:

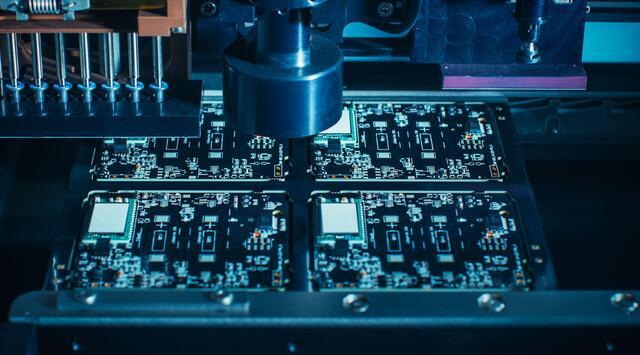

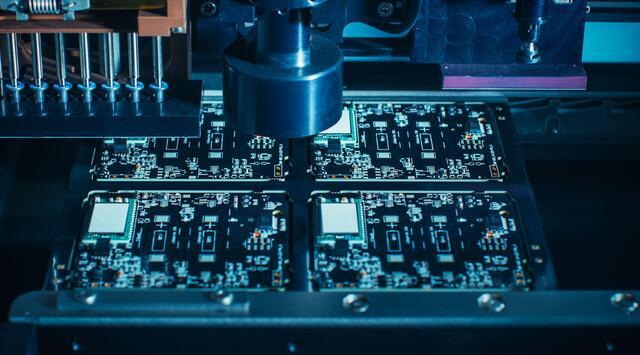

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by allowing for more compact and efficient designs of electronic circuits. An SMT line operator plays a crucial role in this process, ensuring that electronic components are accurately placed on printed circuit boards (PCBs). This article delves into the responsibilities, skills, and career prospects of an SMT line operator, providing a comprehensive overview of this vital position in the electronics sector.

Understanding the Role of an SMT Line Operator

An SMT line operator is responsible for operating and maintaining the machines that assemble electronic components onto PCBs. This job requires a meticulous approach, as the placement of components must adhere to strict specifications to ensure functionality and reliability. The operator's duties encompass a range of tasks that are essential for the smooth operation of the SMT assembly line.

Key Responsibilities

The primary responsibilities of an SMT line operator include:

- Operating SMT Machines: The operator must set up and operate various types of SMT machines, such as pick-and-place machines, solder paste printers, and reflow ovens. They ensure that these machines are correctly calibrated and functioning optimally.

- Quality Control: Operators perform regular inspections of assembled boards to check for defects or misalignments. They must follow quality control protocols to maintain high standards.

- Material Handling: Loading materials according to production specifications is a critical task. Operators prepare materials based on the bill of materials (BOM) and ensure that all components are available for production.

- Troubleshooting: When issues arise during production, operators are responsible for diagnosing problems and making minor adjustments or repairs to machinery.

- Documentation: Maintaining accurate records of production runs, machine maintenance, and quality checks is essential for tracking performance and ensuring compliance with industry standards.

- Collaboration with Engineers: Operators often work closely with engineers to provide feedback on machine performance and suggest improvements based on their hands-on experience.

Skills Required

To succeed as an SMT line operator, individuals must possess a variety of skills:

- Technical Proficiency: A solid understanding of electronics and familiarity with SMT processes is crucial. Operators should be comfortable working with complex machinery.

- Attention to Detail: Given the precision required in component placement, operators must have excellent eyesight and dexterity to handle small parts effectively.

- Problem-Solving Skills: The ability to troubleshoot machinery issues quickly is vital for minimizing downtime on the production line.

- Teamwork: While operators often work independently, they must also collaborate with engineers and technicians to address any challenges that arise during production.

- Knowledge of Quality Standards: Familiarity with quality standards such as IPC-A-610 is essential for ensuring that assembled boards meet industry requirements.

Educational Requirements

Most SMT line operators are required to have at least a high school diploma or GED. However, additional qualifications can enhance job prospects:

- Specialized Training: Completing a training program in electronics or obtaining certification from organizations like the Surface Mount Technology Association (SMTA) can provide a competitive edge.

- Experience: Previous experience in manufacturing or electronics assembly can be beneficial. Many employers prefer candidates who have hands-on experience with SMT equipment.

Work Environment

SMT line operators typically work in manufacturing facilities dedicated to electronics assembly. The environment is often fast-paced and requires standing or sitting for long periods while focusing on intricate tasks. Operators must adhere to safety protocols due to potential hazards associated with machinery and soldering materials.

Career Advancement Opportunities

There are several pathways for career advancement within the field:

- Technician Roles: With experience, operators can transition into technician positions where they take on more complex troubleshooting and maintenance tasks.

