Content Menu

● Understanding Wholesale SMT Stencil Machines

● Latest Innovations in Wholesale SMT Stencil Machines

>> 1. Integration of Artificial Intelligence and Automation

>> 2. Enhanced Precision for Fine-Pitch Components

>> 3. Modular and Customizable Designs

>> 4. Industry 4.0 and IoT Connectivity

>> 5. Eco-Friendly and Sustainable Manufacturing

>> 6. Advanced Materials and Construction

>> 7. Expanded Application Range

>> 8. Improved User Interface and Software Integration

>> 9. Faster Setup and Changeover Times

>> 10. Enhanced Cleaning Technologies

● Market Trends Driving Innovation

● Examples of Latest Wholesale SMT Stencil Machines

● Conclusion

● FAQ

>> 1. What is a wholesale SMT stencil machine used for?

>> 2. How does AI improve SMT stencil machines?

>> 3. Can wholesale SMT stencil machines handle different PCB sizes?

>> 4. What industries benefit most from SMT stencil machines?

>> 5. Are there eco-friendly options for SMT stencil machines?

Surface Mount Technology (SMT) stencil machines play a crucial role in the electronics manufacturing industry, particularly in the precise application of solder paste onto printed circuit boards (PCBs). As the demand for miniaturized, high-density, and high-reliability electronic devices grows, wholesale SMT stencil machines have evolved significantly. This article explores the latest innovations in wholesale SMT stencil machines, highlighting technological advancements, market trends, and new product features that are shaping the future of PCB assembly.

Understanding Wholesale SMT Stencil Machines

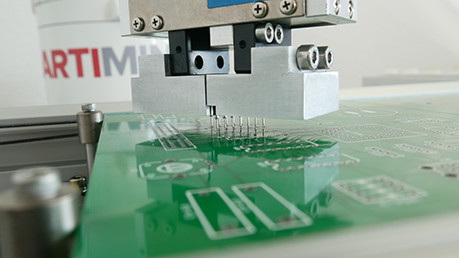

Wholesale SMT stencil machines are automated or semi-automated devices designed to produce or utilize stencils that apply solder paste onto PCBs in the surface mount assembly process. These stencils are templates that ensure solder paste is deposited accurately on the PCB pads before component placement, which is critical for the quality and reliability of electronic assemblies.

These machines vary in size, precision, and automation level, catering to different production volumes-from prototype development and small-batch manufacturing to high-volume industrial production. They are widely used across industries such as consumer electronics, aerospace, automotive, medical devices, and more.

