Content Menu

● Understanding Surface Mount Assembly Technology

>> Key Components of Surface Mount Assembly

● Latest Trends in Surface Mount Assembly Technology

>> Miniaturization of Components

>> Increased Automation

>> Enhanced Quality Control

>> Eco-Friendly Practices

>> Flexible Manufacturing Systems

>> Internet of Things (IoT) Integration

>> Advanced Materials

>> 3D Printing in SMT

>> Smart Manufacturing

>> Global Supply Chain Management

● Challenges in Surface Mount Assembly Technology

● Conclusion

● FAQ

>> 1. What is surface mount assembly technology?

>> 2. What are the benefits of using surface mount assembly services?

>> 3. How does automation impact surface mount assembly?

>> 4. What are the latest trends in surface mount assembly technology?

>> 5. What challenges does the surface mount assembly industry face?

Surface mount assembly technology (SMT) has revolutionized the electronics manufacturing industry, enabling the production of smaller, more efficient, and more reliable electronic devices. As technology continues to evolve, so do the methods and practices associated with surface mount assembly services. This article explores the latest trends in surface mount assembly technology, highlighting innovations, challenges, and future directions in the field.

Understanding Surface Mount Assembly Technology

Surface mount assembly involves the mounting of electronic components directly onto the surface of printed circuit boards (PCBs). This method contrasts with traditional through-hole technology, where components are inserted into holes drilled in the PCB. The advantages of SMT include reduced size and weight of electronic devices, improved performance, and lower manufacturing costs.

Key Components of Surface Mount Assembly

1. Surface Mount Devices (SMDs): These are the components used in SMT, including resistors, capacitors, and integrated circuits. SMDs are designed to be soldered onto the surface of PCBs, allowing for a more compact design.

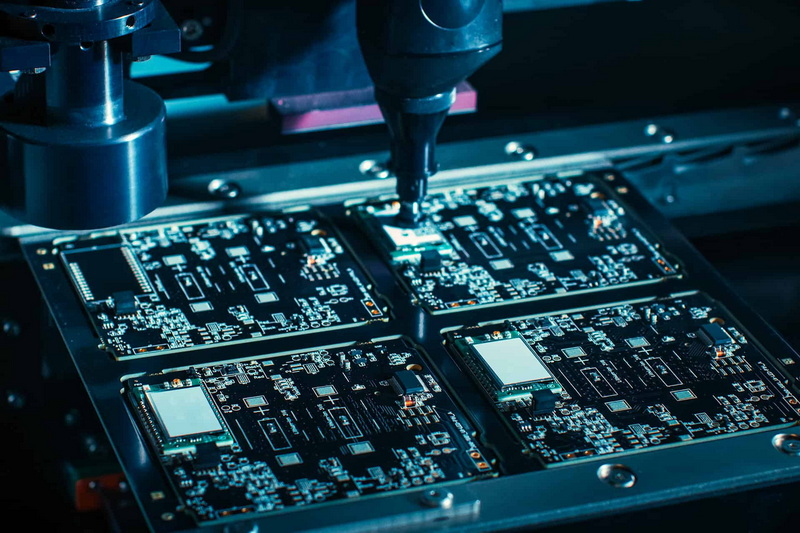

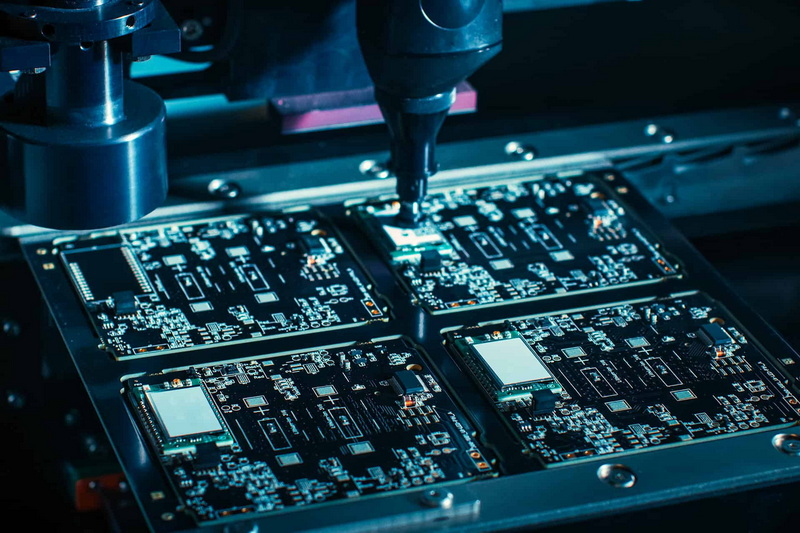

2. Pick and Place Machines: These automated machines are essential in SMT processes. They accurately place SMDs onto the PCB, ensuring precision and speed in assembly.

3. Soldering Techniques: Various soldering methods are employed in SMT, including reflow soldering and wave soldering. Reflow soldering is the most common, where solder paste is applied to the PCB, and then the assembly is heated to melt the solder.

