Content Menu

● Introduction to SMT Assembly

● Key Features of SMT Assembly Machines

● Benefits of SMT Assembly

● Challenges in SMT Assembly

● Choosing the Right SMT Machine

● Innovations in SMT Assembly

>> Automation and Miniaturization

>> Integration with Emerging Technologies

● Overcoming Challenges in SMT Assembly

● Future Trends in SMT Assembly

● Cost Reduction Strategies through SMT Mastery

● Emerging Trends and Innovations

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary function of a pick-and-place machine in SMT assembly?

>> 2. How does reflow soldering work in SMT assembly?

>> 3. What are the advantages of using SMT over through-hole technology?

>> 4. What role does inspection equipment play in SMT assembly?

>> 5. How does solder paste printing contribute to SMT assembly?

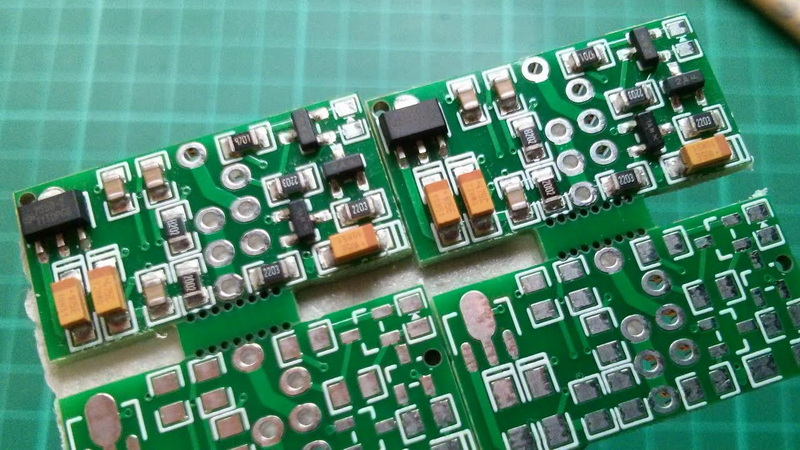

When it comes to PCB Surface Mount Technology (SMT) assembly, selecting the right machine is crucial for efficient and reliable production. SMT machines play a pivotal role in modern electronics manufacturing by enabling the assembly of complex printed circuit boards (PCBs) with high precision and speed. In this article, we will explore the key features to look for in a PCB SMT assembly machine, highlighting the importance of these features in enhancing productivity and quality.

Introduction to SMT Assembly

Surface Mount Technology (SMT) is a method of mounting electronic components directly onto the surface of a PCB. This technology has revolutionized the electronics industry by allowing for more compact, efficient, and reliable electronic devices. Unlike traditional through-hole technology, SMT components do not require holes drilled into the PCB, which simplifies the manufacturing process and reduces production costs.

SMT assembly involves several key steps, including solder paste printing, component placement, and reflow soldering. Each of these steps requires specialized equipment to ensure precision and quality. The primary machines involved in SMT assembly include:

- Pick-and-place machines: These machines are responsible for placing components onto the PCB. They come in manual, semi-automatic, and fully automated versions, each suited to different production needs.

- Solder paste printers: These machines apply solder paste onto the PCB pads where components will be placed.

- Reflow ovens: These ovens melt the solder paste to secure components to the PCB.

- Inspection equipment: Automated optical inspection (AOI) machines check for defects and ensure components are correctly placed.

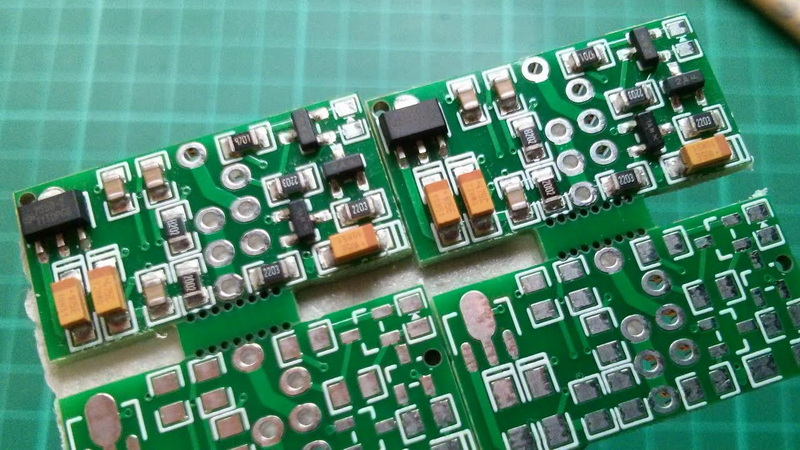

Key Features of SMT Assembly Machines

When selecting an SMT assembly machine, several features are critical to consider:

1. Accuracy and Precision: The machine should have high accuracy, typically around 0.0001 inches, to handle fine-pitch components. This ensures that components are placed correctly, reducing errors and rework.

2. Speed and Throughput: For high-volume production, machines with fast placement rates are essential. Automated pick-and-place machines can place thousands of components per hour.

