Content Menu

● Introduction to SMT PCB Standoffs

>> Key Functions of SMT PCB Standoffs

● Common Mistakes to Avoid with SMT PCB Standoffs

>> 1. Incorrect Material Selection

>> 2. Inadequate Standoff Placement

>> 3. Insufficient Standoff Height

>> 4. Failure to Consider Thermal Impacts

>> 5. Ignoring Manufacturer Guidelines

● Best Practices for Using SMT PCB Standoffs

>> 1. Material Compatibility

>> 2. Optimal Placement

>> 3. Correct Standoff Height

>> 4. Thermal Considerations

>> 5. Follow Manufacturer Guidelines

● Advanced Considerations for SMT PCB Standoffs

>> Vibration and Shock Resistance

>> Environmental Factors

>> Aesthetics and Accessibility

>> Design for Manufacturability (DFM)

>> Future Trends in SMT PCB Standoffs

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary functions of SMT PCB standoffs?

>> 2. How should SMT PCB standoffs be placed on a PCB?

>> 3. What materials are commonly used for SMT PCB standoffs?

>> 4. What are the consequences of using conductive standoffs without insulation?

>> 5. How many standoffs should be used for a typical PCB?

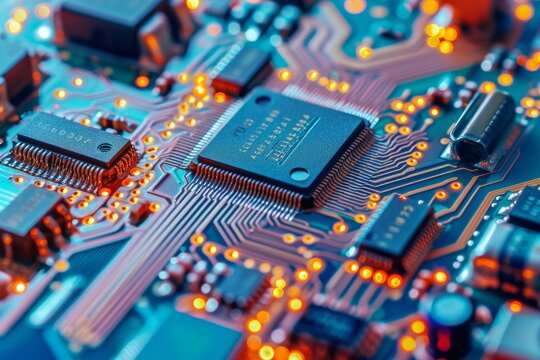

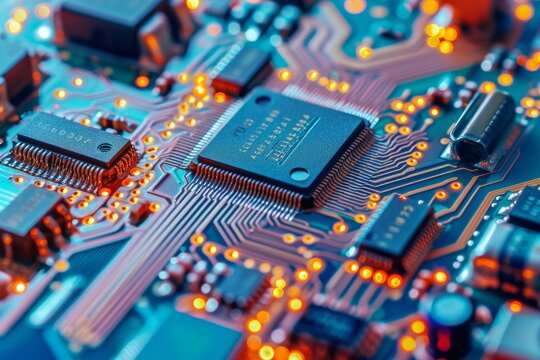

Surface Mount Technology (SMT) has revolutionized the way Printed Circuit Boards (PCBs) are assembled, offering advantages such as compactness, efficiency, and cost-effectiveness. Among the various components used in SMT assemblies, SMT PCB standoffs play a crucial role in providing mechanical stability and ensuring proper spacing between the PCB and other surfaces. However, like any other component, the use of SMT PCB standoffs can be marred by common mistakes that may compromise the integrity and functionality of electronic systems. This article delves into these mistakes and provides insights on how to avoid them.

Introduction to SMT PCB Standoffs

SMT PCB standoffs are designed to elevate PCBs from their mounting surfaces, ensuring adequate airflow and heat dissipation, which are critical for preventing overheating and maintaining the overall thermal management of electronic systems. They also provide structural support, preventing PCB flexing, warping, or damage caused by vibration, shocks, or mechanical stress. Furthermore, standoffs made from insulating materials can prevent short circuits and interference between components by maintaining electrical isolation.

Key Functions of SMT PCB Standoffs

- Mechanical Stability: Standoffs secure the PCB in place, reducing the risk of damage from mechanical stress.

- Thermal Management: They facilitate airflow under the PCB, enhancing heat dissipation.

- Electrical Isolation: Insulating standoffs prevent electrical shorts by isolating the PCB from other conductive surfaces.

- Protection: Standoffs safeguard the PCB against potential damage from spills, moisture, and contaminants.

Common Mistakes to Avoid with SMT PCB Standoffs

1. Incorrect Material Selection

Choosing the wrong material for standoffs can lead to several issues. For instance, using conductive materials like brass without proper insulation can cause short circuits on the PCB underside. It is essential to select materials that are compatible with the PCB and the environment in which it operates. Insulating materials such as nylon or polycarbonate are often preferred to prevent electrical interference. Additionally, materials should be durable enough to withstand environmental conditions such as temperature fluctuations, humidity, and chemical exposure.