4. Inspection and Testing: Quality control is critical in SMT. Automated optical inspection (AOI) and X-ray inspection are commonly used to ensure that components are correctly placed and soldered.

Latest Trends in Surface Mount Assembly Technology

Miniaturization of Components

One of the most significant trends in surface mount assembly technology is the miniaturization of electronic components. As consumer demand for smaller devices increases, manufacturers are developing smaller SMDs that can be used in compact designs. This trend is particularly evident in the smartphone and wearable technology markets, where space is at a premium.

Increased Automation

Automation is transforming the surface mount assembly process. Advanced robotics and artificial intelligence (AI) are being integrated into SMT lines to enhance efficiency and reduce human error. Automated systems can quickly adapt to different production runs, allowing manufacturers to respond to changing market demands more effectively.

Enhanced Quality Control

With the rise of complex electronic devices, ensuring quality in surface mount assembly has become more critical than ever. Manufacturers are adopting advanced inspection technologies, such as machine learning algorithms and AI-driven analytics, to improve defect detection rates. These technologies can analyze data from various stages of the assembly process, identifying potential issues before they escalate.

Eco-Friendly Practices

Sustainability is becoming a priority in electronics manufacturing. Surface mount assembly services are increasingly adopting eco-friendly practices, such as using lead-free solder and reducing waste through efficient production methods. Manufacturers are also exploring the use of recyclable materials in packaging and components to minimize their environmental impact.

Flexible Manufacturing Systems

The demand for customization in electronic devices is leading to the development of flexible manufacturing systems. These systems allow manufacturers to produce small batches of customized products without significant downtime. By integrating SMT with flexible manufacturing, companies can offer tailored solutions to meet specific customer needs while maintaining efficiency.

Internet of Things (IoT) Integration

The rise of the Internet of Things (IoT) is driving innovation in surface mount assembly technology. As more devices become interconnected, the need for reliable and efficient assembly processes is paramount. SMT is well-suited for IoT applications due to its ability to produce compact and lightweight devices that can easily integrate with other technologies.

Advanced Materials

The development of new materials is also influencing surface mount assembly technology. Manufacturers are exploring advanced substrates and solder materials that enhance performance and reliability. For instance, the use of high-frequency materials is becoming more common in SMT for applications in telecommunications and aerospace.

3D Printing in SMT

3D printing technology is making its way into surface mount assembly services, offering new possibilities for prototyping and production. This technology allows for rapid development of custom components and can significantly reduce lead times. As 3D printing continues to evolve, it may play a more prominent role in the future of SMT.

Smart Manufacturing

The concept of smart manufacturing is gaining traction in the electronics industry. By leveraging IoT, big data, and AI, manufacturers can create smart SMT lines that optimize production processes in real-time. This approach not only improves efficiency but also enhances the ability to predict maintenance needs and reduce downtime.

Global Supply Chain Management

The COVID-19 pandemic highlighted the vulnerabilities in global supply chains. As a result, many companies are reevaluating their supply chain strategies, focusing on local sourcing and diversification. Surface mount assembly services are adapting to these changes by establishing more resilient supply chains that can withstand disruptions.

Challenges in Surface Mount Assembly Technology

While the trends in surface mount assembly technology are promising, several challenges remain. These include:

- Complexity of Designs: As devices become more complex, the assembly process must adapt to accommodate intricate designs. This complexity can lead to increased production times and costs.

- Skill Shortages: The rapid advancement of technology has created a skills gap in the workforce. Finding qualified personnel who can operate advanced SMT equipment is becoming increasingly difficult.

- Cost Pressures: While automation can reduce costs, the initial investment in advanced machinery and technology can be significant. Manufacturers must balance these costs with the need for competitive pricing.

Conclusion

The landscape of surface mount assembly technology is continuously evolving, driven by advancements in materials, automation, and the growing demand for smaller, more efficient electronic devices. As manufacturers embrace these trends, they must also navigate the challenges that come with them. By staying informed and adapting to the latest developments, companies can leverage surface mount assembly services to enhance their production capabilities and meet the demands of an ever-changing market.

FAQ

1. What is surface mount assembly technology?

Surface mount assembly technology (SMT) is a method of mounting electronic components directly onto the surface of printed circuit boards (PCBs), allowing for more compact and efficient designs compared to traditional through-hole technology.

2. What are the benefits of using surface mount assembly services?

The benefits of using surface mount assembly services include reduced size and weight of electronic devices, improved performance, lower manufacturing costs, and the ability to produce complex designs efficiently.

3. How does automation impact surface mount assembly?

Automation enhances the efficiency and accuracy of surface mount assembly processes. Automated machines can quickly place components, reducing human error and increasing production speed.

4. What are the latest trends in surface mount assembly technology?

Latest trends include miniaturization of components, increased automation, enhanced quality control, eco-friendly practices, flexible manufacturing systems, IoT integration, advanced materials, 3D printing, smart manufacturing, and improved global supply chain management.

5. What challenges does the surface mount assembly industry face?

Challenges include the complexity of designs, skill shortages in the workforce, and cost pressures associated with investing in advanced technology and machinery.