Latest Innovations in Wholesale SMT Stencil Machines

1. Integration of Artificial Intelligence and Automation

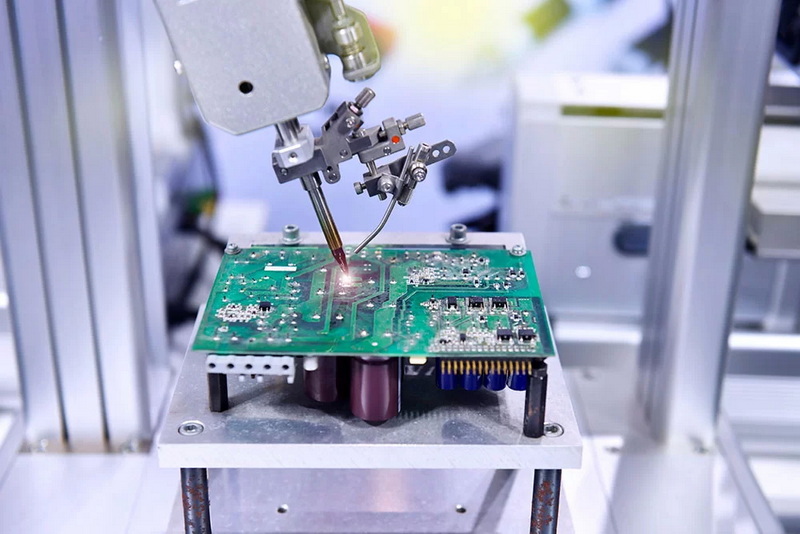

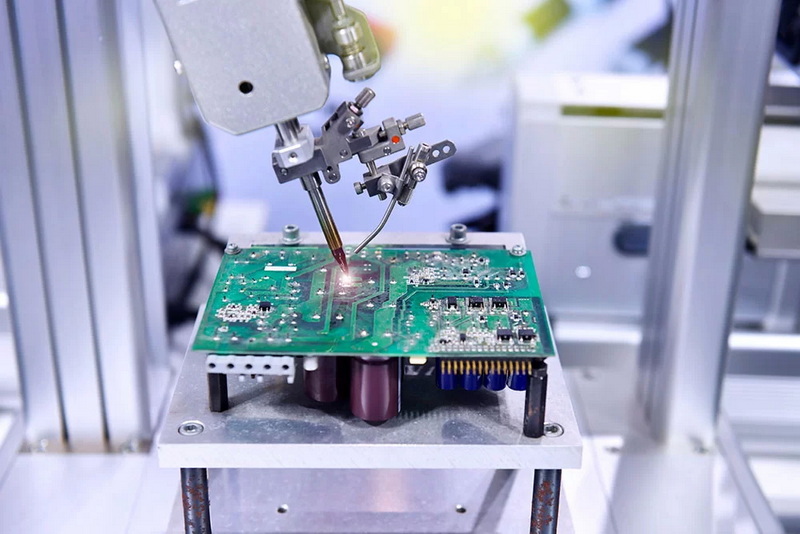

One of the most significant innovations in wholesale SMT stencil machines is the incorporation of artificial intelligence (AI) and advanced automation technologies. AI-powered stencil printers can automatically adjust printing parameters in real-time based on feedback from vision systems. This capability ensures consistent solder paste application quality, reduces human error, and increases throughput.

Automation features now include automatic stencil loading and unloading, automatic waste cleaning, and vision alignment systems that precisely position the stencil relative to the PCB. These enhancements reduce manual intervention and improve overall production efficiency.

2. Enhanced Precision for Fine-Pitch Components

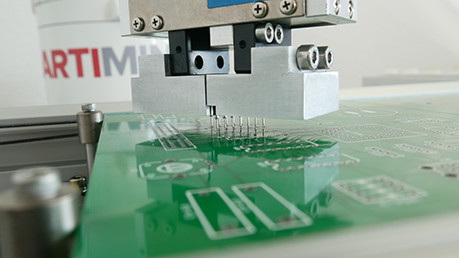

With the increasing use of fine-pitch and ultra-fine-pitch components in modern electronics, stencil machines have been upgraded to deliver higher precision and finer resolution in solder paste deposition. Innovations in laser-cut stencil manufacturing and improved mechanical design allow for stencil apertures with tighter tolerances, enabling the reliable printing of solder paste on very small pads.

This precision is essential for manufacturing high-density PCBs used in smartphones, wearables, medical devices, and automotive electronics, where space constraints and performance requirements are stringent.

3. Modular and Customizable Designs

Manufacturers are now offering wholesale SMT stencil machines with modular architectures that can be customized to meet specific production needs. These machines can accommodate a wide range of PCB sizes, thicknesses, and component types, providing flexibility for different manufacturing scenarios.

Modular designs also facilitate easy upgrades and maintenance, allowing manufacturers to scale their production capabilities without investing in entirely new equipment. This adaptability is particularly beneficial for electronics manufacturers who handle diverse product lines or rapidly changing designs.