- Supervisory Positions: Demonstrated leadership skills can lead to roles such as SMT Supervisor or Production Manager, where individuals oversee entire production lines and manage teams.

- Engineering Careers: For those interested in further education, pursuing a degree in engineering can open doors to engineering roles within electronics manufacturing.

Challenges Faced by SMT Line Operators

While the role of an SMT line operator can be rewarding, it also comes with its challenges:

- High Precision Required: The need for accuracy means that even minor mistakes can lead to significant issues down the line.

- Machine Maintenance: Operators must be proactive about machine upkeep, as neglecting maintenance can result in costly downtime.

- Fast-Paced Environment: Meeting production deadlines while maintaining quality standards can be stressful.

The Importance of Quality Control

Quality control is one of the most critical aspects of an SMT operator's job. Operators utilize various inspection methods throughout the assembly process:

- Automated Optical Inspection (AOI): This technology helps identify defects by using cameras to scan PCBs after assembly. Operators must understand how to interpret AOI results and make necessary adjustments based on findings.

- Functional Testing: After assembly, some PCBs undergo functional testing to ensure they perform as intended. Operators may assist in setting up these tests or troubleshooting any failures that occur during this phase.

Maintaining high-quality standards not only ensures customer satisfaction but also reduces waste and rework costs associated with defective products.

The Role of Technology in SMT Operations

As technology advances, so does the complexity and capability of SMT machinery. Modern operators often work with sophisticated equipment that incorporates automation and artificial intelligence:

- Smart Manufacturing Systems: These systems allow real-time monitoring of production lines, enabling operators to respond quickly to any irregularities or inefficiencies.

- Data Analytics: By analyzing production data, operators can identify trends over time that inform better decision-making regarding machine maintenance schedules or workflow optimizations.

The integration of technology into SMT operations enhances productivity but requires operators to continually update their skills and knowledge base.

Material Management Challenges

Effective material management is crucial for smooth operations in an SMT environment. Operators face several challenges related to material handling:

- Component Shortages: Global supply chain disruptions can lead to shortages of critical components, impacting production schedules. Operators must be adept at communicating these issues to management promptly.

- Inventory Management: Keeping track of materials used in production is essential. Operators often utilize inventory management software to ensure accurate stock levels are maintained without excess waste.

- Traceability Issues: Ensuring all components are traceable throughout the manufacturing process helps maintain quality control standards. Operators play a key role in documenting material usage accurately.

Conclusion

In summary, an SMT line operator plays a pivotal role in the electronics manufacturing industry by ensuring that electronic components are accurately placed on PCBs. This position requires a combination of technical skills, attention to detail, problem-solving abilities, and effective communication skills. With opportunities for career advancement and continuous learning in an evolving field, becoming an SMT line operator can be a fulfilling career choice for those interested in technology and manufacturing.

FAQs

1. What qualifications do I need to become an SMT line operator?

To become an SMT line operator, you typically need at least a high school diploma or GED. Specialized training in electronics or certifications from relevant organizations can enhance your job prospects.

2. What are the primary responsibilities of an SMT line operator?

The primary responsibilities include operating SMT machines, performing quality control inspections, handling materials according to production specifications, troubleshooting machinery issues, and maintaining accurate production records.

3. Is prior experience necessary for this role?

While prior experience in manufacturing or electronics assembly is beneficial, it is not always required. Many employers provide on-the-job training for new operators.

4. What skills are essential for success as an SMT line operator?

Essential skills include technical proficiency with electronics, attention to detail for precision tasks, problem-solving abilities for troubleshooting issues, teamwork skills for collaborating with colleagues, and knowledge of quality standards like IPC-A-610.

5. What career advancement opportunities exist for SMT line operators?

Operators can advance to technician roles, supervisory positions like SMT Supervisor or Production Manager, or pursue further education leading to engineering careers within electronics manufacturing.

Citations:

[1] https://www.zippia.com/smt-operator-jobs/what-does-an-smt-operator-do/

[2] https://www.jobhero.com/resume/examples/production/smt-operator

[3] https://www.controltek.com/sites/www.controltek.com/files/job-opportunity-documents/SMT%20Machine%20Operator%20I%20(1).pdf

[4] https://www.criticalmanufacturing.com/blog/material-optimization-in-the-smt-and-electronics-assembly-industries/

[5] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[6] https://hrblade.com/job-descriptions/smt-operator

[7] https://www.ziprecruiter.com/career/Smt-Operator/What-Is-How-to-Become

[8] https://www.zippia.com/smt-operator-jobs/skills/

[9] https://www.circuitinsight.com/pdf/Modeling_SMT_Line_Improve_Throughput_smta.pdf

[10] https://levisonenterprises.com/5-advantages-to-using-smt/