3. Component Handling Capability: The machine should be able to handle a variety of component sizes and types, including small components like 01005 and larger components like BGAs.

4. Repeatability: Consistency in component placement is crucial. Machines with good repeatability ensure that components are placed in the same position every time, reducing variability in the assembly process.

5. Integration with Other Machines: The ability to integrate with other SMT machines, such as solder paste printers and reflow ovens, streamlines the assembly process and improves efficiency.

6. Software and Programming: Advanced software capabilities allow for easy programming and adjustment of assembly parameters. This flexibility is important for adapting to different PCB designs and production requirements.

7. Maintenance and Support: Easy maintenance and reliable customer support are vital for minimizing downtime and ensuring continuous production.

Benefits of SMT Assembly

SMT assembly offers several benefits over traditional through-hole assembly:

- Higher Component Density: SMT allows for more components to be placed on a smaller area, enabling the creation of compact electronic devices.

- Improved Reliability: SMT components are less prone to vibration and thermal stress, improving the overall reliability of the PCB.

- Lower Production Costs: While initial investment in SMT equipment can be high, automation reduces labor costs and improves efficiency in large-scale production.

- Flexibility: SMT components can be placed on both sides of the PCB, allowing for more complex designs.

Challenges in SMT Assembly

Despite its advantages, SMT assembly also presents some challenges:

- Component Fragility: Small SMT components are fragile and can be easily damaged during handling.

- Soldering Complexity: The soldering process requires precise temperature control to avoid defects.

- Inspection Difficulty: Due to the small size of components, visual inspection can be challenging, making automated inspection essential.

Choosing the Right SMT Machine

When choosing an SMT machine, consider the following factors:

- Production Volume: For high-volume production, fully automated machines are more suitable.

- Component Variety: Ensure the machine can handle the types and sizes of components used in your designs.

- Budget: Balance the cost of the machine with its capabilities and your production needs.

Innovations in SMT Assembly

Recent innovations in SMT assembly include the use of 3D printing for prototyping. This technology allows manufacturers to quickly iterate and test different PCB designs, significantly reducing the time-to-market for new products. Additionally, smart soldering techniques have been developed to enhance the efficiency and consistency of the soldering process, ensuring reliable joints and contributing to the longevity of electronic devices.

Automation and Miniaturization

Automation is a key trend in SMT, with robotic pick-and-place machines and automated soldering systems streamlining the assembly process. This automation increases production efficiency and consistency, allowing manufacturers to boost cost savings and improve quality control. Furthermore, the push for miniaturization drives the development of smaller, more complex devices, necessitating advancements in component design and manufacturing techniques.

Integration with Emerging Technologies

The integration of SMT with other manufacturing methods, such as 3D printing and additive manufacturing, offers new opportunities for design flexibility and customization. This integration enables the creation of complex electronic assemblies with intricate shapes and innovative features, catering to various markets.

Overcoming Challenges in SMT Assembly

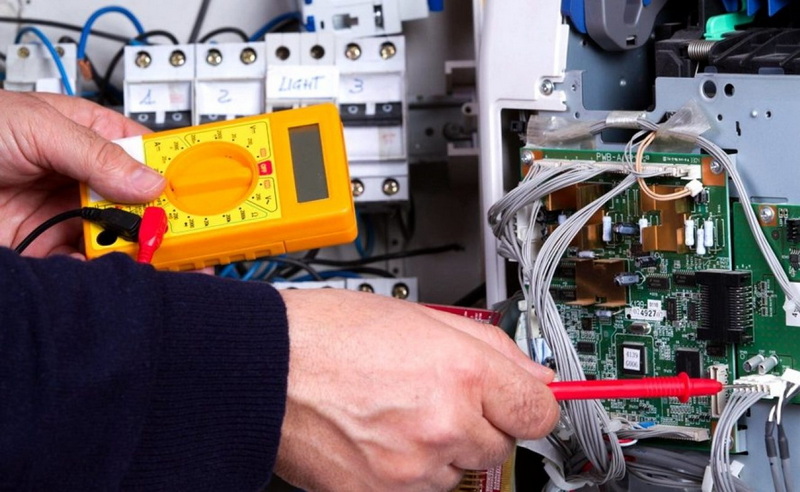

To overcome common challenges in SMT assembly, manufacturers can employ several strategies:

1. Warpage Prevention: Use support fixtures during the reflow process to minimize PCB warping, especially for large or thin boards. Selecting PCB materials with low thermal expansion coefficients can also help.

2. Component Placement Accuracy: Invest in high-precision placement machines and regularly calibrate them. Training operators on the importance of placement accuracy and maintaining equipment is also crucial.

3. Consistent Solder Paste Application: Utilize high-quality stencils designed for your PCB layout. Ensure proper alignment and cleaning of the stencil, and implement automated solder paste inspection (SPI) systems to catch defects early.

