Content Menu

● Introduction

● Commonly Used SMT PCB Components

>> Resistors

>> Capacitors

>> Inductors

>> Diodes

>> Transistors

>> Integrated Circuits (ICs)

>> Additional Components

● Advantages of SMT Components

● Challenges in Using SMT Components

● The Role of Automation in SMT

>> Key Benefits of Automation:

● Future Trends in SMT Technology

● Conclusion

● FAQ

>> 1. What is SMT in PCB design?

>> 2. Why are resistors and capacitors commonly used in SMT?

>> 3. What are the challenges of using SMT components?

>> 4. How do SMT components improve PCB performance?

>> 5. What are the common packages for SMT ICs?

● Citations:

Introduction

Surface Mount Technology (SMT) has revolutionized the electronics industry by allowing components to be mounted directly onto the surface of printed circuit boards (PCBs). This method contrasts with traditional through-hole technology, where components are inserted into drilled holes. SMT enables manufacturers to produce smaller, lighter, and more efficient electronic devices, making it a preferred choice for modern electronics. In this article, we will explore the most commonly used SMT PCB components, their types, applications, advantages, and challenges.

Commonly Used SMT PCB Components

Resistors

Resistors are fundamental components in electronic circuits that limit current flow and divide voltages. In SMT applications, resistors come in various types:

- Surface-Mount Resistors: These are designed specifically for SMT applications and are smaller than traditional resistors.

- Precision Resistors: Used in applications requiring high accuracy and stability.

- Power Resistors: Designed to handle significant power levels, often used in power management circuits.

Applications: Resistors are utilized for current limiting, voltage dividers, pull-up/pull-down configurations, and filtering noise from signals.

Capacitors

Capacitors store electrical energy and are vital for smoothing out voltage fluctuations in circuits. Common types of capacitors used in SMT include:

- Ceramic Capacitors: Widely used due to their small size and reliability.

- Electrolytic Capacitors: Suitable for applications requiring larger capacitance values.

- Tantalum Capacitors: Known for their stability and reliability in high-performance applications.

Applications: Capacitors are employed for energy storage, filtering in power supply circuits, coupling signals between stages of amplifiers, and decoupling to reduce noise.

Inductors

Inductors store energy in a magnetic field when electrical current flows through them. They are classified as:

- Fixed Inductors: Have a constant inductance value.

- Variable Inductors: Allow adjustment of inductance value as needed.

Applications: Inductors are primarily used in filtering applications, energy storage in power supplies, and tuning circuits.

Diodes

Diodes allow current to flow in one direction only and are essential for controlling electrical signals. Common types of diodes in SMT include:

- Rectifier Diodes: Convert AC to DC.

- Zener Diodes: Provide voltage regulation by allowing current to flow backwards when a specific reverse voltage is reached.

- Schottky Diodes: Known for their fast switching speeds and low forward voltage drop.

Applications: Diodes are utilized for current flow control, voltage regulation, signal demodulation, and light emission (in the case of LEDs).

Transistors

Transistors act as switches or amplifiers in electronic circuits. The main types of transistors used in SMT are:

- Bipolar Junction Transistors (BJTs): Used for amplification and switching.

- Field-Effect Transistors (FETs): Known for their high input impedance and fast switching capabilities.

Applications: Transistors are employed in signal amplification, digital logic circuits, and power management systems.

Integrated Circuits (ICs)

ICs combine multiple functions into a single chip. Common packages for SMT ICs include:

- Small Outline Package (SOP): A common package type for low pin-count ICs.

- Quad Flat Package (QFP): Suitable for high pin-count applications.

- Ball Grid Array (BGA): Provides excellent thermal performance and is used for high-performance microprocessors.

Applications: ICs can be found in microprocessors, memory chips, controllers, and various analog/digital processing tasks.

Additional Components

Beyond the primary components listed above, several other SMT components play crucial roles in PCB design:

- LEDs (Light Emitting Diodes): Used extensively for indicators and displays due to their compact size and efficiency.

- Crystals & Oscillators: Essential for timing applications within circuits.

- Connectors: Various types of connectors such as USB interfaces or HDMI sockets that facilitate connections between different circuit elements.

Advantages of SMT Components

SMT components offer numerous advantages over traditional through-hole components:

- Compact Size and Lightweight: SMT components occupy less space on PCBs, allowing for smaller device designs.

- High Component Density: More components can fit on a single board due to the reduced size of SMT parts.

- Improved Performance at High Frequencies: The shorter leads reduce inductance and resistance at connections, enhancing performance at high frequencies.

- Cost-Effectiveness in Mass Production: The automated assembly processes associated with SMT lead to lower labor costs and faster production times.

Challenges in Using SMT Components

Despite their advantages, using SMT components comes with challenges:

- Repair and Prototyping Difficulties: The small size of SMT components makes them harder to handle during repairs or prototyping phases.

- Thermal and Mechanical Stress Issues: SMT components can be more susceptible to damage from thermal cycling or mechanical stress compared to through-hole components.

- Solder Joint Reliability Concerns: Smaller solder joints may be less reliable under certain conditions, leading to potential failures.

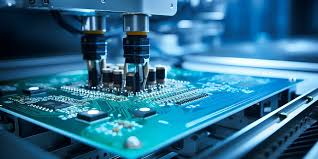

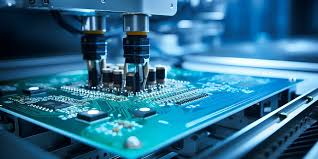

The Role of Automation in SMT

The rise of automation has significantly impacted the efficiency of SMT processes. Automated machines can place thousands of components per hour with precision. This not only speeds up production but also reduces human error. Automation technologies such as AI-driven systems further enhance this process by optimizing component placement based on real-time data analysis.