Some designers mistakenly assume that all standoff materials perform equally under thermal stress. However, nylon standoffs, while excellent insulators, tend to soften or deform at higher temperatures, which can compromise mechanical stability. Polycarbonate or glass-filled nylon standoffs offer better thermal resistance but may be more brittle. Metallic standoffs, such as aluminum or brass, provide superior mechanical strength and thermal conductivity but require proper insulation to avoid electrical shorts.

2. Inadequate Standoff Placement

Improper placement of standoffs can compromise the mechanical stability of the PCB. Standoffs should be placed near board edges and corners to distribute stress evenly and prevent flexing. They should also be positioned away from tall components on the backside of the PCB to ensure clearance and avoid obstruction.

A common mistake is placing standoffs too close to sensitive components or connectors, which can cause interference during assembly or maintenance. Additionally, placing standoffs only at the corners of large PCBs without intermediate support points can lead to board warping or bending during operation or shipping. For larger or heavier boards, additional standoffs should be strategically placed to reduce mechanical stress and vibration effects.

3. Insufficient Standoff Height

Using standoffs that are too short can result in inadequate spacing between the PCB and the mounting surface. This can impede airflow, leading to overheating and reduced system performance. Conversely, standoffs that are too long may cause mechanical instability or interfere with other components.

The height of the standoff should be carefully selected based on the specific requirements of the PCB design and the components used. For example, if the PCB has components mounted on the bottom side, the standoff height must be sufficient to prevent contact with the mounting surface. Additionally, standoff height affects thermal management — too low a clearance reduces airflow, while too high a clearance can increase the risk of mechanical vibration.

4. Failure to Consider Thermal Impacts

Standoffs should be positioned to facilitate airflow around heat-generating components. Blocking airflow paths can exacerbate thermal issues, potentially leading to component failure or reduced lifespan. In high-power applications, it is crucial to ensure that standoffs do not obstruct the natural convection currents around components like CPUs, GPUs, or power supplies.

Another thermal consideration is the thermal conductivity of the standoff material itself. Metallic standoffs can act as heat sinks, helping dissipate heat away from the PCB, but only if properly integrated into the thermal design. Conversely, insulating plastic standoffs may trap heat if airflow is inadequate. Engineers should evaluate the overall thermal profile of the PCB assembly and select standoffs accordingly.

5. Ignoring Manufacturer Guidelines

Not adhering to manufacturer guidelines for standoff placement and selection can lead to compatibility issues and reduced system reliability. It is crucial to follow these guidelines to ensure optimal performance and longevity of the PCB assembly. Manufacturer recommendations often include specific standoff dimensions, materials, and placement strategies tailored to the PCB's design and intended application.

Ignoring torque specifications when installing standoffs is another common mistake. Over-tightening can crack the PCB or damage components, while under-tightening may result in loose assemblies prone to vibration and mechanical failure.

Best Practices for Using SMT PCB Standoffs

1. Material Compatibility

Ensure that the standoff material is compatible with the PCB and its components. Insulating materials are recommended to prevent electrical shorts. Additionally, consider the chemical resistance and durability of the material in harsh environments. For applications involving exposure to solvents, oils, or corrosive agents, select standoffs with appropriate resistance properties.

2. Optimal Placement

Place standoffs near corners and edges for stability, and distribute them evenly to avoid stress concentrations. Avoid placing standoffs directly under components with high thermal output or sensitive circuitry. For larger PCBs, intermediate standoffs should be placed to prevent flexing and vibration damage.

3. Correct Standoff Height

Select standoffs that provide adequate spacing without obstructing airflow or interfering with components. The standoff height should be sufficient to allow for easy maintenance and repair. When in doubt, consult PCB layout files and component height data to determine minimum clearance requirements.

4. Thermal Considerations

Position standoffs to enhance airflow around heat-generating components, ensuring effective thermal management. Consider using thermal interface materials (TIMs) if necessary to improve heat transfer. In some cases, integrating heat sinks with standoffs or using thermally conductive standoff materials can improve overall thermal performance.

5. Follow Manufacturer Guidelines

Adhere to guidelines provided by the PCB manufacturer for standoff placement and selection to ensure compatibility and optimal performance. This includes following recommended torque specifications for standoff screws to prevent over-tightening or under-tightening.

Advanced Considerations for SMT PCB Standoffs

Vibration and Shock Resistance

In applications where the PCB may be exposed to vibration or shock, standoffs should be selected for their ability to absorb these stresses. Materials with high damping coefficients, such as certain plastics or elastomers, can help mitigate the effects of vibration. Additionally, consider using locking mechanisms or thread-locking compounds to prevent loosening over time.