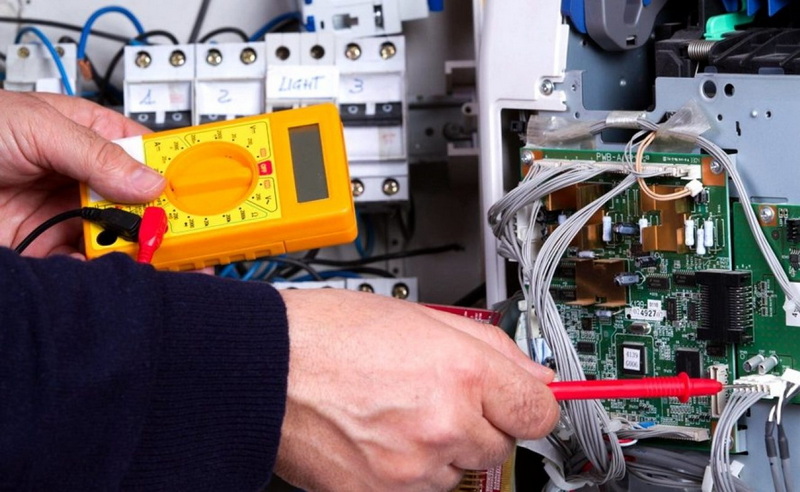

Future Trends in SMT Assembly

Looking ahead, several trends are shaping the future of SMT assembly:

- Automation and AI: The integration of automation and artificial intelligence (AI) will continue to enhance efficiency and precision in SMT processes. Machines will become smarter, capable of making decisions and solving problems autonomously.

- Big Data and Connectivity: The use of big data and enhanced connectivity will improve real-time monitoring and decision-making in SMT assembly lines. This connectivity will also facilitate better integration across different manufacturing processes.

- Sustainability: There is a growing emphasis on sustainable practices in SMT, including the use of environmentally friendly materials and processes. This trend aligns with global initiatives to reduce waste and promote eco-friendly manufacturing.

Cost Reduction Strategies through SMT Mastery

Mastering SMT assembly offers significant opportunities for cost reduction:

- Automation: Implementing automated pick-and-place machines can dramatically enhance throughput while minimizing human error, leading to decreased materials wastage and improved product reliability.

- Optimized Assembly Line Layout: Efficiently designing the assembly line layout can lead to better space utilization and faster processing times, reducing cycle times and improving productivity.

- Advanced Inspection Technology: Investing in high-quality inspection technology ensures defects are identified early, mitigating costs associated with rework and scrap.

Emerging Trends and Innovations

The SMT industry is witnessing significant advancements driven by technological innovations and market demands. Some of these trends include:

- Increased Use of Robotics and AI: The integration of robotics and AI in SMT assembly is expected to enhance precision and efficiency. Machines will become more autonomous, capable of adjusting parameters in real-time based on production data.

- Sustainability and Environmental Considerations: There is a growing focus on sustainable manufacturing practices in SMT. This includes the use of lead-free solder pastes and adherence to environmental regulations such as REACH and RoHS.

- Customization and Flexibility: As consumers demand more customized products, SMT assembly lines need to be flexible enough to handle a variety of PCB designs efficiently. This requires machines that can quickly adapt to different production configurations.

- 3D Printing Integration: The integration of 3D printing with SMT assembly offers new possibilities for creating complex PCB structures. This can enable the production of devices with unique geometries and functionalities.

By embracing these trends and innovations, manufacturers can stay ahead in the competitive electronics industry, ensuring they meet the evolving demands of consumers while maintaining high-quality production standards.

Conclusion

In conclusion, selecting the right PCB SMT assembly machine is critical for achieving high-quality and efficient production. By focusing on key features such as accuracy, speed, component handling capability, and integration with other machines, manufacturers can optimize their SMT assembly processes. Understanding the benefits and challenges of SMT assembly helps in making informed decisions about equipment selection and process optimization. As the industry continues to evolve with trends like automation, miniaturization, and sustainability, mastering SMT assembly will remain essential for electronics manufacturers seeking to stay competitive.

Frequently Asked Questions

Here are some common questions related to SMT assembly machines:

1. What is the primary function of a pick-and-place machine in SMT assembly?

- The primary function of a pick-and-place machine is to accurately place electronic components onto the PCB. These machines come in manual, semi-automatic, and fully automated versions, each suited to different production needs.

2. How does reflow soldering work in SMT assembly?

- Reflow soldering involves heating the solder paste to melt it, securing components to the PCB. This process is conducted in a reflow oven with controlled temperature zones to ensure proper soldering.

3. What are the advantages of using SMT over through-hole technology?

- SMT offers higher component density, improved reliability, lower production costs at volume, and increased automation potential compared to through-hole technology.

4. What role does inspection equipment play in SMT assembly?

- Inspection equipment, such as automated optical inspection (AOI) machines, plays a crucial role in detecting defects and ensuring components are correctly placed on the PCB. This step is essential for maintaining quality and reducing rework.

5. How does solder paste printing contribute to SMT assembly?

- Solder paste printing applies solder paste onto the PCB pads where components will be placed. This process is critical for ensuring components adhere properly during reflow soldering.