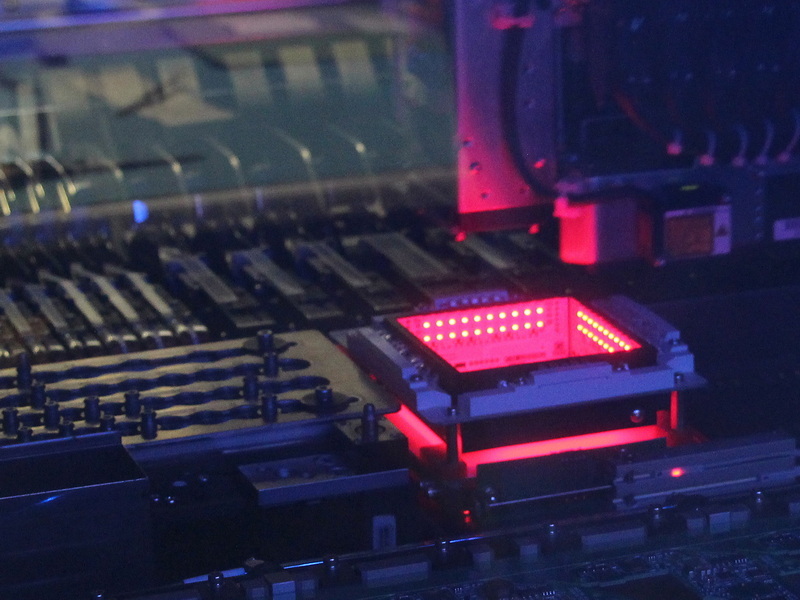

4. Industry 4.0 and IoT Connectivity

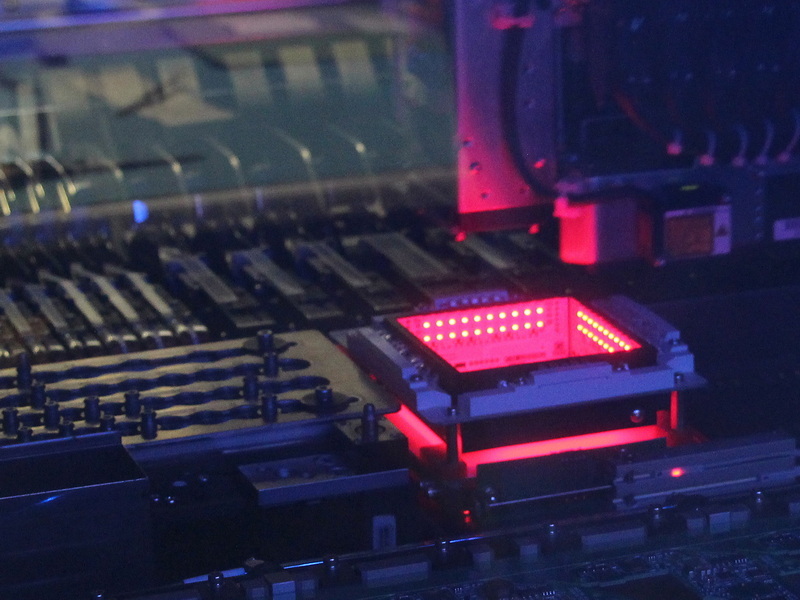

The adoption of Industry 4.0 principles has led to the integration of Internet of Things (IoT) connectivity in wholesale SMT stencil machines. These machines can now communicate with central manufacturing execution systems (MES) and other production equipment, enabling real-time monitoring, data collection, and predictive maintenance.

IoT-enabled stencil machines provide valuable insights into production performance, help identify issues before they cause downtime, and support quality control through traceability. This connectivity enhances operational efficiency and reduces costs associated with unplanned maintenance.

5. Eco-Friendly and Sustainable Manufacturing

Sustainability has become a priority in electronics manufacturing, and wholesale SMT stencil machines are no exception. Newer models are designed to minimize solder paste waste, reduce energy consumption, and support lead-free soldering processes.

Manufacturers are developing stencil machines that use less material during printing and incorporate energy-efficient components. These eco-friendly features align with global environmental regulations and help companies reduce their carbon footprint while maintaining high production standards.

6. Advanced Materials and Construction

Recent innovations include the use of high-quality materials and precision engineering in the construction of stencil machines. Adjustable rubber footings, mechanical fixation frames for quick stencil replacement, and enhanced PCB clamping methods improve flatness and alignment during printing.

These improvements contribute to consistent print quality, reduce setup times, and extend the lifespan of stencil machines, providing better return on investment for buyers.

7. Expanded Application Range

Wholesale SMT stencil machines are no longer limited to traditional PCB solder paste printing. They are increasingly used for applying adhesives, brazing materials, and other substances in complex assembly processes. This versatility expands their use in industries such as medical device manufacturing, aerospace, and automotive electronics, where precise material deposition is critical.

8. Improved User Interface and Software Integration

Modern wholesale SMT stencil machines come equipped with user-friendly interfaces and advanced software integration. Touchscreen controls, intuitive programming, and recipe management systems allow operators to set up and switch between jobs quickly and efficiently.

Software integration with factory automation systems enables seamless data exchange, production scheduling, and quality control. Enhanced traceability features help manufacturers comply with industry standards and regulations by recording detailed printing parameters and production history.

9. Faster Setup and Changeover Times

To meet the demands of just-in-time manufacturing and small-batch production, stencil machines have been engineered for rapid setup and changeover. Features such as quick-release stencil clamps, automated thickness adjustment, and programmable alignment reduce downtime between jobs.