Key Benefits of Automation:

- Increased Production Speed: Automated processes can significantly reduce assembly time compared to manual methods.

- Enhanced Quality Control: Automated inspection systems can detect defects early in the production process.

- Cost Reduction: By minimizing labor costs and maximizing throughput, automation contributes to lower overall production costs.

Future Trends in SMT Technology

As technology continues to evolve, several trends are shaping the future of Surface Mount Technology:

1. Miniaturization of Components: As consumer demand increases for smaller devices such as smartphones and wearables, manufacturers are focusing on producing even smaller SMDs that maintain performance integrity while reducing size.

2. Integration with AI Technologies: The incorporation of AI into manufacturing processes will enhance predictive maintenance capabilities and streamline operations further.

3. Sustainability Initiatives: With growing environmental concerns, manufacturers are adopting eco-friendly practices within SMT processes—such as lead-free soldering techniques—to comply with regulations like RoHS (Restriction of Hazardous Substances).

4. Advanced Materials Development: Research into new materials that improve thermal conductivity or reduce weight is ongoing. These developments could lead to more efficient designs that enhance performance while reducing costs.

5. Increased Use in Automotive Applications: As vehicles become more reliant on electronics—particularly with the rise of electric vehicles—SMT technology will play a crucial role in producing reliable automotive electronics that meet stringent safety standards.

Conclusion

In conclusion, Surface Mount Technology has become an integral part of modern electronics manufacturing. Understanding the commonly used SMT PCB components—resistors, capacitors, inductors, diodes, transistors, integrated circuits (ICs), LEDs, crystals/oscillators, and connectors—along with their applications and challenges is crucial for anyone involved in electronics design or production. As technology continues to advance towards miniaturization and increased functionality within devices, the importance of these components will only grow as they enable the development of smaller yet more efficient devices that meet the demands of today's market.

FAQ

1. What is SMT in PCB design?

SMT stands for Surface Mount Technology. It is a method of mounting electronic components directly onto the surface of a printed circuit board (PCB), allowing for compact designs with high component density.

2. Why are resistors and capacitors commonly used in SMT?

Resistors and capacitors are essential components that perform critical functions such as current limiting, voltage division, filtering noise from signals, and energy storage within electronic circuits.

3. What are the challenges of using SMT components?

Challenges include difficulties in repair due to small sizes, susceptibility to thermal stress during operation, and concerns about the reliability of solder joints which may lead to failures under certain conditions.

4. How do SMT components improve PCB performance?

SMT components enhance PCB performance by enabling compact designs that support high-frequency operations while reducing resistance and inductance at connections—thus improving signal integrity.

5. What are the common packages for SMT ICs?

Common packages include Small Outline Package (SOP), Quad Flat Package (QFP), and Ball Grid Array (BGA). Each package type provides unique advantages depending on application requirements such as pin count and thermal performance.

Citations:

[1] https://www.raypcb.com/smt-components/

[2] https://www.protoexpress.com/kb/basic-components-overview/

[3] https://www.mpe-electronics.co.uk/2024/10/22/advantages-and-disadvantages-of-surface-mount-technology

[4] https://www.jt-int.com/how-smd-and-smt-are-building-blocks-of-modern-electronics/

[5] https://www.mycronic.com/product-areas/pcb-assembly/news-and-press-releases/news/ten-key-smt-trends-you-need-to-know/

[6] https://www.pcbonline.com/blog/smd-electronic-components.html

[7] https://jlcpcb.com/blog/the-characteristics-of-surface-mount-technology

[8] https://vectorbluehub.com/smt-assembly

[9] https://www.pcbway.com/blog/PCB_Assembly/Advantages_and_Disadvantages_of_Surface_Mounting_Technology.html

[10] https://www.7pcb.com/blog/what-types-of-products-can-smt-be-applied-to

[11] https://www.rhsmt.com/news/smt-industrys-future-trends-the-impact-of-ai-and-automation/

[12] https://vectorbluehub.com/smd-components-a-look-at-different-types-and-how-to-identify-them

[13] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[14] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[15] https://blueringstencils.com/top-5-smt-industry-trends-for-2019/

[16] https://www.wevolver.com/article/smd-components

[17] https://levisonenterprises.com/5-advantages-to-using-smt/

[18] https://www.jycircuitboard.com/news/smt-assembly-powering-electronics-innovation-across-industries-493.html

[19] https://www.globenewswire.com/news-release/2024/10/14/2962707/28124/en/Surface-Mount-Technology-Equipment-SMT-Market-to-Surge-to-8-32-Billion-by-2028-Global-Long-term-Forecast-to-2033.html

[20] https://jhdpcb.com/blog/fully-understand-pcb-components/

[21] https://www.pcbasic.com/blog/surface_mount_technology_smt.html

[22] https://www.swfuliusmt.com/automotive-electronics-industry/

[23] https://en.wikipedia.org/wiki/Surface_mount

[24] https://www.renishaw.com/resourcecentre/download/feature-article-why-future-smt-placement-needs-absolute-encoder-feedback--84260?userLanguage=en

[25] https://www.electronics-notes.com/articles/electronic_components/surface-mount-technology-smd-smt/packages.php

[26] https://www.grandviewresearch.com/industry-analysis/surface-mount-technology-market-report