Environmental Factors

Standoffs used in harsh environments, such as high-temperature or high-humidity conditions, should be made from materials that can withstand these conditions without degradation. This includes resistance to corrosion, UV exposure, and chemical attack. For outdoor or industrial applications, stainless steel or coated metallic standoffs may be preferred for their durability.

Aesthetics and Accessibility

While not always a primary concern, the design of standoffs can impact the overall appearance and accessibility of the PCB assembly. Standoffs should be designed to facilitate easy assembly and disassembly for maintenance purposes. Low-profile standoffs may be preferred in compact designs, while taller standoffs can allow better clearance for connectors or cables.

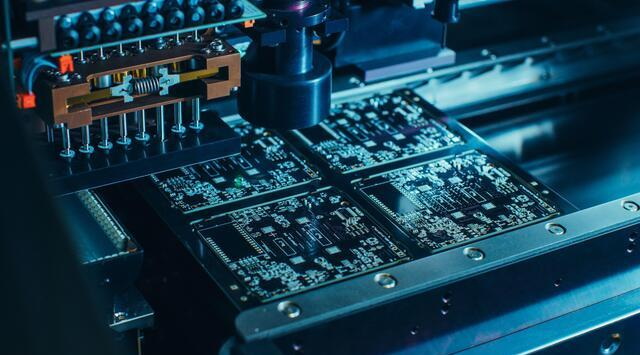

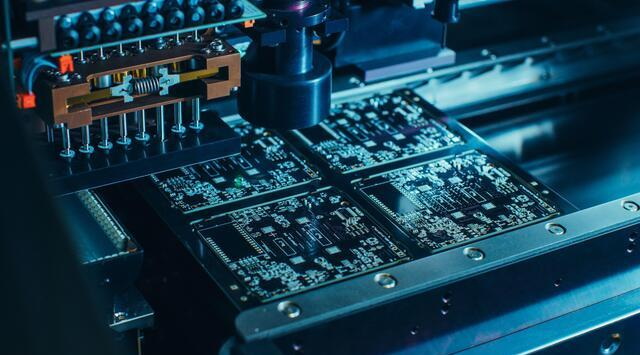

Design for Manufacturability (DFM)

When designing PCB assemblies with standoffs, it's essential to consider manufacturability. Standoffs should be easy to assemble and disassemble for maintenance and repair. This includes selecting standoffs with simple screw mechanisms and ensuring that they do not obstruct access to other components. Using standardized standoff sizes and thread types can reduce assembly errors and speed up production.

Future Trends in SMT PCB Standoffs

As electronics continue to miniaturize and become more complex, the demand for innovative standoff solutions will grow. Future trends may include the use of advanced materials with improved thermal conductivity and mechanical strength. Additionally, there may be a shift towards more integrated designs where standoffs are combined with other components to reduce overall size and enhance functionality. Smart standoffs with embedded sensors to monitor mechanical stress or temperature are also an emerging area of interest.

Conclusion

SMT PCB standoffs are indispensable components in modern electronics, offering mechanical stability, thermal management, and electrical isolation. However, their effectiveness can be compromised by common mistakes such as incorrect material selection, inadequate placement, insufficient height, failure to consider thermal impacts, and ignoring manufacturer guidelines. By understanding these potential pitfalls and adopting best practices, engineers can ensure the reliability and performance of their PCB assemblies. Proper selection, placement, and installation of SMT PCB standoffs are critical steps that contribute significantly to the longevity and functionality of electronic devices.

Frequently Asked Questions

1. What are the primary functions of SMT PCB standoffs?

SMT PCB standoffs primarily provide mechanical stability, ensure proper spacing for airflow and heat dissipation, offer electrical isolation, and protect the PCB from environmental hazards.

2. How should SMT PCB standoffs be placed on a PCB?

Standoffs should be placed near board edges and corners to distribute stress evenly. They should also be positioned away from tall components on the backside to ensure clearance.

3. What materials are commonly used for SMT PCB standoffs?

Common materials include nylon, polycarbonate, brass (with insulation), and aluminum. Insulating materials are preferred to prevent electrical shorts.

4. What are the consequences of using conductive standoffs without insulation?

Using conductive standoffs without insulation can lead to short circuits on the PCB underside, compromising the electrical integrity of the system.

5. How many standoffs should be used for a typical PCB?

At least four standoffs are recommended, one near each corner. Larger boards may require additional standoffs distributed along the edges.