These time-saving innovations increase production flexibility and allow manufacturers to respond swiftly to design changes or urgent orders without sacrificing print quality.

10. Enhanced Cleaning Technologies

Maintaining stencil cleanliness is vital for consistent solder paste deposition. New cleaning technologies integrated into wholesale SMT stencil machines include ultrasonic cleaning, automatic wiping systems, and solvent-free cleaning cycles.

These cleaning systems reduce manual labor, minimize stencil damage, and ensure high-quality printing throughout extended production runs. Some machines also feature automatic cleaning schedules based on usage data, further optimizing maintenance routines.

Market Trends Driving Innovation

The wholesale SMT stencil machine market is growing steadily, driven by several key factors:

- Miniaturization and High-Density Packaging: The trend toward smaller, more complex electronic devices demands stencil machines capable of handling fine-pitch components with high precision.

- Rising Demand in Asia-Pacific: The Asia-Pacific region, especially China, Japan, and South Korea, leads in electronics manufacturing, fueling demand for advanced stencil printing solutions.

- Smart Manufacturing: The push for automation and smart factories encourages the adoption of AI-enabled stencil machines with IoT connectivity.

- Sustainability Focus: Environmental concerns drive the development of eco-friendly stencil printing technologies.

- Customization Needs: Manufacturers seek flexible stencil machines that can adapt to various PCB sizes and production volumes.

- Increased Demand for Medical and Automotive Electronics: Stringent quality and reliability requirements in these sectors push for stencil machines with enhanced precision and traceability.

Examples of Latest Wholesale SMT Stencil Machines

- NeoDen FP2636 SMT Stencil Machine: Features adjustable rubber footing for flatness, rulers for stencil frame alignment, and mechanical fixation frames for quick stencil replacement. It supports multiple PCB types with precise positioning control.

- Advanced Solder Paste Stencil Machines: Models with programmable elastic side clamps, automatic thickness adjustment, and vacuum support methods enhance PCB clamping and printing accuracy.

- Machines with Automatic Waste Cleaning and Vision Alignment: These features reduce downtime and improve print quality, making them suitable for high-volume production environments.

- AI-Enabled Stencil Printers: Incorporate real-time monitoring and automatic parameter adjustment to maintain consistent print quality.

- Modular Systems with IoT Connectivity: Allow integration into smart factory environments for data-driven production optimization.

Conclusion

The latest innovations in wholesale SMT stencil machines reflect the evolving needs of the electronics manufacturing industry. From AI integration and automation to modular designs, enhanced precision, and sustainability, these advancements enhance precision, efficiency, and flexibility in PCB assembly processes. As the demand for miniaturized, high-density, and reliable electronic devices continues to grow, wholesale SMT stencil machines will remain critical enablers of quality and productivity.

Manufacturers investing in these cutting-edge stencil machines can expect improved operational performance, reduced waste, faster setup times, and the ability to meet diverse production requirements across various industries. The integration of smart technologies and eco-friendly features ensures that these machines not only meet current manufacturing challenges but also align with future trends in digitalization and sustainability.

FAQ

1. What is a wholesale SMT stencil machine used for?

A wholesale SMT stencil machine is used to apply solder paste or adhesives onto PCBs with high precision during the surface mount technology assembly process. It ensures accurate deposition of materials on PCB pads before component placement.

2. How does AI improve SMT stencil machines?

AI enhances SMT stencil machines by enabling real-time adjustments during printing, reducing human error, and improving consistency. AI-powered vision systems can monitor print quality and optimize parameters automatically.

3. Can wholesale SMT stencil machines handle different PCB sizes?

Yes, many modern wholesale SMT stencil machines feature modular and customizable designs that accommodate a wide range of PCB sizes, thicknesses, and component types, providing flexibility for various production needs.

4. What industries benefit most from SMT stencil machines?

Industries such as consumer electronics, medical devices, aerospace, automotive, and industrial manufacturing benefit from SMT stencil machines due to their need for precise and reliable PCB assembly.

5. Are there eco-friendly options for SMT stencil machines?

Yes, recent innovations include eco-friendly stencil machines designed to reduce solder paste waste, lower energy consumption, and support lead-free soldering processes, aligning with global environmental standards.